|

By DualQuad312 - 12 Years Ago

|

Has anyone experimented using the '56 Lincoln carburetors as dual quads? What size jets are recommended for the primaries and secondaries? I have two Lincoln carbs that I'm currently rebuilding and modifying to dual quad status. #55's are used for the primaries in one carb. while #59's are used in the other. which ones are correct for the stock Lincoln? #96's are used in both carbs for there secondaries. I'm pretty certain that #43's are used as the primaries and #55's for the secondaires on the authentic dual quad ECJ 9510 AA or AB carbs. What sizes would work best with the Lincolns?

Jeff P.s. thanks to all for the help.....it's most appreciated

|

|

By Ted - 12 Years Ago

|

|

If you get the Y-Block Magazine, then issues #115 & 116 went into detail on dyno testing of the various dual quad intakes where different pairs of Lincoln Teapots were also in the mix. For the List #1094-1 carbs, the primary jets were happy at #60 and secondary jets at #82. For the List #1094-4 carbs, primary jets were #57 and secondary jets were #82. I don’t recall the power valve numbers off hand as they are also players on the primary jetting side. That information is here but currently buried.

|

|

By DualQuad312 - 12 Years Ago

|

Hi Ted,

thank you for the quick response and the very helpful info. I was thinking you or someone else would respond and say it's too much carburetion for the 312 engine. I'm using the original '57 ECG aluminum intake. Is this acceptable to use with the jets you mentioned and the Lincoln carburetors? I, really want to keep the set up as stock as possible. I'm working on the Carb bases and have made vacuum ports (under the fuel inlet at the rear uses a 1/4" pipe thread) as if the Lincoln carbs were the 1956 ECZ Carbs (or the actual dual quad carb ECJ 9510 AA-AB). I, put in the balance tubes, put in the small 1/8th diam. plugs for the Right side secondarys. (I, believe it's a plug and not a tube?) I'm getting aluminum plugs made to block off and seal the hole where the spark control valve would go. Removed the brass idle tubes in the primary venturies (I, believe there called idle tubes?) Ted, I, don't mean to make this a long drawn out message :-) The job is a little bit intricate and like running through the steps that I've taken to some one more knowledgeable like yourself. Unfortunately I don't get the y-block Mag. that you mentioned. If you do come across the the power valve # that I, should be using that would be great.....I, know I have more changes to make the Lincoln's. While I'm thinking of it.....Is it necessary to have the #58 type air horns (fuel bowl cover) like the actual ecj 9510 aa-ab carbs? It's hard to describe through text but how do the larger circles on the #58 covers matter? I, believe the Lincoln's are #48's? and the same for the ECZ 1956 carbs...I, got a little bit long winded on this mssag....Lol.

Thank you you again for the info and the interest

Best Regards,

Jeff Abate

|

|

By Ol Ford Guy - 12 Years Ago

|

|

The original 57 Holley 4000 Dual Quads use smaller power valves than the original single quad applications. The larger power valves cause the engine to bog.

|

|

By DryLakesRacer - 12 Years Ago

|

Personally I have found that jetting is pretty close from one carb to another but what I found was if I put it on an engine of higher compression a change was needed. The stock jetting was to the ventuii size and the compression and not as much relevant to cubic inches all things being equal.

Bigger carbs have bigger venturiis so a larger jet is needed to compensate for the increase in air to keep at the prescribed ratio of fuel to air. When I would raise comp ratio it would then be lean and I would change jetting.

As an example I use a 331 1953 Cadillac Carter WCFB on my 1956 292 small base. The Cadillac comp ratio is 8.25 and the Ford is 8.4 and it runs great with no changes. Exhaust is clean and the plugs do not soot up with mostly city driving.

After market carbs today are set for what would be the norm in compression 8 thru 9 to 1 and you need to keep an eye on the plugs pretty quickly after installation......Good Luck

|

|

By DualQuad312 - 12 Years Ago

|

Thank you for your input on helping me keep the CFM in perspective to engine displaclement. And actuality one doesn't have a lot to do with the other. I, understand what your saying that the cfm is greater in a particular carburetor and this demands an increase in the jets.....I, need to figure out what size power valves I, need? Ted Eaton Got me on track with the primary and secondary jets.....So I'm off to a good start....I, appreciate everyone's input and support.....Haven't put them back together yet....Need to clean parts, order another reb. kit with sec. diaph. and finish the conversion..... thanks again for the help

Jeff

|

|

By DualQuad312 - 12 Years Ago

|

Thanks Paul,

Your helping me get a better perspective on how the Carbs work and the reasons why Holley did what they did to make them work properly......What do you think would happen if I, used to small of a power valve? Was #33 the correct one for the Orig. dual quad? I, can't remember?

