|

By Glen Henderson - 14 Years Ago

|

|

I have done a little research on E85 since 110 race gas is going for $10.50 a gal around here. I think it avg's around 105 octane, but it depends on the time of year and where you are.

|

|

By Glen Henderson - 13 Years Ago

|

|

I think you are going too find the weak link, if you can get that beast to hook!

|

|

By Glen Henderson - 13 Years Ago

|

|

An orginal four wheel drive slick in that condition is worth quite a lot of cabbage! My suggestion is drive it while looking for something more approiate for that much power, roller race cars can be found for cheap these days.

|

|

By Jim Rowe - 13 Years Ago

|

What a motor. BOOM? you didn't blow it up?

Hope not.

Enjoy

Jim

|

|

By pegleg - 14 Years Ago

|

|

Turns out the octane rating of E-85 is higher than you might think. RB worked with this a year or so back. He may be a source on relative timing and Jetting. I know it's going to require more fuel than it would on Gasoline. But with 85% alcohol it'll run a lot cooler than gas and burn slower. will need more than 22 degrees I'd bet

|

|

By pegleg - 14 Years Ago

|

|

Royce, What about the supposed corrosive effects. Is it really an issue?

|

|

By pegleg - 14 Years Ago

|

|

[Engines really like this stuff Burns cool and clean.. And your race car smells like stale beer[/quote] HMMM.........................Wonder if I can find jets big enough for my Edelbrock?

|

|

By pegleg - 14 Years Ago

|

|

Have your machinist be careful not to machine the pistons too much. You'll need at least .200'' wall thickness left on the piston tops. And that's pushing it at 18/20 #.

|

|

By pegleg - 14 Years Ago

|

|

Charlie, We have a couple around here that run high 13's with bolt ons Exhaust, cold air etc. Where they really rock is out of the hole with the 4 wheel drive thing.

|

|

By pegleg - 13 Years Ago

|

|

I don't know about Southern trucks, hopefully it's a good rust free example, but up here most of them have gone to the graveyard because the frames became too rusty to drive. Make sure to check everything in the front, around the motor mount and streering areas of the frame. I tried to repair one a couple years ago, Lasted about 6 months then tore itself apart. This was a lifted "Big Tire" truck just like yours.

|

|

By pegleg - 13 Years Ago

|

The two wheel deal might work. I'd love to see it in a reinforced frame, short wheel base truck. That could be spectacular! The two wheel deal might work. I'd love to see it in a reinforced frame, short wheel base truck. That could be spectacular!

|

|

By pegleg - 13 Years Ago

|

|

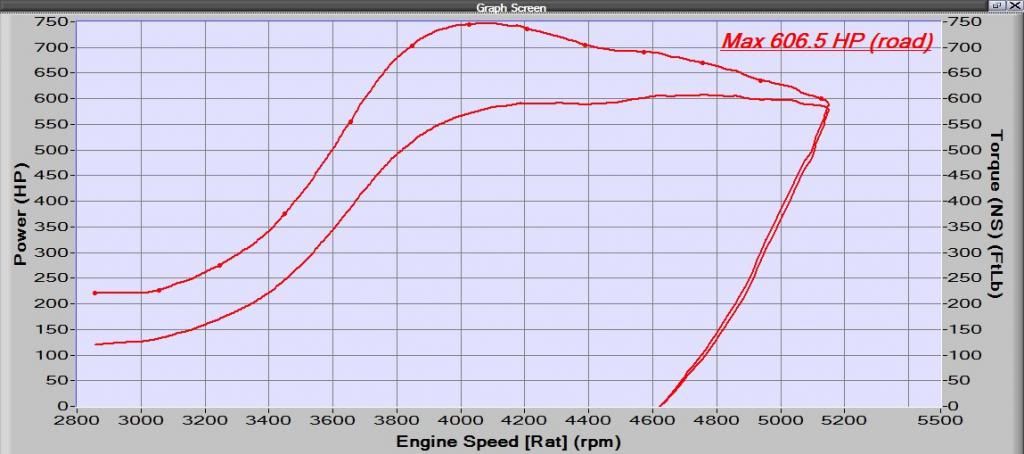

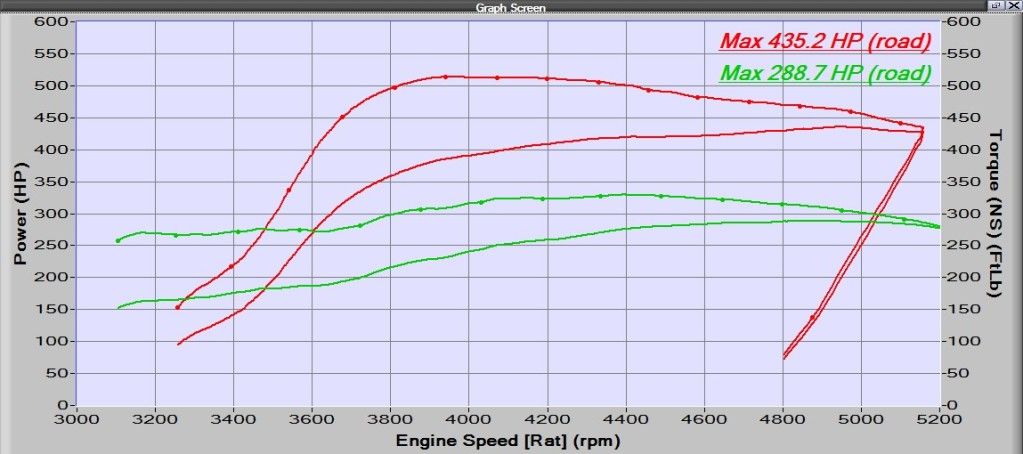

I love those torque numbers, that's diesel territory.

|

|

By pegleg - 13 Years Ago

|

|

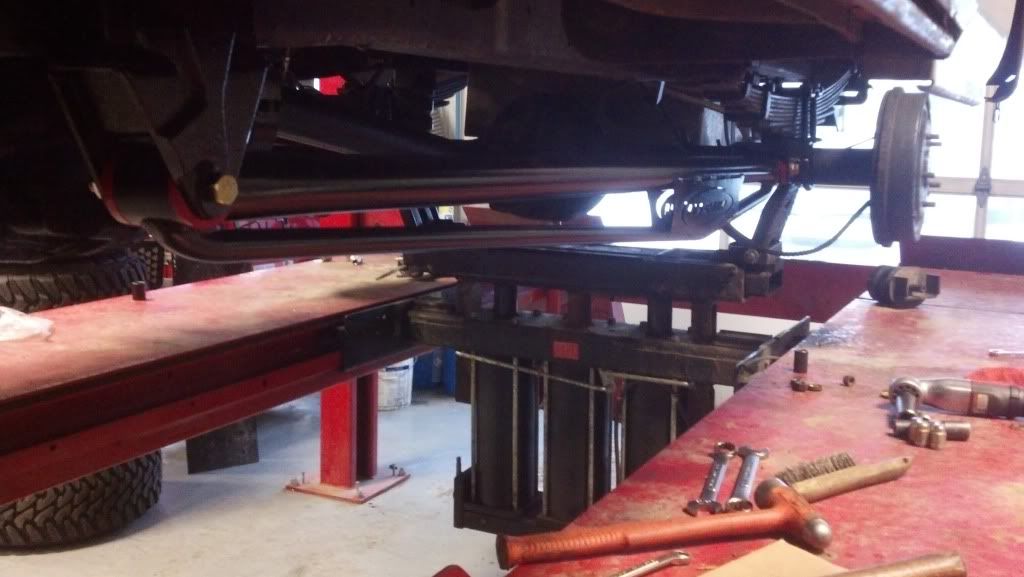

On my 57 I had to re-enforce the original spring pads as well. I wound up plating them with 3/16 steel and extending the rear portion back a couple inches over the spring to prevent the housing from rotating. I'd consider a 3 or 4 link or ladder bars in your case. The torque numbers are way more than leaf springs are going to be able to handle.

|

|

By pegleg - 13 Years Ago

|

|

How did you run all the instruments etc. without the computer?

|

|

By pegleg - 13 Years Ago

|

|

I'll bet someone makes an electric sending unit for the speedo, the rest could be old style mechanical/electrical add ons/

|

|

By GREENBIRD56 - 14 Years Ago

|

|

What diameter are these push rods? - mechanical column strength is based on the tube OD, so aren't the Isky pushrods out at 3/8 diameter.....?

|

|

By MoonShadow - 14 Years Ago

|

|

Any chance the cylinder was under pressure and hydraulic'd? Chuck

|

|

By MoonShadow - 14 Years Ago

|

I think you are correct in basic theory Charlie but there are examples that seem to indicate the Y, if correctly prepped, will take a lot of boost. My new block was in a boat with a 6v-71 GMC supercharger on it. Ted can possibly shed some light on this.

As far as the twin turbo is concerned I just wondered if there was a shot of fuel or something that would hold back the piston on restart and cause the two bent push rods. Perhaps the piston to wall clearence needs opened up a bit. The extra heat that is generated after a hard pass and shut down could cause expansion of the piston slug causing it to drag in the block. They say it ran fine all the way through and on the way back. It was on a later restart that the miss developed.

