|

By MplsMike - 9 Years Ago

|

Hi all,

I've taken the first step to replace the 272 in my Parklane. Jerry Christenson was willing to part with a standard bore 292 - here he is after we loaded the block on the trailer on a winter-like day last Friday:

Boy am I glad Jerry is willing to advise me! I cold called him a couple of years ago when several people suggested that he is the local guru on y-blocks. He tore down the engine and had it atop an oil pan he modified so it sits nice and flat.

I've been accumulating some parts for a while:

On the left are mismatched heads, a 113 and an unposted G. On the right under plastic is a set of rebuilt G heads. Jerry wasn't too impressed with the rebuilt ones, so he is going to find a head to match one of the two on the left and port the set for me. R&R Performance in Spring Lake Park, MN will do the head work for me.

The crank is from a 312 that I found for $50 (!) that I will use in the rebuild. Jerry and I are talking about stroking the engine - would be nice to stroke it in a fashion where I can use standard connecting rods.

I brought the block to Les of Lester Prairie Engines in Lester Prairie, MN, about an hour west of my home in Minneapolis. I wonder if the town was named after Les?

Les has been in the business for 49 years. The adjacent business is Berry Cam which is run by his brother in law. The two of them married sisters - their father started the businesses. I will post some pics of the two shops in my next post.

|

|

By mark9088 - 9 Years Ago

|

Hi Mike,

I am a Minnesota Y member also, (as well as SBF and FE). I also am in the early stages of a Y block build for my 56 customline gasser. I will be following your post with interest. Though I am a long ways from needing it,I wonder if any of the builders you mention have a torque plate for honing 292 cylinder bores.

thanks for posting,

Dean Markuson (DEANs427 on other Ford forums)

|

|

By MplsMike - 9 Years Ago

|

Hi Dean,

I'm not sure what equipment Les has but for future reference, his number is (320) 395-2881. He walked me around his shop and the cam shop and showed me their equipment. There seemed to be an abundance of marine engines. I think there is a marine y-block in the picture below on the right.

Several of the engines he had were Hercules engines. I don't know anything about them. He said a customer stores engines with him and routinely has Les rebuild them for boat restorations.

In the background you can see some of his equipment. He pointed out his boring and honing machines, although I can't tell one from another.

Over in the cam shop, they had an impressive selection of cams.

Apparently they can reproduce lots of cam grinds for lots of engines with the equipment they have. Among all of the old vehicle references I saw one bin labeled "1906 Oakland". They work on lots of tractor engines too.

Here's a picture of my block after it was unloaded.

|

|

By MplsMike - 9 Years Ago

|

So here is the beginning of the recipe. I am starting with a standard bore 292 and want a very respectable street engine. I'm running a C4 with a 2500 stall converter.

I'll bore the cylinders to a 312 bore plus 60 over. I'll be using a 312 crankshaft. Forged pistons with Moly rings. I'll use a Mummert intake and one of his valley pans (with PCV grommet) for a little more bling. I will also buy a damper from him and new bolts for the mains and heads.

Jerry suggested a Comp Cam, either a grind of XS 274 S or XS 268 S. I think I will go with the 268.

I'm not sure if I will end up with a matched set of 113 heads or G heads. Yestertech will port them. I haven't sorted out parts for the heads yet. Carb is yet to be determined. I have a '57 and up distributor and plan on adding a Petronix unit. A Cloyes timing set.

Would love to get general impressions of the plan so far and I also have a few questions:

1) Jerry is bullish on Trend lifters. The only ones I saw appear to require customs push rods, and another posting I read might suggest they are overkill. Any lifter suggestions?

2) I don't know much about MSD versus a Petronix set-up. I know MSD is more expensive - what benefits do the $$ provide?

3) given what I read about the cams, I think the 274 would be a little too aggressive.

Thanks for any comments!

|

|

By charliemccraney - 9 Years Ago

|

Make sure the 292 will bore safely to .060 over 312. Have the cylinder walls sonic checked.

