|

By texasmark1 - 6 Years Ago

|

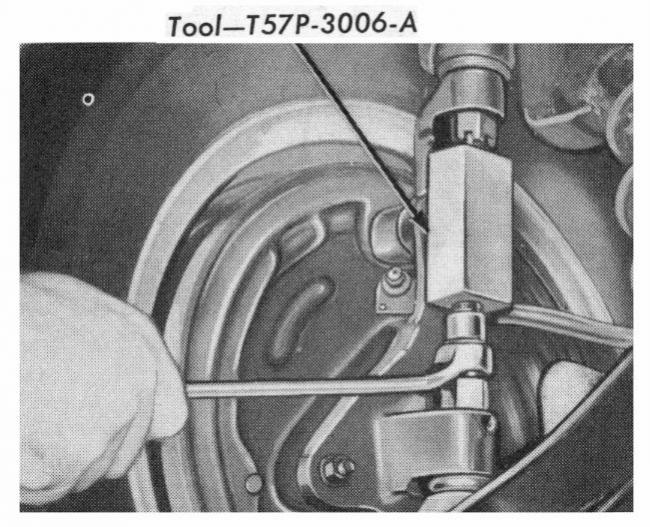

In my 1957 Fairlane service manual, page 4-7 "Front Suspension Repair", there is a picture of Ford tool T57P-3006-A.

It's used to break the upper and lower ball joints from the steering spindle.

I seriously doubt that I can locate this tool so I'm seeking a substitution...

Anyone have any suggestions? I'm trying to remove the ball joints from the spindle but leave then in the upper and lower control arms.

Suggestions would be greatly appreciated.

thanks, Mark

|

|

By 57RancheroJim - 6 Years Ago

|

I use a pickle fork. That may do damage the the rubber boots, something I don't worry about because I usually change the ball joints anyway.

|

|

By texasmark1 - 6 Years Ago

|

well, I was trying to keep the ball joints as I believe they are still good... no looseness and such...

plus, I'd prefer not to install Chinese parts which is about all that I've been able to find.

|

|

By oldcarmark - 6 Years Ago

|

I made a Tool similar to the Ford Tool. Using Hardware from Home Depot. And it works.   Don't destroy the Ball Joints as the replacements are inferior. Most are made Offshore U know where. Don't destroy the Ball Joints as the replacements are inferior. Most are made Offshore U know where.

|

|

By texasmark1 - 6 Years Ago

|

That's exactly what I'm looking for... put tool between the upper and lower ball joints and turn the tool so that it extends in length and pushes the ball joints our of the spindle!

could you provide a few specifics about the various parts that you used to construct it??

thanks in advance, Mark

|

|

By MoonShadow - 6 Years Ago

|

|

Check your local Oreilly's auto parts. They have a lot of "loaner" tools including a ball joint removal tool. They require a deposit for the replacement value of the tool. So if you don't get back with it in a few days you've bought it.

|

|

By texasmark1 - 6 Years Ago

|

|

... not trying to remove the ball joints from the control arms; trying to back them out of the spindles without damaging them...

|

|

By Robs36Ford - 6 Years Ago

|

I use this one to push the stud and pop it out of the spindle. It has never damaged the boot.. so far. Sometimes called a pry bar!

|

|

By texasmark1 - 6 Years Ago

|

|

where can these items be found?

|

|

By Vic Correnti - 6 Years Ago

|

|

I have used threaded rod cut to length with a nut at both ends then back off the nuts to pop them loose. Nothing fancy but works for me.

|

|

By Robs36Ford - 6 Years Ago

|

oriely sells a couple and others likey have them.

|

|

By 62bigwindow - 6 Years Ago

|

|

I used a pickle fork on mine. It will tear up the boot and cup washers but those are available new and probably should be replaced anyway

|

|

By KULTULZ - 6 Years Ago

|

|

where can these items be found?

This type of tool is best found (IMO) at OTC TOOLS. They were (are) a major supplier of FORD SPECIAL SERVICE TOOLS.

|

|

By Hoosier Hurricane - 6 Years Ago

|

|

I back the nut off a couple of turns, and take a big hammer and hit the spindle where the taper of the ball joint stud is seated. Hit it squarely on the side of the spindle boss. 2 or 3 raps usually unseats the ball joint. Do not support the A arm at this point, let the spring pressure help you. That's why the nut is left on but loose, so the thing won't fly apart. After you break the joints loose, then you can support the A arm and take the ball joints out. Also works on the tie rod ends.

|

|

By Florida_Phil - 6 Years Ago

|

I assume you are going to replace the control arm bushings too? I borrowed a bushing tool kit from the local auto parts store. Made the job a little easier. No charge unless you don't return it. Have fun.

|

|

By texasmark1 - 6 Years Ago

|

Thanks for all the suggestions!

