|

By Florida_Phil - 5 Years Ago

|

I have a stock 1957 Ford distributor with a Pertronix unit in my 292. I would like to replace it with a full centrifugal advance distributor with an adjustable advance curve. Did anyone ever make such a thing? What are my options?

|

|

By Ted - 5 Years Ago

|

Many of the Mallory distributors were mechanical advance only.

It’s easy enough to convert the Ford distributors to be mechanical advance function only by doing some reconfiguring the mechanical advance curve and simply not hooking up the vacuum advance chamber. Just making the curve where it comes in quicker with no other changes is a big improvement for those OEM distributors. The 406 and 427 Ford distributors were mechanical advance only so that would be the baseline for modifying a Y distributor to fit your needs.

I use a large number of MSD distributors for the Ford Y builds and while these have vacuum advance capability, the mechanical advance portions of those distributors are easily tailored to be suitable for mechanical advance only. The MSD distributors also come with instructions and parts to remove the vacuum advance chamber from their distributors.

|

|

By Florida_Phil - 5 Years Ago

|

A few more questions please. Assuming you are going to modify a stock 1957 Ford YBlock distributor by removing the vacuum canister. Do you cement or otherwise fix the vacumn advance plate so it doesn't move? How much total centrifugal advance do I want for a street driven YBlock? Does this require modifications to the distributor's centrifugal advance mechanism? If so, what are those modifications? At what RPM do I want all the advance in? Thank you!

|

|

By Joe-JDC - 5 Years Ago

|

|

The simple thing is to put a rubber plug on the vacuum cannister, and just set the centrifugal advance with the springs/towers. There is a stiff spring, and a weaker spring attached to the weights and two studs. You can control the amount of tension on the springs by bending the studs outward to stiffen/slow the rate, or inward to quicken the rate of advance. If your distributor has a round stud, you can put a sleeve over the stud to limit travel for less total timing. It is best to have all your timing in by 2500-2800 rpm by most opinions. Some folks like to set the full at 3000 rpm to help stave off detonation if under a long uphill pull. A smooth linear advance is best, and you may have to change either spring to get the best results. Joe-JDC

|

|

By Florida_Phil - 5 Years Ago

|

I wish to remove the vacuum advance canister totally. I assume I could engineer a fixed plate for my 57 distributor? Anyone ever tried this? Why would you want to limit total timing in the distributor?

|

|

By Flatrod - 5 Years Ago

|

|

When I remove the vac advance unit, I first faze the advance plate to line up with terminals in the cap, then drill a hole down from the advance plate to the bottom plate and with a small spacer bolt the two together. Its then locked and only centrifugal advance works and is fazed correctly with the dist cap.

|

|

By Cliff - 5 Years Ago

|

|

A street car needs a vacuum advance system, my car likes 50 deg. advance cruising down the freeway, when I push on the gas the vacuum goes away and so does the advance, without it your car will feel like it's laboring to run at steady highway speeds.

|

|

By Ted - 5 Years Ago

|

I’ll have to ask if you have a Thunderbird distributor or just a car unit that does not have the tach drive. If it’s a Thunderbird distributor, then it’s obviously worth a lot more unmodified. I have had to reverse engineer one of those tach drive distributors on a Thunderbird rebuild where a previous owner had eliminated the vacuum advance chamber and the current engine build required it.

I’m assuming you are just going for the ‘look’ in wanting the advance chamber removed. If it’s just a plain car distributor without the tach drive, then modifying that distributor so it does not have the vacuum advance chamber is doable but that’s a lot of work for the appearance gains you get considering the distributor is essentially hidden behind the intake manifold. Be aware that the ball bearing breaker plate assembly in the 1957-1959 distributors are just a tad more difficult to work with than the later model pivot style breaker plate assemblies. But if intent on having no advance chamber, then another suggestion is using a 289 HiPo distributor (does not have the vacuum advance chamber) and move the shaft and other related parts from a 1960 and newer Y distributor into the 289 HiPo distributor housing. While you’re in there, the springs and advance curve can be modified for optimal driving and performance. The advance specs provided by Joe-JDC above are a good starting point.

