|

By Deyomatic - 2 Years Ago

|

Finally got around to looking into the casting numbers on the Y block in my Model A. The block says "B9AE-6015-F" and the heads are ECZ-G, but I have no idea how to tell if they're big or little. It's cast into that spot next to the driver's side intake coolant mating surface.

One source doesn't even have those as options. One suggested it may be a Mercury block.

What do the experts say?

|

|

By 55blacktie - 2 Years Ago

|

Your block was used in 1959 cars and trucks. It was also used in 1959 Mercurys. Fords were 292, Mercurys 312. If the main bearing caps are ECZ, it's a 312.

ECZG heads were manufactured in 1957-58. Whether Big/Little, they have the same valve, port, and chamber size. If they were manufactured after May, 57, they should be "posted." "113" & "471" heads were manufactured in 1959, both of which are big-valve heads like the "G" heads, but have larger combustion chambers. You can find all of this information at ford-y-block.com. Thank you, John.

|

|

By Deyomatic - 2 Years Ago

|

Thanks for the info. I just checked out John's page. Doesn't sound like there are any other EXTERNAL clues on this block to tell what it came from. My Big M/Mercury Man valve covers feel a little more at home, knowing that at least the number matches up as being (possibly) a Mercury.

|

|

By 55blacktie - 2 Years Ago

|

|

As far as the block is concerned, there's no external difference, whether 292/312.

|

|

By Ted - 2 Years Ago

|

|

Deyomatic (10/15/2023)

Finally got around to looking into the casting numbers on the Y block in my Model A. The block says "B9AE-6015-F" and the heads are ECZ-G, but I have no idea how to tell if they're big or little. It's cast into that spot next to the driver's side intake coolant mating surface.

One source doesn't even have those as options. One suggested it may be a Mercury block.

What do the experts say?

You will first have to determine if your engine is a 292 or a 312. As Jeff mentions, the outside of the block or casting numbers will not help you there. If you spot the aspirin size dot on the outside edge of the flywheel flange of the crankshaft, then the engine at least has a 312 crankshaft. Internally, if the block has EBU main caps, it’s a 292; ECZ main caps and you have a 312.

If a 312, then odds are very good your B9AE block is a Mercury block. If a 292, then it’s a Ford car, pickup, or truck block.

|

|

By Deyomatic - 2 Years Ago

|

Thanks, Ted.

Well, I'm planning a transmission swap for the winter so I'll look at and maybe get some photos of the flywheel flange on the crank. Is this something that the flywheel would need to be removed to see?

My money's on a 292- that's how it was sold to me and the previous owner. If it was a 312, I would think that whoever put it in would have advertised that well knowing that it was more desirable.

|

|

By 55blacktie - 2 Years Ago

|

|

Whether it's a 292/312 makes no difference as far as transmissions are concerned. If you're thinking about installing a transmission that was not used with Y-blocks, the required adapter will fit either. Let us know which transmission you're considering, and one of us will tell you which adapter you'll need and where to get it.