Jeff

|

|

By DualQuad312 - 12 Years Ago

|

Didn't mean to repeat what you just explained to me....just wanted you to know that I, get what your saying on CFM and compression ratios.....and how changes maybe needed? I'm running some where around 9.1 to to 1 Might be slightly higher?

Jeff

|

|

By Ted - 12 Years Ago

|

|

The aforementioned dual quad testing was performed on a +060 over 312 that uses an older Crower 238° @ 050”camshaft. Depending upon the heads being used, the static cr is 9.1-9.6:1. This particular short block would have been a pretty typical build for many of the performance Y builds in the 50’s & 60’s. The Lincoln T-Pots on this engine did outperform both the factory dual quad carbs (which included both List 1268’s and 1434’s) and a pair of modified List 1161’s in most instances so over-carburetion with the Lincoln Teapots on this particular combination is not an issue. Port work on the intakes is always a big help as the HP numbers with ported intakes really takes off with the larger carbs. . The fuel bowl covers on both sets of Lincoln carbs used in the dual quad testing are #48's. As delivered from the factory, those covers contain air bleed holes that are sized as per application. On the Teapot dual quad applications, it’s important that the same ‘numbered’ covers be used on each carb. By using the wide band oxygen sensors on the dyno, the fuel curve throughout the rpm range can be evaluated and modified as deemed appropriate. The key here is having a fuel curve that’s consistent throughout the rpm range and not lean on one end and rich on the other. Swapping covers can alter the idle and/or high speed fuel mixtures depending upon the bleed hole sizes. Cover changes by number are a quick way to do this once the various hole sizes are measured. To do this you’d need a stack of the various covers in lieu of either soldering up holes and redrilling or making the existing holes larger. . If the brass tubes to which you refer are the tubes that protrude from the bottom of some of the Teapot covers, those are necessary to richen up the high speed circuit. Removing them may cause a serious off idle stumble while also creating a lean condition jetting changes cannot fix. I’ve found that the idle bleed holes in the Lincoln Teapots are on the large side when using them as pairs on the smaller cubic inch Y’s. Sticking various sizes of small diameter wire in those holes on both carbs while running the engine at idle helps to determine exactly what hole size is ultimately needed for the idle mixture. With the right size idle bleed hole in place, the idle mixture screws are happy at ~1 turn off of closed. . As a general rule, whatever jets are correct for a single four barrel application will be too large for the same carbs when used as pairs. This is simply due to the reduction in cfm that takes place through each carb when using them as pairs. The larger the carbs, the more sensitive they are to jet changes. For the optimum air/fuel ratio when switching single four barrel carbs to dual quad pairs, the jet sizes in both the primaries and secondaries are reduced accordingly. Otherwise the carbs tend to run on the rich side.

|

|

By DualQuad312 - 12 Years Ago

|

Hi Ted,

The tubes that I'm referring to are the ones in the primary venturi's found on the ECZ 1956 holley 4000 teapot carbs. They come up from the bottom and are at an angle. These are not present on the ECJ 9510 AA or AB dual quad carburetors. To help some-up what I'm doing....I'm converting the Lincoln Carbs, To match the original Dual quad Characteristics. I, hope I'm correct in doing so for proper running.....e.g. I, installed the balance tubes. Making a plug for the spark control ports, etc. If i'm understanding you correctly on the "air horn or "lid" of the carburetors the #48 air horns are ok to run as a pair? Thank you for your time in explanation and research you've done.....Honestly some of it is a little over my head....

I'm running a 312 engine .030 over ECZ-G heads. .005 milled off both decks, Heads were milled by someone before I, bought them. The person milled enough off of them to where they started to cut into the lettering that's cast into the head surf. It, could be .020 to .030 milled? You probably have better other standing as to how much? I, run the M-260 cam. .434 lift 268 degrees of Duration (this is what was printed on the grind card) I'm currently running with the factory orig. dual quad set-up no problems.....just wanted to try something else... Curious to hear your thoughts and imput....