I now have some more ammo with which to attack the job.

Mark

|

|

By oldcarmark - 6 Years Ago

|

|

The Tool shown in Shop Manual will not separate Ball Joint from the Control Arm on its own. It is used to put pressure on the Stud and then a good rap from Hammer on the Spindle should cause the Stud to pop out. Just pay Attention to what You loosen and how much. There's a lot of tension on the Suspension from the Coil Spring. Work safely.

|

|

By texasmark1 - 6 Years Ago

|

|

BTW OTC Tools is still with us; just checked out their website.

|

|

By KULTULZ - 6 Years Ago

|

|

I never use piclke forks when it can be avoided. They always destroy the rubber boot, and leave gouges in the spindle. When working on a Shelby worth $100,000 or more, gouging the spindle is considered bad form.

Read this - https://www.vintage-mustang.com/threads/found-the-best-ball-joint-separator.977657/

Just SAY NO to pickle forks and BFH's

|

|

By texasmark1 - 6 Years Ago

|

about to get desperate...

went to Home Depot; found a "coupling" used in plumbing, threaded all the way thru, but then could not find any bolts with the same thread pattern to screw into both ends then put the tool in place and back out the screws/bolts to break the ball joints loose.

been beating on the spindle bosses too but can't get any movement that way.

there's an outfit named Grainger in my area; sells all sorts of industrial parts and tools. Guess they'll be my next place to try.

again, thanks for all the suggestions... sure wish I could locate the old Ford tool shown in the shop manual!

Mark

|

|

By pintoplumber - 6 Years Ago

|

|

Plumbing threads and bolt threads are different. They make threaded rod couplings which are bolt threads. Get one of those.

|

|

By KULTULZ - 6 Years Ago

|

|

sure wish I could locate the old Ford tool shown in the shop manual!

Mark

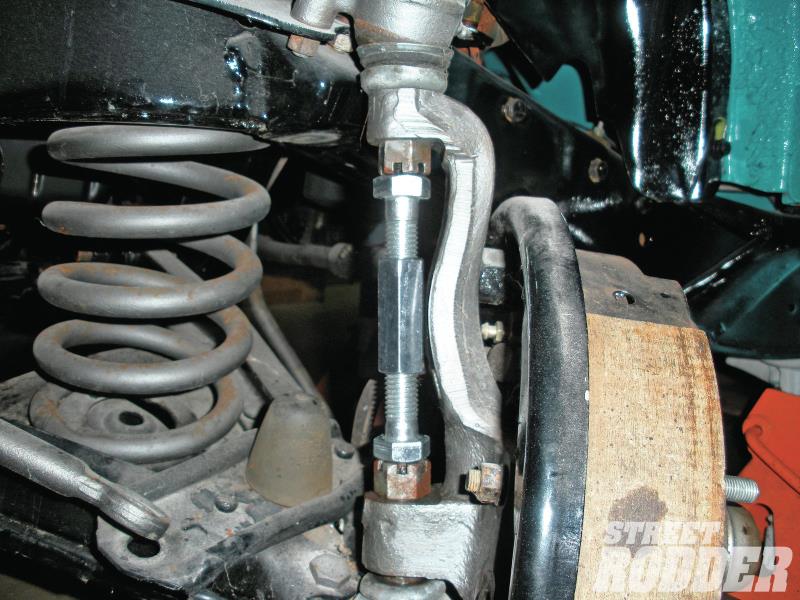

Here is a home made version and they are dangerous as they are not hardened -

Now here is a copy of the FORD TOOL using hardened steel, acme threads and a bearing to make the turning easier. All of this can be sourced from the OTC Catalog. They have loose parts such as this to service old tools or fabricate.

Be careful of using one not hardened as it can explode in your face.

|

|

By texasmark1 - 6 Years Ago

|

so a threaded coupling and a couple of bolts...

OTC here I come!

in the same vicinity as my ball joints, I'm trying to get my idler arm off but the two grease-fitting equipped nuts refuse to come off... they will turn a few rounds then tighten back up!

anybody else have this happen?

|

|

By MoonShadow - 6 Years Ago

|

|

Thanks for the picture. I couldn't see how it worked but now it is clear.