1) I don't know about trend lifters, but I'll comment on the pushrod part. One detail that most people don't do is to correct rocker geometry. Do a search here, Google it, there's all kinds of info about that. What it boils down to is assuming the geometry was correct to begin with (it's not) the bigger cam, head / block milling, valve job and other stuff I may not be thinking of at the moment make it so that you have to change the geometry to get it back to optimum. This inevitably means that you need different pushrods because the length requirement will be different. There are only 2 lengths of Y block pushrods available off the shelf so unless you are fortunate and one of those happens to be just what you need, you really need custom pushrods and since they are custom, you can have them made to fit any ball and cup arrangement you need. Even if you don't correct geometry, custom pushrods are not that expensive, $100-$120. And I'm sure comp will have good lifters to go with their cams, and if not, there's Isky, and Mummert.

2) Comparing MSD and Pertronix, in the case of the Y, anyway, is apples and oranges. Pertronix is only a conversion for stock distributors, from points to electronic. MSD is a complete, totally brand new distributor. So that is where a big part of the difference in cost is. You will still save money if you go with a rebuilt distributor and the pertronix conversion, and that should make for a pretty solid ignition. The MSD will be easier to tune because you don't have to take the distributor apart to get to the weights and springs and there is value in that.

The later distributor you have, have it rebuilt if you have not already.

3) I'd probably go with the 268 as well. I think with either, you are going to have to change the rear gear ratio. You'll also need to get the compression up. The heads and displacement increase will get that to a reasonably good spot, but those cams might like a little more and you'll need domed pistons to do that. With the G heads, 0 deck and composition head gaskets you'll be at about 9.35:1 With the 113s you'll be at about 9.04:1. Don't be afraid of premium fuel. You're going to kick the efficiency up enough that you might actually get better mileage than you do now (no promises) but also, bigger cams simply need more compression.

|

|

By MplsMike - 9 Years Ago

|

|

Thanks, Charlie, for the insight. With regards to the Mummert intake, is the high rise version a better choice? I don't imagine there would be clearance issues in my wagon - is there a performance difference between the two choices he offers?

|

|

By charliemccraney - 9 Years Ago

|

|

As long as it will fit, go with the high rise. You might also want an inch or two of spacer on top of that.

|

|

By NoShortcuts - 9 Years Ago

|

Charlie's steering you correctly on JM's intake manifold.

The reason John offers the low rise unit is for those who have to fit everything under a '55, '56, '57 'Bird hood.

Hope this helps.

|

|

By thundercat - 9 Years Ago

|

|

Are you still looking for heads ?.. I finally went thru my extras and I have a mismatched pair like yours .. An unposted G and a 113 . They came off the same engine . I tag everything when I remove . [I always wondered how it ran?] Both appear in good shape. Reasonable.. You can give me a call at 724-272-7396 or Email LMCDONAL@ZBZOOM.NET Regards Thundercat

|

|

By MplsMike - 9 Years Ago

|

Hi Thundercat,

Thanks for the offer but I'm all set in the heads. Most of the parts have arrived or are in route - I'm going to have to wait a couple of more weeks for a Mummert intake and for the forged Pistons.

|

|

By PF Arcand - 9 Years Ago

|

As Charlie pointed out, a core shift in your block, not uncommon,, could make a 312+ .060 overbore a dicey situation. And even if it is feasible, that might be the limit.. no cleanup re bore available. Apparently Ford only supplied pistons up to a 0.040 overbore for 312s... that equates to aprox 319 cu inches.

|

|

By Bob Gardner - 9 Years Ago

|

Be sure to check the oil ring groove depth on the pistons against the oil ring width. The set I got from John where slightly undersized and forced the oil ring into the cylinder walls at temperature. I had to buy a different set of oils rings to corrent the problem.

Bob

|

|

By MplsMike - 9 Years Ago

|

|

Thanks for the tip, Bob.

|

|

By MplsMike - 9 Years Ago

|

Hi Bob,

I was thinking about your post. I assume you must have discovered the ring-piston mismatch after your engine was assembled and run. I'm not a builder, but is there anything that can be done to detect the problem you described during assembly? Did the mismatch cause any damage?

|

|

By Bob Gardner - 9 Years Ago

|

Mike,

Yup, we discovered the problem the first time that the engine was run on the dyno. As the engine came up to temperature during the break in, there was a noticeable drop in engine rpm. The run was terminated and post run tear down revealed some odd scoring on the cylinders. It was caused by the oil rings being pressed into cylinder walls by the expanding piston. The engine was cleaned,machine work was freshened, and reassembled.