Of course you know I'm no expert and not really that informed about these things. All I can do is recall the past and theorize the cause. I just want to see some 9's and maybe 8's out of this awesome rig. Chuck

|

|

By MoonShadow - 14 Years Ago

|

|

HollowHead, While replying to Charlie I recalled a situation with piston clearence being to tight and causing the piston to drag in the hole after shut down. When you make a hard pass and go straight back to the pits and shut the engine off the heat will build some. Just a thought. When I was in Hawaii I helped out a fellow with a 71 Firebird running an Oldsmobile engine. Basicly a Super Stock car. After a pass we had a quick disconnect water inlet on the block and carried a water tank with a 12V electric pump in the chase vehicle. Once connected the radiator drain was opened. As we towed the car back to the pits the hot water ran out and was replaced with cooler water. We never had a problem with the pistons again and were on top for quick turn arounds during eliminations. We always started with a cool block. Just a thought, I'm sure the Twin Turbo's make some heat. Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

Are you going to play in the mud with it? Awesome horsepower! Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

We have such a wide span of users here. Some are stock or modified daily drivers some are show cars some are drag cars and we even have at least one round D round dirt track car and a couple of NASCAR replicas. So adding a mud truck would just expand our many horizons.

|

|

By MoonShadow - 13 Years Ago

|

|

And another camp heard from. Didn't think about pulling. Make sure you get video. The sound should be interesting. Chuck

|

|

By MoonShadow - 12 Years Ago

|

|

I'd love to see the faces when people figure out you are running a Y-Block. Put a camera under the hood! Chuck National Tails Raceway Y-Block Nationals 2014 Bring the Dyno. Lots of Y's guys would love to see their numbers!

|

|

By MoonShadow - 11 Years Ago

|

|

Man time has flown. I just reread the article on the Y-Block forum. What a totally awesome story, not to mention the truck. Did you ever get a chance to run it on a track? Still love to see you at Columbus for the shootout. Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

Friend of mine here in New Hampshire had a vanity plate of 3MTA3. We are a two plate state so he had one back and front. Write 3MTA3 on a piece of paper then hold it up to a mirror. Now you know why a state trooper stopped him after passing him and lookng in his rearview. The trooper then made him remove and surrender the plates! Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

Is there really a Y-Block under all those hair dryers and tubes! You will need to paint your valve covers a really bright color so people can see them! Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

I recently found a speedometer from Speedhut. Its a GPS unit! Works great, wont care about changes in tire size or gear and is very accurate. They build them as various diameter round gauges and I expect soon as more stock appearing assemblies. All you need is a power source and a place to mount the small sensor. Chuck

|

|

By MoonShadow - 13 Years Ago

|

Sorry, didn't think about it. Here is the link to their GPS gauges. I think they will be making more stock replacement or conversions in the future. A great idea who's time has come. Chuck

http://www.speedhut.com/gauges/GPS-speedometers

|

|

By MoonShadow - 13 Years Ago

|

|

Not really hijacked. He did mention a speedometer problem. I had one made for my 28 Chrysler similar to the original gauges. Even says "1928 Chrysler Series 72" on it. Chuck

|

|

By MoonShadow - 13 Years Ago

|

Wow! Talk about a serious street sleeper. I pity the fool that takes it on. I hope you get good coverage and a good Dyno result at the show. Might dumbfound the crowd if the numbers are as good as before. Can't wait to see it at Columbus  . Chuck . Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

One of the great benefits of farm life there always seems to be a few spare vehicles scattered around. Especially it you are looking for pickups. We got an old chevy sedan running when I was barley a teen. Used it for a "gully racer". basicaly that meant go as fast as the crapped out old 6 cylinder would allow and up a bank to see who could go highest on roll over the neatest. Glad my parents and other relatives never caught on. We thought we were good enough to be "hell drivers". Sure, fat chance! Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

You are crossing over into gasser or altered country with that engine. Did the axles twist on that first banzai run or previously? What are you running for transmission? You are going to need a really stout driveline to handle this beast. Ok, give up, put in a straight axle front end with a nose up attitude, use the extra 5" to put in tubs and BIG slicks and go crazy! Chucik

|

|

By MoonShadow - 13 Years Ago

|

|

What a pleasent supprise, to start a project and pour your knowledge and experience into that and then find out you created a MONSTER! Wish we all had such tough luck. Chuck

|

|

By MoonShadow - 13 Years Ago

|

Looking good, again. I'll bet this time there will be a lot of checking around the fuel linkage!

I bought a new Fairlane back in 69 and drove the s(&^% out of it. I was lucky to get one of the dealer prepped 428 Super Cobra Jet, Fairlane Cobra's. Lightened with a 4:30 Detroit locker and 4 speed. It was everything they say it was. Super fast car. 6 months later me, the wife and the Cobra were all transferred to Germany. Now that there was FUN! Conrad never saw it coming. But thats another story. Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

SCRBKILR, Y-NOTA-Y, FAST-Y, ETC. ETC. Chuck

|

|

By MoonShadow - 13 Years Ago

|

I would think something like AWSHI$ would pay homage to the old truck too?  Chuck Chuck

|

|

By MoonShadow - 13 Years Ago

|

Geez would you guys quit! Shooting for 1K? Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

Guilty as charged! Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

Your truck is really looking good. I think we have all had the drill vs carpet experience. Sometimes you just gotta do it! Chuck

|

|

By MoonShadow - 13 Years Ago

|

Very sorry to hear about the damage but the "ride" is one you will never forget. After this quarter mile blasts will seem tame I'm sure. At least all the important things survived, the engine and oh yeah you too!  Trucks are easier to replace/fix than people. Chuck Trucks are easier to replace/fix than people. Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

Maybe one of those tiny Ford Rangers would be a spot for the engine. There seem to be a lot of them on the dragstrip now. That would really be scary! Chuck

|

|

By MoonShadow - 13 Years Ago

|

Did you ever see the 56 Ford nose kit that was around for the newer F150's? I saw one at Carlisle one year and it was great. They made a complete nose out of fiberglass that was massaged to fit in place of the original front end. The truck was a stepside and had the supercharged motor in it. Package was about $50,000! I'm sure they didn't sell many at that price. Even counting the new truck and trir ck motor I figure about $15,000 overpriced. Looked good though. That said I have no idea how much work would be required to modify a fiberglass 56 nose to fit your F150. Would be cool though.  Chuck Chuck

|

|

By MoonShadow - 13 Years Ago

|

Nice article. I do believe we have their attention now!  Chuck Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

As someone already mentioned you are going to find some weak links when you hammer on this setup. I would recommend a drive shaft safety loop on both shafts and make sure the differentials are in good service. Check all the U-Joints and other connections. I remember reading somewhere that the pickup frames are mostly ladder frames and are somewhat flexible. Along with the ladder bars and welding all the existing cross members you might build an X member to tighten it up. Thanks for sharing your project I think it is exciting. Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

Check the frame for torsional twist. I'd also search the web for competition trucks to see what they have done to strengthen the chassis. Torquing up on mud or dirt is a lot different than pavement. Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

Ladder bars look great! And is is wild the way the spring mount worked for them. High or low the truck is definately going to turn some heads. Trucks have a bigger problem with torsional twist due to the ladder type frame. Over the years they have gone to x members and kickup's to strengthen them. It you have ever driven slowly over really bumpy terrain and watched the area between the bed and cab you know how much they can move around. I would still suggest welding all of the current cross members to the frame and adding a X member. Sorry for harping on the subject but I've seen some bad things happen when frames break under pressure. Chuck

|

|

By MoonShadow - 13 Years Ago

|

Definate improvement. You will need to paint little gm scrub logo's on the fenders for each one you eat one the street. Super sleeper. Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

Wow, looking great. What a sleeper you've built, you are going to terrorize the streets in that. Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

You have to bring the truck to Columbus, Ohio Labor day weekend! We NEED to see that wild motor. Chuck

|

|

By MoonShadow - 13 Years Ago

|

On all 4 wheels! Shades of Tommy Ivo. Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

Any riveted frame member should be welded it should make an apparent difference in the launch. Ladder bars are a great idea and on a truck you can make them longer. It will also come apparent if your springs rates have varied from side to side. Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

Off in a different direction then. I have seen some really storming 4wd trucks on ESPN at the drags. Might be ineresting. Chuck

|

|

By MoonShadow - 13 Years Ago

|

It's not impossible to do!

http://www.youtube.com/watch?v=NSyXpT_68QI

Chuck

|

|

By MoonShadow - 13 Years Ago

|

|

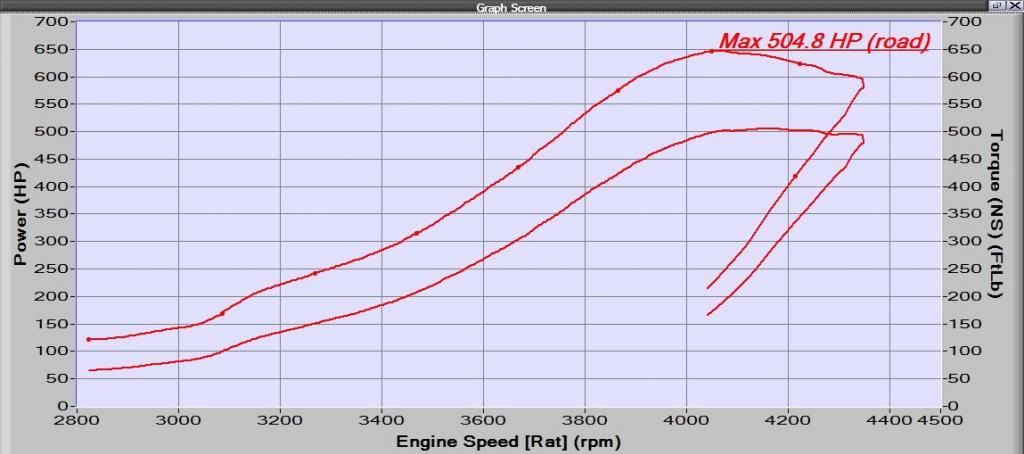

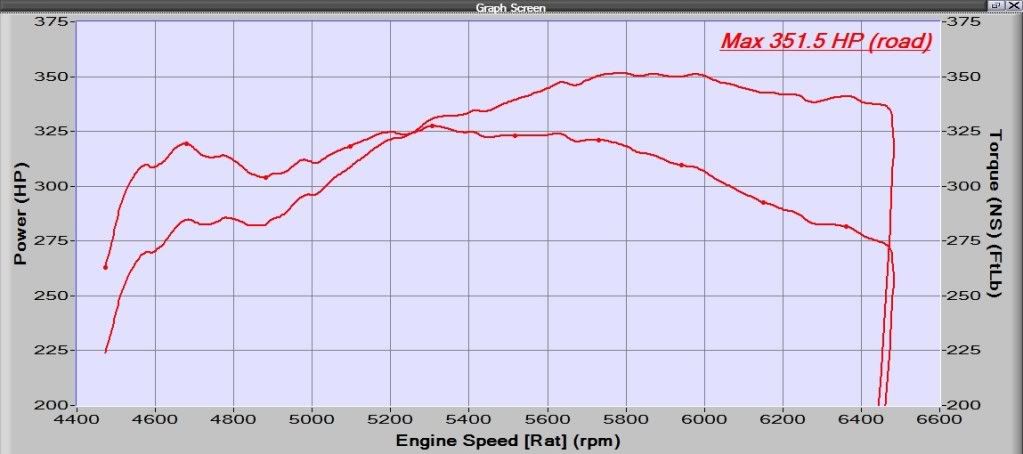

Those numbers are pretty consistant for a new engine that isn't totaly dialed in. I think you may have a scrub killer there. It wouldn't hurt to set it up lower with the ladder bars and some sticky tires. I'd love to see what it would run in that trim. If it's not putting up the numbers then you could still go to 2WD and try again. The idea of a balls out 4wd Ford pickup smoking all four tires is getting my imagination working overtime! Go get em! Chuck

|

|

By glrbird - 14 Years Ago

|

|

http://www.y-blocksforever.com/forums/Topic71011-3-1.aspx here is the info on copper headgaskets.

