|

By charliemccraney - 4 Years Ago

|

Some stuff I've found, from other intended uses.

Baking / cooling rack for letting oil filters drain. This particular one is almost 4" tall.

Makeup brush for dusting off plastic lenses, like those for my Firebird's instrument panel. I don't know if this is actually a good idea. I stumbled upon the idea while looking for "scratch free brushes" one review for one I was looking at stated something like "it's just a makeup brush with a longer handle." I didn't need a long handle and makeup brushes were cheaper. It does feel very soft.

Baking tray for storing funnels. Note that I wipe them down as much as possible or rinse, where applicable, after each use and put paper "plugs" in the ends of some to prevent different fluids from mixing. They are kept in a cabinet with doors to be relatively protected from dust.

The pencil that photo-bombed in the top right... I can't think of one use for that. Weird invention.

|

|

By Daniel Jessup - 4 Years Ago

|

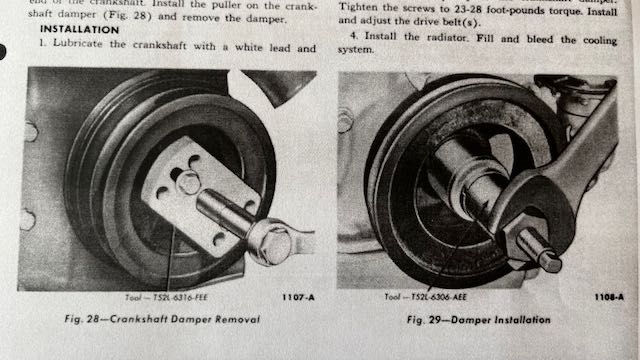

Charley - good post here and I hope we can keep these going. Let me add a shop tool that I recently used to re-install my crankshaft damper after upgrading to an E4 camshaft. While I do have video on my YouTube channel and my website, I am sure the photos posted here will suffice. As we all know, pounding your damper on the crank with a hammer is certainly not the way to go. The rubber insulator sandwiched in your damper and your main thrust bearing will appreciate the effort to find another way.

If you look at the 55 Ford Shop Manual, it literally says to use a soft metal hammer to reinstall the damper. The late 50's Ford Engine manual I have in digital format says to use a Ford tool that draws the pulley back onto the damper. Obviously, tools like these are hard to find. In this instance a simple installer is not difficult to make. I used 9/16"-18 all thread, two large nuts, two medium size washers and two large washers (one set used to hold sleeve, the other for the crank/nut), and a piece of metal tubing/pipe to draw the pulley back onto the crank.

|

|