|

By Ted - 12 Years Ago

|

|

DualQuad312 (9/23/2013)

Hi Ted,

...... I was wondering if maybe you might of heard about dished pistons being used in place of supercharged heads or even the trucks heads? A friend had told me this who has a supercharged custom 300...Have u heard of this? I'd assume I, would sill use the large intake valves the ECZ-G heads? I, understand the compression ratio is supposed to be 8.3 to 1 for the supercharged engine.....I, appreciate any insight on this topic,,,

Jeff

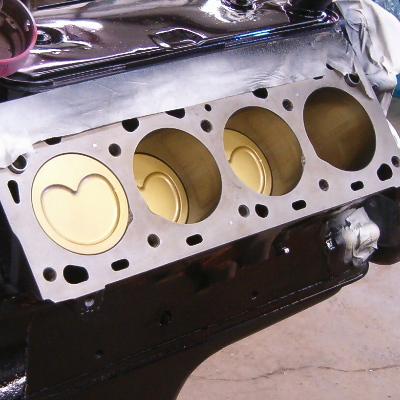

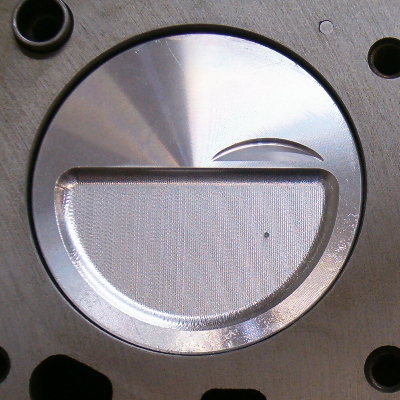

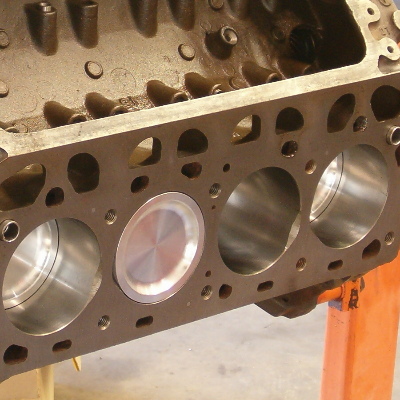

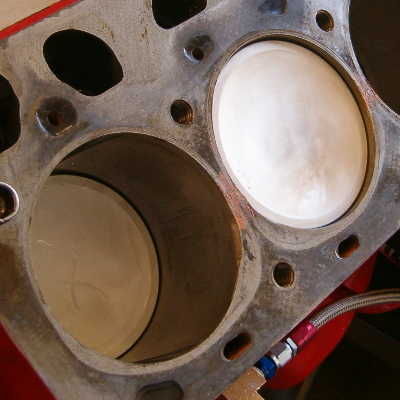

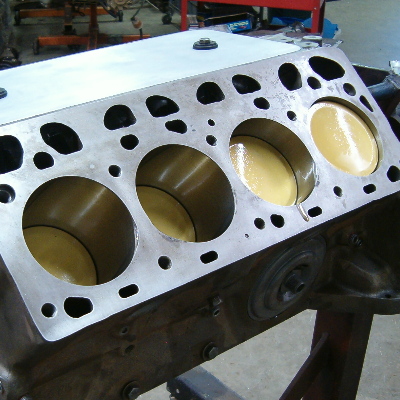

Wben it comes to lowering the compression ratio, dished pistons are an alternative option versus using big chambered heads. With that being said, there are several options on the dish design. Here are some pics of various dished pistons for the Y. For an all out blown application, I lean heavily toward the reverse hemispherical design.

|

|

By skygazer - 12 Years Ago

|

Thanks for the pics, Ted! Fascinating!