|

|

By glrbird - 13 Years Ago

|

|

I haven't owned one of the truck for a few years, but aren't the cross members rivited in? You could weld the cross members to the frame,(the one's you don't need to remove), but for the most part the frames were pretty strong, but they weren't built for that kind of torque.

|

|

By glrbird - 13 Years Ago

|

Hutz

While you are waiting for better weather, you should write an article on you adventures with turbos. Alot of the guy's know how to squeeze compresion and flow to make HP, but you are going in a direction that I have always been interested in. I never thought the head gaskets would take that kind of boost. Great job,

|

|

By glrbird - 13 Years Ago

|

|

2 TURBO Y

|

|

By pintoplumber - 14 Years Ago

|

|

Ted, boy your son really must have had a lot of weight in the trailer.

|

|

By suede57ford - 14 Years Ago

|

|

Hutz, Keep up the good work. The only way to figure to it out and get everything sorted is to jump in and expirement like your doing and work out one detail at a time. Just make sure it doesn't ping. Starting with the lower boost is a good idea until you get the fuel to it. It took me a while to get my VR57 blower car working right with the teapot, but now it is pretty darn fast. My original set-up with the blower had cast pistons and all stock everything including head gaskets. That long block is still in running condition, but in storage today. I started breaking stuff when I began building hotter combo's with more cubes, better flowing heads, and bigger cams. It was sort of a grenade for awhile. I think the first thing to go when I added the blower was the t5 which I broke three in a row before I upgraded to a Tremec TKO. Of course then I started wasting motors, but I got really good at tunning it and have really figured out a good combo. You may break a few things, but if you just keep working on it you will develop your own combo and the thing will be a thrill to drive. Good Luck with the dyno, and keep having fun.

|

|

By suede57ford - 14 Years Ago

|

|

Great Job! I have enjoyed watching your progress. Looks like you are having fun now. A really unique ride. Keep up the good work, and thanks for posting the results.

|

|

By Hollow Head - 15 Years Ago

|

How are you going to arrange oil return from the turbo? Nice work and good to see more people dealing with turbos and efi set ups  . .

|

|

By Hollow Head - 15 Years Ago

|

Grhmmm... that is the turbine wheel in that last picture. Compressor wheel AKA impeller wheel is on the other side  . Well, one could think down pipe as a screen over the open hole. . Well, one could think down pipe as a screen over the open hole.

|

|

By Hollow Head - 15 Years Ago

|

You will end up to buy at least 30 % larger fuel injectors  . Current injectors may be open all the time with lots of pressure. You will get it running, but will not get it tuned to high rpms. Trust me, we have faced the same problem. Our eight 30 llbs/hr injectors run out of capacity after 330 HP and 630 Nm at 5300 rpm with pump gas. With E85 you will need about 90 lbs/hr or even much more... . Current injectors may be open all the time with lots of pressure. You will get it running, but will not get it tuned to high rpms. Trust me, we have faced the same problem. Our eight 30 llbs/hr injectors run out of capacity after 330 HP and 630 Nm at 5300 rpm with pump gas. With E85 you will need about 90 lbs/hr or even much more...  . Good Luck and take some videos to show us. . Good Luck and take some videos to show us.

Ah, sorry... you have 900 cfm Holley Tbi. Really don't know how much fuel it will deliver.

|

|

By Hollow Head - 15 Years Ago

|

|

Simo, you remember when at dyno, we tried about 45-50 psi and then the injectors started flooding. 40 psi equals 2.7 bar of pressure. 20 psi is very low 1.4 bar.

|

|

By Hollow Head - 15 Years Ago

|

Hutz.... is it running yet  . We are waiting.... . We are waiting....

|

|

By Hollow Head - 15 Years Ago

|

Good work Hutz! Can't wait to see it roaring down the streets  . More pics about the truck and engine? . More pics about the truck and engine?

|

|

By Hollow Head - 13 Years Ago

|

|

Hutz, congrats! We all knew you will do that someday and now you did. Great effort from you all!! Now get that truck to Columbus and show them all what it can do. Would sure be crowd pleaser.

|

|

By Hollow Head - 13 Years Ago

|

How about just adding traction masters or similar build ups? Like these used with Mustangs...

These are known to reduce wheel hopping. Easy to do yourself too.

|

|

By Hollow Head - 13 Years Ago

|

Or then just buy a decent frame for it and shock the chevy guys some more  . .

Like this?

|

|

By Hollow Head - 13 Years Ago

|

Hutz, when I first got your message, I thought it would be even worse. That ain't bad at all. Just get a new cabin for your truck, but please don't do anything as stupid as above  That red one is ugly as hel... That red one is ugly as hel...

|

|

By Hollow Head - 13 Years Ago

|

Eeehh... really don't get the point with that fuel pump block off / oil distributor thing. You still have to hook it to oil gallery from somewhere... This is how we did. Fuel pump block off plate is just a block off and oil feed comes from the gallery and splits to two. That system is still in use though that picture is from early twin turbo days  . .

|

|

By Hollow Head - 14 Years Ago

|

I like your attitude, Hutz! Keep going  . .

|

|

By Hollow Head - 14 Years Ago

|

|

There is some good info about spark plugs and heat ranges here http://www.championsparkplugs.com/charglossary.asp?kw=Heat+range As, we have had Champion RF14YC plugs now and when we took those of, they were very close to be melted if those pictures are exact  . So, we will definetely move to colder plugs but that means that we have to start the engine with hotter ones due E85 fuel and that we don't have any cold start enrichments. Then, after engine is warm, we can change to colder ones . So, we will definetely move to colder plugs but that means that we have to start the engine with hotter ones due E85 fuel and that we don't have any cold start enrichments. Then, after engine is warm, we can change to colder ones

|

|

By Hollow Head - 14 Years Ago

|

John's comment may well be the issue. We have new k-liners in our heads and Ferrea stainless steel valves on both sides, And as said, we lost couple of push rods at the starting about an half hour after previous run. But, last weekend went without problems on the engine side  . Chevy parts keep breaking... . Chevy parts keep breaking...

|

|

By Hollow Head - 14 Years Ago

|

Good to hear you are still running  . Just put 20 psi under the hood and that rice burner is toasted . Just put 20 psi under the hood and that rice burner is toasted  . .

|

|

By Hollow Head - 14 Years Ago

|

WoW! Now all you have to do is to turn that #2 compressor side 180 degrees to get even more symmetrical look and get that center section pointing downwards to drain the oil back to oil pan  . Also, as those turbos have that flange on the compressors, that gives an opportunity to add brackets to hold them up better. Just fab brackets from the timing cover etc... . Also, as those turbos have that flange on the compressors, that gives an opportunity to add brackets to hold them up better. Just fab brackets from the timing cover etc...

|

|

By Hollow Head - 13 Years Ago

|

|

Lookin' so good so far! One serious build, have to say. Hutz, what are you going to use as a head gaskets?

|

|

By Hollow Head - 14 Years Ago

|

What a waste  . Good pop ups milled to nothing! No, I hope that you get the engine running ok and you will break that 800 hp barrier soon . Good pop ups milled to nothing! No, I hope that you get the engine running ok and you will break that 800 hp barrier soon  . .

|

|

By Hollow Head - 14 Years Ago

|

|

Absolutely boost sensing fuel regulator. We have AN8 sized fuel lines and a Mallory regulator which has a fuel return line back to fuel cell. And we have about 43 psi pressure now.

|

|

By Hollow Head - 14 Years Ago

|

... Bent push rods seem to be common problem with turbocharged Ys ... Bent push rods seem to be common problem with turbocharged Ys    .: We have plenty of those too! But so far, we have had no problems with pre ignition. Luckily, last weekend went without problems with engine... 6.04 at 1/8 mile. .: We have plenty of those too! But so far, we have had no problems with pre ignition. Luckily, last weekend went without problems with engine... 6.04 at 1/8 mile.

|

|

By Hollow Head - 14 Years Ago

|

Twisted Fate, you have to remember that current Y-block WR is 7.966 at 1/4, so we are not even close to that  . Yet.... . Yet....

|

|

By Hollow Head - 14 Years Ago

|

|

Hutz, we really don't know for sure, but first problems were caused by loose adjusting nuts and too wide adjusting balls on rockers. When the push rods cracked due too large balls, adjustment of the valves got loose and let the push rods to drop. Those are not affected by boost. The last problem was odd, because when Jyrki came back from that 10.020 run, the engine idled correctly. But, after we fired it again after about half an hour it run with only 7 cylinders and when we opened the covers, #5 had no push rods and they were badly bent after we found them from lifter valley later. Last weekend we run six 1/8 mile runs without any problems. But, we had only 10 psi of boost as we had on the dyno earlier this summer and those Fel-Pro blue gaskets are still holding ok.

|

|

By Hollow Head - 14 Years Ago

|

Moonshadow, that's what we consider as a reason too. And, someone has to discover the limits, so Hutz, we are keeping the thumbs up for you and your experiments. It's very highly possible, that we will also raise our boost level at the next race and we hope we don't break anything  . .

