|

By geo56 - 2 Years Ago

|

|

I adjusted the valve lash on my 292 today and noticed a considerable accumulation of a yellowish jelly like goo on the inside of both valve covers, and it wasn't just a light smearing. There were blobs hanging from end to end. The rocker assemblies and troughs in the heads were clean though. I have also noticed this residue when I cleaned out my road draft assembly. It is not sludge as it is a rather clear jelly with a light yellow tint. I am thinking it might be detergent condensing out of my motor oil. I have been using 10-30 Quaker State for all engines. I also have been adding a risolone zinc supplement with each oil change. Does anyone know what this goo is? Is it harmful?

|

|

By Deyomatic - 2 Years Ago

|

|

I don't know but about 20 years ago someone told me that Quaker State can leave a coating of paraffin. Just a thought.

|

|

By HT32BSX115 - 2 Years Ago

|

That "goo" sounds a lot like emulsified water/oil

Very common in marine engines that might have a cracked block or other water intrusion into the oil

|

|

By 1946international - 2 Years Ago

|

|

Agree with above, water vapor in with the oil film. I get this sometimes, you need better crankcase ventilation or just run the car longer/harder. Maybe the thermostat not working?

|

|

By geo56 - 2 Years Ago

|

|

I have not noticed a drop in coolant level over time . However, I am retired and live in town and do mostly short trips and a lot of them. I guess that the goo will not harm anything and assume that it only accumulates on the outer sheetmetal assemblies, such as the oil filler tube, the stock valve covers, or the road draft tube assembly. By the way, this situation has come up with various oils I have used : including Rotella, Valvoline, Quaker State. Quaker State is the only non synthetic oil I can find in stores.

|

|

By HT32BSX115 - 2 Years Ago

|

Well,

There's certainly nothing wrong with synthetic oils. I run them in everything I own.

If you have a low temp t-stat installed, and/or don't drive it much it or not for very long, the oil may never get up to operating temp.. Then when you do run it, if it doesn't make it to at least 180-200 degrees F (oil temp) any water accumulated inside due to condensation will collect in the oil and condense on the cooler surfaces (like the top of valve covers etc

It's very common in (raw water cooled) marine engines because they typically have 140 degree F T-stats so the oil in them rarely gets hot enough to evaporate the water out of the oil. Air cooled aircraft engines also have a similar problem when operated in winter time for short periods where the oil temp doesn't get hot enough.

That water will also combine with any acidic combustion products to produce corrosion causing components that can only removed by changing the oil.

|

|

By geo56 - 2 Years Ago

|

|

Your reasoning seems to correlate well to the problem I have been having. Seems like the best solution would be to do frequent oil changes. I rely on the stock temp guage in my car and it never seems to go past 1/4. I can't remember what thermostat I put in during my build years ago. What temp thermostat would be recommended for my car?

|

|

By HT32BSX115 - 2 Years Ago

|

The thermostat temp depends somewhat on the health of your cooling system in general and the cap pressure.

Napa indicates that for a 1960 F100 292, the OEM thermostat is a 180 degree F (opening) unit. (I don't think it's different for cars)

Newer engines operate at MUCH higher temps for emission reasons and all gasoline engines seem to run at higher efficiencies when operated at a higher vs lower temp. (200+ vs 170-180)

The problem is that the older cooling systems aren't really designed to handle the pressures needed at the higher temps. (hence the 7psi caps on many 50's cars and trucks)

When I had my radiator completely rebuilt and the 3-row core replaced with a 4-row core, I asked the "Rad-Man" what (MAX) pressure cap I could use on this radiator.

He told I could use up to a 13PSI cap ( almost double the pressure with the original 7PSI cap)

I then started looking at temp/pressure curves for 50/50 mix ethylene glycol based coolants just to satisfy myself that I could safely raise the thermostat temp to 190-200 F and use say, a 10PSI cap for a limit

Here's an interesting article on cap selection.

https://www.dewitts.com/blogs/news/13852841-what-pressure-cap-rating-should-i-use

Maybe someone can jump in here with experience using higher pressures with stock Y-block cooling systems

I will be putting a gage on mine if I raise the T-stat temp just to make sure I do not exceed whatever cap I decide on.