|

|

By PF Arcand - 5 Years Ago

|

For regular street use, doesn't removing the vacuum advance tend to hurt fuel economy?..

|

|

By Florida_Phil - 5 Years Ago

|

Thanks for the input. My TBird currently has a stock 1957 passenger car distributor. The only modifications are a Pertronix Unit and lighter Mr. Gasket springs in the centrifugal advance. My vacuum canister is new and functioning. I set my timing with a degree timing light at 36 degrees full advance with the vacuum disconnected. My car seems to respond better with the vacuum line connected. My car does not ping and pulls strong for what it is. I am happy with the performance, but I am always looking for ways to improve it.

I have had a lot of hot rods in my day. I'm old school and have never used a vacuum advance distributor. I always considered vacuum advance distributors as low performance. All my Hipo Fords used either stock full centrifugal advance or aftermarket distributors. When I put a timing light on my engine and watch the pointer, the timing mark does not advance quick enough. It seems to lag compared to my previous experience with Ford distributors. I'm trying to get all the advance in by 3,000 rpm. Years ago, this could be remedied by a quick run down to the machine shop. No one has a distributor machine these days. Should I leave well enough alone or is there performance to be gained here?

|

|

By Tedster - 5 Years Ago

|

There are a LOT of misconceptions bandied about vacuum advance, which stems from the fact it is generally so poorly understood, even by those who should probably know better.

It might be considered "low performance" by some from the standpoint that drag racing application distributors don't even include it. Performance engines aren't driven on the street, these engines are intended to operate exclusively at wide open throttle, consequently the vacuum advance mechanism itself is simply another potential failure point. Since it isn't ever going to be operational, it isn't needed, therefore it isn't used. See the difference?

But vacuum advance has nothing to do with inhibiting or retarding performance as such, because there is no affect at all if it is working correctly i.e. no diaphragm leaks, advance plate sticking etc. Another source of confusion is the terminology itself. "Total Timing" numbers often discussed, does not include vacuum advance. Sounds strange, but it's true.

For street driving, part throttle operation, and cruising on flat ground especially, there is no practical way to achieve the optimum necessary ignition timing advance with mechanical centrifugal weights and springs alone. That's why vacuum advance was invented in the first place. The proper "curve" is not possible.

Estimates vary, though there is somewhere around a 3 to 4 hwy mpg economy loss without it. Engines have better all around driveability and run significantly cooler. I found my Y likes about 52° BTDC cruising. Now this isn't an exact figure because it is measured in the garage, in neutral, with no load on the engine. Vacuum advance is inherently a load operated device. So far though, I've been unable to find anyone willing to sit in the engine bay with a timing light to check it out on the highway at speed.

The Shop Manual shows somewhere around 45° BTDC - total + vacuum advance using a distributor machine if everything is added up - keep in mind OEM numbers are always listed in distributor degrees - not crankshaft degrees - and most Ys had an initial timing of only 3° or 6°.

Short answer: "Yes you want vacuum advance". Nod your head yes.

|

|

By Lord Gaga - 5 Years Ago

|

Leave it alone.Florida_Phil (2/21/2020)

Thanks for the input. My TBird currently has a stock 1957 passenger car distributor. The only modifications are a Pertronix Unit and lighter Mr. Gasket springs in the centrifugal advance. My vacuum canister is new and functioning. I set my timing with a degree timing light at 36 degrees full advance with the vacuum disconnected. My car seems to respond better with the vacuum line connected. My car does not ping and pulls strong for what it is. I am happy with the performance, but I am always looking for ways to improve it. I have had a lot of hot rods in my day. I'm old school and have never used a vacuum advance distributor. I always considered vacuum advance distributors as low performance. All my Hipo Fords used either stock full centrifugal advance or aftermarket distributors. When I put a timing light on my engine and watch the pointer, the timing mark does not advance quick enough. It seems to lag compared to my previous experience with Ford distributors. I'm trying to get all the advance in by 3,000 rpm. Years ago, this could be remedied by a quick run down to the machine shop. No one has a distributor machine these days. Should I leave well enough alone or is there performance to be gained here?

|

|

By KULTULZ - 5 Years Ago

|

|

So far though, I've been unable to find anyone willing to sit in the engine bay with a timing light to check it out on the highway at speed.

