|

By 58F600 - 2 Years Ago

|

Hey guys. We're finally on the road and the truck is doing well. We are having trouble controlling the heat on long hills and I think the water pump is part of the problem.

So, seeing how truck water pumps are NLA. I was looking at doing the swap to a car pump. I see the Mumert spacer, but I don't have a way to get one on the road. We will be at Summit in Reno tomorrow to get a replacement fan.

Can I install a car pump and a generic Ford pulley (that summit might have in stock) of some kind and have the pulleys line up? The water pump is running off the groove closest to the block.

|

|

By charliemccraney - 2 Years Ago

|

I don't think there is a pulley that will line up but you will be able to shim the pulley, if you get one that is a little too deep. Shim kit are available, https://www.summitracing.com/search/part-type/water-pump-pulley-shims?PageSize=100&SortBy=Default&SortOrder=Ascending

|

|

By Deyomatic - 2 Years Ago

|

I think I used a pulley from a '66 or '68 mustang...was a little smaller diameter so it pumps more...I guess. Mine's not a truck engine, though.

What made a huge difference on My 292 was going to a Napa thermostat...the part number is simply "6." It's 170 degrees and solved all my problems.

|

|

By paul2748 - 2 Years Ago

|

The thermostat that Deyomatic mentions is THM6. It is a 170 degree wide mouth thermostat that shoukl give you better flow.

|

|

By Tazx100 - 2 Years Ago

|

You may want to check your belt width with the pulley you are purchasing

|

|

By 58F600 - 2 Years Ago

|

Stopped at Napa and tried to get the #6 thermostat, but not in stock. We limped into Summit Racing in Reno and I was able to get the Robert Shaw #304 160° high flow thermostat. We got the right 3,000 CFM fan to fit our shroud so that can go back on, a stock replacement GMB car water pump and 68 Mustang 5.85" pulley. Tape measure on the parts counter suggests it's the same distance as my truck pump.

Belt width looks the same! Good tip, lots to go wrong here.

We got a motel next to O'Reilly's and I'll swap everything early in the morning when its cool, and hit the road again.

Today was brutal. 300 miles stoping every 5-10 miles to pour water over the radiator to cool it back down. Luckily we never really got hot and over heated, we were able to pull over and get it back under control and rolling again.

Poor Jess was cooking with the heater full blast.

|

|

By Ted - 2 Years Ago

|

Great pics. Thanks for sharing.

You do not mention it or I simply missed it whether your current water pump has the 5/8” or ¾” pilot.

The ’63 & ’64 pickup/truck engines used a ¾” pilot at the front of the water pump versus the earlier models using a 5/8” pilot. The fan belt spacing for the ¾” pilot pumps is different than that on the 5/8” pilot pumps. To the best of my knowledge, the ’62 and earlier water pumps are interchangeable between the cars and pickups/trucks assuming the truck w/p is not using the upper fan mounting bracket on the pump itself. The ’54 model pumps are smaller in diameter and not easily interchanged with the later model pumps.

With that being said, the car and pickup/truck dampers are the same in that the generator belt location is the same. When switching from a ¾” pilot water pump to a 5/8” pilot water pump, then use the car water pump pulley as that will restore the fan belt alignment. The Mummert adapter does allow the small pilot water pump to be used in place of a large pilot pump while retaining the original large pilot water pump/fan pulley.

|

|

By 58F600 - 2 Years Ago

|

Our current pump is the 3/4" piloted truck pump(engine is all 62-64 truck from what I can tell). No top fan mount.

We are trying to do exactly as you describe. Car pump, and got a car pulley. I'm heading out the hotel parking lot with new parts and jelly donut and will report back if it all works!

I appreciate everyone's ideas and experience. This is a big enough challenge without having you guys to bounce ideas off of!

|

|

By 58F600 - 2 Years Ago

|

Gentlemen! A heat felt thanks for the ideas and advice.

New car pump installed. Old truck pump had a bad bearing. Installed the new summit pulley and high flow #304 thermostat and 3,000cfm fan and shroud.

Just idled uphill in through Reno and the highest we saw was 187° and it quickly dropped as soon as we started moving. It stays just under 180° pretty constant.

Thank you all so much!

|

|

By 58F600 - 2 Years Ago

|

Spoke too soon. As soon as we got on the highway up to speed the temp climbed to 210.

I'm almost out of ideas. Thinking it might have a head gasket starting to go. Going to to a hydrocarbon test and test the radiator cap.

Just to sum up.

New 4 core aluminum radiator

New 16" Electric Fan 3,000 CFM in good shroud

New GMB stock pump

Smaller Car Pulley

New #304 Robert Shaw thermostat.

It's fine until it gets under load, then the temp starts climbing.

|

|

By 58F600 - 2 Years Ago

|

Stopped at O'Reilly's and tested the brand new radiator cap and found it weak and leaking down. While stopped we did the hydrocarbon test in the radiator and it was negative, so I don't think we have a engine hardware issue.

Open to other suggestions

|

|

By charliemccraney - 2 Years Ago

|

That shroud is blocking a significant amount of airflow. It may not allow enough to cool under load.

If the temps stabilize at 210 and it does not boil over, then it is ok. 210 is not too hot. It does seem like something is not right but in this circumstance, I would simply keep my eye on it and get it home for troubleshooting.

|

|

By 58F600 - 2 Years Ago

|

Home is 2500 miles away on the other side of the Rockies!

We went to Lowe's and got some rubber pipe insulation and sealed up the core support to hopefully force more air through at speed. It's fine in town/traffic now.

I could live with 205-210 steady, problem is once it passes 210 it gets into thermal run away, and we have to stop to cool it off.