All the above is based on a using a 50/50 mix of distilled water and (concentrated) antifreeze.

|

|

By Deyomatic - 2 Years Ago

|

|

OH...THAT goo. Forget what I said earlier. I would bet that your short trips are exactly the problem. I know my 292 takes a LONG time for the gauge to show operating temp. I run a 170* (Napa #6, I think) thermostat. Start making extra time for longer cruising.

|

|

By 58F600 - 2 Years Ago

|

HT32BSX115 (9/26/2024)

The thermostat temp depends somewhat on the health of your cooling system in general and the cap pressure. Napa indicates that for a 1960 F100 292, the OEM thermostat is a 180 degree F (opening) unit. (I don't think it's different for cars) Newer engines operate at MUCH higher temps for emission reasons and all gasoline engines seem to run at higher efficiencies when operated at a higher vs lower temp. (200+ vs 170-180) The problem is that the older cooling systems aren't really designed to handle the pressures needed at the higher temps. (hence the 7psi caps on many 50's cars and trucks) When I had my radiator completely rebuilt and the 3-row core replaced with a 4-row core, I asked the "Rad-Man" what (MAX) pressure cap I could use on this radiator. He told I could use up to a 13PSI cap ( almost double the pressure with the original 7PSI cap) I then started looking at temp/pressure curves for 50/50 mix ethylene glycol based coolants just to satisfy myself that I could safely raise the thermostat temp to 190-200 F and use say, a 10PSI cap for a limit Here's an interesting article on cap selection. https://www.dewitts.com/blogs/news/13852841-what-pressure-cap-rating-should-i-useMaybe someone can jump in here with experience using higher pressures with stock Y-block cooling systems I will be putting a gage on mine if I raise the T-stat temp just to make sure I do not exceed whatever cap I decide on. All the above is based on a using a 50/50 mix of distilled water and (concentrated) antifreeze.

100% pressure test in the garage before using a modern pressure cap.

The engine itself won't be the limiting factor in the cap, in fact higher pressure caps help eliminate hot spots from localized boiling at the engines hottest parts. the head gasket will see well over 19psi on the cylinder side of the gasket vs the water jacket side.

We just ran a 19psi cap seal level to 12,000ft and temps up to 220° for over 3,000 miles. The cap was a help, not a hindrance. We did have an aftermarket radiator and heater core which would be #2 and #1 guesses on parts that won't tolerate the added pressure. Not because of design, but due to age and deterioration. If either won't hold 19psi, it's not very far off from failing at 3psi IMO. Both components new, or good used condition ,would take the added pressure with no issue.

|

|

By 58F600 - 2 Years Ago

|

|

The jelly issue is water. You need a PCV valve, 180 degree T stat and longer drives to mitigate the issue. Even with a PCV the Y block doesn't have great crank case evacuation in the valve covers, if any. There is a baffle on the valley plate, but zero chance that works as well as a breather in one valve cover and PCV in the opposite end of the other cover.

|

|

By KULTULZ - 2 Years Ago

|

I don't know ...

If the deposits are that heavy, I would maybe consider an exhaust gas(es) test on the coolant and a system pressure check. With the pressure test, I would hold pressure on the system at the least for a few hours to see if the pressure drops any. If it does, it indicates an external/internal leakage. You might be able to borrow a pressure tester from a box store.

Is the milky substance white or cream colored?

How often do you change the coolant and what color are you using? If extended drains, was the coolant tested for Ph between drains?

When you serviced the road draft canister, did you change the filter? Is the oil filler cap fresh air filter clean and open?

Merely changing the oil (and filter) more often will not prevent the damage that can occur and is a waste of money (IMO). If the CCV SYSTEM is not performing correctly, there are other conditions other than water that can/will damage the engine.

What area of the country do you live in as it will also determine water (humidity) ingestion? Engine oil is also hygroscopic.

|

|

By geo56 - 2 Years Ago

|

|

I think I found the problem. I have gone through about 4 oil changes without pulling the cap off my road draft assembly. I took the cap off yesterday and a little water trickled out before I discovered the filter to be totally covered with the goo. I removed the entire assembly and cleaned everything with solvent. I felt no need to buy a new filter as the old one seemed to wash out thoroughly with solvent and compressed air. I also washed out and blew out the filter on the oil filter neck that also had goo on it. I believe I will now service the road draft tube at each oil change.

|

|

By KULTULZ - 2 Years Ago

|

Is the filler cap open and has a filter element in it? The original (OEM) had a hog hair filter.

This is where the ROAD DRAFT SYSTEM draws outside air.

