|

By 55 GLASS TOP - 5 Years Ago

|

|

Hello when I put my oil pump in I put the washer on the bottom near the pump , I was just told the shaft is inserted from the bottom with the washer on top. Can some one point ME in the right direction . Thanks

|

|

By 55 GLASS TOP - 5 Years Ago

|

|

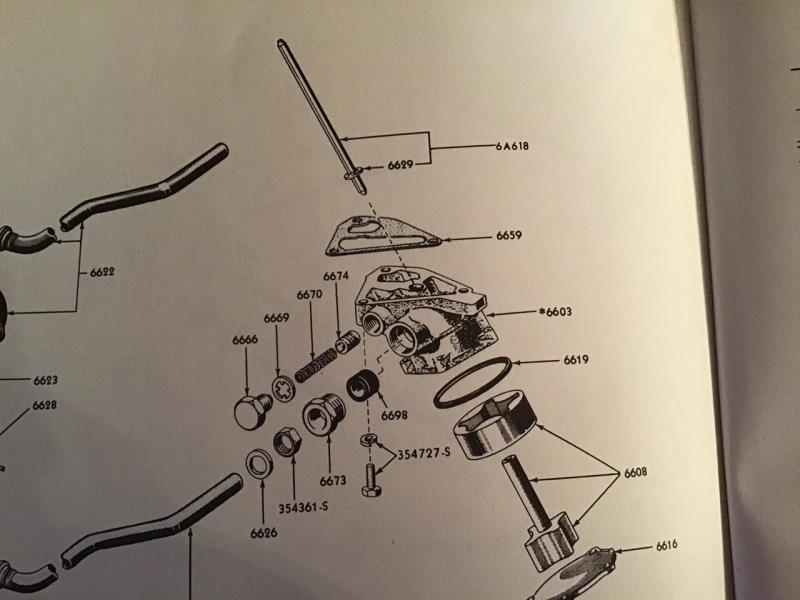

The engine was rebuilt I was going by the old ford unlock rebuild book it shows the washer on the bottom

|

|

By charliemccraney - 5 Years Ago

|

The washer goes on the oil pump end. The shaft is installed from the oil pump end.

The washer prevents the shaft from pulling out with the distributor. This requires that the od of the washer be larger than the id of the shaft hole in the block, making it impossible to install from the distributor end.

|

|

By 55 GLASS TOP - 5 Years Ago

|

|

That is where I put it ,but I was told I was wrong

|

|

By paul2748 - 5 Years Ago

|

They person who told you that is wrong

55 GLASS TOP (2/29/2020)

That is where I put it ,but I was told I was wrong

|

|

By 55 GLASS TOP - 5 Years Ago

|

|

Thanks everyone my confidence has been renewed

|

|

By panel driver - 5 Years Ago

|

Has anyone had one come out of the distributor? I have a ARP oil pump shaft and removed the washer from the shaft. I think i read

a note on Mummerts site that said it was ok to remove it. Thanks

|

|

By 57RancheroJim - 5 Years Ago

|

I wouldn't remove it, thats what prevents the shaft from coming out with the distributor. ARP shafts are known to have the washer on the wrong end, I don't know if that was ever corrected? When I went to install the last one I bought I found the washer was too small and it went right through the hole in the block. I had to remove the larger diameter one from my old shaft and use it. I don't know if anyone else had that experience or I just got a fluke one that someone installed wrong.

|

|

By Ted - 5 Years Ago

|

In the normal course of running the engine, the intermediate drive shaft washers are not required on the oil pump drives. It’s during engine assembly and/or performing any service work that requires the distributor to be removed from the engine that the washers are on the shafts.

The washers are on the oil pump shafts for two reasons. The first is so that the oil pump drive stays in place during engine assembly and doesn’t allow the shaft drop out of the engine when the engine is upside down with the distributor not yet in place. For this reason it’s important that the washer be installed on the oil pump end of the intermediate shaft.

The second reason is to prevent the shaft from disengaging from the oil pump and coming out with the distributor in the event the distributor is being removed from the engine later for service work. Even with the washer in place on the intermediate shaft, there’s no guarantee that the shaft is not engaged in the distributor hard enough to prevent the washer from sliding off the shaft when removing the distributor. But the washer does help in keeping the shaft in the engine when removing the distributor.