|

|

By Deyomatic - 2 Years Ago

|

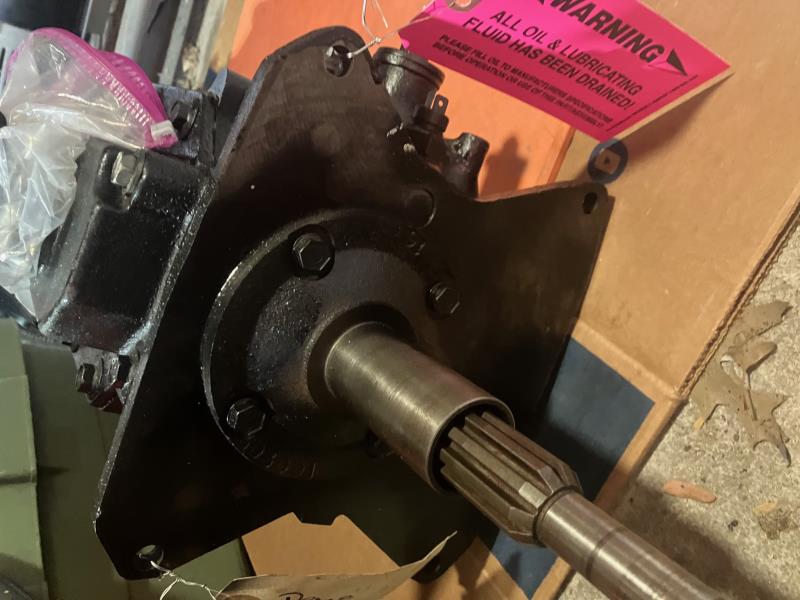

Here is a shot of the transmission that I will hopefully be picking up soon. I currently am running a 3-speed toploader that I guess is referred to as a "3.03" in Ford circles. Someone on the HAMB tipped me to the fact that for 1975-1976, AMC used a T150 with a Laycock de Normanville overdrive unit, and that he'd had over a decade of trouble free driving with one behind his Hemi. As luck would have it, there was one I found on Car-Part.com in a junkyard in Pelham, NH- not too far from where my sister lived, so I called one day on my way back from her house and they still had it and the price was right...another "as luck would have it" came about when I found out that the "GO-TO, guru" for these things has a shop just under an hour from my house, so I dropped off with him back in February. He emailed a week ago to tell me it was ready.

Sounds like the only thing I'll need to change is to massage a fraction of an inch off of the tip of the input shaft and it "SHOULD" mate right up. I'll just have to figure out mounting the back half of it, since it's WAY different...

|

|

By 55blacktie - 2 Years Ago

|

|

I hope it all goes well. Let us know how it's progressing.

|

|

By paul2748 - 2 Years Ago

|

You may have to turn down the front bearing retainer a little to fit in the Y bell hole.

|

|

By FORD DEARBORN - 2 Years Ago

|

|

Very interesting trans, never seen one thanks for posting. Looks like it's electrically operated and it indeed looks like the Ford 3.03 3 speed transmission which is a very sturdy reliable fully synchronized trans. Nice find............

|

|

By miker - 2 Years Ago

|

There was some recent discussions over on the HAMB about those. It is the electric Laycock de Normanville, just like the so many British cars used. Volvo used them too. Pretty slick little unit, Gear Vendors bought them (or the rights). I think they were licensed to Doug Nash for that 4+1 they used in the early 80’s vetted. Pretty well spoken of by the guys using them. Syncro first IIRC.should be great in your A .

What I never saw was the torque rating on the overdrive parts. I know in my Volvo it would only engage in 4th, and was told that was due to the torque limits. But I don’t know if that’s true. A good y has a lot more torque than that 1.8 4 banger had, don’t know about how AMC set them up.

|

|

By Deyomatic - 2 Years Ago

|

|

Thanks for that tip, Paul. I was wondering about that. If that's the case, I wonder if the one I am currently using would bold right on.

|

|

By 55blacktie - 2 Years Ago

|

|

You only need overdrive in high gear while driving on the highway.

|

|

By Deyomatic - 2 Years Ago

|

Thanks for getting them up to speed, Miker....

Yeah- one of the guys on the HAMB sung the praises of the unit behind his early Hemi, which is probably WAY torquier than my 292. I guess there's a solenoid and a pump that pressurizes fluid that engages a planetary gear...some kind of magic like that, anyway....

If my research is correct, the gear ratios are the same as what I am currently running. If that's the case, I won't know the difference until I flip the switch. I plan to run it off a toggle.

The guru that's been rebuilding it has cautioned me against two things...reversing while the OD unit is on, and using it under too much torque. He was hoping to be able to wire up a Reverse lockout feature, and also something that would only allow engagement in third, but I don't think he was....For THOSE reasons I plan to ONLY use it on the highway- I feel like I'm way less apt to shift into reverse on the highway. I think my HEMI friend said he uses it to have a "6 speed," or maybe it was a different guy on the HAMB...but I really don't want to chance it.

