|

By pops - 15 Years Ago

|

|

Good morning Y-Blockers! I have two minor nags that I could use some advice on. My 312 has idled flawlessly for about the last 500 miles. Now (at idle) it has a slight miss about every 5-8 seconds. Just a little "bump" that you can sense only for a slit second. The second nag is at a steady cruise speed (+-60mph) the car surges a little. It stops pulling for just a second, then starts pulling again. If I hit the gas, it pulls as it should. The car has a new gas tank, fuel lines, mechanical pump, fuel filter, carburator, distributor, plugs and plug wires. None of these items has more than 1,000 miles since new. Would any of you have some ideas as to what might be causing these two glitches? Thanks, in advance, gentlemen.

|

|

By Ted - 15 Years Ago

|

|

I’ll suggest looking at the carb first. Idle fuel mixture could be just slightly off for the intermittent miss at idle. The ignition spark being on the weak side or the spark plug gap being excessive can also be contributing factors. You might try a vacuum gauge on the engine and look for any blips in the gauge reading that correspond to the intermittent miss as that can point you towards a valve or valve adjustment issue. For the surge while cruising, then double check the fuel float level in the carb. If that checks out, then double check both the mechanical and vacuum advance curves in the distributor. Knowing more about what carburetor and ignition system you have might also help pin point some other items.

|

|

By Jeff - 15 Years Ago

|

|

Your surging while cruising sounds like a lean surge. In other words the size of the main jets are right on the edge of being adequate. Trying increasing the main jet size up one or two sizes.

|

|

By oldcarmark - 15 Years Ago

|

|

According to Holley each size increase in jet size increases flow by 4%.You need to go 2 sizes to really see a difference in performance(according to the Holley book).

|

|

By pops - 15 Years Ago

|

UPDATE:

I have not looked deeper into the carburetor, and have put several hundred more miles on the car since this initial post. Most of those miles had the consistent surging a cruise speeds and I just sort of learned to live with it. But this past Sunday the car suddenly got far worse. This time on the lower end of the speed. It started bogging down severely while trying to accelerate. It has had a little hesitation or stumble, but giving it a little more throttle had made it respond. But on Sunday, I had all I could do to get the thing home. I really had to feather and jab the throttle to keep it running.

I had good confidence in all the shorter runs I was making for a big one that I need to make in the next week or two as I am moving from Chambersburg, PA to Cleveland, OH and its a 275 mile trip for the Thunderbird. I have lost the confidence needed to drive the car in its present condition, but need to make this trip.

So, yesterday, I went out and purchased a vacuum gauge and timing light. I need a lesson in the correct order of tests, but this is what I did:

1. Disconnected the vacuum line to the distributor and plugged the hole in the carb where it was attached.

2. Started the car and let it fully warm up to operating temp

3. Checked the RPMS (via the timing light) and they were about 850-900 in neutral.

4. Checked the timing and if I did this correctly it was 55 degrees advanced at idle without vacuum advance!

I've never used a digital timing light before so I'll explain what I did:

Hooked up the light and could not see the timing mark on the damper at all. There are two buttons on the light marked advance. I pressed one of them until the timing mark lined up with the pointer on the block. The timing light was showing 55 degrees!

I thought I have read here that initial timing should be about 18 degrees. So, I loosened the distributor and turned it counter clockwise until I could get the timing light to register 18 degrees with the timing marks aligned.

The idle dropped substantially so I upped the idle speed back to around 900. I then shut the car off to see how it would restart. It started fine. I then took it for a very short trial to see if this improved things. It was drizzling, the top was down so it was a very short run. It still has the slight hesitation when starting out, couldn't drive at cruising speeds to see if it was still surging, but the severe bogging and cutting out at low speeds was no longer evident on this short run.

I'm assuming (a stretch) that I did the timing correctly. If so how could this have had 55 degrees of initial advance?

Have I done something wrong to get this reading? I have not yet attached the vacuum gauge, nor have I opened the distributor or looked at the plugs. And as mentioned above, I have not touched the carburetor yet.

I suspect I might be starting in the middle when I should start at the beginning looking for my problem. Could you guys suggest a sequence I should use to troubleshoot this issue? I'm under a bit of a gun to move this car either this upcoming weekend or very latest next weekend.

Specs:

'57 312

'57 Ford Distributor with/tach drive

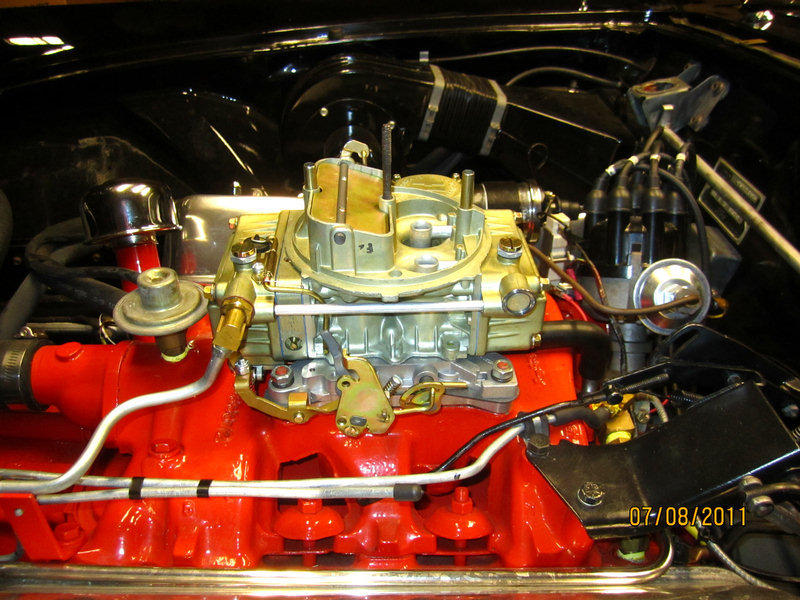

Holley 84057-5 / 1786 carb. Looks to be a 600 CFM aftermarket carb built 178th day of a year ending in 6

Ford O Matic 2-speed automatic

Sorry to be so long winded and thanks, in advance for some needed help.

|

|

By MarkMontereyBay - 15 Years Ago

|

|

The idle speed seems a bit high. I would check that. My manual says 450-500RPM in drive for the Fordomatic and 6-8 Degrees initial timing. Also, make sure you are using #1 plug wire for the timing light, #1 is the front(nearest the radiator)spark plug on the passenger side. After that, I would check the plug wires for arcing. Easiest way to do this is to fill a sprayer bottle with water then at night or in a darkened garage, mist the plug wires with the engine idling looking for sparks along each plug wire. A surge can also be caused by a leaking vacuum advance diaphram. Pull a vacuum on the nipple of the distributor advance mechanism and make sure it holds. If it leaks down, it will need replacing.

|

|

By Talkwrench - 15 Years Ago

|

|

If its a 600 Holley and you dont really know whats been done too it I would says its on the lean side as the Carb is a little too big. Look here and this may help http://www.y-blocksforever.com/forums/Topic51072-3-1.aspx?Highlight=600+holley Dissy doesn't sound right either, Go with whats been suggested, knock the idle back to closer to what it should be, A little high is ok with the Holley. Your intial timing is best around 10 - 16 degrees but you will have to see what your total mechanical advance is. Plenty on this if you search.. Also I found that marking the crank pulley in stages to be just as good as using a dial back light.

|

|

By paul2748 - 15 Years Ago

|

While you didn't say, based on the TBird forums have seen you on I guess its a Tbird you are talking about. The timing marks on a Tbird are not on the damper - they are on the pulley nearest the pointer. Check the pulley carefully. Time usually has made these marks hard to see, but they should be there. Mark them with white paint.

Once you locate the marks, then you can check timing. Start with around 10 degrees, vacuum plugged.

TBird and sedan engines are basically the same, but there are important differences. The balancer assembly is one of them.

|

|

By pops - 15 Years Ago

|

Thank all of you for the tips so far.