It does cool off much faster now. Even half way on it's own without water on the radiator. And we can cool it to 145° while idling. Yesterday we could barely get it under 190°

|

|

By Hoosier Hurricane - 2 Years Ago

|

|

The Studebaker guys found that the brand new aluminum radiator was beautiful, but the fins on the core were so tightly woven that not enough air could flow through at speed to cool their engines. Slow speed running was acceptable, but not highway speeds and loads.

|

|

By KULTULZ - 2 Years Ago

|

"tested the brand new radiator cap and found it weak and leaking down."

You replaced it and you are using coolant instead of water?

|

|

By charliemccraney - 2 Years Ago

|

Have you verified that the temperature indication is correct? 145 idle is low.

|

|

By 58F600 - 2 Years Ago

|

KULTULZ (9/6/2024)

"tested the brand new radiator cap and found it weak and leaking down." You replaced it and you are using coolant instead of water?

Yes new Stant Cap tested at the counter with the same tester used to condem the cap we were using.

It's always had coolant in it. A touch stronger than 50/50 mix

|

|

By 58F600 - 2 Years Ago

|

Yes the temp reading is verified correct.

The #304 thermostat is a 160°. We can get to 145° pouring cold water over the radiator with it idling. We only did this once to get it cold enough to safely pull the radiator cap for testing.

From a cold start it will get to about 163° and cycle back to the fan shut off at 155°.

We just checked back into the same motel as last night. Everything we have done has made a dramatic difference. But it still wants to creep at 50mph with any hint of a hill. The good thing is today when it got to 210° we could pull off the road and it will start cooling down on it's own, yesterday it would continue to climb.

We have played with the AFR and timing going down the road and have it set at the coolest settings for our particular combination. We went back to premium gas today and no difference. FWIW ethanol free is 100° hotter in EGT vs E10 of the same octane.

We've decided to wrap the headers and down pipe after we go split a $17.99 Steak and Lobster at the casino.

If that doesn't cure it, we have a igloo cooler that holds 5 gallons of ice water, it'll get a bulkhead fitting, ball valve and tubing to the front of the radiator for corrective cooling while moving.

We also have the old heater box complete with heater core and fan we can plumb/wire and run to help out.

We have the original brass radiator with us, but the top tank has a leak. If we refit that it would take some reengineering of the fan situation as well.

|

|

By 57RancheroJim - 2 Years Ago

|

How is your lower radiator hose ? A soft hose maybe collapsing at the higher RPM. More water then coolant is better. I usually use 60-70 % distilled water. Where exactly are you?

|

|

By charliemccraney - 2 Years Ago

|

I would try removing the shroud. Most OEM shrouds are contoured to funnel air through the fan or the fan is so large that it is nearly equal in size to the core area, leaving the core largely unobstructed. And they don't usually have a large intercooler in front of them. At present, the radiator has a significant obstruction in the front and in the back.

There are "zip tie" style mounting "brackets" you can use to mount the fan directly to the core, https://www.summitracing.com/search/part-type/electric-fan-mounting-brackets-hardware?SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=fan+mount If you have tools, you can make brackets. A mechanical fan can also be used. You can remove the fan and shroud on the side of a highway, to test it on an open road. Neither the fan nor shroud is needed at typical highway speeds.

I've had a thermostat that didn't open completely. At low speed it cooled fine but above about 50, the temp climbed rapidly.

|

|

By DryLakesRacer - 2 Years Ago

|

|

With shopping if you come across a 12v pump like a windshield washer and tank and plumb it to a copper tube in front of the radiator with about 10-12 small holes drilled in it. You can switch it on when needed to squire down infront of the radiator. I had to do that on an 60’s pickup with a camper when I towed on hills. Good luck.

|

|

By KULTULZ - 2 Years Ago

|

1) 10-4 on the lower hose collapsing @ speed. It has to have a SS spring inserted

2) You kept the take-off pump to be rebuilt?

3) While I was looking at your build photos and drooling all over the place, it did not dawn on me how large the inter-cooler is. It almost blocks the radiator core and may be a reason it overheats @ speed.

4) Did you keep the original WP pulley or go to a car style? It may be that the pulley dia is not moving coolant quickly enough. With the rad cap off and looking into the top tank, is coolant moving after thermostat opens? This is a problem on the 55/57 BIRDS.

5) What is the rear ratio? It may be winding the engine too high for today's roads/speeds. Is the trans a direct or OD in final gear?

6) And I never figured this one out. The TEMP SENSOR is on the left driver's cyl head and actually measures coolant temp coming off the cylinder barrels left bank. The temp may vary greatly between there and the thermostat.

7) The wife seems to be in good spirits but maybe block off the heater core so she doesn't get too hot?

Possibly, if there is a large air gap between the rad and inter-cooler, the air-flow is disrupted.

|

|

By 58F600 - 2 Years Ago

|

charliemccraney (9/6/2024)

I would try removing the shroud. Most OEM shrouds are contoured to funnel air through the fan or the fan is so large that it is nearly equal in size to the core area, leaving the core largely unobstructed. And they don't usually have a large intercooler in front of them. At present, the radiator has a significant obstruction in the front and in the back. There are "zip tie" style mounting "brackets" you can use to mount the fan directly to the core, https://www.summitracing.com/search/part-type/electric-fan-mounting-brackets-hardware?SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=fan+mount If you have tools, you can make brackets. A mechanical fan can also be used. You can remove the fan and shroud on the side of a highway, to test it on an open road. Neither the fan nor shroud is needed at typical highway speeds. I've had a thermostat that didn't open completely. At low speed it cooled fine but above about 50, the temp climbed rapidly.

We tried the zip tie mounts and that was the main reason for our detour to Summit. The fan without the shroud couldn't keep up in any condition.

The fan in the shroud on our particular application has been better in every phase. It's hard to see, but there is louvers in the corner to allow some air to pass at speed. I don't care for this design and would much rather have the rubber flap design, but we don't have a way to do this on the road.

Thermostat is a brand new #304 Robert Shaw 160° and working much better that the standard flow we had in when we left.