... hmmph ...

Can we stop at DAIRY QUEEN afterwards ...

|

|

By charliemccraney - 5 Years Ago

|

|

While you can't check timing easily while driving, you can map the mechanical curve according to rpm and the vacuum advance according to vacuum and use that while taking note of engine rpm and vacuum while driving in order to figure it out. It's probably not all that important, unless you just want to know.

|

|

By kevink1955 - 5 Years Ago

|

Now for the question, with a holley dual bowl replacement carb would you use ported carb vacuum or manifold vacuum and why ?

I understand the concept of bringing advance in at cruse during high vac low load cruse but from which port ??

|

|

By charliemccraney - 5 Years Ago

|

|

Use which ever you like best or works best with the engine. At cruise, the advance behavior should be the same with those. The difference is at or near idle.

|

|

By Ted - 5 Years Ago

|

|

kevink1955 (2/21/2020)

Now for the question, with a holley dual bowl replacement carb would you use ported carb vacuum or manifold vacuum and why ?

I understand the concept of bringing advance in at cruse during high vac low load cruse but from which port ??

As Charlie mentions, you can try it both ways. I find that the engine will have a cleaner idle using the staged or ported vacuum port at the carburetor assuming you are using an unmodified distributor. Unless you set up the distributor accordingly, you could end up with a rough idle with the vacuum hooked up to a direct vacuum source either at the carburetor or the intake manifold. Here’s the link to a past thread on the subject.

http://forums.y-blocksforever.com/FindPost44648.aspx

|

|

By LordMrFord - 5 Years Ago

|

Tedster (2/21/2020)

There are a LOT of misconceptions bandied about vacuum advance, which stems from the fact it is generally so poorly understood, even by those who should probably know better. It might be considered "low performance" by some from the standpoint that drag racing application distributors don't even include it. Performance engines aren't driven on the street, these engines are intended to operate exclusively at wide open throttle, consequently the vacuum advance mechanism itself is simply another potential failure point. Since it isn't ever going to be operational, it isn't needed, therefore it isn't used. See the difference? But vacuum advance has nothing to do with inhibiting or retarding performance as such, because there is no affect at all if it is working correctly i.e. no diaphragm leaks, advance plate sticking etc. Another source of confusion is the terminology itself. "Total Timing" numbers often discussed, does not include vacuum advance. Sounds strange, but it's true. For street driving, part throttle operation, and cruising on flat ground especially, there is no practical way to achieve the optimum necessary ignition timing advance with mechanical centrifugal weights and springs alone. That's why vacuum advance was invented in the first place. The proper "curve" is not possible. Estimates vary, though there is somewhere around a 3 to 4 hwy mpg economy loss without it. Engines have better all around driveability and run significantly cooler. I found my Y likes about 52° BTDC cruising. Now this isn't an exact figure because it is measured in the garage, in neutral, with no load on the engine. Vacuum advance is inherently a load operated device. So far though, I've been unable to find anyone willing to sit in the engine bay with a timing light to check it out on the highway at speed. The Shop Manual shows somewhere around 45° BTDC - total + vacuum advance using a distributor machine if everything is added up - keep in mind OEM numbers are always listed in distributor degrees - not crankshaft degrees - and most Ys had an initial timing of only 3° or 6°. Short answer: "Yes you want vacuum advance". Nod your head yes.

Something around 50 sounds right for me for light highway cruising.

I tried 55 but it was quite high for stock Y.

Even Hollow Heads dragster got cruising area in the spark map. It may never use it but wont hurt a bit.

|

|

By Florida_Phil - 5 Years Ago

|

Ted, thanks for the explanation. I am still confused about a few things.

