|

By DiLL - 4 Years Ago

|

|

Getting ready to have my crank offset ground. What is the maximum allowable side clearance? Crank will be ground to 1.85" journal, 3.6" stroke. I have a set of Carrillo rods with a big end width of .890". Im assuming that if you add the width of two rods together it gives you 1.78". With the crank journal width being 1.81" and subtracting the big end width of the rods that leaves me with .030". Is that too much side clearance? Also, what rod bearings are used with these rods? My research has led me to Clevite CB-1780H STD bearings. Thanks for the Help!

|

|

By Ted - 4 Years Ago

|

I will suggest that you mic the I.D. of the bearing holes in the connecting rods you have. There are two different Honda rod bearings with each having two slightly different O.D. measurements. The journal measurements are the same for each though. For the Eagle and Cunningham connecting rods using the Honda rod bearings, I use the Mahle/Clevite CB1780H, CB1780HX, CB1780H-001, or the ACL 4B1912H, 4B1912HX, 4B1912H-.025. While the 1780H is the std bearing, the 1780HX has an additional 0.001” clearance while the 1780H-001 has 0.001” less clearance. The uppers and lowers on these bearing sets can be mixed so that 0.0005” changes in oil clearance can be made. The Oliver parabolic beam rods I have for the Y (6.750” long) use the other part number bearing with a different O.D. and that part number currently eludes me. The other option is to call Carrillo and get their recommendation for a bearing number.

I will typically target for 0.020”-0.025” rod side clearance for a street engine. No problem with 0.030” though for a more performance minded engine. When grinding the crankshafts to a smaller journal so that they can be offset ground, I will aim for no more than a 1.810” journal width on the cast cranks to keep from intersecting the oil supply holes going through the journals at the journal edges or filets. Steel cranks seem to be more prone to exposing the oil holes at the filets when widening the journals so be cautious about that. Cutting the crankshafts to the full width to accommodate unmodified 0.940"-0.945" rod widths when using the wider aftermarket rods increases the chance for the oil holes to be exposed at the journal edges and especially when grinding the crankshafts for the Honda rod journal.

With that 1.810” journal width number in mind, the connecting rods are cut so that they are 0.895” wide for 0.020” rod side clearance. For the Engine Masters competition engines, rod side clearance is targeted for 0.100” or more and then the wrist pin end of the rod is shimmed accordingly so that the rods do not connect each other and/or the journal edges. In this instance, any metal to metal contact is being minimized. Keep in mind that the connecting rod side clearance has no effect on the oil pressure so excessive clearance is not a player in that regard.

|

|

By cos - 4 Years Ago

|

|

Dill I have a couple of questions about your project as Iam interested in doing a offset grind on 312 crank (2" journal). What lenght rods, customs pistons ? I guess you are using a 292 crank. Did you find a crank grinder that can leave oil sling and how do check to be sure it is indexed right? Would like to hear all details. Thanks

|

|

By DiLL - 4 Years Ago

|

Ted, thank you for the information! I guess I should mention that the bearing holes measured out at 2.008" Which was what lead me to thinking that if the crank was ground to 1.85" that the 1780H STD would work.

@ COS the rods are Carillo (from eBay) the specs are Length: 6.350" Journal: 2.008" BE width .890, wrist pin .827", pin end width: .820" and weigh 535g. They came with new SPS Carr bolts. Yes, the pistons will have to be custom and they will fit a 3.81" bore and will need to be sized for the rods im using. I'm leaving it up to the machinist to spec them out for me as my engine will need a lower compression to support 8-10 psi.. The crank is a C1TE steel crank that measured 2.188" on all the journals. As far as the oil slinger goes I don't think it'll be an issue as it is a 292 size crank. I'm under the impression that the 312 (due to its larger mains) is the only time you have to worry about the stone size because you have to grind the mains to fit a 292 block. I seem to recall reading somewhere on the forum that it isn't the end of the world if the oil slinger gets ground off...Hopefully ted or someone who has more knowledge on this will chime in to confirm. As far as checking the index if you YouTube "checking the index on jakes new crank" Tim McMaster has a video on how to check it. I will however be leaving that up to the machine shop to check. As far as rods for yours go id get ahold of Mummert, they offer rods that will fit a 2" journal. Other than that it'll have ported 113's, Harland Sharp 1.6:1 rockers, EFI and a Mummert DP intake. I spoke with Ted a few weeks ago and he suggested a cam in the 228/238 113 LSA range would work for what im doing so that's probably what ill go with.

|

|

By Ted - 4 Years Ago

|

The lack of the rear oil slinger on the Y crankshafts is not necessarily considered to be a show stopper. While having that rear oil slinger is desirable, I have not experienced any oil leakage issues as a result of not having it. This is of course using a neoprene rear seal instead of the original rope type of seal.