As has been already mentioned, the ARP replacement shafts for the Ford Y-Block are problematic in that the washers are installed on the wrong end of the shaft and the washer itself is much smaller than the original sized washers. It’s unfortunate that ARP used the FE, MEL, SBF, and BBF oil pump shaft washer installation scenario on the Ford Y-Block. While this has been brought to ARP’s attention, the ARP shafts for the Ford Y are still being offered with the both the wrong size washers and with the washers installed on the wrong end of the shaft. It’s important that the washer be 5/8” O.D. and not smaller as it takes the larger diameter washer to keep the shaft from moving upwards in the distributor shaft hole in the block.

Maybe if everyone that purchased a ARP intermediate shaft for the Ford Y sent ARP a note about the problem, this problem might eventually be resolved.

|

|

By Joe-JDC - 5 Years Ago

|

|

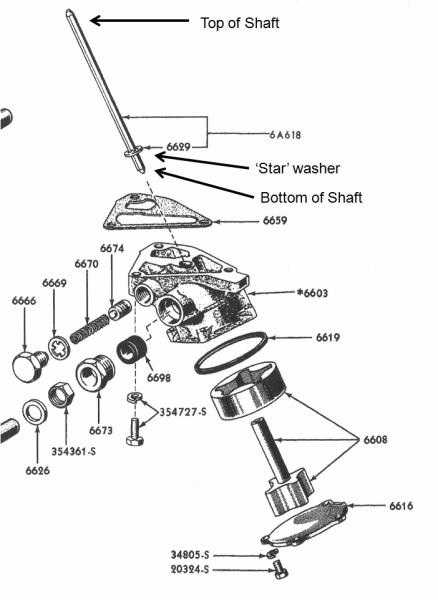

OK, I am confused now. I always install the star washer next to the block under the distributor mounting end of the intermediate shaft, not next to the oil pump end. Joe-JDC

|

|

By 57RancheroJim - 5 Years Ago

|

Assuming you installed the shaft from the oil pump side and the washer ended up at the distributor boss that means the washer is too small. The correct washer won't let it go past the oil pump end hole in the block.

|

|

By Joe-JDC - 5 Years Ago

|

|

Ok, someone needs to clarify terminology. The distributor/oil pump intermediate shaft has two ends, one goes into the oil pump, and one goes into the distributor. The star washer is supposed to be 5/8" diameter, and it fits on the end of the shaft that engages the distributor, not the oil pump end. The star washer butts up against the block so that the shaft cannot be disengaged from the oil pump. To put the star washer on the oil pump end would not stop the shaft from becoming dislodged from the oil pump. Joe-JDC

|

|

By 55 GLASS TOP - 5 Years Ago

|

|

So let me see if I have this right , let’s assume the 292 is attached to an engine stand. I rotate the engine so the crankshaft is up and the intake manifold is down. I now take the oil pump driveshaft with the washer installed and insert the assembly into the engine with the washer towards the floor or the down. The washer is on the end the dizzy fits into. The oil pump slips over the shaft and gets bolted to the block . The washer is out of sight way up in the engine at the bottom of the dizzy. If that is the case I have the washer in the wrong place. But I am beginning to think it just does not matter. Since the pump is not in the pan and if the rod gets displace it really can’t go to far.

|

|

By oldcarmark - 5 Years Ago

|

|

Depends on which Washer You have. Too big to go into Block means it goes on the End that goes into the Oil Pump. That's where it is supposed to go with the 'Original Washer that's too big to go into Block.. If You re-read Ted's Post that gives the Explanation. The Washer supplied with the ARP Shaft is smaller than the Original Proper Washer originally used.

|

|

By Joe-JDC - 5 Years Ago

|

|

I said it correct. The star washer fits on the distributor end. It is on the crankcase side of the block, not the valley side. It is on the end that fits into the distributor shaft to keep it from pulling up through the block and disengaging the oil pump. Joe-JDC

|

|

By oldcarmark - 5 Years Ago

|

Joe-JDC (3/1/2020)

I said it correct. The star washer fits on the distributor end. It is on the crankcase side of the block, not the valley side. It is on the end that fits into the distributor shaft to keep it from pulling up through the block and disengaging the oil pump. Joe-JDC

The washers are on the oil pump shafts for two reasons. The first is so that the oil pump drive stays in place during engine assembly and doesn’t allow the shaft drop out of the engine when the engine is upside down with the distributor not yet in place. For this reason it’s important that the washer be installed on the Oil Pump end of the intermediate shaft. This is from Ted's Post.