Do do have the stock fan and shroud but I'm not sure we have a way to put it all back on without fab work.

|

|

By 58F600 - 2 Years Ago

|

DryLakesRacer (9/6/2024)

With shopping if you come across a 12v pump like a windshield washer and tank and plumb it to a copper tube in front of the radiator with about 10-12 small holes drilled in it. You can switch it on when needed to squire down infront of the radiator. I had to do that on an 60’s pickup with a camper when I towed on hills. Good luck.

That's why we were at Lowe's yesterday! We have an igloo cooler we are getting set up on the headache rack to gravity feed water to a spray bar

|

|

By 58F600 - 2 Years Ago

|

KULTULZ (9/7/2024)

1) 10-4 on the lower hose collapsing @ speed. It has to have a SS spring inserted 2) You kept the take-off pump to be rebuilt? 3) While I was looking at your build photos and drooling all over the place, it did not dawn on me how large the inter-cooler is. It almost blocks the radiator core and may be a reason it overheats @ speed. 4) Did you keep the original WP pulley or go to a car style? It may be that the pulley dia is not moving coolant quickly enough. With the rad cap off and looking into the top tank, is coolant moving after thermostat opens? This is a problem on the 55/57 BIRDS. 5) What is the rear ratio? It may be winding the engine too high for today's roads/speeds. Is the trans a direct or OD in final gear? 6) And I never figured this one out. The TEMP SENSOR is on the left driver's cyl head and actually measures coolant temp coming off the cylinder barrels left bank. The temp may vary greatly between there and the thermostat. 7) The wife seems to be in good spirits but maybe block off the heater core so she doesn't get too hot?  Possibly, if there is a large air gap between the rad and inter-cooler, the air-flow is disrupted.

#1. Lower hose does have the spring. Verified yesterday during the water pump change. I'll give them both a squeeze again to double check.

#2. Yes we kept the pump but I have no intention of rebuilding it. We have changed over the car pump and smaller 68 Mustang pulley.

3. The intercooler. This could be an issue, but it's heating up before we start making boost and IATs aren't much above ambient.

4. Smaller car pulley. Which helped for sure.

Our temp sensor is mounted right next to the thermostat on the front top of the intake.

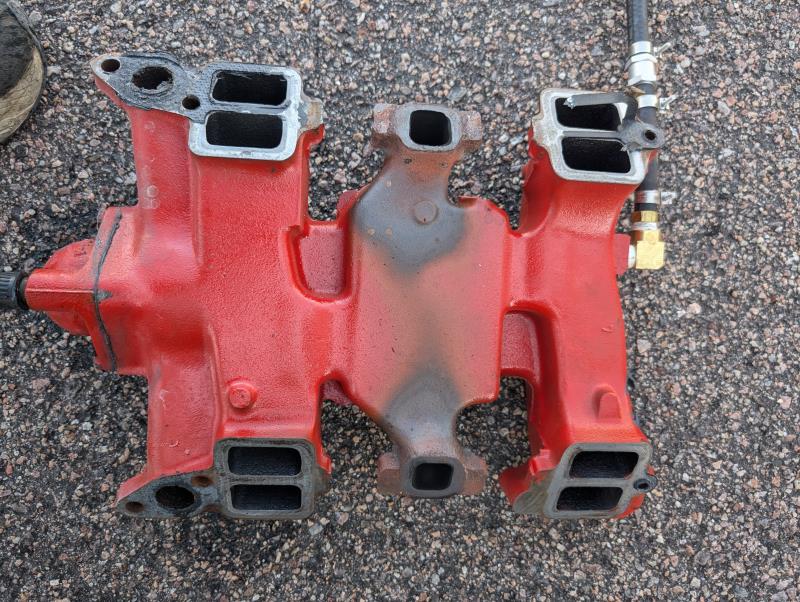

One thing I did notice is one of the exhaust cross overs seems to have burned out and burning the paint on the intake. I wouldn't think that would cause the issue, but maybe?

|

|

By KULTULZ - 2 Years Ago

|

"One thing I did notice is one of the exhaust cross overs seems to have burned out and burning the paint on the intake. I wouldn't think that would cause the issue, but maybe?"

That is a natural occurrence. You didn't use the truck intake gaskets to block some of that crossover exhaust heat (well duh! you have headers - no crossover provision)? There is also a tube in that intake crossover that if corrodes will allow exhaust gases to escape out of the tube inlet/outlet ports under the carb flange.

Anyways, you are doing one heck of a job getting it across the Rockies.

BTW - Does the wife smile when she hears the turbo?

|

|

By 58F600 - 2 Years Ago

|

Getting better!

I'll read everyone's replies and respond later. It's not fixed, but we're moving!

Thanks everyone for the ideas!

|

|

By HT32BSX115 - 2 Years Ago

|

Howdy,

I think I am probably going to be worrying about the same thing in the not too distant future.

My radiator is original in that it was originally came with my 55 F-600 when it had a 6-cyl engine installed. I got it with a 239 Y and later found a 272 from a 59 F100 and rebuilt it.

I am not using the "High Mount" pump and fan position opting for either a set of electric fans or a much bigger clutch fan.

The radiator I mentioned I took to a radiator shop in Tacoma, Wa and had them completely rebuild it removing the 3-row core and replacing it with a 4-row core.

My water pump is the (non high mount) pickup type pump and I'll likely be building a shroud to match up with it if I stay with the belt driven, water pump mounted fan.

Here's where I am on your problem.

I do not think 3000 CFM is enough for an F250/350 pulling any sort of load.

And since the F-600 is a "load" all itself, I am thinking that if I do go with electrics it will have to be something similar to Flex-A-Lite's 6000CFM fan system for the Superduty F-250/350 diesels. like below.

Flex-A-Lite 6000 CFM

I am a little suspect of the fan marketeers that claim you save all sorts of HP by using electrics but they don't really save all that much over a good clutch fan since the clutch is disengaged most of the time.