The early Ford Y’s did not have those rear oil slingers on the cranks and it was not until 1955 when the rear oil slingers appeared. Those early blocks did not have the groove in the block to accommodate the oil slinger so if doing a 312 crankshaft in one of those blocks, the slinger would have to be completely removed anyhow.

When grinding the 312 crankshafts to the 292 main journal size, it is preferred to also machine the existing 312 oil slinger so it’s the 292 size. But in retaining the oil slinger, it does require a narrow grinding rock to do that seal surface. Because the grinding rock to do that operation is very narrow, it is prone to chatter and breakage. Hence the reasoning why some shops do not retain the slinger on those 312 crankshafts that are ground to fit the smaller mained 272 and 292 blocks. On my end, the rear seal area and oil slinger are cut down in lathe and then a narrow grinding stone is used to finish grinding the seal surface. I typically cut the rear seal surface in the lathe to within 0.010” of where it needs to be and then finish it with the narrow rock on the grinder. That saves a lot of wear and tear on the grinding rock. If not using the narrow rock, the oil slinger on the crankshaft would be eliminated without much concern in doing so.

|

|

By pegleg - 4 Years Ago

|

Ted, do you have any photos of the cranks using the Honda bearings? Curious to see the finished jourals.

|

|

By 55blacktie - 4 Years Ago

|

|

Is going from a 2.1180 rod journal to 1.85 recommended for anything other than an engine intended for racing? Will the strength of the crankshaft be compromised? I do realize that the smaller journal will have some benefit, regarding reduced friction.

|

|

By Joe-JDC - 4 Years Ago

|

We turned down my 292 crankshaft and indexed it for 3.310 stroke with Honda Rod journal for the 2019 EMC 303Y. That engine made 461 hp on Ted's dyno when we got back from the EMC competition. It had about 30 dyno pulls before the competition, and several at the competition, as well as re-testing after we came back. We had a .600" lift camshaft, tried three different sets of heads, several intake manfiolds, and carburetors. The dyno testing was done from 3500-7300 rpm on all pulls. We scored the EMC at 3600-7100 for scoring with 100 rpm run over. The little 303 Y was rock solid and very repeatable. I am a bit hesitant to try for more horsepower, however with the cast crankshaft. We were going to change pistons, up the compression to 11.45:1, and use the Mummert Race intake for the 2020 EMC, but that got cancelled. I would think a steel crankshaft would be safe at the 500 hp level if it is balanced correctly and assembled for the power intended. Joe-JDC

|

|

By Ted - 4 Years Ago

|

|

pegleg (1/25/2022)

Ted, do you have any photos of the cranks using the Honda bearings? Curious to see the finished journals.

55blacktie (1/25/2022)

Is going from a 2.1180 rod journal to 1.85 recommended for anything other than an engine intended for racing? Will the strength of the crankshaft be compromised? I do realize that the smaller journal will have some benefit, regarding reduced friction.

The key to maintaining strength to a crankshaft has to do with maintaining a given amount of material between the main and rod journals. You can call this the ‘offset’ material. This explains why FoMoCo increased the main journal size for the 312 engines; when the stroke increased from 3.3” to 3.44”, the amount of offset between the mains and rods would be reduced had the 312 crankshaft stayed with the 2.500” main journal size. FoMoCo instead went with the 2.625” main journal size for the 312 crankshafts and that restored the amount of offset that was deemed necessary to reduce any potential for crankshaft failures. For Ford, it came down to keeping warranty issues at acceptable levels for warranty purposes. If you look at the history of the small block C H E V Y engines in the late Sixties and early Seventies, you’ll see where GM tried to short cut the journal size increases when increasing the stroke on the SBC engines and learned very quickly why there were some minimum requirements for crankshaft offsets. Lots of warranty issues on those small journal 350 engines as broken crankshafts came to the forefront. Both the mains and rod journal sizes were increased and the issue solved for the 350 engines. And then when the 400 SBC was introduced, yet another increase in main journal size. Lessons learned.