Jeff

|

|

By DualQuad312 - 12 Years Ago

|

Ted, the brass tubes are actually pressed into the primary veturies. As mentioned before they come in at an angle from the bottom-up. There actually pressed into the side walls of the venturies at an angle. Holley omitted them on the factory dual quads for a reason....not sure why? Don't know what they do? the part that's confusing is the tubes "lead" to the base of the carb. The holes get covered up when mounted on the intake. This would only leave the brass tube open at that end?

Thanks again for the help and explanation

Jeff

|

|

By NoShortcuts - 12 Years Ago

|

This is a bit of a bunny trail from your carburetor questions, Jeff.

My understanding is that the pads located below the cylinder head exhaust ports, adjacent to the cylinder head surface area that mates with the cylinder block... those pads were 1.000 inch thick when new from the factory.

Sooo... if you measure the thickness of your pads, you'll know how much each cylinder head has been milled over time.

Hope this helps.

|

|

By DualQuad312 - 12 Years Ago

|

Actually the area is in the machined surface of the head.....I'm not sure but I, think it might have ecz there? Not to be confused with the corners of the head that are visible with the heads installed. ECZ-G

Jeff

|

|

By Ted - 12 Years Ago

|

|

Charlie has it right on the heads in regards to determining how much they have been milled. Any measurement less than 1.000” at those pads will give an approximation on how much the heads have been 'flat' milled.

|

|

By DualQuad312 - 12 Years Ago

|

I'm aware of how ford claimed to have made there "machined" thickness blocks and how they made it so that the thickness could be determined. I, found it to be inaccurate. I, measured heads that were machined verses one that I, felt were not. Never felt like I, came up with a confident # with the different heads I, measured. I, work in a machine shop on diesel engines. In some instances the manufacturer (caterpillar) would mill the coil spring seat area and then you could use a depth mic with a strait edge on the deck surface. ....Unfortunately there is nothing machined on the valve cover side of the y-block cylinder heads. Ted, you probably have a lot more experience with the y-blocks then I , have but I, never felt confident with fords way of measuring cylinder head deck thickness

Jeff

|

|

By Ted - 12 Years Ago

|

|

DualQuad312 (11/9/2013)

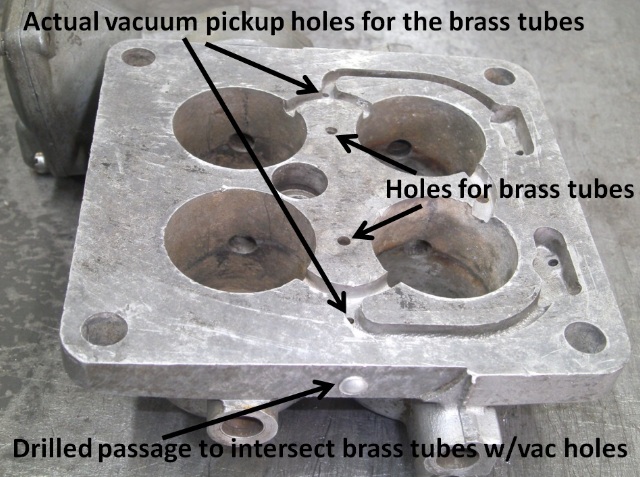

Hi Ted, The tubes that I'm referring to are the ones in the primary venturi's found on the ECZ 1956 holley 4000 teapot carbs. They come up from the bottom and are at an angle. These are not present on the ECJ 9510 AA or AB dual quad carburetors. To help some-up what I'm doing....I'm converting the Lincoln Carbs, To match the original Dual quad Characteristics. I, hope I'm correct in doing so for proper running.....e.g. I, installed the balance tubes. Making a plug for the spark control ports, etc. If i'm understanding you correctly on the "air horn or "lid" of the carburetors the #48 air horns are ok to run as a pair? Thank you for your time in explanation and research you've done.....Honestly some of it is a little over my head.... Jeff. The brass tubes within the throttle bores sees the manifold pressure (vacuum) via a passage that’s drilled width wise at the bottom of the carburetor. Those tubes being in the throttle bores at an angle boosts the negative pressure signal at the fuel discharge nozzles when the throttles are opened just beyond the idle position. This would have been Holley’s answer for that time period for a transition circuit or a way to get some extra fuel to the engine between the idle and high speed circuits. On the Holley 4150/4160 carbs, this is accomplished with slots in the throttle bores that would allow an extra amount of idle fuel into the engine when the throttles are opened up slightly. On the model 4000 Holleys (Teapots), that extra amount of fuel is by way of an earlier discharge from the high speed fuel circuit which also helps to prevent an off idle stumble. . The brass tubes were likely not needed on the dual quad carbs due to the brass rings on the boosters which by themselves increases the air flow through the venturies at the lower rpms. The original purpose of the brass rings was for a cfm reduction in the carbs which makes them more responsive at the lower rpms. That increase in air flow also promotes an earlier discharge from the main fuel circuit which makes the brass tubes that were standard fare on the larger Teapots no longer needed. But a secondary reason for getting rid of those internal brass tubes was that they were simply in the way of the brass rings on the atomization nozzles found in the factory dual quad carbs. . Here’s a picture of the bottom of a non dual-quad Holley model 4000 carb showing the ‘crossways’ drilled passage that allows the vacuum signal below the throttle blades to be transferred to the brass tubes going up to the primary venturies.

