|

By peeeot - 3 Years Ago

|

With 10w-30 oil, I am seeing hot pressure at idle somewhere under 10psi and at 2000 rpm around 30-35psi. Thinking these numbers indicative of loose bearing clearances, I switched to 15w-40 (after rebuilding the gerotor pump, which made no difference). With the heavier oil I picked up about 5 psi at both idle and 2000 rpm.

Would it be prudent to move up to 20w-50, stick with 15w-40, or revert to 10w-30? This is a stock-style street-driven engine.

|

|

By Cliff - 3 Years Ago

|

|

10/30, however why don't you put in a set of bearings?

|

|

By paul2748 - 3 Years Ago

|

I don't see any harm going up to a 20-50. Been running that in a 302 for years summer or winter.. A 10-40 should be good to use too.

|

|

By 2721955meteor - 3 Years Ago

|

|

who rebuilt the greater oil pump.if the alum jeroter has ware of the housing a newer and inner steal rotor will do nothing. with my 292 all new bearingscam bearings etc 1040 oil gives 25 pounds at idle,40 at2500 hot.. my issue with jeroter is content drips at mount gasket. the issue is over torque trying to stop drips warp housing. have purchased a gear pump with cast iron body. haven't installed yet. will shortly. just my takeongeroter pumps

|

|

By Lord Gaga - 3 Years Ago

|

You could try shimming the oil pump pressure relief spring with a few small washers and see if that helps.

|

|

By Lord Gaga - 3 Years Ago

|

Are you sure your gauge is accurate?

|

|

By Ted - 3 Years Ago

|

Excellent point on checking the accuracy of the gauge.

The hot oil pressure specification in the 1957 service manual is 45-50 psi at 2000 rpm. You do not mention how many miles are on this engine so if it’s relatively low mileage since it was last worked on, then it might be worth revisiting the oil pump. I have found that the end play or bottom clearance on either style of pump is critical.

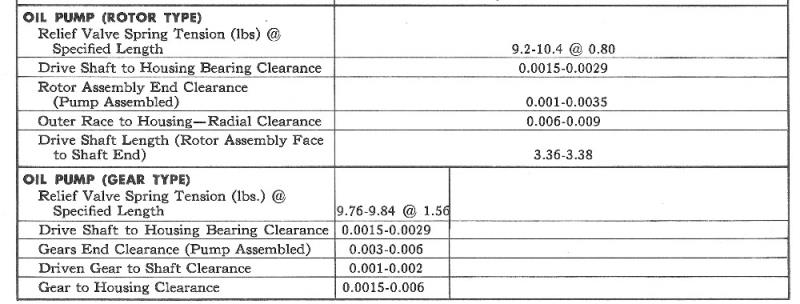

Here are the specifications for both the spur gear and gerotor (rotor) oil pumps when rebuilding them. Per the manual, the oil pump to cover plate torques to 12-15 lbs/ft.

|

|

By peeeot - 3 Years Ago

|

I do not know the engine’s history. I have had it for less than a year, it is not original to the car, and I am sure that the previous owner did not rebuild it. My best guess would be that it was removed from a 1956 Thunderbird to replace the car’s original engine sometime in the 80s-ish.

The pressure gauge is new, but of course that doesn’t guarantee accuracy. I installed it because my oil light was flickering on at hot idle with the 10w30.

I installed the rebuild kit in the gerotor pump. I checked clearances per a shop manual (I think I used the one from 1959) and resurfaced the steel plate. Everything checked out ok as I recall. The old rotor had some pitting at the rotor tips.

I don’t plan to overhaul the engine anytime soon, so I’m just trying to determine what oil will give the engine the best longevity as-is, until a potential future rebuild.

Presumably if observed pressure is lower than spec, the volume of oil reaching the end of the line (rocker shafts, correct?) will be reduced at a given engine speed because of internal leakage. More viscous oil may not leak internally quite as much, thus somewhat increasing the volume to the later parts of the oiling system and also the pressure at the gauge. I do not know how important the actual pressure or film thickness of the oil at the bearings is. I am sure that oil is getting everywhere in the engine, even with 10w30, but not whether increasing viscosity will actually reduce internal wear relative to a lower viscosity.

|

|

By DryLakesRacer - 3 Years Ago

|

There is only wear if there is no oil. With the engine warm after running and you can easily remove the rocker arm covers, take one off and start the engine to see if oil comes out the overflow. I use a cardboard defector and there is very little splash. If there is oil on both sides I would not worry at all as all the passages are oiled and there is enough pressure to get oil to the rocker system.

10 psi at idle and 30 when running is fine for most engines in light use.