As is, without OD, I'm cruising at 65 spinning around 3160 rpms. With the .68 OD- 65 will be about 2150... and 100 would be about 3300. That should keep this engine happy. If, for whatever reason, I grenade it, maybe GearVendors will service or make a direct replacement that's more stout.

|

|

By miker - 2 Years Ago

|

If my eyes are still good that’s a top loader with the side shift. Rig a limit sw on the shift linkage so the relay (you are using a relay?) only engages in 3rd. Then put the sw in the middle of that circuit. Better safe than sorry. You’ll still have to remember to drop it out of o/d before you downshift to second. Or set the limit sw on the first/reverse arm. Bunch of ways to do it.

On the other hand, nosed into the wall and left in o/d makes a hell of an anti theft device. Expensive though.

|

|

By Deyomatic - 2 Years Ago

|

|

One of the things that this guru did was make it a top shift- like my current 3.03 so there are no more side levers. He was very worried that there wouldn't be a way to lock it out of reverse. I thought maybe a relay that was hooked up to the reverse light switch (car doesn't have reverse lights, anyway) that would cut power to the OD solenoid. But, ultimately, I've driven quirky stuff all my life so I'll get used to it.

|

|

By Deyomatic - 2 Years Ago

|

Picked it up today! I'm pretty psyched. The guru gave me some tips on how to use it and a box with a couple pounds of broken parts.

What he DID say was not to worry at all about the torque that this Yblock is making- this J-Type Laycock de Normanville OD can handle that...once it's engaged. He said that going in and out of OD is more of a trick that I'll get used to...basically you want to flip the switch on or off while trying to get close to the RPMs that you'd have when going back into third without OD...so, "blipping" the throttle or "rev matching" as they say now.

I asked if I'd be able to floor it once it's in OD and he said that once it's engaged it can handle a lot more than the 300 lb/ft that this 292 may or may not have.

Probably just going to be compiling parts until the winter, at this point.

|

|

By Ted - 2 Years Ago

|

|

Deyomatic (10/21/2023)

...What he DID say was not to worry at all about the torque that this Yblock is making- this J-Type Laycock de Normanville OD can handle that...once it's engaged. He said that going in and out of OD is more of a trick that I'll get used to...basically you want to flip the switch on or off while trying to get close to the RPMs that you'd have when going back into third without OD...so, "blipping" the throttle or "rev matching" as they say now.

I asked if I'd be able to floor it once it's in OD and he said that once it's engaged it can handle a lot more than the 300 lb/ft that this 292 may or may not have.

I had a Gear Vendors overdrive unit behind a granny four speed in a ’86 Ford F250 with a 460. With the overdrive switch mounted on the shifter, I simply treated the overdrive like another gear and simply disengaged the clutch whenever engaging or disengaging the overdrive. If engaging the overdrive without using the clutch, it was a very harsh shift.

As a FYI, the Gear Vendors unit I had was rated for 30,000 lbs. vehicle weight. I had many trouble-free miles with that unit with that truck primarily being used for trailer towing.

|

|

By 57RancheroJim - 2 Years Ago

|

That seems like a great trans, I have never seen one. Just out of curiosity I can't tell from the picture but it looks like it has a wide mounting pattern holes? Some trans had dual pattern for wide and narrow mounting.

|

|

By Deyomatic - 2 Years Ago

|

Ted- thanks for that info. It SEEMS like you'd want to use the clutch for the reason you said- ease the load onto the system- but he's said a couple of times not to use the clutch....maybe what he meant was that you don't need to push the clutch in, and I just heard what I thought I heard.

Jim- The bolts holes from side to side are 8.5" on center. The ones in the car are narrower, and I poked a nail into the hole in the current trans to see if there was a threaded hole in the bellhousing and there is not. I'm guessing it's nothing that a drill and tap can't fix. Does that give a clue as to what size the bearing retainer hole in my bellhousing may be?

|

|

By 57RancheroJim - 2 Years Ago

|

If nobody chimes in with the bell housing hole measurement I can get it later this morning for you, it's still dark here..

|

|

By Deyomatic - 2 Years Ago

|

I'm not worried about it...this swap won't be happening while it's still cruising season up here.

I re-read what I said before and even I had a tough time understanding it! My current 3.03 is drilled for both bolt patterns, and it is using the narrow holes to mount to my bellhousing. I used the nail to poke into one of the wider holes to see if it went through, indicating a mounting hole, and it did not. This current 3.03 being drilled that way should make it easier to drill and tap for the wider holes...assuming the wide pattern matches.