You stated the following. "For street driving, part throttle operation, and cruising on flat ground especially, there is no practical way to achieve the optimum necessary ignition timing advance with mechanical centrifugal weights and springs alone."

If this is so, why did Ford use all centrifugal advance distributors in their performance engines? HiPo 390, 406, 427 and 289 engines did not have vacuum advance and they were street operated. I have driven many cars with these engines and they seemed optimal to me. However, I can see how that would have a negative effect on gas mileage.

Assuming I can get all my centrifugal advance in by 2,500 rpm, would that make my TBird accelerate faster?

Would timing my engine at 50 degrees total advance (centrifugal plus vacuum) with the vacuum line connected be better than 36 degrees with the line disconnected?

|

|

By charliemccraney - 5 Years Ago

|

It may have something to do with the intent behind those performance engines. I don't know any of the history but for instance, if it is a street / strip intent then simply leaving out the vacuum advance would be a benefit for the strip portion of that. It could also have something to do with warranty. In a drag racing scenario, the vacuum advance can result in over advanced timing in some circumstances, which might cause engine damage. The vacuum advance would still be a benefit for the street portion but since it is a production vehicle with warranty considerations, the manufacturer has to make decisions that reduce warranty claims.

Were some distributors for those vehicles dual points?. Were there dual points distributors with vacuum advance? There may simply not be much room left for that in that case.

|

|

By KULTULZ - 5 Years Ago

|

|

Were some distributors for those vehicles dual points?. Were there dual points distributors with vacuum advance? There may simply not be much room left for that in that case.

Yes and yes.

Dual points were used to increase dwell for a hotter spark.

The BOSS 302 used a DUAL POINT - VACUUM ADV for one example.

The mechanical only DIST were used for a HP Engine(s). People who bought them had no concern for easy drive-ability or fuel economy.

Unless you are operating a SATURDAY NIGHT SPECIAL on the street, the engine needs a vacuum advance, signal source of your choice properly curved (IMO).

|

|

By FORD DEARBORN - 5 Years Ago

|

The HP cars equipped with centrifugal advance only were concerned with strictly one mode of operation, WOT through the RPM range. This would mean the vac advance, if so equipped, would be useless. I fully agree with all above that the vac advance is our friend on the street. In the event the throttle goes wide open, then the vac advance goes back to base and the centrifugal will then be in full control anyways. I like to first set the springs to have all in by about 2800-300 engine RPM. I prefer using a 13* distributor cam so at say 2800 engine RPM that would mean 26* and the rest of the advance will have to come from the initial timing being set at around 10* to 12* or what ever YOUR engine likes best by trial and error as there are many factors that come in to play here. Once I have that set then, and only then will I hook up the vacuum can and begin that process. I must admit I can cheat as I have a Allen distributor machine but a timing light and tack will work also. Fellas, I often have trouble putting in text what I'm thinking so hopefully I didn't muddy the water too much. Hope this helps, JEFF.........

|

|

By Tedster - 5 Years Ago

|

Yes, if you can get the mechanical centrifugal advance portion "all in" at a lower RPM than it is right now, it will most definitely accelerate faster. Can also break stuff, too, if you get carried away.

There are many factors affecting, or limiting this. Both "how much" and "how soon", if you talk to somebody with a distributor machine, they will want to know everything about the car - the engine compression ratio, weight, local elevation, gearing, transmission, fuel quality, etc. "What color is it?" is usually in there somewhere, and they are only half joking. But as mentioned a tach and some experimentation can do the same thing. Just not very quickly. And Ford distributors are not particularly user friendly or convenient for disassembly down to the weights and springs. Particularly the Y Block, with it stuffed back at the firewall.

What people generally overlook is the mechanical and vacuum advance are two totally independent isolated and separate systems, they work in tandem though more or less they work at odds with each other. Clear as mud right?

The mechanical advance is strictly RPM based. The vacuum advance on the other hand is strictly based on engine load. So in typical "street" driving, stop and go, constantly accelerating and decelerating, both mechanisms are constantly adding in, and taking out, small to large chunks of ignition timing, depending on RPM and engine load. In some ways, if it was called "vacuum retard" it would maybe be better understood.