I mis-spoke about the timing marks on the damper. They are, in fact, on the pulley bolted to the damper, and there is a white paint mark on what I assume to be TDC. I did get the idle down to about 550 RPMS, but I have yet to bring the initial timing down to ~10 as it is presently at ~16. At 16 acceleration (under load) seems more sluggish than when it was before. I hope to be able to spend more time with it tonight or tomorrow.

Dwell is showing to be ~17. The Ford spec says it should be ~26-28. Should I be concerned about this at this stage?

|

|

By oldcarmark - 15 Years Ago

|

|

Couple of things I wanted to mention.Initial timing at 16 is too much.8-10 maximum.You should also regap the points however I am not sure if resetting used points to the specs is correct procedure because they are used.You should try it and then check the dwell and see if its correct.Changing the point gap after setting timing will change the timing.Total timing advance adding initial+vacuum+centrifugal should total preferably 42-44 max.How long have the points been in service?Not a bad idea to replace with a new set depending on how old yours are.Also backing the timing down to 8-10 will bring the idle speed down so you may have to bring it back up.Before you do too much more I would get the points situation fixed up as the points have a lot to do with how well your ignition system works.Without proper dwell the the coil does not build up sufficient spark.You should replace both points and condensor as a set.

|

|

By pops - 15 Years Ago

|

I made a new discovery last evening. I brought the timing down to 8 BTDC and readjusted the idle to 550-570. All of this with the carb plugged at the vacuum advance port. A test drive resulted in pretty sluggish low speed the hesitation from any stop was very evident, and the surging continued at cruise speed.

I then decided to open the distributor for the first time since I purchased the car. I found it has an PerTronix Ignitor conversion installed. Would having this require any changes in my investigation tests to find out why this car isn't running well?

SIDEBAR:

Turning the distributor counter-clockwise to bring the initial timing down to 8 degrees had a scary side effect. During the test drive, when I pressed hard on the throttle, the throttle suck partially open, causing a immediate stain in my shorts. I had to quickly get my foot under the gas pedal and lift it up. Once back in the garage, further inspection found that the tach drive cable got tangled in the throttle linkage holding partially open. This was not an issue when the distributor was turned much further clockwise. I modified the routing of the tach cable to prevent this from happening again.

|

|

By Hoosier Hurricane - 15 Years Ago

|

|

Pops: You said there is awhite paint mark at what you assume is TDC. Better verify that, someone may have put the dot at 42 degrees and used it to check total advance. If it's at about 40 and you add 10 to that for the initial setting, you'll have 50 degrees at idle. Way too much.

|

|

By RB - 15 Years Ago

|

|

If you are running a pertronix, make sure the red wire is getting 12v and not reduced voltage from the ballast resistor. The pertronix needs 9-12v to function properly.

|

|

By pops - 15 Years Ago

|

Okay guys, I will get #1 to TDC on the compression stroke to confirm the position of the white mark, and will also confirm the red wire is getting 9-12VDC and report back.

Thanks for sticking with me on this.

|

|

By pops - 15 Years Ago

|

I can confirm the red wire going to the dissy is getting 12V (on the incoming side of the ballast resistor) and the coil is getting just over 6V via the ballast resistor.

And I THINK I can now confirm the white mark is TDC. Took #1 plug out, brought the white mark to the indexing point, felt air pushing out of spark plug hole, took off the dissy cap and the rotor is pointing to #1 cylinder. Also, there are 4-5 graduated marks above the white mark each about am eighth inch apart. So, I think the white mark is TDC.

While I had the plug out I took a pic of it.

|

|

By Pete 55Tbird - 15 Years Ago

|

|

Pops Can we start over please. Tell us what car, what transmission, what year? The car ran well for 500 miles with only a couple of minor items and the it suddenly did not run well ? Is this correct? And now you are convinced that the problem is the timing, right? May I suggest that you first find the Ford factory mark on your pulley and that you put a paint mark on this so you can see it. Try to determine if your Pertronix is Ignitor or Ignitor II (they are different) Ignitor will use a ballast and runs on reduced voltage not full 12 volts. Try to keep an open mind about the cause of your problem it might be a lot of different things so do one thing at a time. Start with the engine timing and when that is set then find out what else is going on with your car. Pete

|

|

By pops - 15 Years Ago

|

I have an open mind because I'm a little lost. I'm not convinced it is the timing, but noting that it appeared to have 55 degrees of advance in it at idle left me scratching my head. And the more I retard it, it seems to be more and more sluggish.

I'm open to try anything that I have the test equipment and the ability to attempt.

Here is what I can tell all about the car. I bought it in October 2010 and have driven it about 500 miles since.

'56 Thunderbird with a '57 312 engine and Ford 'O Matic trans

Holley 4bbl list 80457-5 Date Code 1786 (appears to be an after market 600 cfm carb from the list number)

'57 dissy with tach drive

PerTronix Ignitor -"Ignitor" is written on the module (does NOT say "Ignitor II")

Autolite 46 plugs

I feel I have identified #1 at TDC by the white mark on the lower pulley. There are 4-5 graduations in the pulley above the white mark. There are NO graduations below the white mark. The white mark was at the pointer with the rotor pointing to #1 cylinder on the dissy.

The car has had a stumble/hesitation starting off from a stop early on.

Stabbing the throttle gets me beyond the hesitation

The car surges when at a steady cruise speed of 55-65mph

Letting off or pressing the throttle further clears the surging until you stay at a steady cruise speed for a little while again. Then the surges re-emerges.

My test equipment consists of a timing light that also measures RPMs. The light has buttons to advance or retard the light

I have a cheapo dwell meter, and I have a vacuum gauge.

|

|

By aussiebill - 15 Years Ago

|

|

pops (6/30/2011)

I have an open mind because I'm a little lost. I'm not convinced it is the timing, but noting that it appeared to have 55 degrees of advance in it at idle left me scratching my head. And the more I retard it, it seems to be more and more sluggish.

I'm open to try anything that I have the test equipment and the ability to attempt.

Here is what I can tell all about the car. I bought it in October 2010 and have driven it about 500 miles since.

'56 Thunderbird with a '57 312 engine and Ford 'O Matic trans

Holley 4bbl list 80457-5 Date Code 1786 (appears to be an after market 600 cfm carb from the list number)

'57 dissy with tach drive

PerTronix Ignitor -"Ignitor" is written on the module (does NOT say "Ignitor II")

Autolite 46 plugs

I feel I have identified #1 at TDC by the white mark on the lower pulley. There are 4-5 graduations in the pulley above the white mark. There are NO graduations below the white mark. The white mark was at the pointer with the rotor pointing to #1 cylinder on the dissy.

The car has had a stumble/hesitation starting off from a stop early on.

Stabbing the throttle gets me beyond the hesitation

The car surges when at a steady cruise speed of 55-65mph

Letting off or pressing the throttle further clears the surging until you stay at a steady cruise speed for a little while again. Then the surges re-emerges.

My test equipment consists of a timing light that also measures RPMs. The light has buttons to advance or retard the light

I have a cheapo dwell meter, and I have a vacuum gauge.

To help with diagonisis, get vacuum reading at idle and that may give ballpark indication of part of problem.

|

|

By oldcarmark - 15 Years Ago

|

|

Specs for output sise of resistor are 5.5-6.5 max so you are OK there.A thought regarding distributor breaker plate ground.There is a copper braide wire inside distributor which goes from breaker plate on top to under it and grounds it to distributor.Have a real good look and make sure it has not broken under the plate causing intermittent loss of ground when the distributor plate turns as timing advances.That has been seen on more than a couple of occasions causing loss of power.

|

|

By Pete 55Tbird - 15 Years Ago

|

|

Clay Take AussieBill`s advice and hook a vacuum gage to your intake manifold and post the reading you get at idle. It seems impossible that your car had 55 degrees of initial advance and still started ( my experience is that it won`t turn over with that much advance) Your timing lite might be giving you wrong info, make another mark about 1 inch from your white paint mark on the pulley AGAINST the direction of rotation of the pulley and check with the strobe lite and your number one sparkplug wire as the engine is revved up and see if the timing is advancing as speed increases. Then set the timing with the strobe lite and WHITE paint mark not the dial-back feature of your timing lite. Another possibility is your coil is failing but only consider that AFTER these simple easy things are done. Pete

|

|

By aussiebill - 15 Years Ago

|

Pops i know this might sound odd but be sure timing light is connected on #1 lead.

|

|

By pops - 15 Years Ago

|

Okay guys, thanks again for riding this out with me.