|

|

By Hollow Head - 14 Years Ago

|

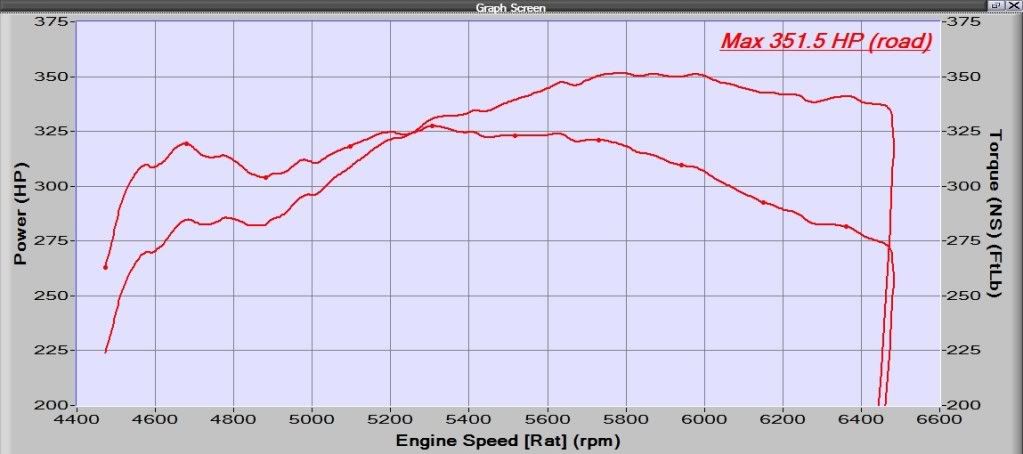

Interesting...  . Your torque curve really begins from 4500 rpm? Is there anything below that? . Your torque curve really begins from 4500 rpm? Is there anything below that?351 hp from rear wheel + about 15% more from the crankshaft. Not bad, but I think you have lots of more to come after you get everything working. Our engine gave best torque at 2600 rpm 630 Nm at engine dyno with single turbo and 0.7 bar pressure. (465 ft pound/10.1 psi). 329 hp / 5000 rpm. Our single turbo just was too small and exhaust back pressure was about 1.07 bar / 15,5 psi  . Not so good and that's partially why HP was so small. . Not so good and that's partially why HP was so small.

|

|

By Hollow Head - 14 Years Ago

|

Good progress! Pull out some video about cruising and the truck. Show us how it goes  . .

|

|

By Hollow Head - 14 Years Ago

|

|

Congrats Hutz!!!

|

|

By Hollow Head - 14 Years Ago

|

I think it is time to go to Columbus now . Good spirit! . Good spirit!

|

|

By Hollow Head - 14 Years Ago

|

Yes, you can, Frank  . And if you don't, put about 50 % beer to your tank and you'll get the same smell . And if you don't, put about 50 % beer to your tank and you'll get the same smell  . .

|

|

By Hollow Head - 14 Years Ago

|

|

We can deliver plates for you. Just tell us how thick you want. Our first test for those plates will be at the end of June, cause our new bottom end has had some delays. So, we have no experience yet.

|

|

By Hollow Head - 15 Years Ago

|

What will be the degrees in your new cam and what you have now? We are running 270 degree grind done here in Finland from original truck cam.I don't even know the lobe angles...

|

|

By Hollow Head - 14 Years Ago

|

|

We ran our Y with 32 deg total at dyno few years ago. Here is the link if you haven't seen it yet. http://www.youtube.com/watch?v=8yFwrPj8SnU And that was with 99 octane gasoline.

|

|

By Hollow Head - 14 Years Ago

|

|

Nowadays 11.1 is more than normal with boost and especially with E85. Go on with your trial, but be sure if you hear any knocking, back up immideately.

|

|

By Hollow Head - 14 Years Ago

|

|

Hutz, do you have a boost sensing fuel regulator or what. If not, that might be the problem. When boost raises, you should have more pressure from the regulator and more fuel to the injectors. What is your fuel pressure at idle and what it is with revs and boost? What is the overlap / LSA of your camshaft. We ordered our new cam from Schneider and it will have 116 deg lobe separation angle, so it will have less overlap.

|

|

By Hollow Head - 14 Years Ago

|

Yes, we are using that 8-point injection. Everything else will change for summer. Different block, new con rods, new pistons, new cam, new heads (but still iron heads), roller rockers, maybe even twin turbos, 90 lbs/hr injectors... So, lots of questions, but we are sure that the limits of Y-block are yet not discovered  . .

|

|

By Hollow Head - 14 Years Ago

|

|

Very light forged SRP pistons and compression ratio close to stock 8.2-8.5:1.

|

|

By PF Arcand - 14 Years Ago

|

|

Copper head gaskets were advertised in YBM about a year or so ago. Maybe someone here can zero in on what issue?

|

|

By PF Arcand - 13 Years Ago

|

|

A suggestion re the 245 degrees your engine is seeing under heavy load. Might be an idea to run the engine no load for a while before turning it off in those circumstances. Over heating is known to result in cracked heads, usually around the center exhaust valves sometimes on Y-Blocks...

|

|

By bird55 - 13 Years Ago

|

I have one of those trucks that is a 64. It is a 223 SIX with 3 on the tree, longbed.

I can't even begin to imagine how it would handle with that kind of HP and torque! And I might add it has a fairly new, tight suspension with disk brakes.

I think what you've accomplished is great, but I would be thinking about a race specific car and frame if I were you.

|

|

By bird55 - 13 Years Ago

|

|

I'm curious to hear if those tig welded cross member welds fatigue over time, or something. I think the original frame was designed to give or flex in those areas and you have obviously strengthened them. This is the reason those old trucks moved around so much on and old crooked road as Chuck has mentioned earlier. This is fun to watch!

|

|

By bird55 - 13 Years Ago

|

Glad everyone's OK.

Apparently the engine can stand the WOT for awhile then huh?

|

|

By LordMrFord - 15 Years Ago

|

|

Hutz 292 (11/10/2011)

We will bump the fuel pressure up to 40psi from 20psi.

What is max pressure rating for injectors if you can double the current?

|

|

By LordMrFord - 15 Years Ago

|

Yes, but when I ran with Chevy TBI, injector normal pressure was 13 psi/0,9 bar(Which I raised to about 1,4 bar).

I tried 55 psi with my current injectors(rated to about 45 psi) without leaks, cause high duty cycle, but I think that was not good thing to do.

So I someday bore out my injector bungs and try with those Mustang injectors which you got.

|

|

By LordMrFord - 15 Years Ago

|

Mild cams have low overlap, so it's better for turbo setup. You dont have to rev engine, just turn turbo srew.

Balance between cam, turbochargers and Torque converter is everything, but I think, cam can be pretty mild if compared to free breathing engines.

I don't know a lot about runner/valve size ratio, but free breathing exhaust must be good for turbos.

|

|

By LordMrFord - 14 Years Ago

|

0.7 Bar boost, big intercooler and flattop pistons. Fuel octane is european standard 99.

Y-Block handles a lot more advance than 5.0L.

|

|

By LordMrFord - 14 Years Ago

|

|

Hutz 292 (3/4/2012)

Are you guys still using that port fuel injection I am interested in if that is working well. I think I could get better response with that.

There is a more smaller acceleration pulse times with 8-point, but I dont think there is not so much differencies.

Fuel/air-mixture is really fast moving stuff on high RMP's, so injector place is not so important.

|

|

By LordMrFord - 14 Years Ago

|

Congratulations!!!

12.5:1 is quite good AFR.

|

|

By LordMrFord - 13 Years Ago

|

|

Hutz 292 (3/24/2013)

If I remember I am running around 6 degrees at 24 psi. We are at 19 degrees @ 0 vacuum or 90 kpa.

Those advances sounds pretty low. I have seen couple of turbo maps where 250 kpa / 3000 rpm advance are 14-19 and if I understand right, 100 kpa / 3000 rpm advance should be close to 36 with iron headed Y with or without chargers.

|

|

By LordMrFord - 13 Years Ago

|

Where's the Y-Block emblems?

|

|

By LordMrFord - 14 Years Ago

|

It looks like those aftermarket rockers may have too big balls for pushrods. We had cracked ball cups and after then bended pushrods.

Your cups looks to be fine, so I think you got no same problem.

Very nice torque btw!

When you move your max torque rpm from 4000 to 5500+, you can get even more hp's.

Whats your intake air temp? With dragster there was stock plugs with same boost levels and with no problems.

Can we a see a first 1000+ftlb with 20psi.

|

|

By LordMrFord - 14 Years Ago

|

Hollow Head (8/22/2012)

And as said, we lost couple of push rods at the starting about an half hour after previous run. But, last weekend went without problems on the engine side  .

Have you count the pushrods for sure?

|

|

By LordMrFord - 14 Years Ago

|

|

Looks like the pistons gonna have hard times.

|

|

By LordMrFord - 13 Years Ago

|

Here, in the continent of million Toyotas and Skodas, I can say nice even that is made by wrong american car company and wrong era.

|

|

By LordMrFord - 13 Years Ago

|

|

Those are pretty awesome numbers. Congrats!

|

|

By LordMrFord - 13 Years Ago

|

Sorry to hear you.

Btw. also sorry to bother you in moment of sadness, but can you post your advance map?

We are getting rid of mechanical advance control (atlast) with dragster and it might be easier to go on dyno with proven map.

Im out of knowledge with timing over 100 kpa Y-Blocks and many other are also in this world.

|

|

By RB - 14 Years Ago

|

I have some experience running E85.. I would say that it's practcal octane is above 105.. I run it in a 12:1 engine with no problem.. Possibly the cooling effect of the ethanol helps it's anti-detonation properties.

Winter fuel has more gasoline and less ethanol fuel you buy during race season should be true 85%

At 3.39 a gallon locally it's a no brainer. Don't spend up for a special carburetor. Jetting up a standard 750 double pumper 30% worked just as well and made same power as a E85 converted carb.

|

|

By RB - 14 Years Ago

|

Frank corrosive effects on aluminum are with Methanol.. Ethanol is not corrosive in my experience.. There is enough gasoline in it to mitigate some of the problems Regular rubber hoses do get soft over time, but in a race car that does not have fuel sitting in it for long periods it is not a problem. The newer OEM hoses are all alchohol resistant.