When the electric fan is running, it still must be driven by the alternator/generator.

Electric fan manufacturers claim you can save up to 27hp . Now granted, if a big belt driven fan is running at max engine RPM it might very well require 27hp to turn it (at that RPM)

But you're getting a commensurate amount of CFM from that fan too.

(I don't think a Y-block fan requires that amount of HP to turn it though) I suppose an enterprising engine rebuilder could dyno test an engine with a fan and without and put that to bed!

But even the 6000CFM fans running at high RPM are requiring a fair amount of current (48A, from the ALT/GEN)

48A @14V produces 672W of power. 1hp = 746W So those fans get around 1hp from the engine (via the ALT/GEN)

If roughly 1HP produces 6000CFM, then the engine driven fan must be producing more CFM (A LOT MORE) And yes, I know the elecrtic fans are better designed fans more efficient blade design yada yada. But they're not "that" much better!

It's not a problem with a car or a pickup someone drives around empty most of the time. But with a Medium duty truck like your 58 F-600 or my 55 F-600.... if we load them up even a little, the CFM requirements for the radiator ramp up sharply.

No automotive electrical system is capable of producing that level of current for any longer than it takes to crank en engine . I.E. the starter in my 2005 F-350 SD Diesel might briefly (initially) draw 1000A of current during cranking but the alternator will never produce more than about 150A or so during normal operations.

So I am thinking I might stay away from electrics for mine because under load, they may not move enough air. And with an A/C condenser in front of the radiator, it'll need even more air flow.

For your truck, I am thinking that you might have to double your CFM (or go back to a belt driven fan) to reduce the overheating. I don't think a 3000CFM fan is going to be adequate for anything other than "straight & level flying" (no headwind)

Regards,

Rick

|

|

By 58F600 - 2 Years Ago

|

HT32BSX115 (9/8/2024)

Howdy, I think I am probably going to be worrying about the same thing in the not too distant future. My radiator is original in that it was originally came with my 55 F-600 when it had a 6-cyl engine installed. I got it with a 239 Y and later found a 272 from a 59 F100 and rebuilt it. I am not using the "High Mount" pump and fan position opting for either a set of electric fans or a much bigger clutch fan. The radiator I mentioned I took to a radiator shop in Tacoma, Wa and had them completely rebuild it removing the 3-row core and replacing it with a 4-row core. My water pump is the (non high mount) pickup type pump and I'll likely be building a shroud to match up with it if I stay with the belt driven, water pump mounted fan. Here's where I am on your problem. I do not think 3000 CFM is enough for an F250/350 pulling any sort of load. And since the F-600 is a "load" all itself, I am thinking that if I do go with electrics it will have to be something similar to Flex-A-Lite's 6000CFM fan system for the Superduty F-250/350 diesels. like below. Flex-A-Lite 6000 CFM I am a little suspect of the fan marketeers that claim you save all sorts of HP by using electrics but they don't really save all that much over a good clutch fan since the clutch is disengaged most of the time. When the electric fan is running, it still must be driven by the alternator/generator. Electric fan manufacturers claim you can save up to 27hp . Now granted, if a big belt driven fan is running at max engine RPM it might very well require 27hp to turn it (at that RPM) But you're getting a commensurate amount of CFM from that fan too. (I don't think a Y-block fan requires that amount of HP to turn it though) I suppose an enterprising engine rebuilder could dyno test an engine with a fan and without and put that to bed! But even the 6000CFM fans running at high RPM are requiring a fair amount of current (48A, from the ALT/GEN) 48A @14V produces 672W of power. 1hp = 746W So those fans get around 1hp from the engine (via the ALT/GEN) If roughly 1HP produces 6000CFM, then the engine driven fan must be producing more CFM (A LOT MORE) And yes, I know the elecrtic fans are better designed fans more efficient blade design yada yada. But they're not "that" much better! It's not a problem with a car or a pickup someone drives around empty most of the time. But with a Medium duty truck like your 58 F-600 or my 55 F-600.... if we load them up even a little, the CFM requirements for the radiator ramp up sharply. No automotive electrical system is capable of producing that level of current for any longer than it takes to crank en engine . I.E. the starter in my 2005 F-350 SD Diesel might briefly (initially) draw 1000A of current during cranking but the alternator will never produce more than about 150A or so during normal operations. So I am thinking I might stay away from electrics for mine because under load, they may not move enough air. And with an A/C condenser in front of the radiator, it'll need even more air flow. For your truck, I am thinking that you might have to double your CFM (or go back to a belt driven fan) to reduce the overheating. I don't think a 3000CFM fan is going to be adequate for anything other than "straight & level flying" (no headwind) Regards, Rick

Great thoughts!

The F600 is a constant load by itself I agree. After climbing a few 11,000' passes over the last few days, here's my current theories.

#1. The water pump sucks. You MUST get the flow cooler pump. If I could get one today I would be installing it instead of posting here. Brand new pump with the smaller pulley and you can watch the temp climb as rpm drops. It not nearly as dramatic as before with the stock truck pulley, but still obvious.

#2. Electric fan CFM. The 6,000 CFM kits you linked are "up to 6,000 CFM". The kit uses 2 of the 16" 3,000 CFM fans that we are currently using. The radiator in my truck isn't nearly big enough to fit that, I'm not sure about yours.

#3 electric vs belt driven fan is an argument as old as blondes vs brunettes lol. Pick your favorite and ride, there is pros and cons to each. For us the electric makes sense.

#4. You'll need slim style electric fans, and I'd recommend a car water pump and smaller pulley. You'll find with the truck pump, standard electric fan in a shroud, there is interference issues with the fan motor and water pump.