When the RPM is increasing, the vacuum advance has dropped out completely. When the RPM starts to level off, the mechanical advance is decreasing, the manifold vacuum starts to come back up. The effect is probably to cancel each other out, and maintain the amount of advance during this transition. This happens very quickly, in just a split second! If you have a vacuum gauge in the cabin you can see this in action while you accelerate, decelerate, steady cruise, climb a hill, etc. The breaker plate obviously gets a real workout! This is why when tuning, the mechanical curve is always setup first, with the vacuum advance disconnected and plugged. Like the vacuum advance isn't there. Like it's a "performance only" distributor. Takes some test drives.

Then, as someone mentioned, when satisfied, finally re-connect the vacuum advance. Make certain it moves freely, well lubed, though not worn out, etc. Further ignition advance tuning or "curving" at this point is only performed with the vacuum advance, no changes are made to the initial timing or the mechanical advance, as it has now been optomized. This is another area of common mistakes. If the vacuum advance is then found to be pulling in excessive advance at part throttle cruise, the remedy here would not be found by retarding the initial timing setting at the distributor.

Each advance mechanism is tuned separately. I've found that a good tune at highway cruise seems to run notably smoother, with a very crisp exhaust note and clean burning plugs.

So to answer your question (really!) if you wanted a range of say, 50 degrees of ignition advance for a street driven car, how do you get that with just weights?

That was the problem the engineers faced. When cruising at a steady speed in high gear on flat ground, as on the highway, very very little horsepower is needed to maintain it. Maybe 50 horsepower. The carburetor at this point is just cracked open slightly. The cylinders have a very lean air fuel mixture.

In this specific condition, 36° BTDC is not nearly enough advance for optimal fuel burning economy, among other things. I know sometimes people will say nobody cared about gas prices or fuel economy before 1972, but that isn't really true, at least if period radio and print advertising and factory literature can be believed. But, lean fuel mixtures the fire needs to be lit far earlier than a rich fuel mixture. It burns slower. Further range gains can be had by jetting for an economical cruise air fuel mixture. This requires even more ignition advance.

3 or 4 "extra" mpg on the highway doesn't sound like much with today's econoboxes but with a V8, it's significant. OHV V8 equipped cars from the 50s and 60s can achieve 20 to 25 MPG hwy with careful tuning, and still smoke the tires.

It would be possible to install very light springs, and long reluctor slots, and achieve a 50° BTDC advance at cruise, but then the engine would detonate terrible on acceleration just pulling away from a stop sign. Ping city.

See the problem?

Remember too, the typical 36° BTDC is seen only at wide open throttle, conversely when in high gear the mechanical ignition advance at a steady highway cruise may settle into somewhat less. So some vacuum canisters by design might add 15° of advance on top (or more) when cruising on flat ground, when manifold vacuum is highest, that's quite a bit of advance. This is kind of the source of general confusion, I think.

The only time (mostly) when both advance mechanisms are additive is under a specific condition of steady cruise on flat ground, when engine load is very low. In virtually all other driving conditions, the RPM constantly varies widely and so does the engine load. The idea generally though, is that at all times, under all conditions, there is very close to the maximum ignition advance possible short of any engine damaging knock or detonation.

Computerized controls and EFI obviated the need for springs and weights and jetting selection, power valve selection, and checking float height and the rest of it. It's really ingenious though what the engineers were able to accomplish 100 years ago with what they had to work with. It's all obsolete now. And so am I, most likely.

|

|

By FORD DEARBORN - 5 Years Ago

|

"It's all obsolete now. And so am I, most likely." Isn't it most rewarding we can get our heads around this particular vintage engine and solve problems to get it performing better than the designers ever hoped for reliably. How interesting is life when some computer solves these problems and makes these decisions for us? I think this means I'm likely becoming obsolete too.

|

|

By KULTULZ - 5 Years Ago

|

|

How interesting is life when some computer solves these problems and makes these decisions for us? I think this means I'm likely becoming obsolete too.