|

|

By panel driver - 5 Years Ago

|

So we are saying the 5/8 washer goes on the upper end of the oil pump driveshaft on the side closest to the oil pan to keep the oil pump

driveshaft from coming out of the oil pump. Has anyone ever had one come out of the oil pump under any rpm? Just wondering if i should take

the oil pump off and install the 5/8 washer on the arp driveshaft and reinstall the oil pump. I have the distributor installed. Thanks

|

|

By 55 GLASS TOP - 5 Years Ago

|

|

|

By 55 GLASS TOP - 5 Years Ago

|

|

|

By Joe-JDC - 5 Years Ago

|

Folks, you are messing up with the pictures. That star washer fits under the block side of the crankcase to keep the shaft in the oil pump, not allowing it to come up with a distributor when it is removed from the topside. That picture is with a stock shaft. On the ARP or whoever's performance shaft, the star washer is installed at the top, and installs before the oil pump to keep the shaft in place. The star washer goes on the pointed end which is rounded to allow the distributor shaft to center the shaft when you drop it in place. The squared off end is installed in the oil pump. There is no star washer on the oil pump end of the ARP performance shaft. I just opened up an ARP package, and per their instructions: "Push the retaining clip(star washer) onto the pointed end of the shaft. Then insert the shaft into the pump with the clip facing up towards the distributor. Pump drive shaft also has a mark showing which end is installed up towards the distributor." Joe-JDC

|

|

By Hoosier Hurricane - 5 Years Ago

|

|

Panel driver asked if anyone had the shaft pull out with the distributor. My answer is yes, but not on a Y Block. In '63 I worked at a Lincoln/Mercury dealership. The service manager insisted during a tune-up we pull the distributor and put it on the distributor machine to install the points. I pulled the distributor up on the first FE I ever tuned, and heard a muffled "clunk" as the shaft dropped into the pan. I couldn't retrieve it with a magnet, so I surmised it couldn't get through the screen in the pump pickup, I got a new shaft and sent the car out. Needless to say, I never pulled an FE distributor for a tune-up again. By the way, I always put a 5/8" washer on the oil pump end of a Y shaft.

|

|

By 55 GLASS TOP - 5 Years Ago

|

|

Boy this subject has become a real monster..........

|

|

By paul2748 - 5 Years Ago

|

As long as the washer is between the block and the oil pump, you are ok. Ideally, the washer should be up enough so the shaft will not pull out of the oil pump

Joe-JDC (3/1/2020)

OK, I am confused now. I always install the star washer next to the block under the distributor mounting end of the intermediate shaft, not next to the oil pump end. Joe-JDC

|

|

By blocky - 5 Years Ago

|

|

boy i am loving this so much! how much fun can you have with a drive shaft?? lots and lots by the look of it. cheers!

|

|

By 55 GLASS TOP - 5 Years Ago

|

|

It just goes to show you it’s the little things in life that count

|

|

By 57RancheroJim - 5 Years Ago

|

Joe-JDC (3/1/2020)

Folks, you are messing up with the pictures. That star washer fits under the block side of the crankcase to keep the shaft in the oil pump, not allowing it to come up with a distributor when it is removed from the topside. That picture is with a stock shaft. On the ARP or whoever's performance shaft, the star washer is installed at the top, and installs before the oil pump to keep the shaft in place. The star washer goes on the pointed end which is rounded to allow the distributor shaft to center the shaft when you drop it in place. The squared off end is installed in the oil pump. There is no star washer on the oil pump end of the ARP performance shaft. I just opened up an ARP package, and per their instructions: "Push the retaining clip(star washer) onto the pointed end of the shaft. Then insert the shaft into the pump with the clip facing up towards the distributor. Pump drive shaft also has a mark showing which end is installed up towards the distributor." Joe-JDC

Read again what Ted and I posted. The ARP shafts are WRONG and always have been., They have the washer on the wrong end and the wrong diameter. Washer goes on the oil pump end.

|

|

By Florida_Phil - 5 Years Ago

|

When I rebuilt my TBird engine, I used an ARP oil pump drive shaft. The shaft did not use a washer and none was included. The shaft was thicker in the middle than the hole in the block below the distributor, which prevented the shaft from coming out with the distributor. On prereassembly, I found the oil pump would not bolt down all the way. The ARP oil pump shaft was was too long and was preventing the oil pump from seating all the way. I ground the oil pump end of shaft slightly for proper clearance. As I recall it took about .020" to get it right. My motor has been running for about two years now. I have had the distributor out numerous times without a problem.

|

|

By Ted - 5 Years Ago

|

How did something so simple suddenly turn into rocket science?

