|

By customline3859 - 6 Years Ago

|

Good morning everyone. I hope you guys had a better weekend than I did. I've gotten my rebuilt 304 ci. Y to fire up and run for a brief time. On the initial start up, it ran fairly smoothly, but when it warmed up a bit, the valves began to get a little noisy. We adjusted the valves and in the process of the tuning phase, the engine began to make this loud tinny, popping noise. It won't stay running. I have a pertronix ignitor and flamethrower coil. I started looking through their troubleshooting information, but it basically states that the pertronix is either going to work completely or not at all. They attribute running issues to low voltage. When it began having issues, the battery voltage was low, so I purchased a maintainer/charger to make sure the battery was not an issue. I found 12.45 volts at the coil with the ignition switch off and about 10.5 volts with the key on. I assumed the ignition switch was just drawing the battery down too far, so I replaced the switch. I'm still having the same voltage drop, so I'm assuming that the switch just requires that much voltage. Is that correct? I'm just not sure where to go at this point. I've reached out to the gentleman who put together my 3x2 setup for baseline carb settings. I can't really set the timing until I can keep this thing from popping and carrying on. Any advice or information would be greatly appreciated. I have about a month until we move and I really have to have this thing moving under it's own power. Thanks in advance.

David

|

|

By Gene Purser - 6 Years Ago

|

|

That voltage drop is not normal. Check to be sure you have 12v at the ignition terminal on the switch. Then disconnect the coil wire at the coil and check voltage at the disconnected end. If still low, you have a loose connection or faulty wire from the switch to the coil, or maybe a resistance wire has been installed. You can try running a jumper wire from the positive post on the battery to the coil to see if it improves the running. If it does, a new wire is in order.

|

|

By customline3859 - 6 Years Ago

|

|

How could I go about finding this resistance wire? It was suggested on another site that there was a ballast wire added that is not needed with the pertronix and coil.

|

|

By Gene Purser - 6 Years Ago

|

|

Check my post for edit. If you have low voltage with the wire disconnected from the coil, replace it.

|

|

By Gene Purser - 6 Years Ago

|

|

I just re-read your post.... 12v volts at the coil with the ignition switch OFF is NOT normal. You might have other problems. Try disconnecting the ignition coil wire and run a separate wire from the battery to the coil. Which Pertronix are you running?

|

|

By Ted - 6 Years Ago

|

|

I’ll suggest revisiting the tappet adjustment. This sounds like a tight intake valve or two.

|

|

By customline3859 - 6 Years Ago

|

|

I'm going to start there and work my way out. I've watched The YBlockGuy's adjustment video about 5 times now.

|

|

By customline3859 - 6 Years Ago

|

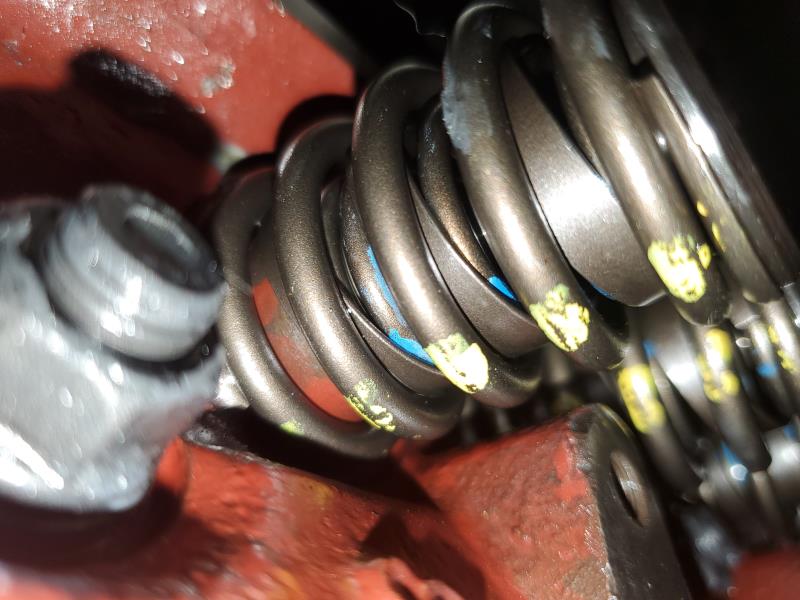

So here's what I found when I removed the valve covers. Two broken rockers and 3 bent pushrods. Valves do not seem to be stuck. Rockers were on new shafts with plenty of oil getting to them. Is it possible that the arms just failed from years and years of use?

|

|

By Florida_Phil - 6 Years Ago

|

Yikes! That's not a tiny popping noise. You most likely have bent valves and maybe a bad piston or two. I doubt the rockers broke due to fatigue. Look for the guy with the size 20 shoe...

|

|

By customline3859 - 6 Years Ago

|

|

I said it was tinny, not tiny. It's been suggested that due to the vehicle not running for approximately 6 months now that it's possible the aging fuel caused a temporary valve sticking issue, which bent the pushrods. With the pushrods being a hardened chrome moly, could have caused the rocker arm breakage.

|

|

By FORD DEARBORN - 6 Years Ago

|

It would be interesting to see the two broken off pieces with adjusters as you found them just for comparison purposes. I wish you the best, like, hope nothing else is bent.