I'll dig into the dissy to confirm the connection of the ground wire. I did check the order of the plug wires and they are correct and my timing light is on #1 cylinder if it is the front passenger side (North America).

I have a couple of pics that illustrates my tests this afternoon:

Brought the car to operating temperature before conducting the tests.

You will note the idle speed is 550rpms

The dissy vacuum hose is disconnected from the carb and the carb side is plugged.

I connected the vacuum gauge to a port at the bottom of the carb. At 550 rpms it reads ~21

Next you will see I'm on the timing mark at 550 rpms. at this rpm it is reading 16.3 degrees advanced

I then brought the rpms up to ~2500

Dissy vacuum REMAINS disconnected.

Timing advances centrifugally to 24.2

I then reconnected the vacuum advance

Last reading with the timing mark lined up is 44.4 degrees total advance @ 2500rpm.

|

|

By Pete 55Tbird - 15 Years Ago

|

|

Clay Somewhat confused by WHERE you are getting the degree of advance numbers from 16.3 and 44.4. Are these from the timing light display? Where is the engine timing tag pointer points at white mark on pulley when the number one cylinder fires, engine at 550 RPM? This should be where the 8 to 10 degrees initial advance is set. Vaccum reading will only be of value if it is engine MANIFOLD vacuum NOT CARB PORTED VACUUM. At idle your distributor mechanical advance is close to ZERO so set your timing light display to what advance you set at the pulley timing mark ( by turning the distributor) Pete

|

|

By GREENBIRD56 - 15 Years Ago

|

|

Hi Clay - I just got back from Wyo and saw this thread - and off this eve to San Diego....but.....have you checked out the float settings of that carb? Didn't see it mentioned. As the level drops - the carb leans out (and surges) - and recently I've had a ton of trouble with gunk (and alcohol) in the gas goofing up needle and seat settings. Also - the Pertronix "Ignitor" model uno will work OK without the ballast resistor - and not hurt the gounding transistor - if the coil primary is over 1.5 OHMs. Are you running the original style of 12v coil?

|

|

By Daniel Jessup - 15 Years Ago

|

|

I would tend to follow Steve's advice, or maybe go back and read Ted's post (carb first, then the rest of it). I would almost think that the surging and bogging would be carb related. I have had ignition troubles before, but have never had the symptoms you are describing to us. Not trying to muddy the water here, but the carb would be my first place to start. Of course, when you got that reading of 55 degrees advance, I would imagine that chasing the ignition would be the first thing on your mind. All of your troubles happen under load right, never under "park" or "neutral" trans conditions? That's why I would be thinking carb issue first. Hope it works out for you...keep us updated with those great pics!

|

|

By pops - 15 Years Ago

|

|

Pete 55Tbird (7/1/2011)

Clay

Somewhat confused by WHERE you are getting the degree of advance numbers from

16.3 and 44.4. Are these from the timing light display?

Where is the engine timing tag pointer points at white mark on pulley when the number one cylinder fires, engine at 550 RPM? This should be where the 8 to 10 degrees initial advance is set.

Vaccum reading will only be of value if it is engine MANIFOLD vacuum NOT CARB PORTED VACUUM.

At idle your distributor mechanical advance is close to ZERO so set your timing light display to what advance you set at the pulley timing mark ( by turning the distributor) Pete

Pete and all,

This is the first time I have used this type of timing light. It has an up and a down arrow and a button marked RPM/Adv, that toggles between being a tach and a timing light.

After attaching the tach wires to the battery and #1 plug wire I then use the timing light and the up/down arrows to get the TDC (white mark) to line up with the pointer. Wile I"m pressing the up or down arrows I can see the TDC mark move one way or the other. And during this time the numbers are changing on the readout on the gun. Once the TDC mark is lined up with the pointer I read the number on the display.

I did turn the distributor to achieve the 16.6 degree timing with the Pointer at the TDC mark. (I'm thinking the timing gun has a built in advance/retard circuit to change the timing of the flashes. This allows one to line up the TDC mark with the pointer with the built in timing difference in the flash. I suspect if one attached a standard timing light it would show the TDC mark well advanced of the pointer. At least that is my understanding of this timing light. If I'm wrong someone please slap me, and set me straight.

I'm guessing that is the advance. As I increase the throttle the TDC mark moves upward and by again using the up/down arrows the display changes (upward) and the TDC mark comes back to the pointer. I then read the display and see what I'm guessing to be the advance either centrifugal or vacuum or both.

I may be doing a rather poor job of explaining this, I'm sorry for that.

A 30 minute test run after the settings in the photos were made showed improvement. The hesitation is still there, but the sluggishness/bogging seems to have subsided. Still have the surging, but at least I'm back where I started.

Hi Steve, I have not done anything on the carburetor. Now that the car seems to be back the where it was earlier, I may place some focus on the carburetor next. The only thing I have done was look at what size the discharge nozzle was and it is a #31.

Question: I have a new Ignitor II and coil. I suspect most would advise to get the carburetor issues worked out firs, but would there be any benefit in swapping out the Ignitor I for the Ignitor II first?

|

|

By Duck - 15 Years Ago

|

|

Pops- For what it's worth, every time I've had the issue at cruising speed you've described, I later realized it was the fuel pump telling me it was getting weak. This new gasoline is really hard on them, so they don't last as long as they used to. Also, everything I've read seems to indicate the Y fuel pumps are marginal at best. Good Luck /Duck

|

|

By Pete 55Tbird - 15 Years Ago

|

|

Clay First do check the distributor internal grounding strap Mark talked about. Do not try a new Pertronix and/or coil until the engine timing is set right. At this point I think that you should consider "STATIC TIMING" your engine. IE, with the engine not running. Do a Google search to find out how. With the engine off and number 1 cylinder at TDC and the timing mark on the pulley lined up at the white paint mark ( whether it is TDC or 8BTDC or 12BTDC or whatever ) this value should show in your timing lite display AT IDLE and WITH THE VACUUM ADVANCE DIS-CONNECTED. So if the pulley and pointer are at ZERO or TDC then you should see ZERO on the dial of the timing lite. Or 8 or 12 or whatever. After you get this straightened out then back to the problem. My experience is electrical faults are ON/OFF, runs or will not run and this leaves the carb to be sorted out. Pete

|

|

By pops - 15 Years Ago

|

|

I'll see where I can tap in to gauge the fuel pressure. Is 7 PSI about reasonable? I will also check the ground wire in the distributor. Did read up on static timing. Am I only trying to confirm the mark on the pulley is TDC with this procedure?

|

|

By Pete 55Tbird - 15 Years Ago

|

|

Clay You wrote " Did read up on static timing. Am I only trying to confirm the mark on the pulley is TDC with this procedure? " ER, no. You are setting the inital timing. Ford put marks on the pulley so you will know when the number one cylinder is at TDC and after 360 of crankshaft rotation at the top of its stroke but this is not TDC because the valves are not closed. After another 360 degrees of crankshaft rotation number one cylinder is again at TDC and the distributor should be turned so that the spark fires now and goes to the number one spark plug. The other marks on the pulley are to allow you to adjust the initial timing. That is why static timing works. Nothing is moving except the distributor to cause it to fire at whatever point you have the pulley mark and the timing pointer at. If you set it to fire at exactly TDC you have set ZEO advance and your initial engine timing is 0 ( zero). If you set your initial timing at 8-10 degrees BTDC (before TDC) your initial timing is set to 8-10 BTDC

Pete

|

|

By YellowWing - 15 Years Ago

|

|

Clay, you are correct about the way the timing light functions. I have a couple of them, they are very handy. I do believe your problem is carb related. I have a friend with a brand X motor and his complaint was surging at cruising speed and a slight hesitation just off idle. Changed two sizes larger on the main jets and both problems are fixed. I am running a 312 with initial timing of 16 degrees, also have a new demon carb that came with .058 mains. Idle was terrible at first and I had a large flat spot off idle. Changing mains to .062 cured about 90% of the off idle problem and I have been driving that way for awhile now. Just change the mains to .064 and boy what a difference! Hesitation is 98% gone, idle picked up 150 RPM (most people think main jets don't affect idle but they do), but most importantly the engine pulls much stronger at low RPMs. I think with a little more tweeking it will run perfect. The only probem I can see with changing the ignition is you are introducing a new variable. If you do so I would run the car before and after installation with NO OTHER chages made so as not to confuse matters. Mike

|

|

By pops - 15 Years Ago

|

Duck,

The fuel pump is new. That being said, I guess proving its capabilities remains a valid suggestion.