Computers can be tweaked too ...

|

|

By Florida_Phil - 5 Years Ago

|

Wow! Thanks for the detailed explanation. I never knew what the vacuum advance did until now. Makes sense. As for my car, I have tried it both with and without the vacuum advance connected and it definitely drives better on the street with the vacuum line on. It idles better as well. I have been working on my 57 distributor and found it to be someone finicky. I think this is due to the roller advance plate mechanism. I can see why they replaced it.

|

|

By FORD DEARBORN - 5 Years Ago

|

If the ball bearing type breaker plate is NOT worn, it can easily be soaked in solvent, flushed and blown out with air thus removing all the hardened decades old lube. It's a precision made part, I believe by Timken. Think of all the saved money by switching over to the stamped pivoting breaker plate. One neat feature of the ball bearing assy. is the points or what ever is mounted on it rotates in a true arc about the cam, for what ever that may be worth. It is important to insure the bonding ground wire is in good shape and secure. Also, I have discovered with success, a Ford Duraspark magnetic pickup assy. can be mounted to the bearing plate with modifications. If anyone is interested in doing this, I'll be glad to post pics. That being said, if the bearing plate is worn, they are pricey when ever one is found. Hope this helps, JEFF....................

|

|

By KULTULZ - 5 Years Ago

|

|

It is important to insure the bonding ground wire is in good shape and secure.

Correct as if the DIST is not grounded correctly the current will pass through the plate and cause the ball bearings to go out-of-round.

This plate style was better but also costly to FORD.

|

|

By oldcarmark - 5 Years Ago

|

Florida_Phil (2/24/2020)

Wow! Thanks for the detailed explanation. I never knew what the vacuum advance did until now. Makes sense. As for my car, I have tried it both with and without the vacuum advance connected and it definitely drives better on the street with the vacuum line on. It idles better as well. I have been working on my 57 distributor and found it to be someone finicky. I think this is due to the roller advance plate mechanism. I can see why they replaced it.

I have a NOS Plate if You need it Phil. Bought it on Ebay for $75.00 and then bought a NORS One which has a lot more Balls in it so I will use it instead. The Balls in the Originals tend to go flat also because they only move a little each time  le each time the Plate Advances as well as because as noted lack of a Ground Strap causes the Balls to deteriorate. le each time the Plate Advances as well as because as noted lack of a Ground Strap causes the Balls to deteriorate.

|

|

By KULTULZ - 5 Years Ago

|

|

NORS One which has a lot more Balls

NORS ... ?

|

|

By oldcarmark - 5 Years Ago

|

KULTULZ (2/24/2020)

NORS One which has a lot more Balls

NORS ... ?

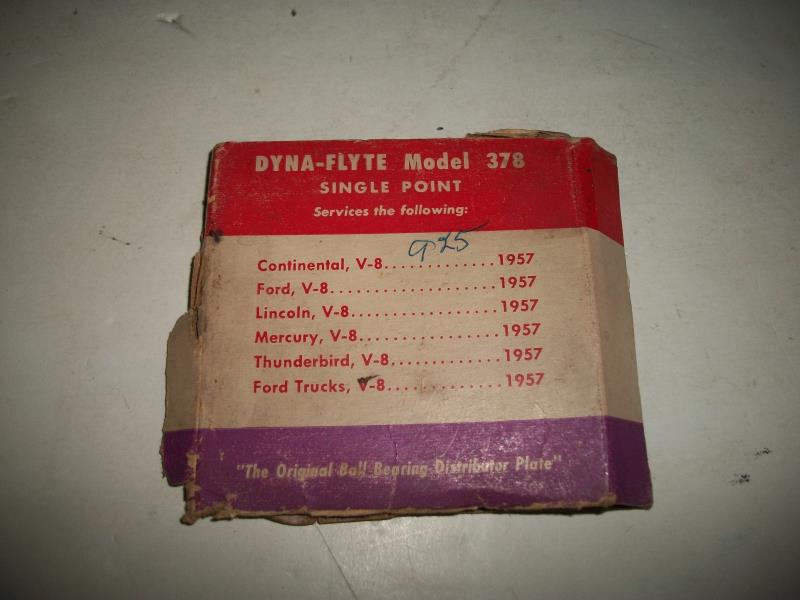

Aftermarket. New Old Replacement Stock. Non Ford. Turns smoother than even the NOS original Ford. The Picture shows about twice as many Balls in the NORS One compared to original Ford.