With all that being said, when offset grinding a crankshaft for additional stroke, the amount of offset is reduced thus taking some strength away from the crankshaft. Crankshafts with reduced amounts of offset must be balanced to a much tighter tolerance as any significant degree of imbalance can have an adverse effect on crankshaft integrity or strength. So yes, any offset grinding of a crankshaft weakens the crankshaft to some degree.

The crankshaft in Joe’s 303” engine was ground for a 0.010” under Honda rod journal (1.879”) but did retain close to the original stroke so any decrease in offset that would have occurred with an increase in stroke was minimized. The stock Honda journal is 1.889” (not 1.85”) which is ~0.300” less than the stock Y journal size. On a stock stroke crankshaft, this takes ~0.150” away from the amount of offset material. As a general rule, I will only go with a 2.000” journal when offset grinding a Y cast or steel crankshaft which minimizes any potential issues with having the offset so small that crankshaft integrity is compromised. Some of that offset can be retained when offset grinding in the opposite direction for a stroke decrease as is done for some of the Bonneville engines to decrease the cubic inches in which to meet a specific cubic inch or class requirement.

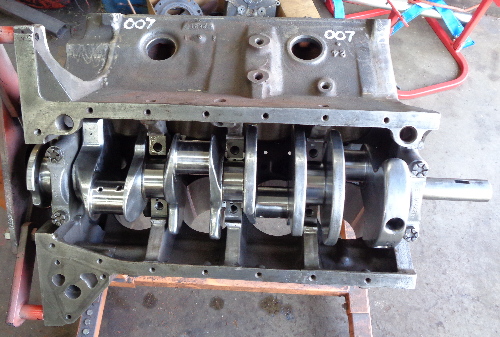

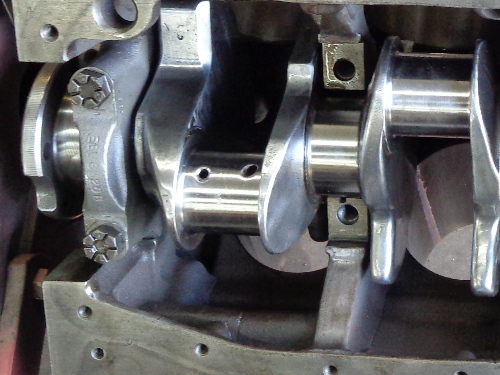

Do not have a current picture of Y crankshaft ground for the 1.889” Honda journals but there are some Moldex crankshafts here for the Y with the Honda rod journals. Here's the picture of a 312 rod journal ground to a 2.000” size while also being offset ground to a 3.600” stroke. With a good balance job, these have presented no breakage issues.

|

|

By cos - 4 Years Ago

|

|

Thanks for info, taking it all in.

|

|

By 55blacktie - 4 Years Ago

|

|

Ted, do the same concerns apply when grinding 312 mains to 292?

|

|

By Ted - 4 Years Ago

|

|

55blacktie (1/26/2022)

Ted, do the same concerns apply when grinding 312 mains to 292?

It’s always a concern anytime the amount of offset between the connecting rod and main journals is reduced whether it’s the mains and/or the rod journals being made smaller. The more the reduction, the more the concern. Keep in mind that FoMoCo increased the main journal size for the 312 crankshafts to maintain what is considered the minimum amount of offset required to keep warranty issues with broken crankshafts at a minimum. And here we are over half a century later reducing those main journal sizes on the 312 crankshafts so they will fit in the 272/292 blocks. We are definitely not smarter than the engineers who originally figured all that out but we are also not making thousands upon thousands of these pieces either.

It’s hard to say if Joe Craine’s 303” engine is pushing the edge of the envelope at this point as the rod journals are cut to a 0.010” under Honda size while the mains are a 0.060” under standard 292 main size. All the journal sizes were made as small as possible to reduce the bearing speeds which in turn makes for more horsepower. As of yet, no broken crankshafts here yet so that horsepower limit if there is one has not been reached yet. There are a number of Ford 312 crankshafts that have been offset ground for more stroke while also having the mains cut to the 292 main size with no issues on my end to date.

