|

By charliemccraney - 14 Years Ago

|

Has anyone here had prototype water jet work done? Where? I want to get a quote for something and can't get anything from local shops. I send the cad drawing for a quote, emails, etc and get nothing back.

... or maybe even laser cutting. I haven't looked into that.

|

|

By Glen Henderson - 14 Years Ago

|

Charlie, I have had some stuff cut at a local shop here in Montgomery, they do good work. What are you wanting, I can talk to them. Charlie, I have had some stuff cut at a local shop here in Montgomery, they do good work. What are you wanting, I can talk to them.

|

|

By charliemccraney - 14 Years Ago

|

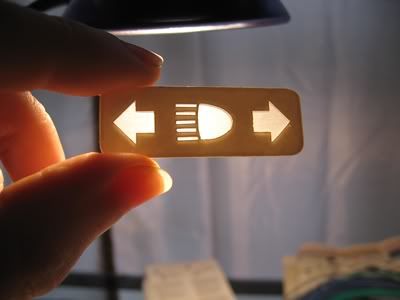

Well, after having pretty well completed my indicator lights, I'm thinking about taking it a bit of a different direction, for a cleaner look, if it doesn't cost an arm and a leg.

Basically, I want to have the part that the light shines through cut out of steel if it is possible with such a small piece.

Rough dimensions are 1 7/8 x 5/8 with the symbols being 5/16 tall and the light rays about .020" wide. I can try to make adjustments if this design is not within the limitations of the cutting technology.

If I do this, I'm going to go with a more period looking design for the arrows, one that I saw in a '62 Mercury. So the pictured design is not exactly what will be made but it will give them an idea.

And if anyone has ideas about how I can make this at home, I'm all ears. It is the light rays that are the trouble. I can't figure out a way to cut .020" wide slots about 3/16 long.

|

|

By Glen Henderson - 14 Years Ago

|

|

I don't think they can cut something that small, this is more of an industral operation, but I will print the picture and ask them. I don't think a waterjet will do it, almost sure that it would have to be a laser machine. The parts that I had cut were done on cc plasma machine.

|

|

By charliemccraney - 14 Years Ago

|

Thanks!

I wish it could be done with a plasma cutter. I have a friend with a homemade CNC plasma cutter. He uses it at his tubing shop.

|

|

By GREENBIRD56 - 14 Years Ago

|

|

Charlie - Our business gets stuff made at a laser shop here, "The Metal Man" - but it has to be metal of course. They usually ask us for an Autocad drawing of XY coordinates that can be directly programed into their machine. There has to be the same sort of thing in your part of the world.....

|

|

By charliemccraney - 14 Years Ago

|

They are around here. They just must not be interested in low volume work or dealing with individuals or no longer in business or something. Some of them even state on their website that hey handle prototype work which is technically what this is. I've sent drawings for a quote to several places and heard nothing back. The cash is burning a hole in my pocket, too. Oh well.

Might The Metal Man do what I need or do they deal only with businesses?

|

|

By jepito - 14 Years Ago

|

|

The water jet I use cuts a .040 kerf. But I have access to a laser cutter that could do .020. The only problem with the laser is it is not built for metal. Could the part be a plastic or wood material?

|

|

By charliemccraney - 14 Years Ago

|

|

It will need to be steel so that I can weld it. If necessary, I can try to modify the design so that it is within the limitations of the technology.

|

|

By GREENBIRD56 - 14 Years Ago

|

|

Charlie - I'll send you a PM with my email address.....get me an XY plan drawing of the item and then we'll see what my purchasing guy can get out of the "Metal Man". He often makes us special little shims and rings and stuff out of sheet metal. I know the last time I was over there with our warehouseman - he had a huge pile of stainless "hummingbirds" he had burned out for some lady in the knic-knac business.

|

|

By charliemccraney - 14 Years Ago

|

Oh, shoot, I thought I already posted it, but I tried some local laser cutting places yesterday and got replies about it so I will see what I can work out with them first.

