|

By Vic Correnti - 6 Years Ago

|

|

Are all car and Thunderbird clutch forks the same? Is the angle from the pivot to the throw out bearing and the pivot to the clutch linkage adjustment ball a different angle? In my 1955 Thunderbird the adjustment end seems to be farther forward with the car fork I am trying to install with a clutch which is not a stock one but one more for street and drag racing. The pressure plate is 1/2 inch taller then the Centerforce one I am replacing which moves the adjustment end farther forward.

|

|

By Florida_Phil - 6 Years Ago

|

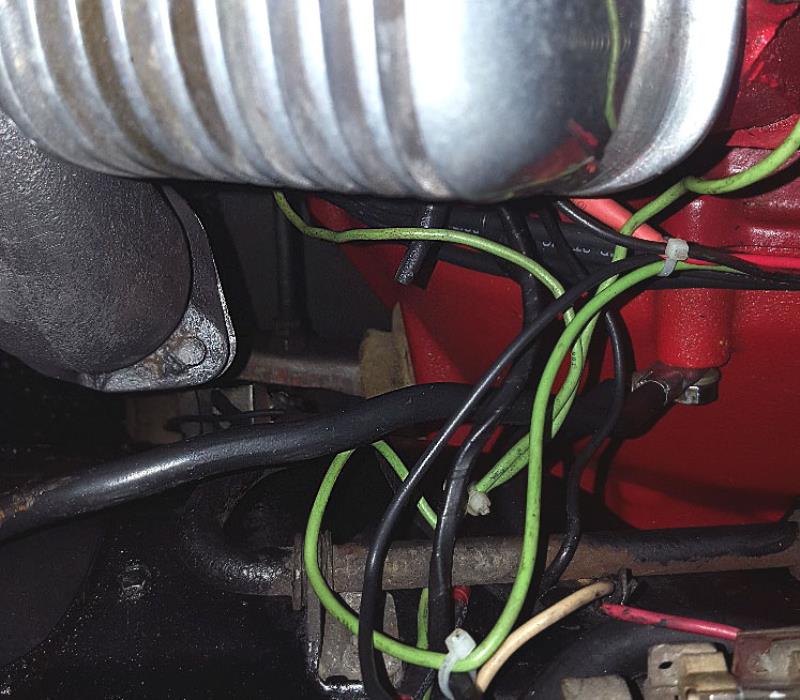

I believe all Y-Block passenger car clutch forks are the same. I could be wrong. Here is a photo of the clutch fork in my 1955 TBird. You can see the angle of the fork as it comes out of the bell housing. My car has it's original linkage and a stock clutch.

|

|

By Vic Correnti - 6 Years Ago

|

|

Phil thanks for the reply and picture. Mine looks pitched more forward by the looks of it. It seems to operate ok just looks quite different then it did. How do you post a picture I forgot how to and it must be a secret on this site because it sure as heck is not obvious?

|

|

By Florida_Phil - 6 Years Ago

|

The photo needs to be somewhere on the device you are using to access this forum. I email my phone photos to my home PC. Hover over the + Inset Button below the edit box. Click Insert Image, then Browse to the photo. Open the image and upload it to the Forum. Most Forums require loading the image to an outside location. This one's easy.

If your clutch disk or pressure plate are thicker than stock, your clutch fork angle will be more toward the front. This shouldn't be an issue unless it messes with the clutch linkage geometry. If they are, you may have to make some modifications.

|

|

By oldcarmark - 6 Years Ago

|

|

To ad Photo click "Insert" at the bottom. This opens several symbols. Click the "mountain with Sun" symbol. Choose your Picture from your Picture file and click on to hilite.. Click open. Picture will download to your Topic.