I’m in the same camp as John on distributor shafts coming out with the distributors. In that same vein of thought, I’ve pulled down several Ford engines with distributor shafts laying loose in the oil pans. It’s doesn’t take a brain surgeon to figure out why those shafts are sitting there. I’ve even pulled down a couple of engines that had miniature flashlights laying in the oil pans along with the distributor drives. One was a 351W while the other was a FE. Those mechanics must have been having really bad days to have also dropped the lights into the engines while trying to fish out the distributor drives. And before you ask, the batteries were long dead in those flashlights.

The Ford Y and the LYB engines are the only Ford OHV V8’s that requires the ‘star’ washer to be installed at the bottom of the shaft rather than at its top. The Ford FE, M-E-L, SBF, and BBF engines do have the ‘star’ washers installed at the top of the intermediate shafts but that is simply due to those engine designs having oil pumps that are internal to the engines rather than being externally mounted. As a point of clarification, the distributor end of the shaft is the top and the oil pump end is the bottom of the shaft.

As per the original design, the star washer for the Ford Y is 5/8” diameter. What is adding confusion to this issue are the ½” diameter washers used on the ARP intermediate shafts supplied for the Ford Y. Those are the wrong diameter washers and are installed on the wrong end or top of the shaft by ARP. I typically just remove the ½” diameter washers from the ARP shafts and install the correct 5/8” washer on the oil pump end of the shaft. That solves the issue with the ARP intermediate oil pump drive shafts. Because there is minimal hex shaft exposed at the top of the ARP oil drive, the potential is there for the shaft itself to be in a bind with the washer installed at the top because the star washer cannot be low enough on the shaft to clear the bottom of the distributor gear boss in the block. Said another way, the washer is rubbing on the bottom side of the distributor gar boss in the block which creates a new set of problems. While the later model Ford V8’s that use the top fitted ½” washer can be fitted successfully into the engines from the bottom with the washer being directly under the distributor gear boss in the block, the 5/8” diameter washer on the Ford Y intermediate shafts will only fit in the block cavity at the bottom of the block; the larger diameter washer does helps to retain that shaft in place and prevent it from falling out of the top of the block.

For the Ford Y, installing the star washer on the oil pump end of the shaft does keep the shaft engaged in the oil pump as the 5/8” diameter of the star washer is larger than the oil pump shaft hole in the block. The only point to having the washer on the shaft is to keep the shaft in place during engine assembly and when the distributor is being pulled for service work. Once the engine is up and running, the washer on the intermediate shaft serves no purpose. The shaft under normal running free floats between the distributor and the oil pump.

|

|

By darrell - 5 Years Ago

|

|

i always found the fe engines to be the worst for droping the shaft.a lot of people would pull the base but i see a lot just got another shaft.same as i did.

|

|

By Ted - 5 Years Ago

|

More clarification.

|

|

By Florida_Phil - 5 Years Ago

|

The first time I dropped an oil pump shaft in the pan was a night before I was suppose to drive to work the next day. Seemed like a disaster at the time. Funny how all those disasters don't seem so bad now.

|

|

By Joe-JDC - 5 Years Ago

|

|

The last 5 Y blocks I have torn down had the star washer in the wrong place, apparently. And the last three ARP shafts I have bought have been updated, so I apologize if I upset anyone, but my experiences dictated my response. The new ARP shafts do have a square end for the oil pump, and a pointed end for the distributor, with the star washer at the distributor end. Mine installed just fine with their instructions. Joe-JDC

|

|

By FORD DEARBORN - 5 Years Ago

|

In defense of everyone on this thread, I think everyone is correct. At least 2 different styles of intermediate shafts, one same size end to end and another with a larger mid section and two different sizes of star washers, I can see several combinations that will work. If the intermediate shaft is installed with nothing rubbing/binding and the shaft won't pull out with the distributor then it's assembled correctly. If the shaft is not the correct length as mentioned above, then that's a different issue. Sounds like an individual thing depending which style parts you have. I cant add to this because too many years have gone by since I rebuilt my engine. Can't remember if I used a star washer at all since the ARP shaft was the style with a larger mid section.

|

|

By KULTULZ - 5 Years Ago

|

|

At least 2 different styles of intermediate shafts, one same size end to end and another with a larger mid section and two different sizes of star washers

One style shaft being discussed is the OEM Shaft.

