|

By RossL - Last Month

|

I installed new exhaust manifold gaskets about 4 months ago (1955 Tbird 292). I tightened them down and after running it a couple of times I tightened them again. I checked them this weekend and a couple were not tight, they needed 1/8 of a turn. I heard if you tighten them too much the manifold could crack.

I obviously have to go a little tighter, is this common? I thought I read someone else had a similar issue.

|

|

By Deyomatic - Last Month

|

I'm no expert, but the 292 in my hot rod does the same thing. Every few months or if I hear a "leaky exhaust sound," I'll just re-torque them.

Someone here will likely have a real fix.

|

|

By DANIEL TINDER - Last Month

|

|

One of the speed shop parts catalogs may still offer ‘locking’ manifold bolts. Once snugged down on the gaskets and locked with their central allen/hex bolt, no leak noise after 70K miles/20 yrs.for me.

|

|

By paul2748 - Last Month

|

|

Are you using lock washers ? The star lock washers may work better that the usual lock washer.

|

|

By KULTULZ - Last Month

|

You don't want to use a composition gasket on an exhaust manifold as this will be the result. The cyl head and manifolds expand and contract at differing rates causing the loosening.

It is metal to metal or steel shim if needed.

|

|

By DANIEL TINDER - Last Month

|

KULTULZ (1/3/2026)

You don't want to use a composition gasket on an exhaust manifold as this will be the result. The cyl head and manifolds expand and contract at differing rates causing the loosening. It is metal to metal or steel shim if needed.

Since the manifolds & heads are seldom perfectly flat, the comp. gasket takes up the expansion/contraction slack, preventing leaks if the bolts never loosen. Just make sure to not initially over-tighten them and snap off a manifold ear. The alternative using the factory metal-to-metal system is likely frequent retorquing, though having the manifold & heads milled may prolong the seal (?).

|

|

By paul2748 - Last Month

|

|

No problem with using the composition gaskets. I have used them on both of my yblocks with no problems - leakage or breaking. If you install the manifolds correctly, I doubt you will ever have broken ear. I use lock washers on all the bolts.

|

|

By RossL - Last Month

|

paul2748 (1/3/2026)

Are you using lock washers ? The star lock washers may work better that the usual lock washer.

I am using flat lock washers with Felpro exhaust gaskets

|

|

By oldcarmark - Last Week

|

|

Maybe the Manifolds are NOT flat. They can be re-surfaced by any Machine Shop. I did mine because they would start to leak after some use and the Gaskets that I used to seal them would burn out. Not supposed to require Gaskets if the Manifolds are in fact flat and not warped.

|

|

By KULTULZ - 6 days ago

|

They came from the factory metal to metal and there was a reason for that.

You ascertain correct surface(s) flatness and go from there.

If you want something that will not loosen, you go to tubing headers where you can apply constant torque.

Main reason for ears cracking.

|

|

By Big Tim - 6 days ago

|

|

The only y block I have seen that the exhaust manifolds didn't leak as you described had the factory style lock washers that you bent around the sides of the bolt heads to keep them from turning. I just chalk re-tightening up to routine maintenance on these things.

|

|

By 55blacktie - 6 days ago

|

|

The exhaust manifolds on my 55 Tbird weren't leaking when I started tearing down the engine, and no broken ears. They are the original manifolds.

|

|

By Ted - 4 days ago

|

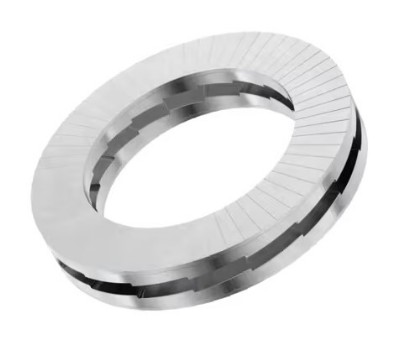

I have been using Nord Lock washers on the headers on my FE powered 1966 Fairlane and they do a good job in keeping the header bolts from backing off. Here’s a picture of what they look like.

|