|

|

By KULTULZ - 6 Years Ago

|

|

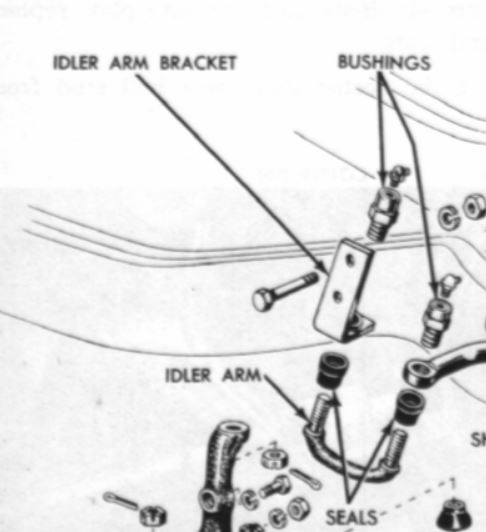

... in the same vicinity as my ball joints, I'm trying to get my idler arm off but the two grease-fitting equipped nuts refuse to come off... they will turn a few rounds then tighten back up!

anybody else have this happen?

It is described in your SHOP MANUAL. There are two sections, one for MS and another for PS.

|

|

By texasmark1 - 6 Years Ago

|

yes it's described in the shop manual... simply says "remove the idler arm from the bushing..."

what I've encountered is no matter how many ways I try to remove it, both nuts will come loose for a few turns then tighten up again.

am I dense on this one?

|

|

By KULTULZ - 6 Years Ago

|

|

what I've encountered is no matter how many ways I try to remove it, both nuts will come loose for a few turns then tighten up again.

No, you are not dense. This is MANUAL STEERING, correct?

|

|

By KULTULZ - 6 Years Ago

|

If MS, the bushings themselves screw into the idler arm bracket and drag link end. Turn the bushings in the opposite direction.

To re-assemble complete arm, follow directions carefully as it determines pre-load adjustment. Actually, read the install section first and this may give you a better idea of how to take apart.

The PS arm is completely different.

|

|

By oldcarmark - 6 Years Ago

|

|

Page 177 of Shop Manual explains how to dis-assemble the Idler Arm. Unbolt the Idler Arm Bracket from Frame. Unthread the arm from nut on Bracket by turning the Bracket. The Arm is removed from end of Drag Link the same way. The Nuts come out last as they are threaded into Idler Arm Bracket and Drag Link. If U are trying to undo Nuts first that is where your Problem is.

|

|

By texasmark1 - 6 Years Ago

|

|

I've tried both directions; they loosen up a bit and then get tight again!

|

|

By texasmark1 - 6 Years Ago

|

just read the latest post... that must be my problem!

will try it the right way now.

thanks!

|

|

By KULTULZ - 6 Years Ago

|

|

The Nuts come out last as they are threaded into Idler Arm Bracket and Drag Link. If U are trying to undo Nuts first that is where your Problem is.

There you go, a more exact description. The arm itself is threaded and must be un-srewed from the actual bushings and then remove the bushings from the idler arm bracket and drag link end. The bushings are threaded externally as well as internally.

|

|

By texasmark1 - 6 Years Ago

|

thanks; figured it would be simple... if I knew what I was doing!

Mark

|

|

By oldcarmark - 6 Years Ago

|

Glad U figured it out. Picture of Parts I used to make Tool. 3/4 inch diameter Bolts and connector. U may have to go to a store that sells Hardware etc as a specialty.

|

|

By texasmark1 - 6 Years Ago

|

bought the same part today.

back to the idler arm, should I leave the bracket attached to the frame and the remove the bushings then the arm?

I've got the bracket and idler arm loose from the frame but can't get any leverage on it.

|

|

By oldcarmark - 6 Years Ago

|

|

Take the Arm and Bracket off the Frame.I would use a Bench Vise to hold the Bracket to undo the Bushing..

|

|

By texasmark1 - 6 Years Ago

|

finally got it!

took my college graduate son to read the shop manual correctly and show me how it's done.

for those of you who have been on this forum for some time, he's the one who had the 63 Monterrey that we restored a few years ago for which I posted some details.

he was smarter than dad before college and now he's even more clever! ... the good kind of clever.

thanks again to all who chimed in on my headscrather!

Mark

|

|

By KULTULZ - 6 Years Ago

|

|

took my college graduate son to read the shop manual correctly and show me how it's done.

Don't feel bad. FORD PUBLICATIONS such as a SHOP MANUAL is printed in a style that usually only experienced FORD TECHS can understand initially. FORD PUBLISHING assumes that the reader has certain skills and experience.

It is not your reading comprehension that is at fault.

|

|

By 2721955meteor - 6 Years Ago

|

|

if you have a obey act torch or can rent 1,very easy to distant your 57 front balljoints,loosen the top nut so you have 1/8 gap nut to spindle jack up the side you ar working on,heat the aria above the loosens nut in 1 ariaupand down when red if it has not separated hit with a hammer,then do the same on other end. the obey and agent is a best investment for working with this ancient iron

|