Steve,

I understand. My Ford shop manual states the grooves in the pulley represent 2 degrees per grove, thus the 4th or 5th grove above the TDC groove should have me at 8-10 degrees of initial Advance.

Then I think I could then prove the timing gun as being accurate two different ways:

1. It should read "0" on the display with the 8-10 degree groove lined up with the pointer.

OR

2. Advancing the up arrow to 8-10 degrees in the timing light display should then show the TDC mark lined up with the pointer.

Mike,

I will hold off making any further additions until this problem is rectified. I guess main jets will be the next item to focus on. Further up this thread I mentioned that I noted the carb has a #31 discharge nozzle installed. While I'm ordering new jets, do you guys think I'm in the right ballpark with the #31 nozzle?

PS Beautiful car!

|

|

By MarkMontereyBay - 15 Years Ago

|

|

I still recommend testing the vacuum advance diaphragm. A leaking advance will cause the timing to fluctuate a cruise and create a tip-in hesitation. Very simple test and a helluva lot easier than digging into a carb without knowing if the ignition advance is malfunctioning.

|

|

By pops - 15 Years Ago

|

Mark,

I've been sitting here thinking on what I might have around the house to create a vacuum to perform the test you mentioned. I think I have it if I can develop enough. I'm going to give it a try as soon as I change.

|

|

By MarkMontereyBay - 15 Years Ago

|

Hillbilly vacuum advance test procedure. Remove the distributor cap. Look at the arm that comes through the side of the distributor body and make sure it is free by pushing the arm back with your finger or suitable hand tool. It should rotate the distributor breaker plate a quarter inch or so. Attach a rubber vacuum hose to the carb end of the advance line and then by oral means, apply a sufficient vacuum on the line going to the distributor advance and pinch off the line with some needle nose pliers. Watch to see the arm move when you apply vacuum and that it doesn't bleed back into position. Releasing the pliers should cause the arm to return to the original position. If the arm doesn't move or moves then bleeds back down the diaphragm is leaking.

Non-hillbilly vacuum advance test procedure:

Substitute a proper tool for the job:

http://www.craftsman.com/shc/s/p_10155_12602_00920930000P?keyword=vacuum+pump&prdNo=2&blockNo=2&blockType=L2

If it needs replacing, Napa Auto parts has them for 57 Tbirds, Part#ECH VC945 $31.95 and be careful removing and replacing the chingadera clip that holds the arm to the breaker plate.

|

|

By Talkwrench - 15 Years Ago

|

|

Do your carb float levels.. When you have sorted and car is running ok change to the Pertronix 2 it has variable dwell and a much better unit. If you have the matching flamethrower .06 ohm coil even better. You wont need the ballast just make sure you have the full 12 volts there and it will run like a champ.

|

|

By Ted - 15 Years Ago

|

|

Both the vacuum and centrifugal ignition advance systems can be checked with the timing light. Simply observe the timing marks at the damper with the timing light while running the engine at various rpms with the vacuum hose both connected and disconnected. If there’s no change in the rate of advance between the hose being hooked up and not, then make sure the hose itself is clear and is hooked up to a suitable vacuum source. When in doubt about the ported vacuum, hook the hose up to ‘direct’ vacuum source on the intake manifold to verify vacuum pot operation with a timing light.

|

|

By pops - 15 Years Ago

|

I performed the static timing procedure and it was within a degree or two of what the timing light showed.

16 degrees initial seems to be the sweet spot.

With 16 degrees initial, the advance reads 24 degrees @ 2500rpm (centrifugal only)

and 44 degrees @ 2500rpm when the vacuum advance is introduced.

I'm convinced the timing is as close as I am able to achieve. I too think it is time to go on to the carburetor. Problem is I may well run out of time before I need to move the car. I have to leave town today and gone for the week. That leaves me with two weekend windows to get the car to Cleveland. I need to go the first weekend that the weather looks good. So, I may have to wait a little while until I can get the carb off to look at the float settings and see what jets are in it in order to up size a couple of sizes to see if this will make a difference in the stumbling. Jury is still out on the pump although it was to have been a new pump when I purchased the car in October.

(Best Arnold voice)

"I'll be back."

|

|

By charliemccraney - 15 Years Ago

|

Do you only have 8 degrees of mechanical advance (24 - 16 = 8)? Is 2500rpm the point at which it stops advancing?

|

|

By pops - 15 Years Ago

|

Charlie,

I only recorded the advance readings at idle and at 2500 rpms. I guess I should I go to the point the centrifugal and vacuum max out to determine the total advance.?

|

|

By GREENBIRD56 - 15 Years Ago

|

|

Clay - We are hoping that the maximum advance (initial and centrifugal summed) adds up to something in the neighborhood of 36°-38° - with no vacuum applied. If it would all be in by say 2700-2800 rpm, you would enjoy some increased low end torque and avoid (most) problems with bad gas causing a knock on acceleration (with low/no vacuum advance). The Pertronix "Ignitors" that are mounted on a swivel plate (to provide vacuum advance) must ground through the plate (hence the concern about retaining the old braided strap used with points) and then through the distributor body back to the block. Installing a "ground extension" that goes from the distributor "point plate" clear to the block is a good idea because every OHM that uses up voltage on the way to the block -eats coil power. Because this problem occurred over time - and the engine was still firing - I doubt if it shifted time. It is more likely a carb problem. What concerns me is that it looks like your builder utilized one of the new style Holley "non-adjustable float" versions of the 600 cfm carb. Like maybe P/N 0-80457S or something like that? Most of us are familiar with the Holley external adjustable float bowls - and know what to do with them but I don't have any idea what the design scheme of the the new carb is. Older versions of this arrangement had to be set with a guage - after you disassembled the carb - a horrible set-up - but cheap. The presence of alcohol in the "new" gas may be working on the needle material - Viton - and making the setting unstable.

|

|

By pops - 15 Years Ago

|

|

Steve, The ground braid is intact inside the distributor. I could add a ground wire fron the distributor to the block to assure a good ground. When I get home this weekend, I can try the centrifugal only advance and see where it tops out at. I note that the carburatort will have to come apart to check the floats. And, if I take it off the car to do so, I may just replace it with something more current. I have a question in at the Holley technical department to see if there is a direct or near direct replacement. The list a 570 CFM version with externally adjustable floats, but it is dual feed so I would have to re-do my fuel feed line. that would not be the end of the world. This begs another uneducated question: Just how reliable or otherwise are the stock Ford mechanical fuel pumps? Do many of you either supliment the mechanical with an electric or would using only an electric be a popular option? During last nights practice run, smashing the pedal at ~50mph the car just lost all power. I let my foot off the gas and pulled off the expressway only to have it pick power back up like nothing had happened. It only did this once, but here again, the trust factor is compromised.