The 2nd style shaft being discussed is aftermarket, ARP. The retaining washer used on the ARP FYB replacement shaft is too small and placed by ARP on the wrong end of their shaft. I think the reason they are doing this is the placement of the washer on later engines such as FE. They are simply confused.

Now just to add a little more confusion, FORD used different shaft lengths according to the style of oil pump (gerotor - gear) used. Add to that, CARDONE use of SBF re-man distributor with the wrong length rotor shaft.

|

|

By 55 GLASS TOP - 5 Years Ago

|

|

HOLY COW different lengths a new piece of the puzzle

|

|

By charliemccraney - 5 Years Ago

|

According to the info in the link below, it was a change during 60/61. If that is the case, then it is not strictly the pump style which determines the correct shaft, since both the gerotor and gear pumps existed before 60/61.

http://forums.y-blocksforever.com/FindPost137028.aspx

|

|

By KULTULZ - 5 Years Ago

|

|

According to the info in the link below, it was a change during 60/61. If that is the case, then it is not strictly the pump style which determines the correct shaft, since both the gerotor and gear pumps existed before 60/61.

OK.

FORD used both styles. The gerotor replaced the gear style (FORD). But you cannot buy a new gerotor pump. Now did either FORD or aftermarket suppliers mention the difference in length of shafts or pump height when replacing? Might be a reason(s) some report strange shaft wear.

Now I want everyone to remove their pumps and compare shaft lengths ...

|

|

By miker - 5 Years Ago

|

|

Bad, K. But you always make me smile.

|

|

By KULTULZ - 5 Years Ago

|

|

Bad, K. But you always make me smile.

I have the same effect on women ...

They must think I have a cute butt also as when I walk past one, will occasionally here them whisper, "... what an a$$ ..."

... wait a minute ...

|

|

By Florida_Phil - 5 Years Ago

|

The ARP shaft that I purchased did not have a washer. This surprised me when I opened the box. Perhaps I received an oil pump shaft for a different engine? I took the extra length on the oil pump end as a way to fine tune the shaft for each application. It sounds to me like there are a number of different styles of these shafts. As long as the pump turns without binding and the shaft can't come out with the distributor, the motor does not care which one you use. I have never seen a YBlock oil pump shaft break. Ted probably has. From my experience, the weakest link in a YBlock are the stock push rods. I useed tubular push rods and so far so good.

|

|

By 55 GLASS TOP - 5 Years Ago

|

|

Hmmmm, grown men “comparing shaft lengths” sounds a bit strange

|

|

By KULTULZ - 5 Years Ago

|

|

As long as the pump turns without binding and the shaft can't come out with the distributor, the motor does not care which one you use.

So having a too short intermediate shaft will have no consequence(s)?

|

|

By KULTULZ - 5 Years Ago

|

|

... grown men “comparing shaft lengths” sounds a bit strange

In this day and age? Nothing would surprise me anymore.

|

|

By FORD DEARBORN - 5 Years Ago

|

Florida_Phil seems to have the best scenario. The mid section (ARP shaft) is too large to pass through the pilot hole in the distributor gear thrust pad so no star washer needed. By being a bit too long he trimmed the pump end to make it fit with out binding. This should also insure full engagement into the distributor and the pump.

|

|

By Florida_Phil - 5 Years Ago

|

|

So having a too short intermediate shaft will have no consequence(s)?

I assume most people on this forum possess at least some mechanical ability. If the shaft is too short and falls out of the oil pump, you are screwed,

|

|

By KULTULZ - 5 Years Ago

|

|

By being a bit too long he trimmed the pump end to make it fit with out binding. This should also insure full engagement into the distributor and the pump.

Well (and I am trying not to be aggravating), if the shaft is not the correct length for whiscruber ...  ... ...

EDIT -

... whiscruber ...

... which ever ...

pump is being used, if too short, the DIST end is tapered for easy DIST install, and may not engage the DIST ROTOR SHAFT fully and begin to booger both the pump shaft and/or the DIST ROTOR SHAFT. If too long and the DIST is force installed, you will have binding in both the DIST and PUMP.