Engines really like this stuff Burns cool and clean.. And your race car smells like stale beer

|

|

By RB - 14 Years Ago

|

|

Try an AR-32 Autolite plug They are very cold do not have a projected tip and come side gapped

|

|

By RB - 14 Years Ago

|

|

It is an 18mm.. Summit carrys them... It is a very cold plug

|

|

By RB - 13 Years Ago

|

|

Couple ideas.. As boost pressure goes up you may need to use a little stronger valve spring.. I have heard of premature valve float with high boost pressures.. Also you are starting to build really high cylinder pressure It could be that your ignition needs more energy to provide a good spark

|

|

By RB - 13 Years Ago

|

|

Hutz292, would you be up for a phone call from Jerry Christenson? He would like to get some details on your truck for a story in Y Block magazine.. He lives in Minneapolis but is not computer savvy

|

|

By RB - 13 Years Ago

|

|

I knew I felt the earth move this afternoon

|

|

By aussiebill - 14 Years Ago

|

|

Hutz 292 (1/30/2012)

Dyno showed up late friday. I couldn't take it I pulled my engine and installed the new cam. I also installed my new high stall converter. I got a chance to take a peak in my engine and was amazed at how clean E85 burns. My valves are spotless and tops of my pistons are nice and clean. I had to order some new titanium header wrap so that should be here tomorow. I will take pics of the completed project and post them tomorow. Chris will be up from Kentucky on friday and saturday to train us on the dyno. By the end of the weekend I should have some dyno sheets on my turbocharged y-block. Cannot wait. When you,re using that aussie dyno, better turn it rightside up!!

|

|

By yehaabill - 14 Years Ago

|

|

Y-Guys......speaking of the WRX, Reed and I went to our local track 2 weeks ago to "tune" my junk to get ready for Columbus(Can't go now...Issac got in the way). Reed had added a 2-step to help with launches and pulled up to the line to try it out....Well, a New WRX pulled in the lane next to him...Reed bogged a little(2500rpm launch)... the WRX beat us to the line...He went 8.64 my Junk went an 8.48 @ 87mph....A big improvement for us @ 10lbs boost. Can't wait for the results from Columbus...hope "Issac" doesn't get 'em. Bill

|

|

By yehaabill - 13 Years Ago

|

|

Looks AWESOME, can't wait to see the dyno #'s.....valve adjustment looks to be a challenge...E85 or prem fuel?

|

|

By yehaabill - 13 Years Ago

|

|

Radio/Stereo!!!! You've got that Y-BLOCK music under the hood.....can't wait to see the 4 wheel burnouts...

|

|

By yehaabill - 13 Years Ago

|

|

YnotYbk....

|

|

By miker - 14 Years Ago

|

Vern Schulman (? Sp) used to sell a set of laminated metal head gaskets. When I got them they looked bit strange, but a long time racing buddy said he was surprised I could get those for a yblock and that was all he used on new Fords and blown head gaskets were pretty well a thing of the past. They're on the car now, but I don't have miles or load to know what's true.

I also read somewhere that alcohol required twice the lbs/hr as gas for the same hp. Not quite sure how that works with E-85, but if you could verify it and adjust it,maybe that would help with a start point.

Your rwhp observations are inline with local dynos near me. At 400 hp off an engine dyno, the wheel unit shows 100 hp less, typically. The gross can be 400, and corrected 210 or so. Big differences.

|

|

By Apache - 15 Years Ago

|

|

Yeah, I want the info on this set-up. Total cost...? Dyno sheet maybe??? :-D Ad don't forget an exhaust clip

|

|

By Apache - 15 Years Ago

|

|

any new updates?

|

|

By mctim64 - 15 Years Ago

|

Looks great in print! Where's the video?

|

|

By mctim64 - 14 Years Ago

|

Can't wait to see it myself.

|

|

By John Mummert - 15 Years Ago

|

Its looking good Robi. You guys have been busy!

|

|

By John Mummert - 14 Years Ago

|

Robi, glad to hear you're getting a handle on that beast.

That's a Mean,Green, Machine!

The 250 Lb Hr injectors might be a little tough to sort out at part throttle but sounds like you're getting close.

|

|

By John Mummert - 14 Years Ago

|

Robi, it looks like you need to check your deck clearance. That old piston looks like it's been gettin' intimate with the head!

A little thicker head gasket might help it.

-471 Heads should be there very soon.

Should be a beast!

|

|

By John Mummert - 14 Years Ago

|

Robi, lookin great!

By my calc's your compression now should be 8.1:1

Pour the fuel to it and see what you get.

|

|

By John Mummert - 14 Years Ago

|

There is probably a lesson here for the guys running turbos and anyone doing the machine work including myself. The guides in Robi's heads were not set-up on the tight side, at all. It appears that the additional heat made by the turbo is causing the valve stems to grow more that expected. This results in sticking valves and bent pushrods.

It appears that guide clearance needs to be in the .0025" range to be safe.

|

|

By jepito - 14 Years Ago

|

|

Do you have a valve spring tester? May have an odd spring. After engine is hot, pull the covers and run a check. I have seen some springs change from temp and others not effected.

|

|

By NoShortcuts - 15 Years Ago

|

CONGRATULATIONS on your engineering, fabrication efforts, and accomplishment! Looks good!

Will you use any type of a screen over the impeller in that last picture?

Best Wishes!

|

|

By Talkwrench - 14 Years Ago

|

|

I would not be running your engine at 10;1 with ANY boost ! Im no expert but I have fitted a supercharger with help from guys that have been doing it for years.. I bought my supercharger from a mechanic that had no idea what he was doing it lasted 11 minutes on his car.. he did learn alot after that. This might be old rule of thumb. but if you want to be running any sort of decent boost you should be at 7.5;1 that should be good for 12lb boost. Timing should have a fair bit of initail advance and maybe no more than 30 degrees all in by 3000rpm that should be a good start depending on your fuel! IF you are running all that MSD gear then go buy their boost retard to add to it. Be careful all that hard work can be undone very quickly.

|

|

By Talkwrench - 14 Years Ago

|

|

have you 'O' ringed this motor ?

|

|

By Talkwrench - 14 Years Ago

|

Hutzie.. I dont know the full extent of what has been done to your motor but I get the feeling you have a lot of "techincal" work done but maybe some basics are missing when it comes to forced induction. If you have gone to the trouble of getting a dyno I think you are going to try and.. how shall we say..." Get the most out of it", I dont think you are going to be happy with just 8 lbs boost  . . What sort of head gaskets are you using? Are you using ARP head studs? The block or heads should be O ringed with a copper ring and a copper head gasket as well. Tip; Dont use a coolant with glycol in it. Glycol has a "serching molecule" and the slightest crack or hole it will find it. Those Finish guys with hollow heads should give you some more info. Hate to see all your hard work come undone too quick.

|

|

By Talkwrench - 14 Years Ago

|

|

Consider O ringing the heads [or block] and use copper head gaskets as well when you re-install.

|

|

By Talkwrench - 14 Years Ago

|

|

You will have to have them made.. Seppo has had some made but he is at the other end of the earth like me. There was a post quite recent about them. Ted, Tim or John may have a contact.

|

|

By Talkwrench - 14 Years Ago

|

|

I think you would defineately need a bigger fuel line, no point mucking around you may as well go 1/2" and use the old line as a retun line. Im not familiar with with injection systems but I would think it would still need to be boost referenced?.. Seppo? What compression did you end up with? Sorry about going on about O ringing, Someone did point out to me that the chamber shape wont allow it. Keep going!

|

|

By Talkwrench - 14 Years Ago

|

No thats kooooll! I dont know how the head gaskets are going stand up to that !

|

|

By grovedawg - 15 Years Ago

|

|

I hope your cam shows up soon! An early Christmas present would be nice! Keep us posted.

|

|

By grovedawg - 14 Years Ago

|

|

Any news or updates?

|

|

By grovedawg - 14 Years Ago

|

|

I wish I had experience with boost, and injection. But I don't so I'm just an interested observing hoping the best for you engine. Keep us posted!

|

|

By The Master Cylinder - 13 Years Ago

|

MoonShadow (3/2/2013)

Geez would you guys quit! Shooting for 1K? Chuck

MoonShadow (3/2/2013)

Geez would you guys quit! Shooting for 1K? Chuck

MoonShadow (3/2/2013)

Geez would you guys quit! Shooting for 1K? Chuck

Guess you missed Ted's memo...

Ted (2/25/2013)

One of the nuances of the new forum software is a time lag between hitting the submit key and the post showing up on the screen.About a minute of dead time has been the worst case on my end. While the screen doesn’t appear to be doing anything, it is doing its job in the background and hitting the submit key a second or third or fourth time before the post appears simply makes for duplicate posts for each time the key is hit.

|

|

By The Master Cylinder - 13 Years Ago

|

Hey, Chuck. Good info. Wouldn't it be neat if they could make a unit to connect to a stock speedo head? I would like to keep the stock speedo/dash in my '55. Just think of the restored/retro-mod cars that could use a device like that for an accurate speed reading.

Or maybe better to modify a stock speedo with the GPS unit.

If those aren't feasible I would go with a 2 1/16" GPS Speedo to fit in with my 2 1/16" mechanical oil and water temp gauges.

Sometimes a link to the product helps others find it.

|

|

By The Master Cylinder - 13 Years Ago

|

Chuck, I was talking about I should put in the link to the 2 1/16" gauge (2 1/16" GPS Speedo) I was referring to, I didn't mean you should have put in a link. That's why I edited my post.

I like the way you can 'customize' the gauge with the bezel of your choice, font, etc. The Standard 'Tick Style' looks pretty close to matching my SW gauges. I don't think the price is too bad considering the hassle it is to get a speedo to read 'close' to what it should.