The biggest issue for these truck I think is the load. They are big and heavy. Last night we pulled Monarch Pass. 11,400' over the top. We started at the "bottom" about 8,500' and didn't cool down enough before starting the pull(we've learned this vastly increases our chances of success). We were at about 190° at the bottom. Made it a few miles before we were 210° and climbing so we pulled over to add ice to our aux cooling water rig. There was a group of 4 semis creeping up the hill that pulled over into the same pull out to cool off. A little hint that maybe we aren't doing as bad as we thought. We refilled the water cooler with ice and water. Cycled the engine a few times and got it down to 155°(you can't do this with a mech fan). Jumped back in and hammered down. Pushing about 3-4 psi of boost, 3,000rpm 4th gear low range in the rear 45-50mph. Pulled like that for 7 miles and went over the top at 11,400' and 202°.

Our intake crossover plug on the turbo side burnt out a week ago and we haven't been able to find a set of intake gaskets, until now.

I'm in Colorado Springs heading to the parts store to grab a set and trim a stainless exhaust clamp to make new block off plates. Swapping the intake along side the road somewhere.

Our situation is pretty unique. I think the higher EGTS and pressure from the turbo was too much for the aluminum block off plate most can use in a N/A application. This being burned out has to be adding a bunch of heat into the engine as it's the only place the paint is burned off, and it's halfway to the carb pad now.

Wish me luck!

Over Ophir Pass! 11,729' up the hard side!

|

|

By 58F600 - 2 Years Ago

|

This can't be helping. Hot tip: use stainless for the cross over blocks

|

|

By HT32BSX115 - 2 Years Ago

|

I LOVE those pictures!

Your 58 F-600 is VERY COOL (maybe the coolant not so much!)

You might be able to tell if your fan isn't up to the task by measuring coolant temps at strategic points, starting with temps at the bottom of the radiator where it enters the pump. (comparing it to the top after exiting the T-stat to get a total temp drop)

If you are getting good temp control under load by spraying cool water through the radiator, You still may not have enough airflow.

Coolant flow rates through the engine are largely controlled by how much can flow through the T-stat (and of course the pump, assuming the engine coolant passages are not too restrictive)

I bought a new (turbocharged) 3/4T 4X4 Diesel GMC Suburban in 1994 (first year with turbocharging and the electronically controlled Stanadyne injection pump)

The T-stat housing had a single stat in it and was determined to be inadequate in terms of coolant flow during towing so GM started using double-thermostat housings to increase the coolant flow through the stats. (I think they also improved the circulating pump too....although I couldn't tell much difference between the 2 pumps)

I changed both the pump and T-stat housing on the Suburban to the double T-stat version and noticed a marked difference in the temps during towing.

For your installation, a higher flow pump might result in an improvement but if the coolant going into the pump (from the bottom of the RAD) is still too hot, you need to address it also (maybe any one of bigger radiator, more rows or more airflow)

You're right. The Flex-A-Lite double-fan model is really wide and tall.

| Height (inches) | 26 3/8 in. |

|---|

| Width (inches) | 29 1/2 in. |

|---|

| Depth (inches) | 4 1/4 in. |

|---|

| Air Flow (cfm) | 6,800 |

|---|

But on my stock radiator installation, I believe I could make it fit by making a shroud "adapter" and making "cutouts" for the upper and lower radiator hoses.

I have 6 3/8" between the radiator core and the water pump-pulley flange.

I have plenty of room for a 4.25" depth electric installation but I am not thinking it would be "better that big 6-blade fan on the clutch above . All I need to do is build a shroud for it. In my case, simpler might be better.

I hope you find a solution to your overheat problem!

Cheers,

Rick

|

|

By Saltshaker - 2 Years Ago

|

|

My suggestion was already covered.

|

|

By 58F600 - 2 Years Ago

|

|

Sadly that didn't make much difference. Still having to use the cooling water.

|

|

By KULTULZ - 2 Years Ago

|

Do you know the rear end ratio? Trans type? Engine RPM at road speed?

|

|

By paul2748 - 2 Years Ago

|

Looking at the fan to radiator distance, you might not need a shroud if you get the fan closer to the radiator. To me, it looks like the fan is too far away.

HT32BSX115 (9/13/2024)

I LOVE those pictures! Your 58 F-600 is VERY COOL (maybe the coolant not so much!) You might be able to tell if your fan isn't up to the task by measuring coolant temps at strategic points, starting with temps at the bottom of the radiator where it enters the pump. (comparing it to the top after exiting the T-stat to get a total temp drop) If you are getting good temp control under load by spraying cool water through the radiator, You still may not have enough airflow. Coolant flow rates through the engine are largely controlled by how much can flow through the T-stat (and of course the pump, assuming the engine coolant passages are not too restrictive) I bought a new (turbocharged) 3/4T 4X4 Diesel GMC Suburban in 1994 (first year with turbocharging and the electronically controlled Stanadyne injection pump) The T-stat housing had a single stat in it and was determined to be inadequate in terms of coolant flow during towing so GM started using double-thermostat housings to increase the coolant flow through the stats. (I think they also improved the circulating pump too....although I couldn't tell much difference between the 2 pumps) I changed both the pump and T-stat housing on the Suburban to the double T-stat version and noticed a marked difference in the temps during towing. For your installation, a higher flow pump might result in an improvement but if the coolant going into the pump (from the bottom of the RAD) is still too hot, you need to address it also (maybe any one of bigger radiator, more rows or more airflow) You're right. The Flex-A-Lite double-fan model is really wide and tall. | Height (inches) | 26 3/8 in. |

|---|

| Width (inches) | 29 1/2 in. |

|---|

| Depth (inches) | 4 1/4 in. |

|---|

| Air Flow (cfm) | 6,800 |

|---|

But on my stock radiator installation, I believe I could make it fit by making a shroud "adapter" and making "cutouts" for the upper and lower radiator hoses. I have 6 3/8" between the radiator core and the water pump-pulley flange.  I have plenty of room for a 4.25" depth electric installation but I am not thinking it would be "better that big 6-blade fan on the clutch above . All I need to do is build a shroud for it. In my case, simpler might be better. I hope you find a solution to your overheat problem! Cheers, Rick

|

|

By HT32BSX115 - 2 Years Ago

|

You're right it is quite a ways away. It was intentional when I was planning electric fan(s)

But even placing the fan "close" will not result in full airflow through the 4-row core. In any case, I believe a shroud is necessary to cool the entire core of the radiator.

|

|

By HT32BSX115 - 2 Years Ago

|

58F600 (9/13/2024)

Sadly that didn't make much difference. Still having to use the cooling water.