And who knows what specs AARP, MELLINGS or any other vendor used according to which style pump or shaft usage?

Please don't hate me ...

|

|

By FORD DEARBORN - 5 Years Ago

|

No hate here, just great we can share all this information for the benefit of all. You picked up on the possibility of a too short intermediate shaft and expanded on it. But if it will make you feel better, I may hold you to your offer from a couple years ago for that beer.

|

|

By Joe-JDC - 5 Years Ago

|

|

After visually checking the block housing, there is a step in the oil pump shaft hole like Ted said that stops a correct size 5/8" star washer. The picture of the star washer makes it look as if the washer goes on the outside of the housing, not inside. That is what started my questioning the answer. As for the ARP shafts, the smaller star washer on the earlier shafts was 1/2", and they would actually pull through the hole where the distributor shaft rests at the distributor end. If you are having trouble wondering if the shaft is too long, or too short, you can easily move it up and down by hand with the oil pump and distributor installed to check for free play movement/engagement. There are many ways to inspect for proper engagement if you take the time and think it through. I found that a small grade 8 washer with a 5/8"od will sit on top of the 1/2" star washer and keep the shaft from coming out when the distributor is removed on my 375 Y back in 2017. I searched the internet for the 5/8" star washers, and came up with zero available. There are all manner of 9/16" and smaller, but no 5/8" I could find. So save any you find when taking apart a rebuilder for future use. Joe-JDC

|

|

By marvh - 5 Years Ago

|

[/quote]

Florida_Phil seems to have the best scenario. The mid section (ARP shaft) is too large to pass through the pilot hole in the distributor gear thrust pad so no star washer needed. By being a bit too long he trimmed the pump end to make it fit with out binding. This should also insure full engagement into the distributor and the pump. [/quote] Florida_Phil seems to have the best scenario. The mid section (ARP shaft) is too large to pass through the pilot hole in the distributor gear thrust pad so no star washer needed. By being a bit too long he trimmed the pump end to make it fit with out binding. This should also insure full engagement into the distributor and the pump.

There was also a problem with some blocks especially when using the ARP HD shafts or Precision Oil Pumps Ford Billet HD driveshaft from slag material left behind when the block was machined at the factory. The drill did not completely pass through top to bottom the machined hole above the oil pump. There was a ring of casting material left un-machined that interfered with installation. Most time rubbing on one side of the HD shafts. Ford even put out a TSB to correct the problem by drilling through this slag material for the early shafts. I would have to check my TSB's for article number. .

|

|

By FORD DEARBORN - 5 Years Ago

|

Very good information as to how the star washer is designed to work at the oil pump end, makes sense. I realize this thread was to question the position of the star washer when after a few posts the ARP shaft was brought in to the fold and that's what I was, and still am trying to clarify. I don't know if the standard stock hex drive shaft is still available or is the ARP the only game in town now? Would be interesting to know if the ARP, with it's larger mid section, is what eliminates the possibility of being pulled up and out through the .454"aprox. pilot hole at the TOP end? Providing the shaft is the correct length, then this would eliminate the need for the star washer, IMHO. Knowing the mid diameter of the ARP should answer this. Thanks, JEFF..............

|

|

By KULTULZ - 5 Years Ago

|

|

I may hold you to your offer from a couple years ago for that beer.

Let it be known that the only reason(s) I imbibe in adult carbonated beverages is social gatherings (including stripper poles), medicinal purposes and supporting the grain farmer community.

That having been said, I also enjoy bull-shiat sessions discussing how fast cars can go ...

|

|

By KULTULZ - 5 Years Ago

|

|

There was also a problem with some blocks especially when using the ARP HD shafts or Precision Oil Pumps Ford Billet HD driveshaft from slag material left behind when the block was machined at the factory. The drill did not completely pass through top to bottom the machined hole above the oil pump. There was a ring of casting material left un-machined that interfered with installation. Most time rubbing on one side of the HD shafts. Ford even put out a TSB to correct the problem by drilling through this slag material for the early shafts. I would have to check my TSB's for article number. .

EXCELLENT INFO!

Please give info as to what period blocks would have been affected.

|

|

By Florida_Phil - 5 Years Ago

|

|

Would be interesting to know if the ARP, with it's larger mid section, is what eliminates the possibility of being pulled up and out through the .454"aprox. pilot hole at the TOP end? Providing the shaft is the correct length, then this would eliminate the need for the star washer, IMHO.