Does the front bearing retainer support the trans weight, or do the bolts do that? Starting to stress out about that potentially not lining up.

|

|

By paul2748 - 2 Years Ago

|

Can you drill the narrow holes in the case? I was told (no experience) that you could drill the narrow holes in the case for a 4 speed toploader, I don't know if it applies to the 303 trans.

Deyomatic (10/23/2023)

I'm not worried about it...this swap won't be happening while it's still cruising season up here. I re-read what I said before and even I had a tough time understanding it! My current 3.03 is drilled for both bolt patterns, and it is using the narrow holes to mount to my bellhousing. I used the nail to poke into one of the wider holes to see if it went through, indicating a mounting hole, and it did not. This current 3.03 being drilled that way should make it easier to drill and tap for the wider holes...assuming the wide pattern matches. Does the front bearing retainer support the trans weight, or do the bolts do that? Starting to stress out about that potentially not lining up.

|

|

By 57RancheroJim - 2 Years Ago

|

The bearing retainer to bell housing hole keeps everything in alignment, the bolts hold the weight.

|

|

By Deyomatic - 2 Years Ago

|

Sure looks like I could drill out for the narrower pattern  , if I wanted. , if I wanted.

|

|

By Ted - 2 Years Ago

|

|

Deyomatic (10/17/2023)

...Well, I'm planning a transmission swap for the winter, so I'll look at and maybe get some photos of the flywheel flange on the crank. Is this something that the flywheel would need to be removed to see?...

The flywheel would not need to be removed. With the flywheel cover at the bellhousing removed, you should be able to see the lower edge of the crankshaft flywheel flange. At this point, rotate the engine so that TDC on the damper is at the 6:15 O’clock position looking from the front. If it’s a 312 crankshaft with the aspirin sized dot, that dot will be evident at the 6:00 O’clock position (straight down) on the bottom edge of the crankshaft flywheel flange.

Just keep in mind that if there is no dot present, there was a small number of those 312 crankshafts made without the identifying ‘dot’. The majority of 312 crankshafts do have that external identifier though. On the flip side of that, there are some 292 crankshafts out there with a dot or dots but those are smaller and not aspirin sized.

Here’s a couple of pictures to help identify what you are looking at.

|

|

By Deyomatic - 2 Years Ago

|

|

Thanks Ted...That's great info. I'll keep this in mind whenever I dig into this little project. Probably be a few months.

|

|

By BamaBob - 2 Years Ago

|

|

Ted, what was the original intended purpose of the crankshaft dots? Were they always there for identification purposes, or, did they serve an alignment or some other purpose needed at the time of their manufacture? I'm just curious about this since my 312 has the aspirin sized dot, but the main crank bearing caps have to be looked at to definitely determine the C.I. of the engine. Thanks for any info!

|

|

By Ted - 2 Years Ago

|

|

BamaBob (11/1/2023)

Ted, what was the original intended purpose of the crankshaft dots? Were they always there for identification purposes, or, did they serve an alignment or some other purpose needed at the time of their manufacture? I'm just curious about this since my 312 has the aspirin sized dot, but the main crank bearing caps have to be looked at to definitely determine the C.I. of the engine. Thanks for any info!

My thoughts point to being just for identification purposes. Likely helped when raw castings were being passed around during the machining process. While I can spot a 312 crankshaft versus a 292 crankshaft across the room, it may not have been that simple in the machining department or the engine assembly area. For what it's worth, the dot on the 312 crankshaft and the blank recess found on some of the 292 crankshafts has that dot or recess aligned with the #1 rod journal which could have been an assembly aid.

|

|

By BamaBob - 2 Years Ago

|

|

Thanks for the reply Ted. I believe your assessment of the machining room ID processes is spot on. I for one would hate to be working on a room full of crankshafts that look just alike without some form of quick identification such as the flange dot or recess on the flange. Would be mass confusion otherwise!

|

|

By Joe-JDC - 2 Years Ago

|

312Y crankshaft vs 292Y crankshaft is easy to spot standing up. Joe-JDC

|