You need to measure the depth of the oil ring groove in the pistons with a caliper and measure the wide part of the oil rings with the caliper. Subtract the piston measurement from the ring measurement to get the actual gap. I am not sure what the gap needs to be (maybe Ted can chime in with the value) since my engine builder did the work.

Bob

|

|

By 314 - 9 Years Ago

|

|

what happened to rebuild

|

|

By MplsMike - 9 Years Ago

|

The wheels of progress move slowly! I just picked up the heads - cleaned and "roughed in" - and dropped them off at Jerry's house for porting Wednesday night. It's always fun hanging out there. He has a lot of cool stuff and I always learn something. He is starting to build a new engine for the t-bird he races. They'll go back to the machine shop once Jerry is done with them.

The engine shop is just starting on the block next week. When I dropped off the block, he wasn't busy but I hadn't accumulated all of the parts. When I got all the parts together, he was busy. Oh well. I'm going to use 40 over pistons versus the 60 over I suggested previously. The input I got including that from the builder nudged me that way.

I was hoping I would be able to enjoy the new engine this year, now I am hoping it is in the car by the time I store it this winter! Winter comes early in Minnesota!

|

|

By MplsMike - 9 Years Ago

|

I picked up the block from the machinist and dropped it off at Jerry Christenson's house last Friday. He is busy with his own project - building an engine for this year's Engine Masters competition. He will get to the assembly stage on my engine after that.

The heads should be done sometime next week.

Time to think about a carburetor. Any advice for this build? I am also thinking about whether I should rob parts from my current engine (like the exhaust manifolds) to use on the new one.

I still hope the engine goes in this year but am beginning to think it may be in the spring.

|

|

By MplsMike - 9 Years Ago

|

How about something to start the conversation. Jerry C seems partial to Holleys and he thought something around 500 cfm would work - I found a Holley street avenger online, 570 cfm. Here is the link, what do you think? What other options to consider?

https://holley.com/products/fuel_systems/carburetors/avenger/street_avenger/parts/0-80570

|

|

By charliemccraney - 9 Years Ago

|

I have the 570 and like it a lot. It's a more modern Holley that comes with lots of great features. It's probably not best for my combo, though.

It is intended for stock or very close to stock configurations. If you use a cam with 220s or higher @.050", the 670 will probably work better.

The best thing you can do is tell the carb manufacturer all of the details about your combo and take their suggestion. If I had asked Holley first, they would have suggested the 670 for mine.

|

|

By Ted - 9 Years Ago

|

|

MplsMike (9/14/2016)

How about something to start the conversation. Jerry C seems partial to Holleys and he thought something around 500 cfm would work - I found a Holley street avenger online, 570 cfm. ....... What other options to consider?

Try to not get hung up on carb cfm ratings. The Y with any improvement in the heads and camshaft will like a larger sized carburetor. I have installed a number of 750 cfm Summit carbs on mild Y engines and they are good street drivers while providing adequate air flow when required. The Summit carb is also offered in a 600 cfm model but for whatever reason, the 750 size tends to be a more suitable carb for most modified Y engines. If never planning on exceeding 4000 rpms, then either a two barrel or smaller sized four barrel carb will provide adequate air flow.

The main thing to remember about a properly tuned vacuum secondary carburetor is that it will only open the secondaries the amount that the engine demands. For this reason, it’s always prudent to go larger than deemed necessary when picking out a vacuum secondary carburetor. Whereas a carburetor with mechanical secondaries is only perfectly sized in the rarest of instances, it’s difficult to be too big with a vacuum secondary carb assuming the base tune up is good.

|

|

By MplsMike - 7 Years Ago

|

What’s the saying? All good things come to those who wait?