.. and the filter is not that expensive.

|

|

By Daniel Jessup - 2 Years Ago

|

Kultulz's question (and anyone's answer) on which part of the country you live in makes a big difference. On my Y block with a good PCV system, I would get a little bit of cream colored goo in my oil filler cap over the winter months when I did not run the engine long enough for a good heat cycle to eliminate any moisture. I lived in southern Ohio in an area known for being cloudy and wet most of the year with high humidity. Since I moved out to Lancaster, California and the high desert in the spring of '23 - I have no issues with any goo. I do drive the car a little more than I did back in Ohio, but with the dry climate out here there is very little to no moisture that gets into the crankcase.

My personal opinion is that if you have the original crankcase ventilation system in your Y Block, you really need to keep the thing going through good heat cycles of 30 minutes or more run time while running the vehicle down the highway at speed. Those original systems were made to suck air from the crankcase via the downdraft tube (either on the side of the block or the version with the long tube down the bell housing) pulingl the air through the filler cap and ventilate while the vehicle was moving down the road - hard to get air moving if only driving around stoplights, short runs to the cars and coffee meet up, and parades and such. If moisture is "burnt off" to a vapor because of a good heat cycle, the vapor in the crankcase still needs to exit somehow.

|

|

By 55blacktie - 2 Years Ago

|

|

This is good advice for any engine; no doubt you've seen condensation coming out of the tail pipe(s) upon start up. The engine needs to run until it reaches normal operating temperature, and make sure you have the correct thermostat; a 160-degree thermostat might prevent your engine from reaching the normal operating temperature.

|

|

By miker - 2 Years Ago

|

|

Winter break my first year in college was cold and damp, typical Seattle. I drove short trips around town seeing friends. At the end of a couple weeks I pulled the valve covers to set the valves. They were full of that light brown “jelly”. Wiping it out it was apparent it was mostly water. I freaked out, checked everything. Radiator fine. Dad came home, took one look, and said too many cold, short trips. Go get on the freeway and warm it up. By then I’d figured out he was getting a lot smarter. The next day I ran across town, 15 miles up the freeway and back at 60-70 mph. I let the engine cool and pulled the valve covers. Perfectly clean, just oil. That was my lesson on how road draft tubes and short trips worked in the winter. I didn’t know enough to put a PCV valve on it, but when I had cars with them I made sure they were clean and working at every oil change.

|

|

By Skyliner57 - 2 Years Ago

|

PCV valve? I would like to find one that fits into the grommet in the valley pan, but has an attached right angle fitting for a hose. I know of the one that Larry sells but that does not have the right angle feature I am looking for. Thanks.

|

|

By miker - 2 Years Ago

|

Here’s an example, but there’s plain ones out there. Have used several of these over the years. Remember you need a baffle under it, or you’ll suck a lot of oil thru. I think Moroso still makes a grommet baffle combination. I’ve had mixed luck with those, but others report they’re ok.

https://www.summitracing.com/parts/sum-440308?rrec=true

https://www.moroso.com/pcv-grommet-baffle-1-per-package68772/

|

|

By Ted - 2 Years Ago

|

|

Skyliner57 (9/29/2024)

PCV valve? I would like to find one that fits into the grommet in the valley pan but has an attached right angle fitting for a hose. I know of the one that Larry sells but that does not have the right angle feature I am looking for. Thanks.

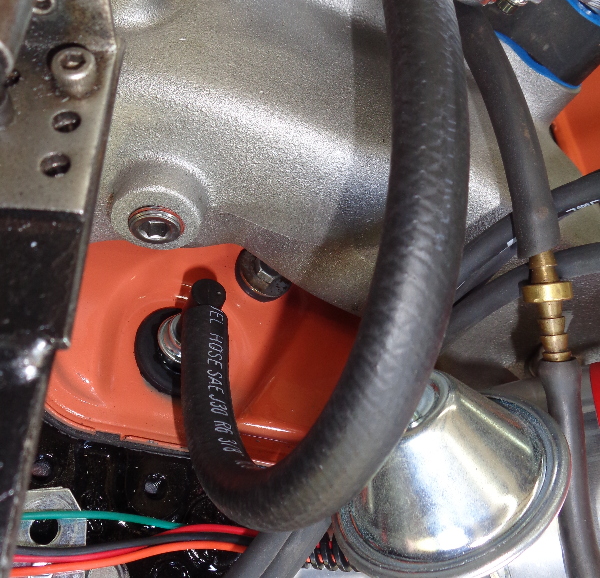

Here are pics of a Microgard PCV2322 power valve on a Y. I get them at the local O’Reilly’s. The 90° nipple is supplied separately with the power valve so the PV can be used either as a straight or 90° configuration.

|