|

By cos - Last Year

|

|

Hello Members Thanks to Ted E I made a tool (jig) to cut center cam bore to connect all three oil holes. Have pic but don't know how to put up. If any would like to use it you are welcome, just for freight and promise it would be returned. Would not include 3/8 all thread or 2" cut off wheel,` that would add freight costs. It is small, bolts to rear main seal retainer holes in block and extents down below rear cam bore. Cos Oregon

|

|

By paul2748 - Last Year

|

If you can email me the picture I can post it for you. pts one two three one at verizon.dot net

|

|

By 55blacktie - Last Year

|

|

Thanks for offering, COS. How deep should the cut be, and how do you measure it?

|

|

By cos - Last Year

|

|

Thanks Paul Will try to send pictures. Other question about depth of cut, Its just a guess how deep it is, my bore gauge feeler point will not fit in cut, guessing .020-.030. Its not a full 360 degree cut just enough to connect three oil gallery holes. Cos

|

|

By Ted - Last Year

|

As Bill points out, it’s not necessary to be ‘dead on’ exact so just eyeballing it will typically get you close enough. If not trusting the eyes, then wire gauges can be used to determine the actual measurements. The location of the machined groove is in a difficult area for measuring with conventional instruments.

For myself, 1/16” would be the minimum value for both the width and depth of the groove intersecting the three holes within the center cam bore of the block. Any shallower than this leaves the possibility of the cam bearing pressing into the groove and further restricting the oil. Any wider or deeper than this can be compensated for by installing restrictors at the rocker arms. I have found that 0.078” restrictors installed at the rocker arm supports still provides an ample supply of oil to the top end of the engine.

|

|

By Blind Willie - Last Year

|

|

A picture and a scale drawing with dimensions would be nice to see.

|

|

By 55blacktie - Last Year

|

|

Are any modifications required/recommended for the cam bearing?

|

|

By Ted - Last Year

|

|

55blacktie (1/29/2024)

Are any modifications required/recommended for the cam bearing?

Assuming the cam bore hole is the correct size, then the answer is No. Adding a groove to the center cam bore hole does not require any additional modifications to the bearing itself. If the cam bore or cam bores are undersized, then putting the cam bearing on a mandrel and grinding the O.D. of the bearing in a crankshaft grinder helps to restore the proper crush on the bearing when installing it in an undersized hole. That’s not just a Y issue but one that covers most engines in general.

|

|

By Ted - Last Year

|

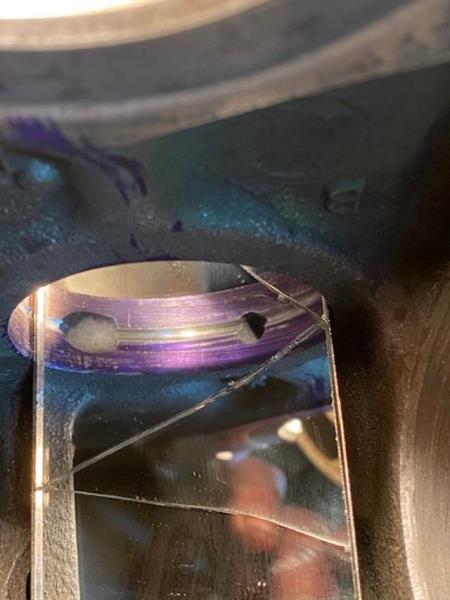

Here are some pictures of the cam bore groove operation that Bill asked me to add.

|

|

By 55blacktie - Last Year

|

Ted, from looking at the diameter of the cutoff wheel in your photos, it looks like your cut is 360 degrees, no?

|

|

By Ted - Last Year

|

|

55blacktie (1/30/2024)

Ted, from looking at the diameter of the cutoff wheel in your photos, it looks like your cut is 360 degrees, no?

Those pics are Bill’s. But to answer your question, it’s not a 360°groove unless the cutting tool is worked around the bore in a circular motion. As long as pressure on the tool is only applied to the crankshaft side of the cam bore, only the three holes will be interconnected, and no groove will be present on the valley side of the cam bore.

|

|

By cos - Last Year

|

Hello the groove extends a little past the oil gallery holes that move oil to head. I put upward pressure ( toward crank shaft saddle ) on all tread to make groove. I might be a little deeper than .020/.030, as I had no way to measure it. Thanks Ted for putting up pics. Bill Oregon

|

|

By Ted - Last Year

|

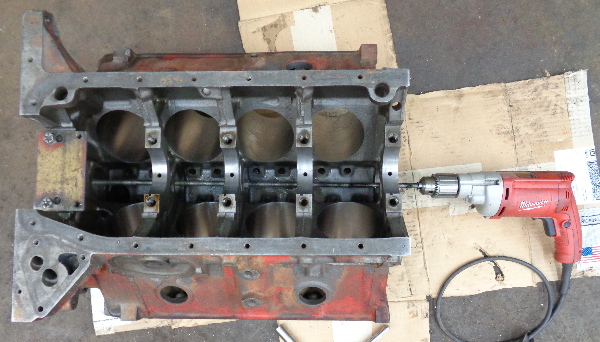

For those of you who emailed me about the cam bore grooving tool I am using, here are some pictures.

|

|

By HazardTBird - Last Year

|

So the all-threa d and two lock nuts spin against the two flat washers with just a little clearance? d and two lock nuts spin against the two flat washers with just a little clearance?

|

|

By Ted - Last Year

|

|

HazardTBird (2/7/2024)

So the all-thread and two lock nuts spin against the two flat washers with just a little clearance?

That’s correct. Just enough clearance to allow the spindle to turn freely.

|