|

|

By GREENBIRD56 - 15 Years Ago

|

|

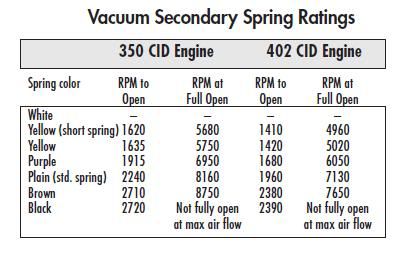

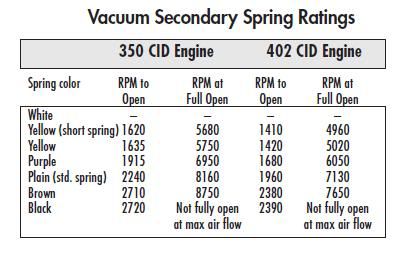

Probably the best all around replacement carb has proven to be the 390 cfm Holley with vacuum secondaries and electric choke. Several guys have special ordered a 400 cfm duplicate of the old '57 Ford carb from them but I don't know the numbers involved. I believe your carb could probably be quickly retro-fitted with adjustable side-hung bowls if they were available to you - it should be a straight forward exchange from what I've heard. Won't require new fuel line plumbing. The 600 cfm carbs will behave just about exactly as you described out of the box - the auto trans fails to downshift and the carb opens the front holes to atmosphere - at zero vacuum - and she just flat quits. Using the Holley "black" spring in the vacuum secondary housing is a good step toward getting things under control. A 600 cfm carb is just about too much for a daily driver and the stiff black spring will tend to make the carb act more like a big two barrel. Are you utilizing the vacuum pump style of fuel pump - with the two vacuum ports on the top - to operate the wipers? If not, the FE (352/390/428) engine fuel pumps fit right on the Y block and are much cheaper to come by. Mine has the pump from a 428 Police engine with minor plumbing changes - it will feed 300+ HP without too much difficulty.

|

|

By Pete 55Tbird - 15 Years Ago

|

|

Clay Before you get too deep into replacing the carb do some trouble-shooting and find out what is wrong. If it is the secondaries opening at 50 as you step on the gas ( I doubt this is it) you can check by disconnecting the linkage from the secondary vacuum diaphram to the carb and drive a what is now a straight 2BBL and see what that does at 50. One of the things that happens when you floor the car at 50 is the fast loss of vacuum advance and the plate inside the distributor snaps back. Recheck that ground strap.

|

|

By Talkwrench - 15 Years Ago

|

|

Steve is right 390 or 465 is the better choice, however I have a 600 on mine and I have it working well, It will only flatspot if its smashed to the floor real fast at standstill. He's how mine is set. "Just an update for anyone wth the Holley 600 situation... I am running 64 main jets and have gone up to a 35 squirter and am using the heavy "blue" cam for the pump [aftermarket one]which I can only get on no. 2 possition. This is working well and I dont need to much throttle to get her going, I have the brown spring from memory for secondaires [other than the very light springs all should be ok as the secondaries would hardly open anyway] . I do have a PCV setup. This is on a B manifold " bare in mind I am in Australia I dont know how much better our fuel is? Have you adjusted your float levels yet?!

|

|

By pops - 15 Years Ago

|

|

I cannot thank ALL of you guys enough. Inspite of myself, I think you are going to get me on the right path sooner than later. Your collective sage advice is registering albeit sometimes it takes a complimentery hammer blow to go with it. If I made a shopping list for the existing 600 cfm carburetor, would it include more than adjustable float bowls and larger secondary jets, and a rebiuld kit?

|

|

By pops - 15 Years Ago

|

|

GREENBIRD56 (7/5/2011)

Are you utilizing the vacuum pump style of fuel pump - with the two vacuum ports on the top - to operate the wipers? If not, the FE (352/390/428) engine fuel pumps fit right on the Y block and are much cheaper to come by. Mine has the pump from a 428 Police engine with minor plumbing changes - it will feed 300+ HP without too much difficulty.Steve, The fuel pump is the type with two vacuum lines on it. One is plugged since I have electric wipers. The other appears to go to the back of the manifold for manifold vacuum. What is the rationale for plumbing the vacuum wipers via the fuel pump and not direct from the manifold?

|

|

By Ted - 15 Years Ago

|

|

pops (7/6/2011)

The fuel pump is the type with two vacuum lines on it. One is plugged since I have electric wipers. The other appears to go to the back of the manifold for manifold vacuum. What is the rationale for plumbing the vacuum wipers via the fuel pump and not direct from the manifold?The vacuum booster on the fuel pump was originally designed to insure additional vacuum at the wipers during acceleration. If you’ve ever driven a vacuum wiper car in the rain without the booster pump,you'll find that the wipers crawl to a stop under acceleration or going up a hill. The booster pump helps in this situation. Seeing as how you’ve converted to electric wipers, then simply run a piece of vacuum hose in a ‘U’ connecting both ports on the vacuum booster. This will keep the dirt out of the booster diaphram while also insuring that the booster pump internals are not being stressed by having the inlet/outlet ports individually plugged. Be sure to plug the intake manifold connection that originally went to the vacuum booster pump as that’s a potential miss or hesitation if it leaks vacuum within the pump.

|

|

By Talkwrench - 15 Years Ago

|

|

you should be able to get a rebuild kit , it wouldn't hurt to have one. But There are a few different types .. some carbs have centre hung bowls and there is two different types of gaskets for the metering plate etc.. Does your carb have the little sight plugs in the side of the bowls? Gonna need to play around a bit with it. I do think you need to adjust your floats first just to make sure, thats easy cost nothing..

|

|

By GREENBIRD56 - 15 Years Ago

|

|

Rob - There is an earlier photo in this thread that shows the "non-adjustable" fuel bowls - they will have to come off for access. I'm thinking that if the setting has changed unexpectedly (and it worked before) - something is "afoot". Either goop in the bowl from manufacture (came loose from a hiding spot) or bad gas has done some evil to the needle and seat. Clay - Take a good look at the Holley web site and see if there are specific intructions for your carb - the "list number" should be on the front of the choke horn - driver side. Its always a good idea to have some replacement gaskets in hand - even if the carb is supposed to have come with the "no-stick" / re-useable type. If you remove one of the lower front bowl screws and use a little catch basin / cup, the primary bowl fuel will drain into it without soaking the engine. A look-see / cleanup / reassembly will be reasonably quick - and as Pete says, won't cost a new carb.

|

|

By oldcarmark - 15 Years Ago

|

|

Did you notice that post from "Marc" regarding his rebuild? Started and ran and kept dying.Turns out the Pertronix went bad even though it started and ran."Pops" has a Pertronix in his.Same problem maybe?

|

|

By pops - 15 Years Ago

|

I'm back in the saddle again.......

I saw this:

And selected this:

Out of the box, the stumbling is gone and the surging at cruise speeds is also gone!

4160/465 cfm with adjustable floats.

The only MINOR issue is I can't get the idle down to the 500-600 range. Idle adjusting needles are set properly, the throttle stop screw is just off and not touching the throttle arm, fast idle screw back way off. There is no secondary adjustment available on throttle body. Lowest I can get it to idle is about 900 rpm.

You guys really taught me a lot in this thread. I think the suggestion to down size the carburetor was excellent. And, all of your collective other suggestions has made me much more confident and knowledgeable. Thank you all!!

|

|

By GREENBIRD56 - 15 Years Ago

|

|

Clay - Many of the Holleys of recent manufacture have a secondary throttle stop screw.

It's located back by the vacuum secondary pot's attachment to the secondary throttle shaft - passenger side of the carb.

|

|

By oldcarmark - 15 Years Ago

|

|

What is your timing set at?Try backing it down to about 12.That should bring idle speed down a little.Before you touch timing check the throttle linkage.Are you sure the fast idle speed screw is backed down?Almost sounds like the fast idle is still in play.One more suggestion.Disconnect the throttle linkage at the carb and see if the idle drops.Sometimes the rod will not allow the carb to return to full idle position.If the idle speed screw is not touching the throttle arm it does sound like its not returning all the way to idle position.Check the linkage and make sure its not hanging up somewhere,

|

|

By pops - 15 Years Ago

|

I backed the fast idle screw out until it un-threaded itself, then screwed it back in only enough to have some spring tension on it. The timing suggestion sounds good since it is presently at 16. I did not see the screw Steve mentioned on the bottom of my carburetor. I had the throttle linkage disconnected when checking the idle rpm. I don't think the linkage is an issue.

