|

By Brent - 3 Years Ago

|

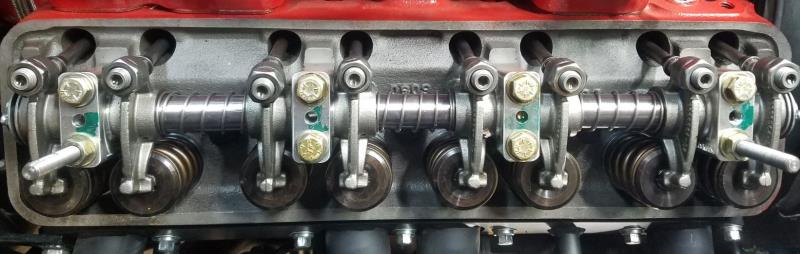

Finally going to fire it up. Pulled the valve covers to see the oil when priming. Found no tubes and the front stand on the passenger side and the rear stand on the driver side have no tubes and the stands are threaded. These are John Mummert rocker assemblies. Should there be plugs or tubes or is it good the way it is?

|

|

By 55 GLASS TOP - 3 Years Ago

|

|

who installed the rocker shaft the must have some parts left over

|

|

By Florida_Phil - 3 Years Ago

|

Some people block off the oil tubes to pressurize the rocker shafts. I believe John has a YouTube video showing this procedure. He taps the oil tube holes and uses screws to plug the holes. Before you fire the engine turn the oil pump by hand or with a drill and you should see oil flow. My engine had the cam oil grove cut deeper and I had so much oil that I left the tubes in the stock configuration.

|

|

By Ted - 3 Years Ago

|

When removing the overflow tubes, it’s customary to put a set screw or machined bolt in the tops of the #1 and #8 cylinder rocker stands to keep the shaft properly orientated. That bolt or set screw will protrude into the existing hole in the shaft where the overflow tube originally inserted. Without those screws or bolts in place, the rocker arm shaft will not maintain orientation with the oil holes in the heads to provide oil to the shafts/rockers. The oil supply holes at the heads that provide oil to the rocker arms are located above the #2 and #7 cylinders and there is a corresponding hole at the bottom of the shafts that must align with those.

|

|

By Brent - 3 Years Ago

|

You guys have saved the day! I got the cam from John, so I think the groove has been machined. I am going to the garage now to verify the shafts are in the correct orientation. I can see the holes in the shaft through the stands, it's approx. 3/16" down the threaded hole in the stand to the hole in the rocker, I think that a set screws long enough to thread down the stand and in into the shaft will be the solution for today. If I recall correctly reducing flow out of 2 and 7 can cause too much oil in places.

EUREKA! looking down the hole with a magnifier, there is set screws in place.

Today is off to a great start! THANK YOU for sharing all of your knowledge!!!

I'll keep you posted

|

|

By 2721955meteor - 3 Years Ago

|

I REMOVE THE ROCKER STAND,RUNA TAP THREW THE HOLE THE TUBE USED. TOOK THE ALLEN HEADED SCREW AND REMOVED SOME THREAD MADE THE ENT TAPERED TO ALICHN THE HOLES RE TEDS ADVICE.. WITH OIL DRAINING AT ALL ROCKERS HAS PLENTY OF DRAIN HOLES(ALL THE PUSHROD HOLES ASWELL THE FDRAIN HOLWS ETHER END OF CYL HEADS. MY TRUCK(292) HAS 3 OR SO YEARS AND HAD THE VALVE COVER OF STARTED UP AND NO EXCESIV OIL,SET VALVES WETH ENGINE RUNNING,NO WEAR ,NO ADJ. REQUIRED. NO SPILAGE AT IDEL. I HAVE NO SPACERS BETWEEN STANDS AND HEAD. AS I USED THE/COMPESISION HEAD GASKETS SO SPACERS DRAIN PLATES ARE THE SAME THICKNESS AS NEW HEAD GASKETS.

FOOD FOR THOUGHT,BUT WORKS FOR ME AND SEVERAL FRENDSI HELPED BUILD THER YS

|

|

By BamaBob - 3 Years Ago

|

|

While we are on the topic of rocker arm oiling, I have questions regarding the grinding of a little sideways trough across the oil hole in the shaft where the rocker arm is oiled. I have seen pictures of this having been done, and I wonder how do you keep the grinding residue out of the shaft inside? Also, has this slot grinding been shown to be a worthwhile operation, or is it just a theory that sounds good? I will admit that the several yblock rocker arms that I have taken apart have all shown excessive wear and galling, both in the arm and on the shaft. I am in the process of rebuilding some rocker arms with new bushings and new shafts at the present time, and need to know if the slot grinding would need to be done, or, would assembling the arms with the factory oil holes be sufficient? The oil holes are all cleaned and fully open in the arms themselves. Anyone with knowledge and/or experience on this, please chime in!

|

|

By charliemccraney - 3 Years Ago

|

There are plugs in each end of the shaft. Remove those plugs and you can clean the inside very well.

|

|

By PF Arcand - 3 Years Ago

|

If you do remove the plugs & need new ones, I believe they were also used on some F.E. Ford engines as well.. Maybe someone can confirm this?