|

|

By Ted - 6 Years Ago

|

|

The rocker arms are reasonably robust so they don’t break without a reason. Can you identify exactly which rockers and pushrods (intake/exhaust) had the problems? What kind of valve lift numbers are you running? Assuming you have ruled out old or sour gasoline, a couple of things to look at would be valve spring coil bind or retainer to guide interference.

|

|

By customline3859 - 6 Years Ago

|

|

Isky 301333 cam. .448 lift. They both appear to be exhaust valves. It's the 5th rocker from the rear on the passenger side and the 4th rocker from the rear on the driver side. The sour gas is certainly a possibility. The fuel in the tank is approximately 6 months old now, maybe a little bit older than that.

|

|

By darrell - 6 Years Ago

|

|

a friends 56 sat for the winter and done the same thing.broke a rocker.no other damage and it didnt do it again.i didnt think they would break that easy.

|

|

By Florida_Phil - 6 Years Ago

|

I am running the same cam in my 292 with flat top pistons. I have stock 1957 "G" heads and rockers with stock valve springs and tubular push rods. I set my valves at .018" hot and never had a problem. It would take a lot of force to break those rockers.

|

|

By Cliff - 6 Years Ago

|

|

Are those FoMoCo rockers?

|

|

By customline3859 - 6 Years Ago

|

|

Yes, they are FoMoCo rockers. Isky #6005 springs, which are 135lbs at 1.750" seat pressure and 285lb open pressure.

|

|

By customline3859 - 6 Years Ago

|

|

So I had planned to remove all my rocker arms that were on this engine and replace them with the rocker arms off of my old engine. Upon further inspection, the rocker arms that were broken are the ECG, higher lift (1.54) rockers and the ones on my core engine are the lower (1.43) ratio. The specs on the camshaft are all based on a 1.5 ratio rocker arm. Would I see a big difference between the two? I'd planned to swap the rockers and reinstall everything once my new pushrods came in and then rotate the engine by hand while checking for coil bind. I wonder if that slight difference in lift would keep the coils from binding, if that was ever my issue in the first place. Just trying to avoid having to take these assemblies apart over and over again, but I may have no choice.

|

|

By customline3859 - 6 Years Ago

|

|

So I set one head with the 1.43s and one with the 1.54s. Both are causing coil bind on the inside valvespring. I've emailed Isky to see if they have any suggestions. The heads have been milled previously and the block was decked a minimal amount when I rebuilt it, but I have no idea how much has actually been removed over the years.

|

|

By DryLakesRacer - 6 Years Ago

|

|

135# on the seat sure sounds like typical Isky. For a street engine 135 is a lot to me. Our 7000 rpm flat tappet cam dirt track engine will run close to that but my 6000 rpm 6’s stay closer to 110 or under. May not have anything to do with the breakage but over time will cause some fatigue from my experience. Good luck.

|

|

By Ted - 6 Years Ago

|

customline3859 (7/4/2020)

So I set one head with the 1.43s and one with the 1.54s. Both are causing coil bind on the inside valvespring. I've emailed Isky to see if they have any suggestions. The heads have been milled previously and the block was decked a minimal amount when I rebuilt it, but I have no idea how much has actually been removed over the years.

You don’t give any details on what the installed spring heights are which is just one consideration. Another consideration is that the heads were not properly machined for the double valve springs. Both springs should be sitting flush with each other at the head. If you are using the #6005 Isky springs, those do require some machining around the guides so that the inner spring sits flush with the outer spring. On some applications I find that the inner springs in the 6005 and 8005 Isky spring sets are sometimes not required and for this, they are simply not used.

|

|

By customline3859 - 6 Years Ago

|

|

How would I determine if the inner spring needs to be used or not? I had the heads machined for newer style valve stem seals instead of the umbrella style.

|

|

By Ted - 6 Years Ago

|

|

customline3859 (7/4/2020)

How would I determine if the inner spring needs to be used or not? I had the heads machined for newer style valve stem seals instead of the umbrella style

You still did not mention if the heads had been properly machined for the inner valve springs. That’s a major player in this scenario and especially where you have rocker arms breaking. Retainer to seal/guide clearance is also a consideration. It’s unusual for the oem rocker arms to break in any circumstance other than where they are in a binding situation.

Measuring both the closed and open valve spring pressures starting with a given installed height with and without the inner springs is required to help determine if you can remove the inner spring in a double spring set and get away with it. Because the valve lift is relatively low on the camshaft you are using, you do have the option of being able to reduce the installed height somewhat to get the outer valve spring pressure higher. Always keep the coil bind measurement in mind as you always want at least 0.050” more than the valve lift before coil bind becomes an issue. Reducing the installed heights can be accomplished by using offset groove valve locks, valve spring shims, and/or reduced height valve spring retainers. Lots of options there.

|

|

By DryLakesRacer - 6 Years Ago

|

|

Ted is so right on the control of valve springs. It seems I have a never ending order thru Summit for different height keepers, retainers, and shims when setting heights and pressure of springs when reassembling cylinder heads. My sons last engine I was able to eliminate the inners and on mine going to beehive style sure changed my parts bins. Too bad nobody will know and understand why have all these boxes of left over “stuff.”.....At least my son understands why we have so many tools.

|

|

By customline3859 - 6 Years Ago

|

|

I will need to look more closely at it, but I believe the heads were machined so that both the inner spring and the outer spring are at the same height.

|

|

By customline3859 - 6 Years Ago

|

Ok, so I was incorrect in my assumption. The inner spring is sitting up much higher than the outer spring. This is definitely my bind issue.

|