I did put about 80 miles on it today without a hitch. Seems to be running, starting and shutting down great!

|

|

By Talkwrench - 15 Years Ago

|

|

Clay did you work out what your total mech advance was? If your dissy is standard do as Mark said as Im sure you will have a little too much and you should be closer to your idle speed.

|

|

By oldcarmark - 15 Years Ago

|

|

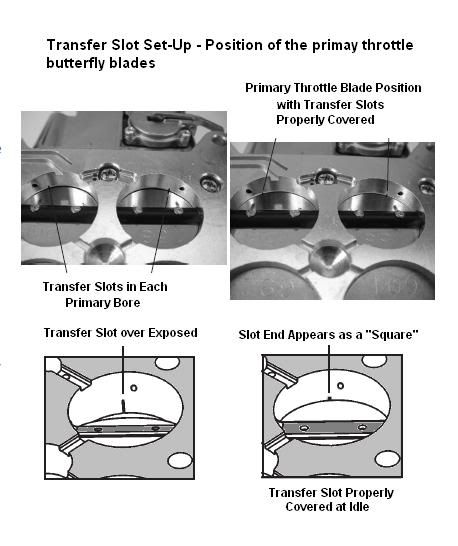

And the fast idle adjusting screw on the other side is completely off when the choke is in the "off" position?On my 390 Holley you have to open the throttle butterfly completely to access that fast idle screw with a box end 1/4 inch wrench.For it to idle at 900 RPM seems more than just advanced timing to me.If the idle speed screw is not controlling the idle speed which its not if its not in contact with the carb lever something else is holding the RPM higher.If you had turned the carb over before installing and looked just above the throttle plate you would see the "transition" slots in the carb throat.The throttle plate should be adjusted with the speed screw so you only see a "square" box below the throttle plate in the closed position.The idle speed screw should not be turned in(raising idle speed) any further than that point preferably.Thats why its a good idea to note the position of the idle screw when set to the preferred position so you do not turn it "in" any futher than that position.You can turn it "out" reducing idle speed if its too high but usually idle speed is very close to correct with the screw set at that position.Thats why I am thinking something is affecting the idle speed because you say the screw is only in enough to put tension on the spring.Anyway it sounds like you have found your problem which I am sure you are relieved to have solved.Little more fine tuning and you will be set.Now you are a "Y" guy with knowledge.Welcome to the club.The secondary speed screw that Steve is talking about is either recessed in the base or it may not be there-just the threaded hole.Thats how mine is-I just got hold of the proper thread machine screw.I ended up not needing to use it.

|

|

By pops - 15 Years Ago

|

I recall the slots at the bottom of the throttle bore, but did not know that only a square should be visible.

I think I will confirm the total timing, and bring the initial advance back down to ~12 degrees and see what this does to the idle.

Removing the carburetor is getting pretty painless, so if the idle is not corrected by reducing the initial timing I will take the carburetor back off and confirm the existence of a secondary idle screw and give a good look to see how much of the slot is showing when the throttle plates are closed.

Today, it is off to a car show with no stumbling or surging.

|

|

By famdoc3 - 15 Years Ago

|

|

You might try rechecking your vacuum at idle, bet it's a little low. Nothing screws with your idle like a vacuum leak. Simple thing will likely get you from where you are to done and happy. Step by step as has been well discribed by others here. MIKE, P.S. how are you posting these great pictures??

|

|

By GREENBIRD56 - 15 Years Ago

|

|

Clay - This is the set-up technique for the idle transfer slot, shown on a diagram. When the primary idle screw is set to provide this function, you'd like to leave it there.....Which then may cause you to need a another way to control air into the carb. The little secondary stop screw shown previously may or may not be fitted to your carb - but inserting one from the bottom with a type of head that can be accessed from outside when the carb is bolted down is a useful tuning tool.

The idle speed being up makes me suspect a vacuum leak as well. You might try using a plumbers propane torch (off) to introduce some fuel around the manifold seal - just to see if the speed jumps up somewhere.

|

|

By oldcarmark - 15 Years Ago

|

|

Hey Steve! I guess its true when they say great minds think alike.I was going to ad another post myself suggesting a possible vacuum leak.That would make the most sense.If the idle speed screw is not holding the RPM at 900 something else is allowing air in for the motor to run.If the speed screw is not in contact with the carb lever the motor should die due to lack of air.If you remember I went through all this idle speed(wont idle in drive) when I installed my rebuild about a year ago.Once I got some help from you and reset the idle speed screw so all that was visible was the little square box for the transition slots I was able to set it properly.As you said everyones first instinct to grab the screw driver and turn up the speed screw.Once you get too much transition slot showing you will never get it to idle properly.

|

|

By Talkwrench - 15 Years Ago

|

Well no one else has said it.. Clay, nice bird mate !

|

|

By MarkMontereyBay - 15 Years Ago

|

|

That is a sharp Bird! Just looked at the photo. I was talking with the owner of a 29k mile original trailer queen yesterday in San Jose and yours is as nice if not much better. Beautiful color scheme.

|

|

By pops - 15 Years Ago

|

|

Thanks guys, and no trailers for me. I love driving this car.

|

|

By 'GB'ird - 15 Years Ago

|

|

From a fellow Bird-er. Looks very sharp and I love the colour combo. I am intrigued about the exhaust exit though. Have you done away with the bumperettes and using a down-turned exhaust? Richard

|

|

By pops - 15 Years Ago

|

|

'GB'ird (7/12/2011)

From a fellow Bird-er. Looks very sharp and I love the colour combo. I am intrigued about the exhaust exit though. Have you done away with the bumperettes and using a down-turned exhaust?

Richard

Richard,

I do have a down turned "shake out" exhaust on the car at this time. I have the continental kit and and/or the bumperettes for it, but am undecided on what direction I want to go with the back end (if any). I really like the clean look it has now. I never have been overly keen on the bumperettes (front or rear) and I have mixed feelings about the continental kits looks. I like the exhaust exiting in the corners of the continental kit's bumpers, just not sure I want to hang all of it over the rear end. Thus there is a quick and dirty "shake out" exhaust until I can be sure of what I want to do at the rear end.

I'm rather liking the minimalist look of the front and the rear.

|

|

By 'GB'ird - 15 Years Ago

|

Yeah I know what you mean at the front but I have to say the exhausts exiting through the bumperettes at the rear is cool. Just so 50's and space-age. It's what gets all the comments at the shows here in the UK Richard

|

|

By GREENBIRD56 - 15 Years Ago

|

|

Richard - Clay's car is a '56 - and the bumper is a '55. Really cleans things up and looks very nice I think. The '56s have the exhaust coming out the corners of the rear bumper and the "Continental Kit" exterior tire carrier as the standard arrangement. The tin internal part the tail pipe exits into - and the bumper itself - suffered from the caustic effects of the exhaust and water vapor over the years. The previous owner of my car had the turndowns added as a "self preservation" move I'm sure.

|

|

By PF Arcand - 15 Years Ago

|

|

Normally I wouldn't like exterior body mods to an early T. Bird, but puting the conti kit up in the rafters suites me just fine. That car looks super clean as is & a person could always put a modern compact spare in the trunk. It has always struck me that when Ford went the conti route on the 56's they were throwing in the towel, as far as them being serious sports cars...

|

|

By pops - 15 Years Ago

|

Paul,

I have a mini in mine too.

Even with it, once I put two canopy chairs, my cleaning and waxing materials, and a couple of jackets, and a blanket it is pretty full.

Hmmmmm.............. Looks like I could lop off a few inches off of the hold down stud.

|

|

By Missouri Mike - 15 Years Ago

|

|

Clay- Glad you got your "nags" worked out and I have to agree with the others, That is a great color combo and I really like it sans the kit. Today they'd say "That is one sweet T Bird". But back in my day we'd have said, "That T Bird is tuff!" Missouri Mike

|

|

By oldcarmark - 15 Years Ago

|

|

OK! Nuff with the compliments.Pops-did you get the idle speed down and find the problem? Oh by the way I agree with everyone else-GREAT car!

|

|

By pops - 15 Years Ago

|

Not yet. My first opportunity to work on it will be tomorrow. I'm going to bring the initial advance down to ~12 from 16 and I'm going to take the carburetor back off to see if there is a hole, or threaded hole to adjust the secondaries. I also want to try Steve's suggestion of squirting propane around the base of the carb to see if the idle raises indicating a vacuum leak.

