|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 34,

Visits: 2.5K

|

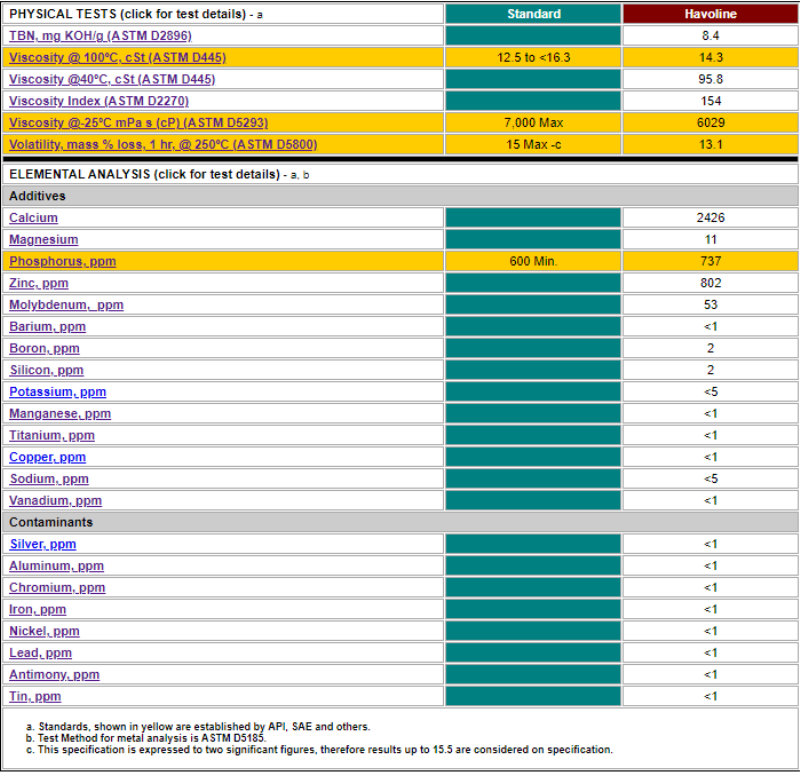

Has anyone used Havoline 10w40 in their y blocks? The zinc numbers look good and the price is right.

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 3.7K,

Visits: 497.9K

|

I'll let Ted speak on this, but I think that is what the oil he usually uses in his builds has - Valvoline conventional 10-30 or 10-40.

54 Victoria 312; 48 Ford Conv 302, 56 Bird 312

Forever Ford

Midland Park, NJ

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.7K,

Visits: 154.3K

|

Evidence indicates the ‘zinc content’ issue is overblown. It’s not what elements an oil contains, so much as how well it prevents wear. Because chemical analysis data seems more publicly available than reliable comparative testing, we tend to grasp at straws.

6 VOLTS/POS. GRD. NW INDIANA

|

|

Group: Administrators

Last Active: 3 days ago

Posts: 7.5K,

Visits: 205.9K

|

|