Steve, got the pm. XY plan, is that just another way of saying 2d?

|

|

By YellowWing - 14 Years Ago

|

|

There is a guy a couple miles from the house that does small jobs all the time. I have not had anything done but a friend had him cut two stainless filler panels for under his hood. He made cardboard templates and the sop did the rest. Another fried has them make things all the time. We are in a small community of a couple thousand and he is one of only a dozen or so businesses so maybe that is why he is so accommodating. If you would like Me to check with him I would be happy to do so. Mike

|

|

By YBLOCKMERC - 14 Years Ago

|

|

Here in the Seattle area, I work with a laser cutting shop frequently. He does a lot of fine cutting for plaques and trophies. Cuts in mild steel, stainless and plexiglas. If your other leads don't pan out, PM me and I can grease the skids.

|

|

By GREENBIRD56 - 14 Years Ago

|

|

Yep Charlie - 2D is what the guy is using - I believe its just an older version of AutoCad. They put the "true" dimensions of the desired finished part in and the cutting machine makes a curf adjustment for the material thickness they tell it is in use. A local shop will work the best for you - but if you get stuck, let me know.

|

|

By charliemccraney - 14 Years Ago

|

Steve,

Email sent.

One of the local laser cutting places can cut steel. The other deals with plastics. The steel place wants more than I'm willing to pay. I'm looking into the plastic but prefer steel.

It's not looking like this project will happen locally. So guys, please post or pm the contact details of shops you've dealt with who laser cut steel so that I can contact them about this.

|

|

By Richard Head - 14 Years Ago

|

Glen Henderson (3/9/2012)

Charlie, I have had some stuff cut at a local shop here in Montgomery, they do good work. What are you wanting, I can talk to them.

Hi, Glen. Are the "rings" in your picture a "Torque Converter Girdle" for the Flat-o C-4 adapter? I remember someone on here mentioning them. Do you have one for sale or know where I can get one?

The setup that comes with the kit just doesn't look like it would hold up long. Thanks.

Sorry for Hijacking your thread Charlie. Now back to the scheduled program.

|

|

By jonnireb - 14 Years Ago

|

|

There is a laser cutting shop here in West Monroe,La. They did a good deal of work for me a few years ago, cutting small steel parts for the paper converting Industry. The Parts were usually thin carbon steel. Their prices were reasonable, but I was ordering in pretty large quantities,don't know how they would have been in small lots. Also don't know if they have a minimum order. Their name is Metalforms,Inc. Located at 260 Huey Lenard Loop Rd. 71292. Phone (318)397 8064. Worth a look.

|

|

By Glen Henderson - 14 Years Ago

|

|

Yes they are Richard, how thick do you need , I have a couple but don't remember if they are 1/2 or 1/4 inch.

|

|

By Richard Head - 14 Years Ago

|

|

Glen Henderson (3/17/2012)

Yes they are Richard, how thick do you need , I have a couple but don't remember if they are 1/2 or 1/4 inch.

Glen, thanks for your response. Too be honest with you I have no idea how thick it should be. I hadn't really thought about it until I notice your picture. Are you using one on your car? Any suggestions?

Thanks.

|

|

By Glen Henderson - 14 Years Ago

|

|

Not to Hi jack Charlie's thread, but if you are using a stock size converter, you should not need a spacer only the studs supplied by Flat o matic. I am using an aftermarket high stall 10" converter with an antiballoon plate and it had larger studs than those that came with the kit.

|

|

By Richard Head - 14 Years Ago

|

|

Yes don't want to hijack Charlie's thread. Thanks for the info. I'm running a TCI converter with a advertised stall of 2400 rpm.

|

|

By Glen Henderson - 14 Years Ago

|

|

You will just have too see if the flat o matic stuff will work, if not time to get creative. Mine is a TCI 3500 stall, but it is a small converter. I have pic's, I'll see if I can dig them out and post.

|