|

|

By Vic Correnti - 6 Years Ago

|

|

|

By Vic Correnti - 6 Years Ago

|

|

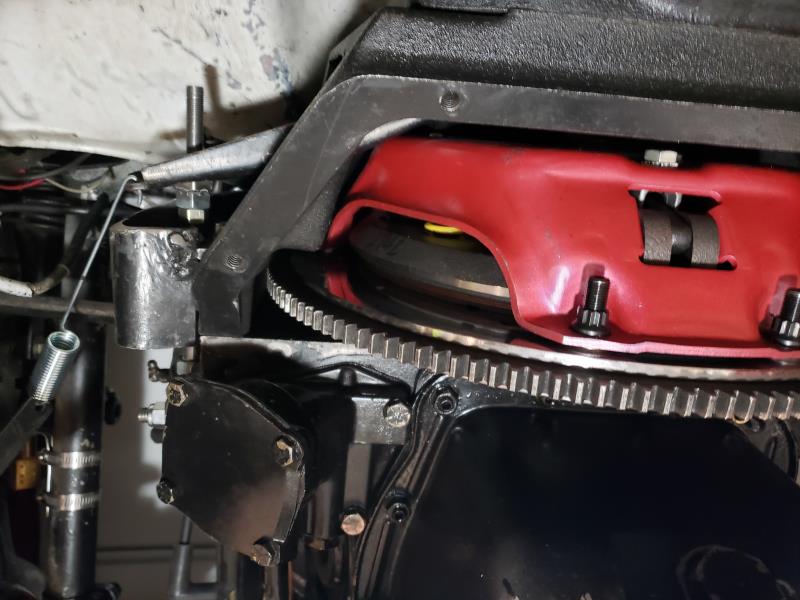

Looks like my text got lost from the picture. In the picture the fork is pitched forward some more then the previous one do to the 1/2" taller pressure plate and that is why I was wondering if there was a different part number car clutch forks that might have a different angle.

|

|

By charliemccraney - 6 Years Ago

|

|

Can you make the pivot on the bellhousing shorter?

|

|

By Vic Correnti - 6 Years Ago

|

|

I'm not sure that will help, I'll try to explain. This clutch is a long style and also as the rpm increases the weight at the end of the forks applies more pressure which in turn pushes the fingers and throwout bearing back towards the transmission, like a 1/4", so it needs more pedal free play. That free play is putting the fork closer to the pressure plate. I had to cut .100 off the throw out bearing collar to get the room for that 1/4" movement. I have the option to remove .020 of shim where the pressure plate is mounted to the flywheel and I believe that will move the 3 forks in .100 which will help. That will require me to get help to remove everything, transmission, scatter shield, bellhousing etc to get to the shim for the fourth time and I am getting real tired of all this!

|

|

By charliemccraney - 6 Years Ago

|

|

Is there a stop under the dash that can be repositioned or modified to get the free play on that end? The pedal will be higher but it might not be too annoying.

|

|

By Vic Correnti - 6 Years Ago

|

|

Charlie, I have it adjusted as far as I can between the transmission collar and the throw out bearing collar which is .225 clearance. This means the clutch pedal is almost half way to the floor before everything is loaded up and starts to unload the clutch.

|

|

By charliemccraney - 6 Years Ago

|

Right, that doesn't change the relation of the fork to the pressure plate.

Removing those shims might be the easiest thing to do. In addition to changing the relation of the fingers, it will give another .020" between the pressure plate housing and fork.

A shorter pivot would also help, if possible. It will change the position of the fork by more than the amount it is shorter because if you move the fork back, it also has to rotate toward the pressure plate in order to achieve the same free play, which moves it even farther from the housing. 1/16" shorter pivot might move the fork 1/8" or 3/16" from the pressure plate housing, whatever the ratio may be.

Did the stock clutch not use a long pressure plate or does this one just behave differently?

|

|

By Vic Correnti - 6 Years Ago

|

|

Your right I'll have to pull everything apart again, crap. The .100 will move things quite a bit and give more clearance at the fork because the bearing will move forward 100. The original was a long style but the one I am replacing was a dual friction Centerforce diaphragm style which was a 1/2" shorter. If I get this figured out it should be the hot setup for a street/strip clutch. It's made to slip on the launch which should mean less broken parts, maximum traction and have a light pedal pressure. Now if I can find someone to help me because these parts get heavier everytime I do this.

|

|

By ian57tbird - 6 Years Ago

|

Hi Vic.

The only thing with dual plate clutch is you may notice you'll have to slow the shifts down slightly. The synchros have to do more work to alter the speed with the extra weight of the clutches.

Good to hear the car is still going strong.

|

|

By Vic Correnti - 6 Years Ago

|

|

Iran, this is a single sintered steel disc that is supposed to slip. The disc does not have any springs in the center area and the sintered steel grabs better then the composite ones so the pressure is less and then as rpm goes up the centrifugal force makes it grabs more. They say I will leave at a lower rpm and once I get things figured out no wheel slip and less chance of breaking parts because of the slippage. It is totally adjustable and street friendly.

|

|

By slumlord444 - 6 Years Ago

|

|

If the clutch goes halfway to the floor before starting to disengage the clutch I would think all you have to do is lengthen the rod from the arm to the piviot. Its the one with the threads that you use to adjust the free pedal. I've had to play with it in the past to get the proper free pedal. Cut it and weld in a piece of rod. Worked for me.

|

|

By Ted - 6 Years Ago

|

I had similar issues on my 427 Fairlane with the clutch linkage flexing when using ‘stiffer than oem’ pressure plates. I ended up welding up the two piece bell crank and adding braces to stop the twist that was occurring when pushing down on the clutch pedal. I also replaced all the original plastic bushings at the swivel points with machined brass. There were two bushings under the hood and two more under the dash. After doing all that, free play in the clutch pedal was greatly reduced.

|