|

By Daniel Jessup - 3 Years Ago

|

Does anyone have an off-the-shelf option for a crankshaft turning nut for our beloved Y Blocks? Would help me degree the camshaft during this upcoming assembly...

thanks

|

|

By 55blacktie - 3 Years Ago

|

|

Without the damper in place, you'll probably want to use a shorter bolt. I removed my damper and sent it out to Damper Dudes. I don't intend to install it until the engine is rebuilt. In the meantime, I want to be able to occasionally crank the engine over to make sure it doesn't freeze up. To avoid breaking the bolt, I will either use washers in place of the damper or find a shorter bolt. So far, it easily turns over, but I put some ATF down the spark plugs holes just in case.

|

|

By Ted - 3 Years Ago

|

A crankshaft turning nut or similar option for turning the crankshaft without disturbing the degree wheel is definitely recommended. For the Ford Y, I am not familiar with an off the shelf item that allows for turning the crankshaft during the cam degree in process that works without some kind of modifications.

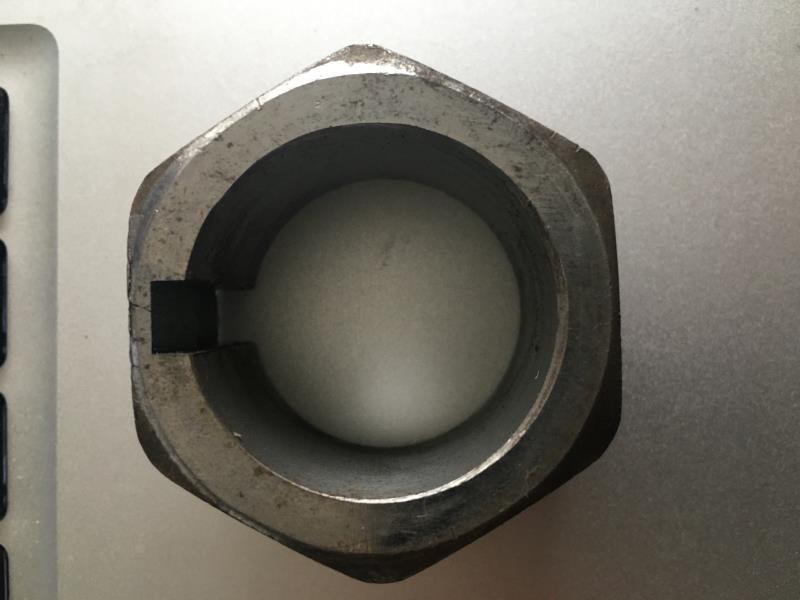

For the Ford Y, I broached an additional and wider key slot in an already existing SBC crankshaft turning nut I had on hand. This allowed the same nut to still be used on a SBC without the additional slop that would be evident if just broaching the existing slot wider.

Machining or grinding a ¼” woodruff key so it’s 3/16” at the crankshaft surface would allow someone to use an unmodified SBC crankshaft turning nut on their Y crankshaft. Another option is to put bolts in the flywheel end of the crankshaft and use a long bar to turn the crankshaft. Yet another option is to use a crescent wrench on the snout where the smooth jaw catches the ¼” woodruff key and turn it that way. Using a pipe wrench on the crankshaft snout is a big no no. Here’s a picture of the modified SBC turning nut.

|

|

By Daniel Jessup - 3 Years Ago

|

Looks like we are going to have to go the modified SBC route. I really do need to turn the crank with a nut (or the bolts at the rear) since the cam degree wheel will be bolted onto the snout. Not really a fan of using the crankshaft dampener bolt to turn the engine but I reckon we have all done it a time or two.  Thanks fellas! Thanks fellas!

|

|

By NY59F100 - 3 Years Ago

|

Daniel, I took an additional suggestion from Ted and had a local machine shop broach a groove in a large nut. I don’t know what size thread it was originally, but the outside measures 1.68”. I gave them the damper to know the inside diameter and the size of the keyway.

Seeing Ted’s picture, I should’ve asked them to make the keyway at the corner, rather than on the flat, of the nut. My friend said he’d give me a “lifetime guarantee “ on the nut, if it ever breaks.

|

|

By Daniel Jessup - 3 Years Ago

|

Thanks Soffiian - that looks like a plan as well. Nothing like the "lifetime guarantee"  But I would think you won't need it. But I would think you won't need it.

I do have another method to try out and will post a picture later on... all depends on whether or not I can get enough leverage with this particular tool. Hopefully, I will get my parts back from the machine shop soon. Time is wearing away before the Y Block Nationals. I may end up pulling the 292 and installing another camshaft in it just because I have a new E4 on the shelf with an NOS set of Ford EAA6500 lifters - plus an adjustable timing gear set to boot. The RexHP headers are supposed to arrive sometime next week. I really want to get those mocked up and ready to go with some type of cap to exit near the front tire when running at the track. I may just make two exhaust sets that I can swap easily. Not sure which route I am going to go on that one. Things are tight in there on the driver's side.

What's the old saying? "Built, not bought" ????

With my travel schedule for what I do in life, this may end up looking like one of those stupid shows on SpeedTV where all the drama comes down to the end where the builders try to get the car finished in the nick of time.

|

|

By MoonShadow - 2 Years Ago

|

|

If you ever get a chance to pick some parts from a Y-Block boat motor they have a spaced on the crankshaft that fits over the keyway. Its round but milling a couple of flat sides on it to fit a wrench make a great turning tool and for cheap money.

|

|

By charliemccraney - 2 Years Ago

|

If a flywheel is installed, you can use a flywheel turning tool.

https://www.summitracing.com/search/part-type/flywheel-turning-tools?PageSize=100&SortBy=Default&SortOrder=Ascending

|