Wouldn't the "reverse hemi" design eliminate the quench, and the better mixing it's supposed to have?

|

|

By MoonShadow - 12 Years Ago

|

|

I've been wondering about the compression issue for the Y blocks. With the amount of compression a lot of street blown cars are running now why can't a flat top piston Y run G heads and a McCullouch? Is it due to the age of the design in the castings or what? I ran G heads with my McCullouch before and didn't see any real problems. ? Chuck

|

|

By charliemccraney - 12 Years Ago

|

G heads on a zero deck 292 will be about 8.6:1. When you consider that most Y blocks are no bigger than a 292, it looks like they should do a reasonable job. Most also will not be zero deck so the compression drops further. For 312s and strokers, the G's and flat tops probably are too much.

Modern turbocharged and supercharged cars do run higher compression but they are also entirely computer controlled and I imagine that is where a lot of that ability comes from. The computer can make adjustments much more effectively than a mechanical system can and keep the engine in the safe zone.

|

|

By John Mummert - 12 Years Ago

|

Compression ratio is much more an issue with Rootes or positive displacement blowers than with centrifugal blowers like the McCullochs. Macs just just don't make much boost below 2500-3000 RPM so detonation is much less likely to occur.Some experienced people have told me the best way to build an engine with a centrifugal blower is to build it like a naturally aspirated engine and add the blower.

Frank RIce's engine does have the -471 heads on flat top pistons and runs very well but the blower is making more boost than a standard Mac or Paxton.

The amount of boost is probably of greater concern than the compression ratio or it does, at least, dictate the C/R. Adding boost increases the effective compression ratio because you are filling the cylinder to more than 100%. Assuming 100% V.E., 7.4 lbs of boost (1/2 atmosphere) will give you a theoretic 150% V.E.

Logic would indicate that a dish that mirror images the combustion chamber would be the best but the Rep at Race Tec pistons swears they made more power with a circular dish (reverse dome in custom piston parlance). I have never done any back to back testing so me opinion would be just an opinion.

|

|

By MoonShadow - 12 Years Ago

|

|

Thanks John and Charlie for your response. I am running the 471 heads on my new motor so the blower shouldn't have a problem. I'm still planning to set up the 4-71 blower for next year but forgot about the hood issue. I may have a line on a fiberglass hood that I can cut for the air cleaner. Didn't think about it sticking out of the hood. I sure don't want to cut the louvered one. Chuck

|

|

By Rono - 12 Years Ago

|

I am also running the 471 heads and flat top pistons in my new supercharged motor, but I relieved the block on the recommendation of Gord McMillen. I didn't have any detonation issues on the limited dyno test I had run, but I was also using an MSD 6BTM box which retards the spark under boost conditions.

Rono

|

|

By Ted - 12 Years Ago

|

|

skygazer (9/25/2013)

.... Wouldn't the "reverse hemi" design eliminate the quench, and the better mixing it's supposed to have?

The idea behind the reverse hemispherical dome is to concentrate the combustion pressure on the center of the piston. This reduces the piston skirt friction that is normally induced when the combustion pressure is non-centered on the piston top with a combustion chamber specific or ‘D’ shaped dish. . I did use the reverse hemi dish on the naturally aspirated EMC Y-Block engine which made 528 HP on the UNOH dyno while burning 86 octane fuel (MON method). Here at the shop that same engine made 540 HP when tuning for a peak horsepower number and not worrying as much about the low end torque values which were otherwise needed to help the EMC score. The EMC engine had a very long connecting rod (6.750”) which maximized dwell time at TDC and helped to defray any detonation issues that may have been present if using a 6.300” or shorter rod with the lower octane fuel. Because of the rod length and paying particular attention to the dynamic compression ratio numbers, I didn’t worry about maximizing the quench on that engine.

|

|

By LordMrFord - 12 Years Ago

|

|

charliemccraney (9/25/2013)

Modern turbocharged and supercharged cars do run higher compression but they are also entirely computer controlled and I imagine that is where a lot of that ability comes from. The computer can make adjustments much more effectively than a mechanical system can and keep the engine in the safe zone.