|

|

By KULTULZ - 5 Years Ago

|

|

Aftermarket. New Old Replacement Stock

Do you know the manufacturer?

|

|

By Lord Gaga - 5 Years Ago

|

JEFF, I'd like to see the pictures of your breaker plate conversion.FORD DEARBORN (2/24/2020)

If the ball bearing type breaker plate is NOT worn, it can easily be soaked in solvent, flushed and blown out with air thus removing all the hardened decades old lube. It's a precision made part, I believe by Timken. Think of all the saved money by switching over to the stamped pivoting breaker plate. One neat feature of the ball bearing assy. is the points or what ever is mounted on it rotates in a true arc about the cam, for what ever that may be worth. It is important to insure the bonding ground wire is in good shape and secure. Also, I have discovered with success, a Ford Duraspark magnetic pickup assy. can be mounted to the bearing plate with modifications. If anyone is interested in doing this, I'll be glad to post pics. That being said, if the bearing plate is worn, they are pricey when ever one is found. Hope this helps, JEFF....................

|

|

By oldcarmark - 5 Years Ago

|

KULTULZ (2/24/2020)

Aftermarket. New Old Replacement Stock

Do you know the manufacturer?

|

|

By FORD DEARBORN - 5 Years Ago

|

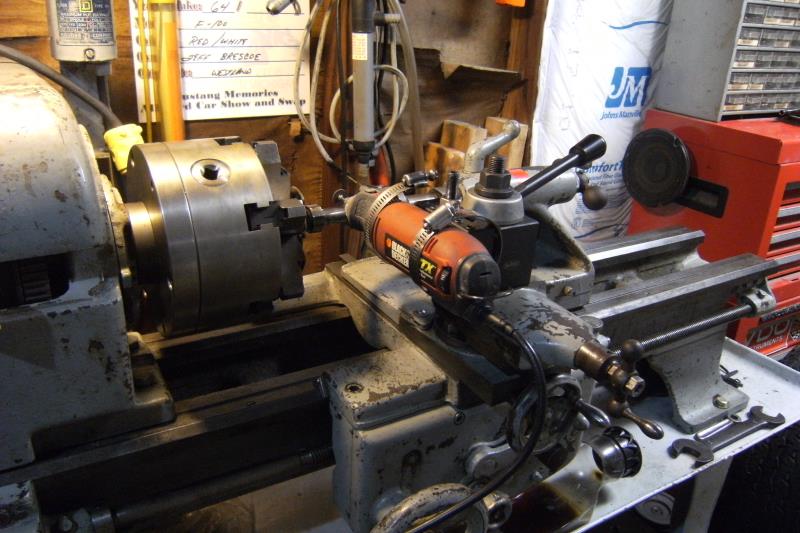

Lord Gaga and all: I'll try to post 6 pics, if the site will allow but please keep in mind there is a great deal of explaining that needs to go with this. Contact info could be exchanged via personal messaging if desired or I'll do my best otherwise

|

|

By KULTULZ - 5 Years Ago

|

THANX! Mark ...

|

|

By Lord Gaga - 5 Years Ago

|

NICE. Thanks.