Speaking of vacuum:

I am noticing something seemingly unique to my car when comparing it cold to others. My upper radiator hose shrivels up when the car cools down as if there is a vacuum in the cooling system. Is this possible?

|

|

By oldcarmark - 15 Years Ago

|

|

I think you may have a bad rad cap.I think it should allow air in as the motor cools to prevent what is occurring with your rad hose.

|

|

By oldcarmark - 15 Years Ago

|

|

When you have the carb off remember to set up the throttle plate position as indicated in Steve's diagram.You might want to make a note for yourself indicating throttle speed screw position once you have it set.You can turn it a little CC to slow idle speed if too high and turn it minimally CW to increase speed if required but as close to the preferred position either way is best.If you know how far to turn the screw once it contacts the throttle lever you can always start over if necessary without taking the carb back off(if you make a note for yourself).The transition slots in the carb allow more fuel to enter as you leave the idle position preventing "stumble" as the intermediate carb circuit activates.If the plate is open too far at idle excess fuel enters from the transition slots and you can never set the mixture screws properly.Before you take the carb off I would look for a vacuum leak.Carb cleaner sprayed around the carb and manifold can also be used as engine speed picks up as the fluid is drawn into a leaky area.Also check the carb mounting surface on the manifold for flatness.Let us know what you find.I do believe you have a small leak somewhere.With the carb speed screw backed out the throttle plate is closed.Motor should quit unless air is entering somwhere else.

|

|

By pops - 15 Years Ago

|

Okay..... The grass is mowed and I'm back on to the important stuff.

Warmed up the car

Got out the propane torch

With the car at idle, I went around the base of the carb with the hand held torch wide open.

Did not notice any difference in the idle speed.

Next step was to set the initial timing advance to 12 instead of 16.

This dropped the idle speed, but I sense a little wrapping out of the exhaust. Still I left it at twelve degrees advanced.

Next, I again took off the carb. Here is the slot on the primaries.

Here is the "no slot showing" on the secondaries.

This next photo has me saying 100 times:

Never doubt Steve.

Never doubt Steve.

Never doubt Steve.

Never doubt Steve.

Never doubt Steve. X 20

I knew I would make matters worse, but I went ahead and adjusted the set screw so only a square was showing on the secondaries. Now I'm back up to about 1,000rpm as a minimum setting with the throttle screw just off of the carb linkage.

Should I go back to no slot showing on the secondaries???

|

|

By pops - 15 Years Ago

|

Dumb question. I deleted it.

|

|

By oldcarmark - 15 Years Ago

|

|

Back it down.The secondary can be adjusted with it running if you can get something in there to turn it or take it out and get a longer machine same thread that you can adjust running.It does not need much and the slot in the secondary can be ignored.All you are trying to do is let a liitle more air in.Looks like your primary is about right.All you want to see is a square below the plate.Did you set it there as it is now or is that how it was when you took the carb off?If you have the primary set there and the timing set back a little to 12-if it idles too slow thats when you would open up the secondary a little to bring idle up to where you want it.It wont take much to bring idle up as you found out when you put it back on this time.

|

|

By pops - 15 Years Ago

|

They didn't put the secondary screw or the high idle screw in a very accessible place did they?

As soon as it cools down, the carb will come back off and I will put the secondary throttle plate back to where it was. I think once I have done that I'll be pretty close. If I have an allen head set screw to replace the slotted one, I might try it with a sawed off allen wrench for future tuning.

Thanks for the continued support.

|

|

By oldcarmark - 15 Years Ago

|

|

If you are talking about the fast idle screw if you rotate the throttle to full open by hand the fast idle screw is accessible in that position.Not sure what the head is on yours but mine takes a 1/4 inch mini wrench.Trial and error getting the speed where you are happy with it.

|

|

By pops - 15 Years Ago

|

Okay, carb came back off and I put the setscrew back to where is was from the factory. The slot is now covered but the idle came down.

What I don't see happening is the opening of the vacuum secondaries at high throttle. While holding the throttle open I can open them by hand, but they are not opening when stabbing the throttle. Does it take a substantial amount of vacuum to open these? Should I not see them start to open under high throttle? Is this going to be another take the carb back off exercise?

|

|

By GREENBIRD56 - 15 Years Ago

|

|

Clay - See if you can come by a longer screw to replace the secondary throttle stop. I usually use a long pan head screw chopped off to a "threaded rod" configuration. And then adjust it with needle nose pliers from below - so much for my hillbilly roots.... The coil is in the way if you use an Allen wrench. The main thing is to retain the ability to adjust idle speed while leaving the front butterfly in just the right spot. Do you have a PCV system hooked up on the engine? Mine provided way too much air and drove the idle speed up - until I realized where the air was coming from and throttled it. I'm using the valve intended for the '64 292 truck and as far as I'm concerned - it's too much of a free opening. Mark used one from a newer smaller Ford and it seems to have done the trick. Anyway - you can quickly plug the PCV hose to the carb and check for this source of your extra idle air. The 10°-12° advance initial idle position is OK - as long as you know she won't go over 36°-38° (vacuum advance disconnected) at full throttle. You won't really be able to get the vacuum secondaries to show you much by blipping the throttle at a standstill. If - when driving - you floor it and there is a notable "kick" when it opens - its probably opening too early and will need a stiffer internal spring - another reason to visit Summit.....

This table helps sort them out as they come from the box.

|

|

By oldcarmark - 15 Years Ago

|

|

The secondaries will not open under idle conditions.Needs a big drop in engine vacuum such as when you floor it under load(driving).I used a PCV for a 78 Zephyr-Fairmont 4 cylinder.Smaller internal worked out good on my setup.

|

|

By Ted - 15 Years Ago

|

|

Verifying vacuum secondary operation on the vehicle can be checked by placing a paper clip on the vertical vacuum secondary diaphragm rod against the housing and then looking to see if the paper clip has moved to a lower position after a test run. The vacuum secondary operation also can be bench tested with the carb off of the vehicle. This is performed by opening up the primary throttle to full open and placing a high speed air nozzle at the ~Five O’Clock position in the right front venturi at its top. If all is good, you’ll see the secondaries open and close as the air is moved over the hole that’s located just below the venturi opening at that point. Here's a picture that will help clarify what's taking place in the bench test.

|

|

By pops - 15 Years Ago

|

GREENBIRD56 (7/16/2011)

Clay - See if you can come by a longer screw to replace the secondary throttle stop. I usually use a long pan head screw chopped off to a "threaded rod" configuration. And then adjust it with needle nose pliers from below - so much for my hillbilly roots.... The coil is in the way if you use an Allen wrench. The main thing is to retain the ability to adjust idle speed while leavingthe front butterfly in just the right spot. Do you have a PCV system hooked up on the engine? Mine provided way too much air and drove the idle speed up - until I realized where the air was coming from and throttled it. I'm using the valve intended for the '64 292 truck and as far as I'm concerned - it's too much of a free opening. Mark used one from a newer smaller Ford and it seems to have done the trick. Anyway - you can quickly plug the PCV hose to the carb and check for this source of your extra idle air. The 10°-12° advance initial idle position is OK - as long as you know she won't go over 36°-38° (vacuum advance disconnected) at full throttle. You won't really be able to get the vacuum secondaries to show you much by blipping the throttle at a standstill. If - when driving - you floor it and there is a notable "kick" when it opens - its probably opening too early and will need a stiffer internal spring - another reason to visit Summit.....  This table helps sort them out as they come from the box.

Steve and all,

This must(?) be the PVC valve(?)

If so, yes, I have one.

I do not get any of the "WHhaaaa" when I floor the pedal. Only a non eventful build up in speed. It's down shifting though.