John Mummert (9/25/2013)

Compression ratio is much more an issue with Rootes or positive displacement blowers than with centrifugal blowers like the McCullochs. Macs just just don't make much boost below 2500-3000 RPM so detonation is much less likely to occur.

Most of turboharged engines are intercooled what cannot be done easily with roots-style chargers.

|

|

By pegleg - 12 Years Ago

|

|

John Mummert (9/25/2013)

Compression ratio is much more an issue with Rootes or positive displacement blowers than with centrifugal blowers like the McCullochs. Macs just just don't make much boost below 2500-3000 RPM so detonation is much less likely to occur.Some experienced people have told me the best way to build an engine with a centrifugal blower is to build it like a naturally aspirated engine and add the blower.

Frank RIce's engine does have the -471 heads on flat top pistons and runs very well but the blower is making more boost than a standard Mac or Paxton. parlance). I have never done any back to back testing so me opinion would be just an opinion.

I do have to run 30 degrees or less total and 110 octane to really make it work though, wish i could legally run a set of your heads!!.

|

|

By MoonShadow - 12 Years Ago

|

Send a set to me Frank and I'll powder coat them Ford red. The scrub guys will never know! Chuck

|

|

By DualQuad312 - 12 Years Ago

|

Hi Ted,

I, wanted to thank you for taking the time to answer my questions and for really going the extra mile down loading photos. Pictures are worth a thousand words for sure! Where would I locate these reversed semi-spherical pistons? Is it possible or even practical to modify a typical flat top piston? Is it a good idea to zero-deck height a y-block and is it ok to on a supercharged block?

I, rebuilt three y-blocks,not many :-) and I'm not clear on how I, would get all eight pistons to be equal in height? I, did a 312 for my '57 Ranchero. If I'm remembering the notes I, jotted down I had between .030 - .040 below the deck height. On a side note I run a factory dual quad on the Ranchero, .437 lift (mild cam). Car really goes down the road nicely...

Thanks again for the help and your interest,

Jeff Abate

|

|

By Ted - 12 Years Ago

|

|

DualQuad312 (9/28/2013)

... Where would I locate these reversed semi-spherical pistons? Is it possible or even practical to modify a typical flat top piston? Is it a good idea to zero-deck height a y-block and is it ok to on a supercharged block?

I, rebuilt three y-blocks,not many :-) and I'm not clear on how I, would get all eight pistons to be equal in height? I, did a 312 for my '57 Ranchero. If I'm remembering the notes I, jotted down I had between .030 - .040 below the deck height. On a side note I run a factory dual quad on the Ranchero, .437 lift (mild cam). Car really goes down the road nicely... Most custom piston manufacturers can put the desired type of dish in a piston if given enough information. If attempting to machine a dish into an existing piston, it’s important to first check the piston deck thickness to insure that there is enough material remaining after the machining operation in which to support the combustion pressure. On normally aspirated engines, I prefer a minimum of 0.200” of material and on boosted applications a minimum of 0.300” of material depending upon the amount of boost. . The top ring land is also a consideration in that you want to make sure any machining to the piston top clears that area adequately. . It’s still a good idea to deck the block even for a supercharged application. Besides insuring that the decks are parallel or flat, decking will help to have all the pistons at the same depth assuming the decks are cut parallel with the main bores or the engine was mocked up with its respective pistons in the bores and cut accordingly. I prefer the installing of the respective pistons and rods in the corner bores and then cutting the block accordingly. This can be performed without having the rings on the pistons and in many cases without actually installing the caps on the rods in which to do this. . Zero deck or up to 0.010” in the hole with a 0.045” thick gasket will still insure a given amount of quench even on a piston that has a semi-hemispherical reverse dish. Making the dish smaller in diameter and then deeper would also help to increase the quench versus the larger dish shown in the pictures posted earlier. The piston blank being used may dictate to a large degree what you can do with the dish.

|