This is via "spraying" water into the front of the radiator/intercooler assembly?

|

|

By 58F600 - 2 Years Ago

|

KULTULZ (9/13/2024)

Do you know the rear end ratio? Trans type? Engine RPM at road speed?

Rear end is 5.83/8.11

Trans is a T98a, 4th gear is direct. No over drive

Rpm is 2650-3100. 49-57mph. There seems to be a heat wall about 54mph. We can run 3100rpm/57mph for ten miles before it finally creeps up to 205°, back off to 2700rpm/49mph for a mile or two and it'll drop back to 188-190° then speed up again.

|

|

By 58F600 - 2 Years Ago

|

HT32BSX115 (9/14/2024)

58F600 (9/13/2024)

Sadly that didn't make much difference. Still having to use the cooling water. This is via "spraying" water into the front of the radiator/intercooler assembly?

Correct. We have an igloo cooler on the headache rack filled with water and a tube ran in front of the radiator. We stop to refill every 20-70 miles.

About the middle of Missouri right now. Running 52mph no additional water and mid 190s on temp. We even ran the a/c a little yesterday and today!

|

|

By KULTULZ - 2 Years Ago

|

|

Rear end is 5.83/8.11

Trans is a T98a, 4th gear is direct. No over drive

Rpm is 2650-3100 @ 49/57mph. There seems to be a heat wall about 54mph. We can run 3100rpm/57mph for ten miles before it finally creeps up to 205°, back off to 2700rpm/49mph for a mile or two and it'll drop back to 188-190° then speed up again.

That is a really low rear gear for a road truck. It must have been built for local heavy haul (or farm use). Road speed (engine RPM) and the size of the inter-cooler (blocking air flow) may be causing all of this.

Are you going to leave the rear in or change ratio? Does the turbo need such a large inter-cooler?

What usage do you have for the truck once it is home?

BTW - Too bad you didn't record all of this as it would make one heck of a U-TUBE SHORT.

|

|

By 58F600 - 2 Years Ago

|

It has lived its whole life on a ranch in Eastern Oregon. Probably seen more miles on dirt than pavement.

I did record a bunch and took a ton of pictures. I might upload some. We used to do a bunch of social media content generation and honestly it gets old. We didn't want to let the entire Internet comment or try and effect a personal vacation.

We plan to use it locally as a dump truck around our small farm/shop here in Tennessee.

We have a '49 Dodge B4c that we plan to travel the world in a few years. This seemed like a good practice trip.

It probably didn't need the intercooler, but we wanted to make sure to keep it out of detonation if at all possible. There is a few things I'll change to help with cooling now that we are home. The lower intercooler mount and shroud flaps being the first place I'll start. I'll probably order the FlowKooler pump as well.

Here locally it seems much happier. We didn't use cooling water at all for the last 250 miles home. It was much cooler and misty/drizzly though.

It makes a lot more boost now than it did out west! Haha

|

|

By KULTULZ - 2 Years Ago

|

|

I'll probably order the FlowKooler pump as well.

Just a quick thought, you can buy just the impeller itself. Might save you a few dollars. I wonder if they offer one just for the truck pump?

Anyways, I didn't know you all were home. What section of TN are you in, west, middle or east TN? Got some good pulls east of Nashville.

GOOD LUCK to you both. Quite an adventure.

|

|

By HT32BSX115 - 2 Years Ago

|

Just now looked at their site and it appears that they replace the impeller in a stock (car) pump with their own aluminum anodized one.

It also appears that they may only offer "car" pumps but suggest (if needed) to use a sleeve spacer for the fan in a truck application.

They do offer impellers for rebuild but I suspect that they're only for a 5/8" shaft. So if you have a "real" truck pump you're rebuilding, the impeller will not fit.

If enough people from here and maybe FTE were to deluge them with emails asking for 3/4" ID impellers, they'd produce them.

Otherwise, I think one would have to chuck one of their impellers up in a lathe or set it up on a vertical mill and carefully cut a 3/4" "interference-fit" hole.

https://flowkoolerwaterpumps.com/products/1635-1954-1964-ford-y-block-221-227-239-272-292-300-312-water-pump

It's amazing what a truck water pump costs nowadays! Just found 2 on eBay (I assumed rebuilt) for over $300 ea!

EDIT:

Ok....

Those dimensions got me thinking (yes, I know.....that's scary all by itself!!!)

I have an extra truck pump that is in otherwise good condx but several years ago, just to be "ready", I bought a rebuild kit for that pump from MAC's Antique Auto Parts in Lockport NY. ( B6C-8591-KT )

The impeller (and impeller end of the new shaft) is 0.625" (5/8") , and the flange shaft is 0.750" (3/4")! I did not know this before but it would appear that all the pumps (car & truck) use the same 5/8" ID impeller!

I found several truck pumps online for around $325 (thanks Joe!) But there may be a LOT of rebuild kits out there and using the FlowKooler impeller might just be the answer for better (increased) coolant flow!

Impeller end 5/8"

Fan side 3/4"

|

|

By 58F600 - 2 Years Ago

|

That's good to know!

I'm going to stick with the car pump as you can't get the smaller mustang pulley over the 3/4" truck shaft snout, and the belt alignment would be off.