There are some brands of oil with lower pressure. Pennzoil always did that from my experience.

|

|

By 2721955meteor - 3 Years Ago

|

|

block off rocker spill tubes, if you have a good flow ther is no need for the loss of oil flowing fact better lube to all rockers improve camshaft life,as well the oil leaking from rocker shafts get to front and rear holes,if no leaks at all rockers rockers farther from spill tubes are probably plugged with sludge.

|

|

By peeeot - 3 Years Ago

|

Two questions about pressurizing the rocker shafts:

1. Isn’t the drainage from the shafts intentionally directed to lubricate the distributor and timing chain areas, such that elimination of that drainage would deprive the intended components of oil?

2. If pressurizing the rocker shafts improves shaft and rocker life, why was it never done from the factory? It would probably have been cheaper than installing the drain tubes, and the factory loves cheap!

Pressurizing them sounds like a good move to me, just curious about the above items.

|

|

By paul2748 - 3 Years Ago

|

Just my take - if your getting enough oil up to the rockers, there isn't a need to pressure them by closing off the tubes, at least completely. And yes, from what has been said here, the tubes do provide oil to the areas mentioned. And I don't think blocking off the tubes will help much with overall oil pressure, although I might be wrong on this

.peeeot (8/2/2022)

Two questions about pressurizing the rocker shafts: 1. Isn’t the drainage from the shafts intentionally directed to lubricate the distributor and timing chain areas, such that elimination of that drainage would deprive the intended components of oil? 2. If pressurizing the rocker shafts improves shaft and rocker life, why was it never done from the factory? It would probably have been cheaper than installing the drain tubes, and the factory loves cheap! Pressurizing them sounds like a good move to me, just curious about the above items.

|

|

By rponfick - 3 Years Ago

|

Peeeot, I had the same questions on the overflow tubes. I just installed a set of Mummert hi-lift rocker arm assemblies, and noticed he puts a set screw in the overflow tube hole. I asked him about the claim of needing that overflow oil to timing chain and distributor area. He dismissed that need and said there was enough other oil splash to lubricate these areas. So, I know he was certainly more knowledgeable than me on these engines.

Just thought I would share.

Ralph

|

|

By DryLakesRacer - 3 Years Ago

|

|

I know it’s personal choice but I like to see flow. I’ve massaged both cylinder head passages/troughs and radiused the block hole to help the oil flow. Tim McMaster has a You Tube on the flow with the over flows closed with is very educational to watch.

|

|

By Florida_Phil - 3 Years Ago

|

I don't believe 10 psi at hot idle and 30 running is all that bad for an older street engine. I would put some 40 weight oil in it and drive. On another note. All these fixes with the rockers and tubes are not necessary if you cut the cam oil grove to .030" deep on rebuild. Mummert does this to all his cams. My Isky cam had .018" from Isky. After this modification, I worried I would have too much oil to the heads. As it turned out, all is perfect with everything stock.

|

|

By DANIEL TINDER - 3 Years Ago

|

|

I agree, though I did do John’s ‘drilled Allen-screw/rocker stand’ trick to balance the flow (early 2000’s Y-Block Mag article?). 10 psi per 1000rpm is traditionally the accepted min. I would use 10W-40 though. Circulation is still more important than pressure. It’s my understanding, that no matter how sloppy the bearings get, as long as the oil coming in is faster than what’s leaking out…..

|

|

By 2721955meteor - 3 Years Ago

|

|

with spill tubes in place rockers and lubrication suffer at opset ends of rocker shafts suffer from poor lubrication.even with deeper grove in camshaft. this becomes even more critical with high lift rockers and wilder cam grinds.i also discard the tin plates between rocker stands and cyl heads. most of the ys now have compassion head gaskets which lift heads .040 the same thickness of the tin plates. now you have restored original rocker and pushrod geometry,

|

|

By DANIEL TINDER - 3 Years Ago

|

|

I wouldn’t toss the tin plates. They could come in handy if you want to experiment with rocker geometry in future.

|

|

By DryLakesRacer - 3 Years Ago

|

|

meteor..early GMC 6’s feed the shaft rocker arm system from their front support stand and have a much larger over flow on the center one. I’ve raced these engines since 1975 with valve lifts over .500” at 6000 rpm and never had a rocker failure or problem on the other end from the feed and its 3 cylinders away. The over flows are always on the top keeping the rocker shaft full and chamfered oil feeds and all is stock. For me personally on a non race YBlock I will always take volume and flow moving in the hollow shaft.

|

|

By 2721955meteor - 3 Years Ago

|

ford counted on the od oil change with good oil.most owners did not listen and rocker shafts plugged up especially the far end from spill tubes.

my first y 55meteor ,272, I worked in a log camp shop. changed oil every month using goo quality oil 30wt.never had to even set valves till50000miles

lesson learned regular oil changes with quality oil and filters.

|