After a “hiccup” with the engine builder, Jerry Christenson took control of the build. Maybe he will write about this journey for the Y-Block magazine.

The engine is running and ready to go in the Parklane. I ended up going with smaller pistons than I wrote about (+40) and a slightly less aggressive cam.

Here’s my son with the engine

Here’s Jerry behind the welding mask

I will try and post a video of it running

|

|

By MplsMike - 7 Years Ago

|

let's see if this video link works

and this one

|

|

By Daniel Jessup - 7 Years Ago

|

|

Sweet music!

|

|

By MplsMike - 7 Years Ago

|

I started this thread a couple of years ago!

This past weekend, the engine went in the car. We picked the rebuilt one up from Jerry Christenson’s place on Thursday night. He was kind enough to lend us his engine hoist for the weekend.

On Saturday, my son and I disassembled as much from the old engine as novice mechanics can in prep for the transplant on Sunday. We put in a pretty long day. We did all of this work, by the way, on the street in front of my Minneapolis home. Lots of people walking or driving by all weekend wanted to find out what was going on.

My brother in law, who is a mechanic, arrived at 9 Sunday morning and we had the old engine out before 11. It was another long day, but we returned Jerry’s hoist around 7 pm. And he now has another old y-block to add to his collection.

There are lots of odds and ends to finish up - throttle linkage, some wiring clean up (went with an alternator), etc. but the car moved into the garage under its own power. So much could have gone wrong but generally didn’t. The new engine sounds wicked - my wife asked “did you pay to make it sound like that”? I may need to look into adding resonators.

Really tiring but fun and rewarding experience.

|

|

By Tedster - 7 Years Ago

|

MplsMike (8/20/2018)

...my wife asked “did you pay to make it sound like that”?

LOL!!

|

|

By FORD DEARBORN - 7 Years Ago

|

Awesome and very cool story. Nothing more rewarding than giving a Ford Y-block a new lease on life. When able, will you share some of the final specs? Cam, carb etc.. Thanks, JEFF.........

|

|

By 57RancheroJim - 7 Years Ago

|

Congratulations. I love father and son projects.

|

|

By MplsMike - 7 Years Ago

|

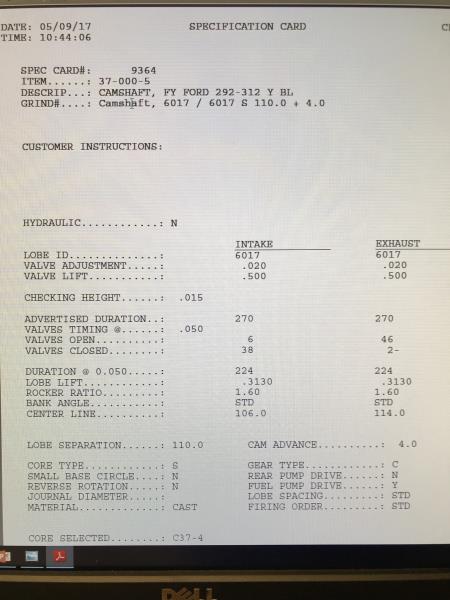

Here are some of the specs. A 292 block bored to 40 over a 312. We stroked a 312 crankshaft. Mummert intake, G heads ported by Jerry Christenson. We used the bigger stock exhaust manifolds - had them coated black. A quick fuel 600 cfm 4 barrel carb. With regards to the cam - I think I bought a “268” grind from Comp Cams that Jerry thought might be too much; ended up with a 270 grind. Tranny is a C4 with a 2200 stall converter. Converted to a Powermaster 1 wire alternator that looks like the old generator. They must have sent one for a T-Bird as Jerry had to fab the bracket a bit to move it forward. We will convert to a petronix with an MSD box and a flamethrower coil.

I’m not super conversant in all of this, but I think I got the facts right!

I will try to post the cam specs.

|

|

By MplsMike - 7 Years Ago

|

Cam card. I had to take a picture of it on my computer screen as a means to post it.

|

|

By Tedster - 7 Years Ago

|

If you want, I can print a copy off and mail it to you... /jk

It's amazing the technology we have at our fingertips these days!

|