FlowCooler sells the impeller separate as noted on their site. Since car and truck are 5/8" on that end, I'll probably just do that on my new car pump and leave the smaller pulley.

Our set up now is so close to the the tipping point of being able to stay cool all the time. Now that we're home I can address a few of the little issues and see if they get us over the hump.

We're in Clarksville TN safe and sound! Two back to back 600 mile days got me home in time to take my nephew to the Indy race for his 21st birthday.

|

|

By HT32BSX115 - 2 Years Ago

|

Howdy,

I'm wondering if you heard anything about the "new" impeller? I sent them an email using their web-based system and have not gotten an answer.

They did respond (auto-responder) but they did not answer my question about them rebuilding my truck pump or buying the impeller outright.

Also, I wonder if you have installed a pressure gage to monitor cooling system pressure when you see 210 degrees?

I have been thinking about using a 190-200 degree stat (and also monitor pressure) with a 10PSI cap.

You might have a "steam pocket" problem at the higher temps unless you allow the pressure to operate at a higher number. So it would probnably be useful to know what pressures are seen at the higher temps.

I would think there's nothing wrong with running the engine at a slightly higher temp (10% higher) Which would be around 200 degrees F but you would need to use a higher pressure cap

https://www.dewitts.com/blogs/news/13852841-what-pressure-cap-rating-should-i-use

Any info on the new impeller?

|

|

By 58F600 - 2 Years Ago

|

High flow impeller is in the mail!

I also have a few thermocouples coming so I can document any changes now that we're home and can make meaningful changes.

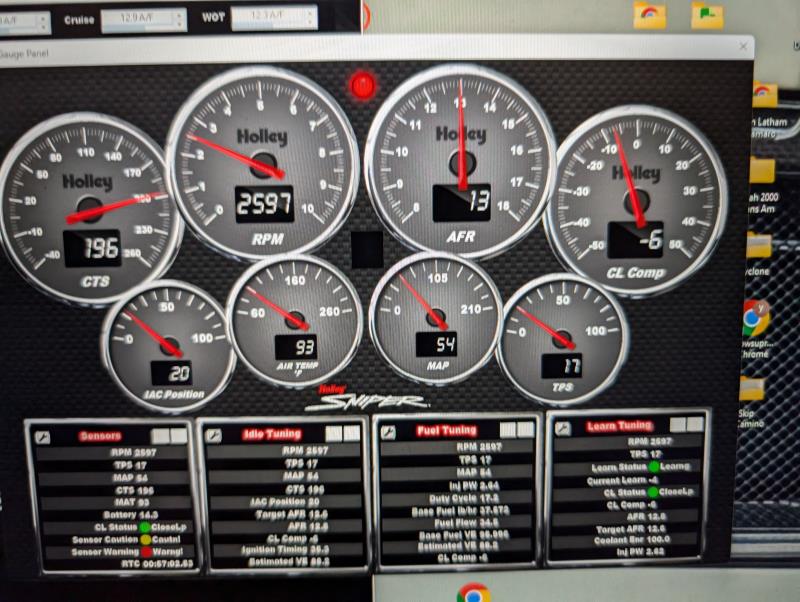

We're running a 19psi cap, tested, since Reno. I would love to monitor cooling system pressure and might if we continue to have issues. We do log this on any modern FI car, as it can show a head lifting that tests fine in the shop. Unfortunately we're running Sniper EFI which doesn't have any open channels to log it. But we can always just add a simple pressure guage and run it into the cab and watch when its loaded and on boost.

I have rubber flaps coming to improve the shroud, and it's in the shop now to fix some other issues that might be blocking air into the radiator.

I'll report back with more data and results! Sorry I'm slow, my health isn't the best and trying to recover from living in a 58 F600 for a few weeks on the road lol

|

|

By HT32BSX115 - 2 Years Ago

|

Wow!

19 PSI would probably blow the top or bottom tank clean off my rad!! (if the pressure actually got that high!)

I installed a coolant pressure gage in my 21ft boat (Mercruiser 454/Bravo III) that I also installed a San Juan Engr closed cooling system in.

The "radiator" is actually a water-to-water heat exchanger. I think I have a 180 stat in it and I don't think I have ever seen more than about 190 degrees and maybe 10-12 PSI. (15 PSI cap I think)

A pressure gage is pretty useful.

I think you'll definitely want to look at temps at the inlet and outlet of the radiator. that will absolutely tell you how much heat is being removed by the fan.

What did the impeller cost?

Hope you're feeling better!

Cheers,

Rick

|

|

By 58F600 - 2 Years Ago

|

|

Impeller was $80, $96 with shipping and tax.

|

|

By 58F600 - 2 Years Ago

|

The more I test and measure the dumber I get! Haha

Got some time to play with it today. Test rig is very simple. Using the coolant temp sensor which is drilled into the manifold right behind the thermostat housing as my "radiator in temp" and I have a thermocouple fed into the hose going into the water pump inlet as my "radiator out" temp.

At idle in the shop, right at 23° temp drop across the radiator. 156°/133°

Drove down the road. 2,800rpm 55ish mph 181°/167°

List of suspects, pictures below.

#1 lower intercooler mount. A simple piece of aluminum angle, must be blocking air flow and hurting us

#2 60 year old non aerodynamic grill, must be blocking air flow

#3 intercooler, huge. Mounted right in front of the radiator, must be contributing to the issue.

Step one removed the grill and lower intercooler mount. Results 188°/179°, yep worse.

Removed the intercooler completely. 183°/173°. The intercooler is maybe adding a single degree. Honestly this is within our measuring tolerance for error.

The grill is such that the head lights and bezels must be removed to pull the grill. With intercooler and grill installed, but headlights out. 188°/180°. Theory is the air pushing in the head light holes is disrupting the air going into the radiator.