Having dealt with Buick 455 engines that had the stroke increased by offset grinding to a smaller journal, there have been zero issues with those, but those engines were internally balanced after offset grinding to eliminate any potential flex in the crankshafts at the higher rpm. Those Buick engines were originally externally balanced and were known to have crankshaft breakage issues when offset grinding and keeping the external balance attributes. The Ford Y is already internally balanced so that part of the equation is already taken care of. The better the balance, the less stress on the crankshaft whether it’s marginal in strength attributes or not. The Ford Y cast crankshafts are also fully counterweighted and that in itself adds an additional level of strength to the crankshaft versus many of the later model crankshaft from all manufacturers that are not fully counterweighted.

|

|

By Ted - 4 Years Ago

|

|

pegleg (1/25/2022)

Ted, do you have any photos of the cranks using the Honda bearings? Curious to see the finished journals.

Here are a couple of pictures of the Y crankshaft with Honda journals.

|

|

By 55blacktie - 4 Years Ago

|

|

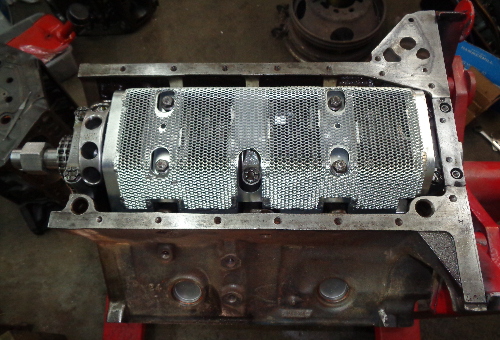

Ted, are you using main studs or bolts on the engine? Stud girdle/windage tray?

|

|

By Joe-JDC - 4 Years Ago

|

|

Those two pictures were of my 303 Y in the early stages of fitment. You will notice the crankshaft is completely polished, rounded edges for windage control. It uses grade 8 main bolts, 289 Windage Tray. Four of the bolts were swapped for 351W windage tray studs. The windage tray had to have the holes moved outboard and enlarged for the Y block spacing. Joe-JDC

|

|

By Ted - 4 Years Ago

|

Here are a couple more pics of Joe’s engine with the windage tray. The original equipment 351W bolts with their built-in studs do use spacers at the main caps to both compensate for the extra length of the bolt and to get the windage tray at a more appropriate height. Those four 351W bolts that were used were originally designed for engines with rear sump pans of which there would be one bolt in each engine to hold the rear sump oil pickup in place.

|

|

By 55blacktie - 4 Years Ago

|

|

That crankshaft started out as a stock cast crank? It's beautiful. A lot of work had to go into it to reach that point. How many hours?

|

|

By Joe-JDC - 4 Years Ago

|

|

Let's just say that I would not polish another one for a customer like I did that one for EMC. Many hours in the porting booth with cartridge rolls, carbides and stones to take off the sharp edges, round over the counterweights leading edges, and polish everything but the bearing surfaces. Ted had to remove a lot of weight for the balance since we were using custom lightweight rods, and forged JE Pistons. Joe-JDC

|

|

By DiLL - 4 Years Ago

|

|

Joe, would you mind sharing the specs on the forged pistons you ordered from JE? I'm in the process of trying to get my pistons ordered and would like a reference. If for competitive reasons you're unable to I understand. thanks!

|

|

By Joe-JDC - 4 Years Ago

|

|

Ted has all the information to order JE Pistons in any compression ratio or head. He made epoxy copies of the -G heads combustion chambers, (both left and right) and sent them to JE for them to duplicate. He also has epoxy combustion chambers of the Mummert heads. If you need assistance in ordering, I would suggest calling Ted. Lead time on parts is an unknown right now. Joe-JDC

|

|

By 55blacktie - 4 Years Ago

|

|

Joe, does that include forged flat-tops/w no valve reliefs and metric rings for EBU and C2 rods? Thanks.

|

|

By Joe-JDC - 4 Years Ago

|

|

Yes, if you are asking about JE Pistons. They will make any bore size, ring thickness, first ring land distance, pin diameter, compression height, or dome, ceramic coating the crown, coating the skirts, etc. You tell them what bore size you need, and they will build the clearances in the piston. Mine have .0045" clearance in the 3.812" bore. Joe-JDC

|