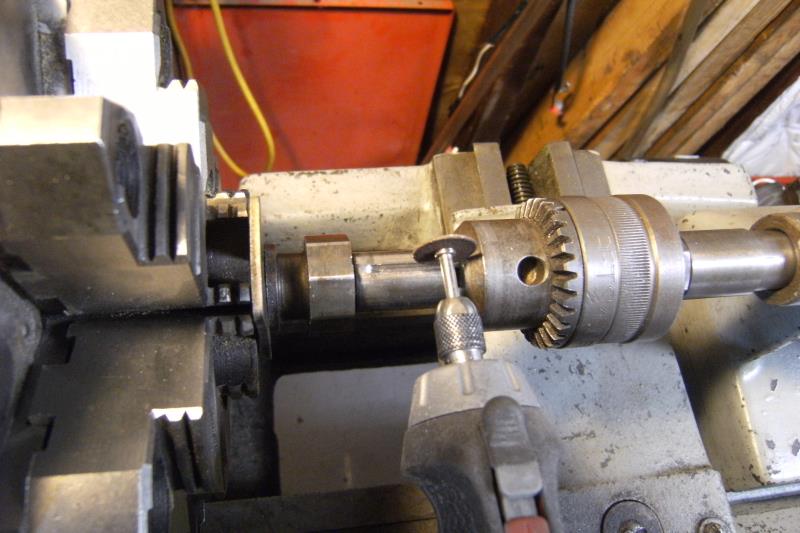

What was the method for locating the roll pin slot and the holes in the breaker plate?

With the Autolite distributors getting real scarce, this is a great way to convert a better designed ball bearing plate dist. to a magnetic pickup (if you have access to a lathe)!

|

|

By FORD DEARBORN - 5 Years Ago

|

I think any Ford Duraspark era shop manual covers phasing of the pole piece and reluctor with the #1 distributor cap tower. That makes utilizing the breaker plate real estate rather cut & dry. If I can remember correctly, I only needed to drill and tap one hole for the modified pickup coil base/bracket. I also drilled/taped another to secure the bonding wire. Like, was able to utilize one of the existing breaker point threaded holes too. The ball bearing plate lent itself very well for this conversion not only because it rotates in a true arc but also for it's flat surface. The reluctor slips over the existing distributor cam and the "paddles" hang down surrounding the cam like a spider with a captured fly. A felt pen marks where the #1 tower is on the dist. rim and with the rotor in place, the parts can be positioned for proper phasing. Then mark the dist. cam where the roll pin needs to be from the slot in the reluctor bore and cut the slot there. The holes are slightly oversized in the pickup coil to allow for tweaking before tightening the two screws. The shim washers elevate the coil to better match the height of the reluctor. Because the reluctor will raise the rotor up, I sanded the open end of the rotor enough to allow it to firmly seat on the can thus engaging the rotor key slot. This doesn't affect the rotor at all. You may ask: Why is he doing all this? I find the Duraspark mag trigger is the most precise trigger out there. It produces a usable clean signal at a much slower cranking speed than the Pertronix device. It will allow the use of a MSD box and it's matching coil. It is also very concentric meaning every trigger event is exactly the same. On an oscilloscope, the pattern is rock solid with no jittery oscillations in cadence with distributor RPM. Not only does the engine start at the touch of the key but the idle is very smooth. I have another distributor equipped with Pertronix and I can notice these differences. Very minor and probably insignificant but if something can be improved upon, then why not? With the MSD box the exhaust smell is also improved. I've been running this setup for a couple years now and IMO, found ti to be the best. There are probably several items I forgot to mention but if brought to my attention, I will try to do my best. I haven't touched on the electrical part of this but MSD supplies the basic schemes for this setup. Hope this helps, JEFF.............. I have to ask: There may be a simpler way to secure the reluctor to the existing cam other than cutting a slot for a roll pin. There is practally no torque/force on it but at the same time, it CAN'T be allowed to slip. One other aspect of this conversion is I can easily go back to Pertronix, points or? anytime.

|

|

By FORD DEARBORN - 5 Years Ago

|

I should have added that a Pertronix will trigger an MSD box also but for reasons stated above, I found the magnetic device to be more precise at a slower speed.

|

|

By Lord Gaga - 5 Years Ago

|

Thanks much for taking the time to share that info. It's a great solution.

I personally never thought much of the tiny reluctor of the pertronix, your comments about a smooth more stable signal with the Motorcraft unit confirm this.

|