It's cooling off and I'm pulling the fan/shroud and adding the flow through holes/flaps

|

|

By HT32BSX115 - 2 Years Ago

|

I wonder if it isn't an airflow thing at all but more of a coolant flow thing (or maybe a combination of both)

A baseline or control would be advantageous. I also wonder what other cars and trucks (that are not over heating) have for top/bottom rad temps for straight and level vs climbing a hill etc....

|

|

By 58F600 - 2 Years Ago

|

I think it's both and I'm going to rely on testing and data to prove it.

Right now I think we have sufficient water flow for an empty truck going down the road or cruising through town. The problem comes with speed, and at this point testing data is pointing to the shroud being the issue. Temp drop of 20° across the radiator in the shop will keep it below 160°. The best temp drop we've seen on the highway is 14° associated with a slow temp creep. We can pull off the road and watch the radiator outlet temp drop, followed by engine temp.

When starting the test, the engine temp only starts climbing following the radiator outlet temp rising(water temp into the radiator stays steady as outlet temp rises, then followed by engine temp creep). This is the main point of the test IMO. I wanted to see what was leading the climb, its obvious it's the radiator with the truck unloaded. If the radiator was working as desired we would see the temp drop remain at 20° but engine temp creeping, we don't see that at all. Instead we see radiator temp drop go from 23° to 14° and engine temp start climbing.

It's possible that after we get it fixed in an unloaded condition, that with a load the engine temp starts the match. But we have the FlowKooler impeller and a new lower radiator hose to put on as well.

Right now, all the data is showing that our radiator/fan/shroud package is the issue, but not far off. I think if we can get to 20° temp drop going down the road empty, that the problem is pretty much fixed. The impeller should help move more water when the engine is really making heat, but wouldn't make any difference now as the radiator is already on the losing side of the equation. More water flow without more air flow would not improve the situation as we have already proven via a 3,000 mile test haha. It made a big difference at idle or crawling through town. But zero effect at speed. Only improving the radiators ability to dissapate heat made any difference(cool water spray).

I've been working on the shroud all day. I'm almost done with all the flaps and opening the center to fit the fan better. The picture below is just the start.

|

|

By 58F600 - 2 Years Ago

|

I don't want to spike the ball early, but the first test with the changed shroud was very promising. It is cooler outside than our testing yesterday, but we rolled back into the shop at 158° after a 10 mile drive. Normally we were 185° and climbing at the 3 mile mark. the highest temp seen was 168° and it actually dropped back to 161° once we got back up to speed 55mph. This is the first time I've seen a temp drop at speed without water spraying on the radiator. Idle cooling was still really good about 27° temp drop so our holes/flaps did not negatively impact slow speed cooling!

Interestingly we were only seeing a 12° temp drop across the radiator. It makes me think the 14° we saw yesterday was a fallacy and the 7-8° results were closer to reality with the 10° being more realistic as a before condition.

High flow impeller install tomorrow! I'll add the last line of holes across the top of the shroud when I pull it to change the water pump.

|

|

By HT32BSX115 - 2 Years Ago

|

It really sounds like airflow is the key when the engine is generating a lot of heat.

If your fan is only capable of 3000CFM maybe it isn't sufficient. It might also be why Flex-A-Lite suggests a 6000CFM for the Superduty F250/350 trucks.

The right amount of airflow should allow you to put 7000lbs on the hitch and maintain a safe temp going up a long hill.

I was so worried about enough airflow across the rad that I bought a (Hayden) transmission cooler that has it's own fan so I can mount it in the back somewhere. And since I am planning A/C, I want to make sure airflow is not going to be a problem. So the OEM 6-blade larger fan/clutch from a 429/460 engine

In my 55 F-600, the original fan is only 4 blade and there's a lot of gap between the blades and the shroud. (and of course, it only had about a 90hp inline 6-cyl engine)

I am thinking (and hoping) that your improving the airflow makes the difference for you!!

|

|

By 58F600 - 2 Years Ago

|

I think we finally got it.

Got the FlowKooler impeller installed today. It made a slight improvement. On my 20 mile test drive it never got over 178°. Before the shroud and water pump it would have been 200+. The shroud flaps made the biggest difference, about 15° I would say. The FlowKooler impeller was worth about 5° steady state.

|

|

By HT32BSX115 - 2 Years Ago

|

Although it certainly improved coolant flow, it sounds like maybe the impeller wasn't necessary after all?

|

|

By 58F600 - 2 Years Ago

|

I think it'll really be evident when we get it loaded. It has helped, but it's not dramatic. I think it's contribution is more in temp gain/loss slope vs total temp. Something that is really hard to measure outside a lab in the actual world, but after watching the digital temp guage for a few thousand miles, the butt Dyno says it's slower to heat up and cools quicker.

Also we learned that temp drop across the radiator is not the right data set to evaluate. I think absolute temp outlet temp, or outlet temp vs ambient would be a better evaluation. The in vs out temp can lead you astray as with improved cooling we actually noticed a drop in the in/out delta, but cooler overall temp. Looking back at the data our "rad out" temp stayed relatively stable, it was the higher inlet temp causing a greater delta across the radiator. This is where the added water flow made a difference. Rad out temp stayed the same, but the water coming out of the engine was cooler. Lower operating temp, but lower radiator temp delta.

Not helping things, our brand new Klein thermocouple decided to drift and become unreliable. The real evaluation is long term temp control and recovery at speed, which for the moment we have achieved, unloaded.

|

|

By 58F600 - Last Year

|

Update time!

The truck runs great!! We've hauled a little over 200yrds of fill material around our new shop. Of course it has a completely new bed hydraulic system now....

The good: temps are much better than before. I can pull a 2 mile hill loaded to 17k lbs, 8-9psi of boost and get to the top of the hill under 180°!

The bad: the Summit Water pump pulley just exploded. Luckily Summit is great to work with and is overnighting me a new one. But it's down for the weekend while we wait.

look look

|