Now that we've hijacked the thread, back to the show that's playing...

|

|

By The Master Cylinder - 13 Years Ago

|

|

I see AutoMeter has a GPS Speedo also if anyone is interested. Auto Meter GPS Speedo

|

|

By Hutz 292 - 15 Years Ago

|

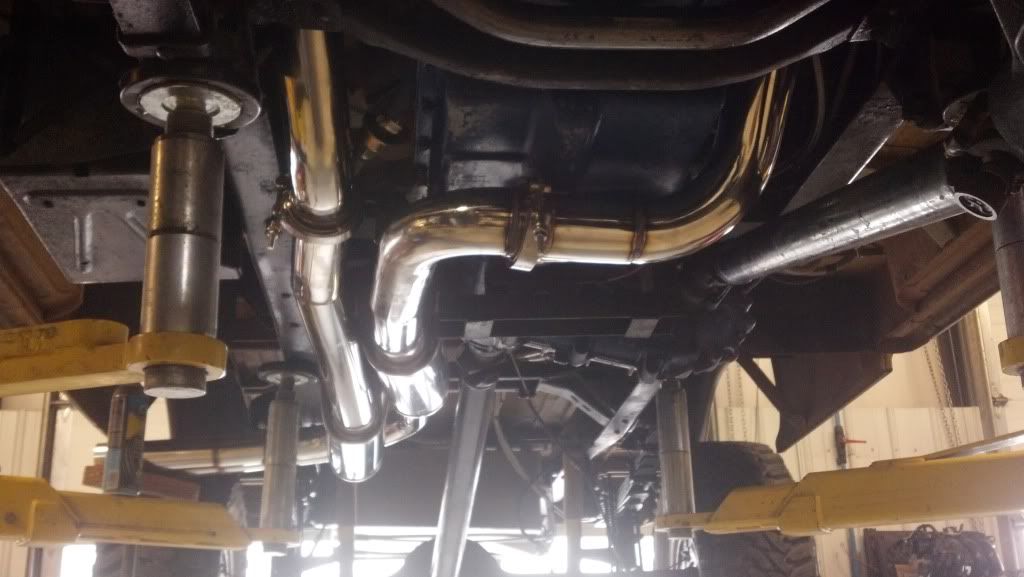

We started by simply swapping the headers side to side so they are facing forward. It worked very well.

Built the y-pipe up to the flange.

Y-pipe with the waste gate.

Turbo location from the top. Drivers side. We will run the air cleaner out the fender well and build some shielding to protect it from the water.

The intercooler sits inbetween the radiator and radiator support like it was made for and intercooler. Bought a pressure plenum from jegs and some intercooler piping kit and only had to use two pieces.

The blow off valve is right above the turbo.

Turbo fits nicely between engine and frame. We are planning on running about 8psi boost. I have a 900cfm Holley TBI fuel injection kit on it and we are going to convert it to E85. I will keep u updated as we get further along.

Found a nice spot in the fender well for the air filter. We built a box out a stock cummins air box so it is sealled up really nice now. Cut a hole behind headlight for cold air intake.

My new gauge assembly from Dakota Digital. It is crazy awesome. I would recommend them to anyone. Comes with everyhting you need and uses existing blinker signal, fuel sender and high beam wires.

Our new toy from down under!!

Don't worry once my bigger injectors get here I will be giving some results. Looks good on it don't it.

Still needs some tuning but not a bad run. Dynotech by Dyno Dynamics.

|

|

By Hutz 292 - 15 Years Ago

|

|

If you look at my pic of the y-pipe you can see the oil drain will go right into the top of the oil pan. We will t into the heater hoses for the coolant for the turbo. I will just have to leave my heater valve open all the time. I cannot wait to hear it run. Right now I just have a 3in straight pipe. The waste gate will just dump behind the engine. If it's too loud we will tie it into the exhaust. Might be ready to start it tomorrow. Very excited will let you know how it runs.

|

|

By Hutz 292 - 15 Years Ago

|

|

We have the down pipe and filter built I will have more pics tomorrow. It turned out great. We had to reengineer the exhuast down pipe today to clear the front diff. Tomorrow is the day we will fire it up. There is going to be some significant tuning to do because we switched over to E85 and we now added the turbo. We will bump the fuel pressure up to 40psi from 20psi. Also added a external fuel pressure regulator to work with the change in manifold pressure. Will definately let you guys know how it goes tomorrow.

|

|

By Hutz 292 - 15 Years Ago

|

|

Hey everyone we got it running friday and took it out for a little driving. Drove it more today and we realized we had to turn fuel pressure down. We are at 30psi right now. Found the injectors were flooding once pressure and duty cycle increased. It is much better at now with lower pressure. We actually just sent off the down payment for a chassis dyno so I have not brought it above 4,000 rpm yet. Air/fuel looks good but we are gonna wait to get crazy until it's under a controlled load. So far I am very, very impressed with the power. You tip into the throttle and feel the engine power and immediately the turbo spools and it's fun. I am running at 8psi max right now. We have down some hard accelerating under boost and still all is well. Like I said I am very impressed with the power gain. I have a E4OD trans in this truck with 33in mud tires so when it got into o/d the truck really struggled to hold speed. The engine is running 2,400 rpm @ 70mph so didn't have a whole lot of power at that rpm. Went out today and did some more tuning and in o/d with t/c locked I could easily pick up speed going up hill. I am very happy and excited with the power. The sound also is awesome wiht a 4in straight pipe it is not to loud and a very nice turbo whistle out the exhaust. If I left anything out just ask we have a little more tuning to do. I will get more pics and some video. Everything looks great we have titanium header wrap on whole exhaust.

|

|

By Hutz 292 - 15 Years Ago

|

|

Hey everyone did some more tuning and having issues with the hight rpm. Engine would cut out tun rough. My buddy asked me about the cam if it's compatible for boost. It never crossed my mind so I called Isky racing cams (thats were I got my current cam from F300) and he said that the cam would not work very well with boost. He said that at high rpm the cam would not breath well enough and would back up in engine. He gave me all the details of what we need for an ideal cam. Longer lobe separation and more intake. He said that the cam I have is great for NA engines but not for boost. So I am having him grind me a custom cam for my engine. That's where we are at right now. It's a lot of fun right now I am just learning about boost as we go. My high stall billet torque converter showed up today. We'll pull the engine and trans and put them cam in at the same time. So far though the very happy the project. I will have cam for sale now if anyone needs one.

|

|

By Hutz 292 - 15 Years Ago

|

|

Unfortunately I don't have all the cam specs right now, he rattled off everything he was going to do and didn't right it down. He was very knowledgeable about what to do though. I do remember 114 lobe separation. It will be 3,000 to 6,000 rpm cam. I have a billet triple disc, 3,500 rpm stall converter to install at the same time. He got all this info from me and said the cam he will build will work perfect. I cannot wait. It should have a nasty whole shot. With the stall converter by the time the converter stalls the engine will be reaching it's power range and there should be a surge of heat in the exhaust and turbo should be spooled so it should a nice acceleration point. As far as the injectors I thought that they were flooding under the high fuel pressure but we turned fuel presure down and it never fully went away. Once I talked to Isky and he told me that the cam I had would not run right at high rpms I am hoping that was our problem. The cam shows up beginning of December so don't worry it won't take long to install i'll let you guys know how it goes.

|

|

By Hutz 292 - 13 Years Ago

|

|

Well I ordered some vent loovers for my hood to try and remove some heat from my engine compartment. They are 11x17 and are made of aluminum and are falt black. Just an update the engine is running great after a summer of getting wooped on and pulling the dyno around the state. I may pull the engine this winter and reseal my rear main. The bracket in the back that holds the rear seal is cracked, sprayed it off and gobbed a ton of silicone up there but, ya, lets just say that didn't plug the hole in the damn. I would love to make a show next year like that y-block gathering so you guys will to keep me posted for next year.

|

|

By Hutz 292 - 13 Years Ago

|

Well I am pumped up, we got the new cooling system done with electric water pump, relocated the p/s pump and were able to install some nice electric fans. We ran it on the dyno today with a few back to back pulls and the temp would hit 196 degrees, the fans kicked in and cooled right down. The temp never creeped at all, I am soo pumped now that I can keep the engine cool, plus it looks kindof cool.

This is the plate Chris built and welded a 1.5 in pipe into.

Relocated the p/s pump and did some bracketeering. It also allowed us to use a shorter belt with everthing on one side, and we didn't need any idler pulley.

We bolted the water pump to the steering gear which gave us room for the lower radiator hose on the other side, plus the engine is bolted solid to the frame so I didn't have to worry about the hose flexing.

Chris built a sweet lower radiator hose adapter. The right fitting goes up to my surge tank and the left fitting comes from the heater core to the suction side of the pump. I decided to just block off the baypass fitting under the thermostat. I think it should be ok but if it's a problem I figure someone will mention something.

|

|

By Hutz 292 - 13 Years Ago

|

Chris decided to decorate my coffee cup so I would know which one was mine. I was like that is badass I have to share that!

|

|

By Hutz 292 - 12 Years Ago

|

|

Well everyone just checking in its been a long winter and it is finally getting nice out. Pulled the Y-block out of the grage and got it up in the air to take care of a rear main seal leak that was bugging me all last year. Pulled tranny out and removed pan and was pleased to see that everything looked like brand in there. Also found out why it was leaking, I thought that the lower seal housing was cracked but I realized I got a little carried away with the silicone when I installed it and is crushed the seal. Got it all put back together the old boy is dry as a bone now. I should have a new video of the Twin Turbo soon we have a dyno day this next saturday and I should have it strapped down. My old video got deleted so I need to get some new ones. I hope this finds everyone in good health and good weather coming there your way, this winter has really been a tough one and cannot wait to get the hot rod back on the road!!

|

|

By Hutz 292 - 12 Years Ago

|

Thought I would just repost my old video. Putting on together with the new truck that it's in.

https://www.youtube.com/watch?v=sGU-A0vtQWc

|

|

By Hutz 292 - 12 Years Ago

|

|

I am planning on making it to one of these y-block gatherings. That one sounds fun but this summer we are cutting back a little on shows. We are having a baby in august and we are building a new house that we need to be moved into by august also. This summer is a little busy for me. I would love to haul the dyno down to a show though.