Yes.

Please don't take anything you read on an Internet forum personal. Typing on a computer is not face to face communication. Some of us try to inject some comedy into our responses. Often these attempts are interpreted as being nasty or sarcastic. We are all friends here.

|

|

By FORD DEARBORN - 5 Years Ago

|

Thanks for the "yes" answer and response - I agree.............

|

|

By 57RancheroJim - 5 Years Ago

|

My confusion continues. Did they make different diameter mid sections at some point? When I installed mine from the oil pump end, engine upside down on the engine stand it fell right through and onto the floor. Luckily I still had my old OEM shaft and used the spring washer from it. As mentioned I never found another place that has a 5/8 spring washer. I have a feeling that ARP didn't have a source for a 5/8 washer either and just stuck the 1/2 on it and called it good..

|

|

By Ted - 5 Years Ago

|

|

In measuring a ARP shaft I have sitting here, the diameter at its middle is 0.370” while the pilot hole for the distributor is 0.450”. That means the shaft without any kind of retention washer (AKA star washer) will come up (or fall down) through the distributor hole.

|

|

By 57RancheroJim - 5 Years Ago

|

Ted (3/5/2020)

In measuring a ARP shaft I have sitting here, the diameter at its middle is 0.370” while the pilot hole for the distributor is 0.450”. That means the shaft without any kind of retention washer (AKA star washer) will come up (or fall down) through the distributor hole.

Thank you Ted, that confirms what I have experienced and I'm not totally crazy..

|

|

By FORD DEARBORN - 5 Years Ago

|

ARP shaft 0.370" - Thanks.

|

|

By Lord Gaga - 5 Years Ago

|

Ad nauseam is a Latin term for argument or other discussion that has continued to the point of nausea. For example, "this has been discussed ad nauseam" indicates that the topic has been discussed extensively and those involved have grown sick of it.

|

|

By tbirddragracer - 5 Years Ago

|

|

|

By Florida_Phil - 5 Years Ago

|

Nice! Looks familiar.

|

|

By KULTULZ - 5 Years Ago

|

|

In measuring a ARP shaft I have sitting here, the diameter at its middle is 0.370” while the pilot hole for the distributor is 0.450”. That means the shaft without any kind of retention washer (AKA star washer) will come up (or fall down) through the distributor hole.

TED,

Any chance of getting the length on the ARP shaft?

THANX!

|

|

By 30 coupe - 5 Years Ago

|

|

tbirddragracer, Ernie, that black 57 bird is the nicest one I have ever seen, although not stock. the pictures of your car do not do it justice, it has to be seen in person. love that car . hope to stop in next time I am down in Mineola.---- Jim

|

|

By Ted - 5 Years Ago

|

|

KULTULZ (3/5/2020)

TED,

Any chance of getting the length on the ARP shaft?

THANX!

The two ARP shafts I have sitting here both measure 8.070” for their overall lengths.

Going through my parts bin, I found 23 used Y-Block oil shafts and they range in measurement from 7.990” to 8.090” with a good number of them being around the 8.070” number. There were enough of those at 7.990” though to realize that they were a legitimate low end number and not an anomaly.

|

|

By KULTULZ - 5 Years Ago

|

|

The two ARP shafts I have sitting here both measure 8.070” for their overall lengths.

TED, again appreciated. I know you are a bust man.

So the change to rotor style pump was in mid/1956 production? That explains a lot. Wish I had all of the PRODUCT SERVICE LETTERS of the period.

BTW - I found the advertised length spec on MELLINGS IS-42 Shaft - 8.06" L if anyone needs the info.

|

|

By 55 GLASS TOP - 5 Years Ago

|

|

7 Pages for a washer has to be a record

|

|

By KULTULZ - 5 Years Ago

|

|

7 Pages for a washer has to be a record

It is not a washer so much as intermediate shaft length difference(s) that can lead to a serious problem(s).

An engine is only as good as its' assembly..

|

|

By ian57tbird - 5 Years Ago

|

|

I found this post slightly informative but incredibly entertaining.🤨

|

|

By Lord Gaga - 5 Years Ago

|

I just threw up in my mouth!

PLEASE STOP!

|

|

By 55 GLASS TOP - 5 Years Ago

|

|

it started as a washer and went everywhere

|