I will try Ted's paperclip suggestion. And oldcarmark's suggestion on the smaller PVC valve.

UPDATE one the home sale.

The New Jersey lender hired an appraiser to appraise our home. It appraised for more than the sale price. Two weeks after the appraisal and after I rented a garage and apartment, and committed to have the movers in this week, the New Jersey lender decides they don't like their own appraisers appraisal and commits to only 90 of the requested loan. The buyers have already bellied up with 20% down. They threw a big monkey wrench into our sale and move. Now the buyers have a new lender and we had another appraiser in this past Wednesday (coincidentally the same one that appraised our home two years ago when we refinanced) Then it appraised for 10% more than the current selling price so we will see what happens.

If anything good came from this, I do have a little more time to get my car ready for the trip.

I'm multitasking today. I don't want the movers to move my hard top. The hard top may, or may not have been from this car. I Know it has not been on since the car was restored. It had no hardware for the rear hold downs. I located all the hardware and this morning drug the top out of the garage, installed the hardware and tried out the top on the car. I'm told that although Ford did not install "factory" vinyl to these tops, the individual Ford dealers did. I am told this is how my top evolved. What do you guys think of the vinyl top? I sorta like it. If you don't go ahead and say so as I have thick skin.

|

|

By 46yblock - 15 Years Ago

|

|

Yes that is a PCV in a common location. I like your top!

|

|

By GREENBIRD56 - 15 Years Ago

|

|

Sorry to hear about the home apppraisal uproar - I'm sure you will be glad when the ordeal is concluded. Personally, I like the tops plain - no portholes, no ornaments - block sanded, "faired" and painted body color or 70's Corvette "Arctic White". What I would like to warn - is to be darned sure it is all secure - SpeedPro56 has had the back window pop out of his (at speed) - and I found a picture on the internet one night of a scarred lid lying on the freeway in Salt Lake City.....arrrrgh! Explain that one to the insurance company. The secondary operation you describe actually might indicate too much spring? In which case you might experiment with the next size down the list - or skip two - whatever seems appropriate. You just don't want it to have the infamous pause .."ka.....wow" as it opens. The pause is actually a slow down of the vehicle as torque is lost - and the kick is when it picks back up. The most rapid smooth change is good. Holley sells a "quick change" lid for the secondary housing that sllows future changes without the teardowns of the vacuum pot. I ususally use the electric chokes - and so I trim off the plastic brackets for the manual to clean the new lid up a bit. The "shooter" for accelerator pump has a part in this as well ... the "list" that comes with the carb may say which size came with it?

|

|

By MoonShadow - 15 Years Ago

|

|

I think the top looks great. The question is do you like it? If so then its "perfect" for you! I sold my sisters house in Atlantic Highlands this year. Took 2 years on the market and went for about $80,000 less than it should have. New Jersey counties just went through a reevaluation for taxes and changed a lot of appraisals. When all was said and done it was only about $10,000 under the NEW appraisal. I was sure glad when it was done. Had to deal with multiple offers, crooks and profiteers before we found the right buyer. Hope it all works out for you. Chuck

|

|

By pops - 15 Years Ago

|

Yep, real estate wise, it is ugly out there. I'm left holding my breath on this one.

Just got back from another 60 mile test run. Engine is shaking the car a little at 550-600 rpm idle, in gear. Smooths starts though and consistent cruise speeds. Still takes a little while to reach higher speeds like there is some lack of power. I'm not really complaining though as I think, from all your help, I'm getting close to having it right. No more working on it this week as I am packing for the early morning drive to Cleveland. Will be there for the week so the next opportunity to work on it will be next Saturday.

Summit has PVC valves right?

|

|

By oldcarmark - 15 Years Ago

|

|

For the PCV you want any auto parts store should have one.Summit might but they are more high performance than stock-but they might have one.One other thing that Steve suggested to me was raising the float level slightly.For some reason it affects idle quality.I turned mine up by 1/4 turn.Having the external float adjuster makes it easy try and see if it helps.5/8 wrench to crack the locknut loose.Turn the screw 1/4 turn CC and lock the nut back down while holding the screw.If it does not flood at idle leave it and see if it helps.I think it made a difference on mine.Also air temp seems to have a noticeable affect on the way it runs at idle.Hotter it is the worse it idles.

|

|

By Grizzly - 15 Years Ago

|

pops (7/16/2011)

Next, I again took off the carb. Here is the slot on the primaries.  Here is the "no slot showing" on the secondaries.  This next photo has me saying 100 times: Clay, What is that jagged edge on your butterfly. It looks like you are going to loose half your butterfly. Very likely the reason for your rough running. Cheers Warren

|

|

By pops - 15 Years Ago

|

Grizzly,

If your speaking of the top photo about in the middle just above the axle for the butterfly; It looks to just be the transition between the dry and the wet portion of the butterfly. I'm getting pretty fast in taking this carburetor off and on. This last time the engine was still running.

This is more evident in this photo.

In the upper left corner is some black (?) that seemed to dislodged itself from where I don't know. Looks like paint from the butterfly, but the butterflies look to be anodized.

Way back in one of my first posts I mentioned a slight miss at rest but in gear. It is still there. I guess one of the future steps would be to check each plug. Still have the Petronix II standing by to go in as well.

|

|

By Grizzly - 15 Years Ago

|

|

Clay, That's better  Odd what a camera can do at times. Odd what a camera can do at times. Cheers Warren

|

|

By GREENBIRD56 - 15 Years Ago

|

|

Clay - You are hereby appointed the site carb photographer.....hope we can use these photos for some future advice???? Just need to put some black arrows on the spots we commonly point out.... Do you have a vacuum gauge in your toolbox? I'm curious what the needle is doing when the engine is sitting at loaded (in gear) idle. When you check your plugs - set them up at standard gaps if they've been opened (as Pertronix recommends) - Ted has some dyno data that shows that the factory gaps give best power (on a Y-block).

|

|

By pops - 15 Years Ago

|

|

I have a vacuum gauge. I note that this carburetor does not have a vacuum tube coming out of its base like the last one did. However, there is a block near the back of the manifold that I can adapt some fitting to allow the gauge to be connected there. What kind of readings would you suggest I record when I return home on Friday?

|

|

By oldcarmark - 15 Years Ago

|

|

You will want to record reading at idle with motor fully warmed up.Gauge should read 19-21 and steady in a motor in good condition.If its not steady how much does it vary?Whatever variance you note is helpful in diagnosing possible problem.

|

|

By GREENBIRD56 - 15 Years Ago

|

|

This chart isn't as cool as some that are animated - but it will show you the information available from the vacuum gauge. http://www.classictruckshop.com/clubs/earlyburbs/projects/vac/uum.htm The tube you have disconnected from the fuel pump - direct from the back of the intake manifold - is as good a tap as you will find. Do you have a thermal break isolator under the carb? Drilling a passage - and adding a short piece of brake line tubing with JB weld or epoxy can add an additional manifold vacuum port. They work best when they sample both chambers of the split intake manifold.

|

|

By pops - 15 Years Ago

|

TOO HOT!!!

Struck out on getting the Zephyr PCV valve yesterday. Really too hot to work outside anyway. I took a bullet and performed "honey do's" INSIDE where it was cooler. I'll try another supplier for the PCV valve today.

|

|

By pops - 15 Years Ago

|

I'm back.....

Three strikes on the 78 Zephyr-Fairmont PCV valve. Went to three different stores and none of them had one.

I did disconnect the vacuum line from the manifold to the fuel pump and looped it back to the other vacuum line to the fuel pump. Then put in a straight fitting in the manifold to accept the vacuum gauge.

Hose/line to fuel pump.

Left hose to power brake, Center hose to fuel pump, Right hose is PCV.

Straight fitting for vacuum gauge. Vacuum lines to fuel pump looped together.

Engine warm, vacuum to carb plugged, brought initial advance down to 10 degrees. Idle speed in neutral = 700

vacuum gauge reads:

700 RPM seems to be as low as I can get the idle.

|