|

|

By Hutz 292 - 13 Years Ago

|

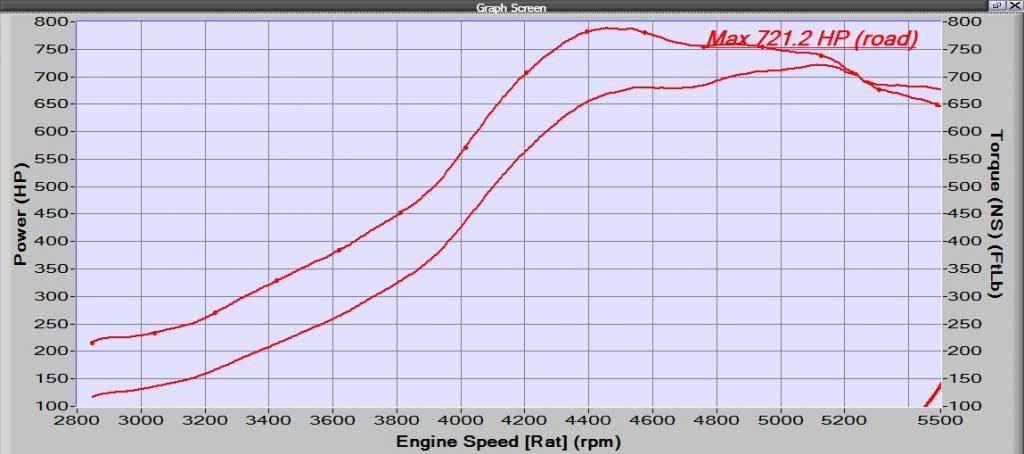

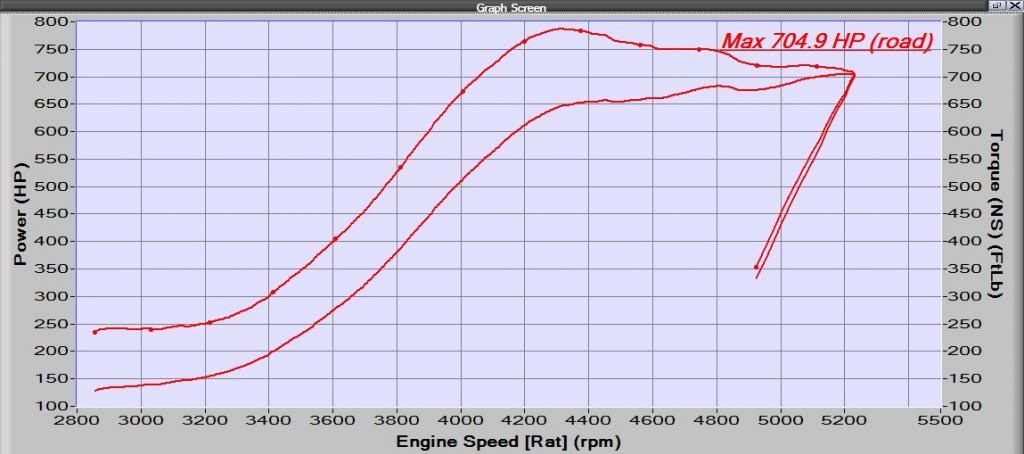

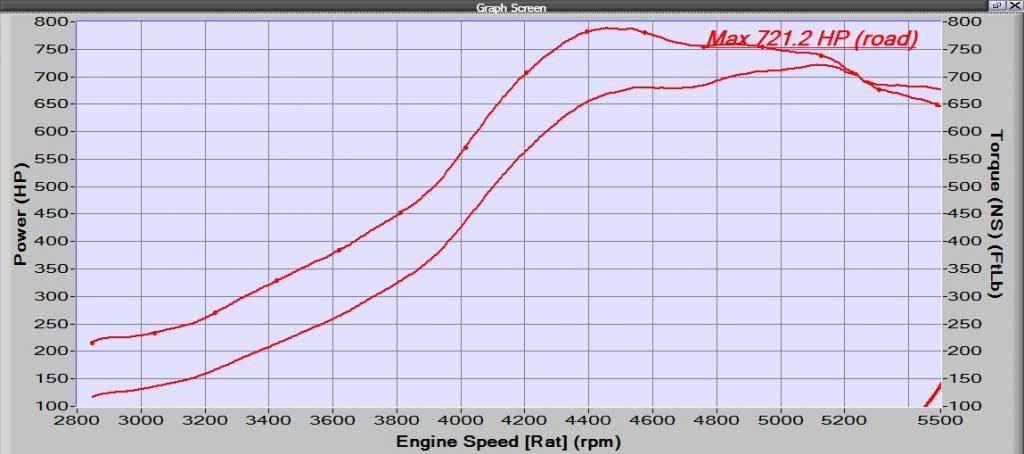

Actually we are still at 24 lbs of boost. I figured what the heck, you can't tell people you have almost a 1,000hp power if it isn't there all the time right! If I want less boost I can just back out of the throttle, which never happens. I still havn't had it back on the dyno but I have done a lot of ripping on it on the street. It kindof makes you giggle a little bit. The torque when you hit third gear and crank up to 24 lbs of boost is like nothing I have ever felt. That little truck is awesome, handles great drives like a dream, don't get me wrong I miss my old 62 4X4 but that 99 F150 is a great pickup I love it. Now with quieter mufflers it is such a pleasant drive down the road. I have got a lot of comments on how quiet the engine itself runs when I show it off and let it run for people they can't believe how smooth and quiet the engine is mechanically. Don't kid yourself I run this thing really hard. We might run some water/meth injection now that we are running 91 octane instead of E85. Here is the last dyno run we made in case everyone hasn't seen it.

|

|

By Hutz 292 - 13 Years Ago

|

You are right, the shield did not initially work. I have since covered it with heat tape from DEI and now it works just fine. I am going to update to a 7al box and a more bad ass coil. Since I have switched back to 91 octane fuel from E85 I am having spark blow out around 17lbs of boost or around 500 whp. I talked to MSD and they said the 6al was not enough for that much boost. Once I change that we will hopefully be able to make some full runs at 24 psi!! Here is a pic of some more stickers I put on.

|

|

By Hutz 292 - 13 Years Ago

|

|

I applied it to the shield and I used the silver tape.

|

|

By Hutz 292 - 13 Years Ago

|

I switched back to 91 because so many stations around here are pulling E85 from the pumps and when I was heading out to a car show with the dyno I ran out of stations with E85 so I has the laptop with me and had to tune on the fly. Actually I like the 91 a lot better my drivability is much better. It idles better and not that I am concerned with fuel economy but it has more than doubled since I switched to premuim fuel.

On the other hand the Y-block has proved it's durability again. I just headed out to my home town for a dyno day and put on over 375 miles with my trailer in over 90 degree heat there and back. My radiator is still the stock one from the 99 F150 and the truck runs pretty warm when pulling the trailer. I runs around 240-245 degree the entire time. It did not get any warmer so I just ran it down the road around 70 mph. It might be a little warm but it ran like a top. Today I ordered a custom radiator for it so that should take care of the problem. I credit the oil I use in this engine to lot of my success. I believe that the Joe Gibbs racing oil I use is top notch. It is HR3 15w-50 synthetic. I would imagine that my engine oil temps were even higher than that to. I pulled my hood off on the way back to my parents house thinking it might run cooler but it didn't help much. Here are a couple of pics from the weekend.

This is when we got to the farm on friday night. The kids love daddy's pickup.

This is after the parade on saturday and parked beside my other 03 F150.

Finally made it home on Sunday night after a weekend of work and pulling. I love this engine. It stole the entire car show and all it does is make power, run great and pull a trailer hundreds of miles a year to car shows. I usually pull at 7-10 lbs of boost and run with the o/d off. The sweet spot with my engine is around 3200 rpm in 3rd gear. At that rpm the engine has great power and turbos spool easily. Pulling the trailer is a breaze at that rpm, it takes very little of the turbos to maintain around 70 mph, and the pickup handles the load great. I did install a new 7al box and a new coil. I think it is going to take care of my spark issue at around 500 whp. I also think I am going to change to autolite AR94 spark plug. It is on step hotter than the 8 heat range ngk I am running now. I think I will be making a few dyno pulls soon.

|

|

By Hutz 292 - 13 Years Ago

|

|

I would always let it cool down to around 212 before I would shut it off. I have a new aluminum 4 core radiator that will be here tomorrow. Can't wait to see if it fits good. Should get it in by the weekend and we are off to a lake party for the weekend so should get to test it out. I won't have the trailer but I should notice a cooler running engine, because it would run just slightly warmer than usual even empty.

|

|

By Hutz 292 - 13 Years Ago

|

Well made it back from another dyno show with the y-block with no hiccups. Truck ran great and pulled great, and it got plenty of attention also. A lot of our friends from the north were down from Canada in Minot,ND for our dyno show. I also installed my new dash from Dakota Digital which turned out great!! Sure is nice to have gauges again.

|

|

By Hutz 292 - 13 Years Ago

|

|

Hey everyone have some great news. The Y is back on the road, have insurance on the truck and took it to town the other day. Engine runs great and I have the tune a little more dialed in. The pickup is fun to drive with power steering and power disc brakes!!!! We hope to have a couple of dyno runs by the end of the week, we have a car show to go to with the dyno this sunday and I am hoping to pull the trailer with it. If it isn't ready to pull the trailer I will still drive it there to show it off. I have been trying to come up with something clever for the liscence plates, I had a few ideas "YBLKPWR" "TTYBLCK" "PWRBY Y" or I think I might just leave it simple like "Y BLOCK". I am excited to tell you that I will be starting a new post on the forum for a Y-block build. There is a retired body man up the street that has a 54ish Ford, not sure on the year, but it has a 292 in it and needs it built for some power. I couldn't talk him into turbo but I am going to build it and tune and he will paint my 99 for me. Looking forward to the new post and if anyone has any ideas for liscence plate would be cool.

|

|

By Hutz 292 - 13 Years Ago

|

|

All good. I will take a pic of the plates I go with. Don't worry I haven't forgotten about the old ford I haven't taken the key off my ring yet.

|

|

By Hutz 292 - 13 Years Ago

|

Well I made my first trip to town and back and the Y ran great. I love this new two wheel drive and newer suspension ride. Truck runs great and engine is a beast. I am running it at 15 psi right now but I haven't ran it on the dyno yet. We have a car show this weekend and I may strap it down just to show everyone what's up. I think I resolved an issure I was having though, when I removed the engine I decided to install a new rear main seal because mine was leaking a little in my old truck. So I installed a new one and since I got it running my engine has been leaking really bad. So tonight I raised the truck and found that the aluminum housing that the seal sits in is cracked and leaking like hell. So I did what every good mechanic would do, I sprayed it off with brake clean and siliconed the crap out of it. Let is dry and no more leak. Here are some finished pics.