|

|

By DualQuad312 - 12 Years Ago

|

Hi Ted,

I appreciate your efforts in helping me to understand why Holley did the changes and modifications to the e-code carbs. Along with that just being able to understand the functions of the teapot Carburetor..... Unfortunately there aren't many people out there that know a lot about them and the Ignorant one's replace then with Edelbrock units and the like. I admit they are a little intimidating cause quite frankly few people know how they work! Walt Nuckles was a guy who knew a lot about the Carbs and Y-blocks and unfortunately has been deceased for about 15yrs. now. He also was from Texas. If you have the chance.....could u put the photos of the different semi spherical pistons as an option for using the "G" heads with the Supercharged engines. You had put these pictures on a month or so ago when I was asking about supercharging an engine....I, tried to find the photos but can't seem to find them?

Thank you again for your help n interest

Jeff

|

|

By Ted - 12 Years Ago

|

|

The main detriment to the Holley model 4000 4V carbs is the single needle seat design which simply limits the amount of fuel that can be supplied to the carb. On 400 or more horsepower, it’s difficult to keep the fuel bowl full through that single needle seat. With horsepower levels steadily going up, the introduction of the Holley model 4150s’s in 1957 was Holley’s answer to the fuel supply issue. The transition between the idle and high speed circuits was also improved. The Carter and Rochester 4V carbs of the time already incorporated a two inlet fuel design (two needle seats) and so they were ahead of the curve at the time. . For the pistons, I believe this is the post you’re looking for. http://forums.y-blocksforever.com/FindPost88522.aspx

|

|

By DualQuad312 - 12 Years Ago

|

Hi Ted,

Thank you for the explanation as to why the Teapot was replaced and thanks for finding me the link on the pistons....Very cool.... :-)

Thanks so much n Best Regards,

Jeff abate.... P.s. If you needed to have a set of Pistons made with the semispherical design...where

would you send them?

|

|

By Ted - 12 Years Ago

|

|

DualQuad312 (11/14/2013)

.... P.S. If you needed to have a set of Pistons made with the semispherical design where would you send them?Jeff. While any custom piston manufacturer can make pistons to your specifications, I use either Diamond or Wiseco for the Y-Block stuff.

|

|

By yalincoln - 12 Years Ago

|

|

say ted, you know that 57 linc. carter carbs are bigger than the 56 merc. carters. witch ones did you test on the dual quad intakes? it would be interesting to see if they are as good as the linc. 1094's.

|

|

By Ted - 12 Years Ago

|

|

Wayne. It was the ’56 Merc Carter WCFB carbs that were tested. There were no ’57 Lincoln carbs available at the time of the tests but some of the mid-Fifties Carters from GM engines were tested and those did have larger venturies than the Merc carbs. The GM Carter carbs (WCFB’s) ran close to the same performance numbers as the Lincoln Teapots but those carbs also had the same carburetor base flange as the Teapots and ’56 Merc WCFB carbs. I’m guessing that the ’57 Lincoln Carter carb is the AFB version and not the earlier WCFB version?

|

|

By yalincoln - 12 Years Ago

|

|

hi ted, no they used 56 linc. manifolds on 57 linc. and turnpike cruisers. the only late holley intake for the linc. is the later big truck intake. it's easy to spot the linc. and merc. wcfb's, they have the secondary vacuum chamber on the side. I think that mid 50' Packard's used the biggest wcfb's. they had dual fours in 56 also.

|