|

|

By Ted - 3 Years Ago

|

|

BamaBob (12/20/2022)

While we are on the topic of rocker arm oiling, I have questions regarding the grinding of a little sideways trough across the oil hole in the shaft where the rocker arm is oiled. I have seen pictures of this having been done, and I wonder how do you keep the grinding residue out of the shaft inside? Also, has this slot grinding been shown to be a worthwhile operation, or is it just a theory that sounds good? I will admit that the several yblock rocker arms that I have taken apart have all shown excessive wear and galling, both in the arm and on the shaft. I am in the process of rebuilding some rocker arms with new bushings and new shafts at the present time, and need to know if the slot grinding would need to be done, or, would assembling the arms with the factory oil holes be sufficient? The oil holes are all cleaned and fully open in the arms themselves. Anyone with knowledge and/or experience on this, please chime in!

There are some rocker arm shaft suppliers that put the angled slots across the oil holes while others do not. You can find both the slotted and non-slotted shafts for the FYB, LYB, FE, and MEL engines depending upon the shaft manufacturer. The advantage of the slots would be additional oil on the loading side of the rocker arm thus reducing the wear factor. When using aftermarket rocker arms, the oil hole or slot in those does not always align with the oil hole in the shaft so the slots help with that.

If grinding the slots in shafts that do not have them, then a thorough cleaning afterwards is mandated. While removing the end plugs would help the cleaning process, flushing them for a period of time without removing the end plugs also works.

|

|

By 2721955meteor - 3 Years Ago

|

my 1st y block was a 1955ford(meteor) worked as a mechanics helper that gave access to free oil(seares1 for Diesel engines. changed oil and filter,every1000. miles.

I sold the car with 90,000 miles. adjusted valves one time. no rocker problems, no rear seal issues . drove the car like most young guysvqlve float to next gear

o

|

|

By Richard - 3 Years Ago

|

|

Regarding the rocker shaft #2 & #7 oiling holes. Are they supposed to have a threw hole, or just a blind hole to feed the shaft.

|

|

By 2721955meteor - 3 Years Ago

|

Richard (12/21/2022)

Regarding the rocker shaft #2 & #7 oiling holes. Are they supposed to have a threw hole, or just a blind hole to feed the shaft. blind hole,

|

|

By Skyliner57 - Last Year

|

I just bought a 56 Victoria, it may have a 312 engine. There is a oil line running from the oil sending gauge to the right side of the engine. I assumed it was capped off and had been used for an auxilary under the dash gauge at one time--nope it goes into the back side of the "head" on the passenger side. I have not pulled the cast aluminum valve cover off to see if the line is an auxiliary line to the rockers. The valve cover does no leak, I would prefer not to disturb this.

For all of you seasoned Y Block experts was this an acceptable fix at one time. Thanks. Harold

|

|

By paul2748 - Last Year

|

Not sure I understand what you mean. Exactly where does the oil line end up ? Right side of then engine is the passenger side. Pics would help a lot

.ote]Skyliner57 (8/9/2024)

I just bought a 56 Victoria, it may have a 312 engine. There is a oil line running from the oil sending gauge to the right side of the engine. I assumed it was capped off and had been used for an auxilary under the dash gauge at one time--nope it goes into the back side of the "head" on the passenger side. I have not pulled the cast aluminum valve cover off to see if the line is an auxiliary line to the rockers. The valve cover does no leak, I would prefer not to disturb this. For all of you seasoned Y Block experts was this an acceptable fix at one time. Thanks. Harold

|

|

By Ted - Last Year

|

|

Skyliner57 (8/9/2024)

I just bought a 56 Victoria, it may have a 312 engine. There is a oil line running from the oil sending gauge to the right side of the engine. I assumed it was capped off and had been used for an auxiliary under the dash gauge at one time--nope it goes into the back side of the "head" on the passenger side. I have not pulled the cast aluminum valve cover off to see if the line is an auxiliary line to the rockers. The valve cover does no leak, I would prefer not to disturb this.

For all of you seasoned Y Block experts was this an acceptable fix at one time. Thanks. Harold

Without more details, that copper line sounds like a ‘fix’ for the rockers not oiling as they should on the right bank. Once you do pull the valve cover, you can actually see where the line attaches and verify that this is indeed the case. I have come across several core engines where overhead oilers were installed only on one side of the engine and most of those were the result of an improperly installed center cam bearing. Installing the line under the valve cover gasket could have been due to not having the kit that used a hollow valve cover retaining stud. Or, if someone was trying to hide the overhead oiler, then the snaking the line under the valve cover would have been an option.

|

|

By Skyliner57 - Last Year

|

Thanks Ted-I will pull the valve covers and send photo's. Harold

|

|

By Skyliner57 - Last Year

|

I plan to remove the cast valve covers to look at this oil system. I have read that it can be hard to get these to seal. Mine are not leaking now so would hate to create a problem. I am guessing there is lots of good advice on what type of gasket works best for the aluminum cast covers, would appreciate the advice.

Thanks

|

|

By KULTULZ - Last Year

|

I would like to know how the rocker cover gaskets seal myself.

|