My new computer bay.

A little shout out to Johnny.

|

|

By Hutz 292 - 13 Years Ago

|

|

Right now I don't have any gauges but the factory fuel and volt gauge work. I am going to get a Dakota Digital dash that will fit later. If I bring the laptop with me when I drive my trans computer software has a virtual dash option that has all my pids it's pretty nice. We have our dyno day tomorrow at the car show and I haven't decided if I am going to run it yet or not. If I do I will have video for you guys.

|

|

By Hutz 292 - 13 Years Ago

|

Well the kids and I got the hose out the other day and washed up the ford. Got all the painting done and she looks pretty good.

We were able to fit the exhaust out he body kit I love the way that looks.

Not bad for a $300 pickup.

Got my boost gauge and wide band mounted and in.

I love my Strange rear diff with 12' disc brakes and the ladder bars are sweet. This thing actually hooks up extremely well through the gears. About half throttle is perfect until late in 2nd gear then once you hit third it turns into a rocket. Have to be careful because it will still break the tires loose in third. I turned the boost down to about 19 lbs of boost and its a little easier to control.

Got some sweet stickers from Johnny so I figured this is a perfect place for it.

We were having issues with my modules overheating so I installed a fan ro move air across them all the time. I will see what this does and then build something mor permanent. I will now this weekend we will be in Jamestown, ND for a car show about 130 miles away. I will be pulling the dyno there with the Y-block. I will let you know how it does this weekend.

|

|

By Hutz 292 - 13 Years Ago

|

Got my licence plates back.

Got some of the badging on. I have some more 292 stuff just havn't decided were to put them.

If you look at the bottom hole in the bumper you can see a new cooler. I know its crazy but we were having issues with my A100 fuel pump vapor locking on really hot days when I would pull the dyno trailer. Called Aeromotive and they said since it's not in the tank it needs a fuel cooler in the return line. It's probably no the safest place for a fuel cooler but it looks great up there.

|

|

By Hutz 292 - 13 Years Ago

|

Got some updated pics from the project. Nice front view of the setup and I don't think I have posted a pic of the new truck yet.

This is the new home for the Y!

My E4OD with the new 2wd output shaft, fit like a dream.

I have my new 2in drop spindles and rear drop shackles installed. I have to wait until my new diff shows up so I can have a driveshaft built. Only thing we will have to build will be the brackets for the shocks to bolt up to. The 12in disc brakes will be installed and my brake cables should work. I already ordered my wheel adapters so we can use the wheels and tires I just bought for my other truck since they have a total of about 5 miles on them!

|

|

By Hutz 292 - 13 Years Ago

|

|

Well I have my computers wired in and my differential is supposed to be here tomorow. I will post some pics if it makes it. I also have a new intercooler on its way. The piping will go in the sides and come out the middle straight to the throttle body. We are having a car show and dyno day at the shop May 18th and I am hoping to have this running by then. I also ordered new front bumper and side skirts and a roll pan for the rear bumper. Hopefully in the next couple of weeks we will make some serious progress on this project since the weather is finally above freezing!!!

|

|

By Hutz 292 - 13 Years Ago

|

|

Hey everyone haven't posted for a while I have my diff installed but had to put off the truck for a while had to much work to do.

|

|

By Hutz 292 - 13 Years Ago

|

Hey everyone just thought I would post a pic of my dad's 68 Torino. It doesn't have a Y in it but I would think you would all appreciate a nice old ford. I has a built 302 with Edlebrock Performer aluminum heads, performer intake, cam and 150 shot of Nitrous. It's a great joy driving this car.

|

|

By Hutz 292 - 13 Years Ago

|

Well we the screaming y-block for the first time in its new home. We jsut have to finish the exhaust and intercooler plumbing and it's ready for a test drive. Hope this video works I was having trouble uploading it.

https://www.facebook.com/photo.php?v=497950446926789

|

|

By Hutz 292 - 13 Years Ago

|

|

We already solved the throttlee issue and I installed a big kill switch in the dash that is very accessible.

|

|

By Hutz 292 - 13 Years Ago

|

|

Well this 99 F150 2wd is a light truck and will handle my dyno trailer as well. Plus we can buy any performance suspension upgrades we want.

|

|

By Hutz 292 - 13 Years Ago

|

|

Don't worry we won't go that crazy. The 99 F150 is a great looking truck . Me and my dad decided we will continue my build with his old 65 F100 2 wheel drive out at the farm. He slid down a hill hunting about twenty years ago and it's been sitting ever since. Nice part is all my stuff from this truck will transfer right over. My engine and transw will stay in the 99 and I will build a new y-block for the 65. I have been looking for an excuse to build another y-block. There are three up the street in a guys grage so I should be able to get ahold of one. We were thinking of using a nice noisy kenne bell on that one. We weill just mount it remotely on the side. That will be this fall.

|

|

By Hutz 292 - 13 Years Ago

|

Hey everyone we are making some progress on the new build. I will have more pics tomorrow. The biggest question has been the differential, we would like to use the original diff in the 99 F150 which is an 8.8in rear diff. I was on the phone for hour today talking to people about if it would handle the power. The consensus came to that they can handle a lot of power but would be borderline for the power we are running. We thought we would just swap the diff from my 62 to that on since it has a locker and Moser 31 spline axles, but would require some modifying and the diff is about 5 inches narrower than the F150. I noticed that one of my axle seals was leaking so I removed the axle to find that those badass Moser 31 spline axles were twisted so I called Moser and they said yeah those probable aren't going to handle 1000 horsepower. So in any situation I would either need to completely rebuild my current 9in or build that 8.8in that might handle the power. So I talked to Strange Engineering and I am ordering a prebuilt custom 9in rear diff that will bolt into the 99 F150 with custom 12in rear disc brakes. It ended up being about $400 dollars more to just order a prebult brand new rear diff than modifying mine. Plus it will have the bigger late Ford rear axle bearing, Detroit locker, 35 spline axles, rear disc brakes and 3 1/2 tubes and a 10yr warranty on everything on the axle. The 35 spline axle should hold up! I will take pics of the axles tomorrow. I do have a pic of the current 9in diff housing though, it is hard to see in the pic but the leaf spring plates are actually tearing away from the axle and on the front side it is crushing the axle tube from all the hp and torque. It is awesome looking at those damaged parts that are damaged, not from abuse, but from simply too much POWER! I cannot wait for this Y to crank that F150 down the road. I will take some pics of the p/s pump bracket that Chris built and the badass turbo oil feed manifold/fuel pump cover that Chris also built.

It's hard to see but that axle is crushing in where the leaf spring pads are.

|

|

By Hutz 292 - 13 Years Ago

|

|

I will admitted I did not plan on making this much power when I put it together. I think the diff tubes caved in before I had the ladder bars installed. We noticed an extreme difference with those installed. My new axle assembly will be built for it. Funny thing is that we are still running the stock size u-joint at the rear diff and that's been hanging in there also. My trans is an E4OD and I am installing the two wheel drive output shaft now and also installing high energy blue clutches. It was working perfectly but some of the clutches were getting a little warm. My torque converter was built for 1300 HP by Midwest Converters so hopefully that hangs in there.

|

|

By Hutz 292 - 13 Years Ago

|

Here is what a twin turbocharged Y-block does to a Moser 31 spline hardened axle shaft!! It is also crushing the housing.

You can see how it has been crushing the housing and bending the leaf spring pad.

Chris is showing off his enginuity. What better than a Y-BLOCK oil distribution for Twin Turbos on a Y-BLOCK that doubles as a fuel pump block off plate. He drilled through the plate so both turbo oil feeds will branch from there. It's pretty cool we think.

We got our p/s pump mounted. I bought a dual belt water pump pulley from Jegs that is for a small block ford. We just had to make the hole bigger and press the mounting pad farther onto the water pump shaft and it lined up pretty well. I seen John's set up which is nice but we have our crank trigger on the crank pulley so it would be difficult to mount another belt down there.

Going into it's new home in a 99 F150 two wheel drive.

My Y is going to be real happy in this truck. We moved the dipstick to the front location in the block because our motor mount is in the way of the old location.

|

|

By Hutz 292 - 13 Years Ago

|

|

The feed oil comes from the oil port back by the oil filter. The inside of the block has been drilled out so the oil will pass right throuh aluminum block. Prior we just had a 4 way block at the oil feed posrt on the engine and ran two lines from there. This will look nice with two braided lines coming from it.

|

|

By Hutz 292 - 13 Years Ago

|

|

He is working on the video. He bought a new go pro and is having trouble with his video manager. I haven't driven the truck on the street yet because i ordered new carpet and headliner so my seats are out right now. But i have had a chance to install my stereo and i built a custom speaker box above my fuel tank. Installed the antenna and some sound proofing in the doors and on the roof. My carpet from lmc will be here tomorrow so I will be busy installing it and i will take some more pics of the interior for everyone. I should have it on the road tomorrow also.

|

|

By Hutz 292 - 13 Years Ago

|

Hey everyone got my carpet today so I began installing it and my seats. Got everything together in just in time today for the snow and crappy roads. So I didn't drive it but it is nice to have my seats and shifter back in the truck. I took some pics of the interior for everyone.

The carpet install went pretty good. It's tough when you have to drill holes through the carpet because it you don't cut it the drill bit will pull the threads out of the carpet in line down the carpet. OOOOPS! At least it only happened under were the seats are.

You can see the beautiful weather in the backround. Also see the new mirrors. I like them, they wil be especially helpful with the dyno trailer on this summer.

New black carpet and seat covers. I like the black interior color it looks great with the chrome.

I finally have a boot on my 4X4 shifter. I install sound deadining in the doors and under the carpet.

I also bought new window cranks, arm rests and the cubby trays for the doors. They look nice with the chrome trim. I am a sucker for the LMC magazine.

My custom speaker box it turned out nice and sounds good right there. I also bought an 8" subwoofer from LMC that only stands about 2.5" high and installed it under the center console. It has been a long time since I have messed with stereo stuff but I like the sound.

The old girl is looking good and is hungry for chevy blood!!!

|

|

By Hutz 292 - 13 Years Ago

|