|

By Rono - 6 Years Ago

|

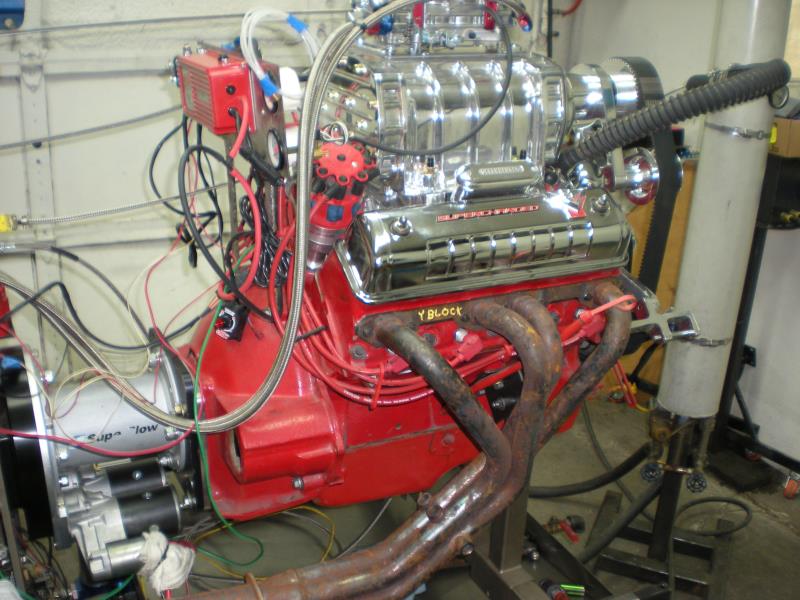

I've been holding off posting anything on the dyno testing of my 331 cu. in. motor because it's still ongoing. We have only done 2 pulls to 5,000 RPM and still are trying to dial in the A/F ratio and timing. The motor seemed to like more advance on the first pull which was 42 degrees all in at 2950 RPM making 5.5 psi boost at 5000 RPM with 10% under-drive pulley set up. We have changed the secondary jets (bigger) and and have modified the power valve restrictors, but something seems to still be holding the motor back. We will be doing more testing today. We have burned up a few O2 sensors, but they have been very helpful in determining how each cylinder is burning.

|

|

By NoShortcuts - 6 Years Ago

|

Rono. Sorting-out the engine set-up you've got on a dyno can make a lot of difference and save you a lot of frustration. NOT inexpensive, I'm sure, BUT money well spent. in dialing it in AND not driving you crazy accomplishing it.

I'm surprised at how much advance the engine likes, but I suspect that tuning a supercharged engine is a different game from anything I've ever worked on.

Best Wishes, Always,

Charlie

|

|

By Rono - 6 Years Ago

|

Charlie;

I've learned a lot over the past couple of days working with the shop owner on this. Today we got the A/F ratio mixture almost perfect by changing jets and the Idle and power valve restrictors. We set the timing back to 37 degrees all in and the boost control dial off the MSD box to 0. We basically tuned it for a street driver. I left the pulley's the way they were, at 10% under-driven and we got 7.5 lbs. boost at 5500 RPM. One issue I didn't consider was the cam which I never changed after giving up on the VS-57 unit. That cam was purchased for that blower and had 110 degrees lobe separation and 17 degrees overlap. For this blower the shop owner Frank said this cam should have 112 degrees lobe separation with only about 7 degrees overlap. I won't be changing the cam any time soon so it is what it is.

|

|

By Daniel Jessup - 6 Years Ago

|

|

any numbers Rono?

|

|

By Rono - 6 Years Ago

|

|

375 Ft. lbs of Torque at 4900 RPM. I'll just say the motor made between 3 and 400 HP, but didn't make any additional power over 4900 RPM and we think it was the cam profile that was the culprit. The Comp Cam that I had installed for the VS-57 supercharger had 17 degrees of overlap and 110 degree lobe centers. I believe the cam choice was based on the fact that you couldn't run the motor above 5500 RPM without over-spinning the supercharger and possibly burning up the ball drive. A more appropriate cam profile for the roots style blower may be a 114 degree lobe center and maybe 7 degree overlap. so that the boost wouldn't just blow out the exhaust. The motor did run well though so I am going to run it the way it is for a while.

|

|

By MoonShadow - 6 Years Ago

|

Talk to Ted about the cam he put into my 4-71 combination. It is super friendly on the street but makes horsepower too.

|

|

By Rono - 6 Years Ago

|

|

Will do, Thanks!

|

|

By Cliff - 6 Years Ago

|

Hi, what cylinder heads did you use and what was done to them? also what is the deck height?

Thanks Cliff

|

|

By Rono - 6 Years Ago

|

|

Cliff; The heads were ported (by me) 471 heads. Not sure of the deck height.

|

|

By Cliff - 6 Years Ago

|

|

I run a 312 .060, with 471 heads, exhaust porting only, Isky RPM 300 cam and kit, stock manifolds (intake and exhaust), Holley 3310, spalding flamethrower, and a vs57 with a sn 2000 back half, it runs hard for what it is, I turn it about 6500, the engine comes on about 3500, I think you should be making at least 450 HP @ 6000, have you checked the cam timing? I have seen timing gears retard the cam as much as 2 1/2 deg.

|

|

By pegleg - 6 Years Ago

|

Ron,

Less over lap and less timing will help. Try to keep the total down to 30 or 32 unless you want to buy race gas.

|

|

By Rono - 6 Years Ago

|

Frank;

Thanks for the advice! Here is some additional information I have learned thanks to Moonshadow and Ted. Comp Cams are NOT a good choice for Y Blocks because of the lifter bore angle. Apparently, Comp Cams grounds their cams based on a 41 degree lifter bore angle common to scrub motors. The Y Blocks use a 43 degree lifter bore angle, so in my case, the valve timing was off. I think this is what caused my issue on the dyno. Ted provided me the Isky cam card he used with Chuck's build, so with Chucks blessing, I plan on having a new cam ground with those same specs. Bad news is I will have to replace the lifters also which requires a complete tear down of the motor. Well, the coupe is not done anyway so I may as well do it now...this winter.

|

|

By MoonShadow - 6 Years Ago

|

|

No blessing required from me Rono. Can't wait to hear that motor whine. Chuck

|

|

By Rono - 6 Years Ago

|

|

Thanks Chuck! I talked to Isky about your cam and it is a custom grind. I'm wondering if I can get the new lifters installed with just removing the crank but leaving the pistons and rods in the block?

|

|

By charliemccraney - 6 Years Ago

|

|

If it is on an engine stand, I would try to do it without removing the crank. People do it in the vehicle with the crank in place so on a stand,with the engine upside down, it has to be a lot easier. That said, as I get older, I'm learning to identify when shortcuts aren't actually shortcuts and if it became evident that it is a big pita, I would remove the crank.

|

|

By Rono - 6 Years Ago

|

|

Thanks Charlie..good advice, but are you saying that the rods and pistons need to be out? The motor will definitely be on an engine stand when I attempt this. I especially hate to pull apart a perfectly good rear main seal.

|

|

By charliemccraney - 6 Years Ago

|

|

I'm saying I wouldn't remove any more than necessary until I tried replacing the lifters with the crank, rods and pistons installed. If it seems too difficult after making an attempt, remove it.

|

|

By Cliff - 6 Years Ago

|

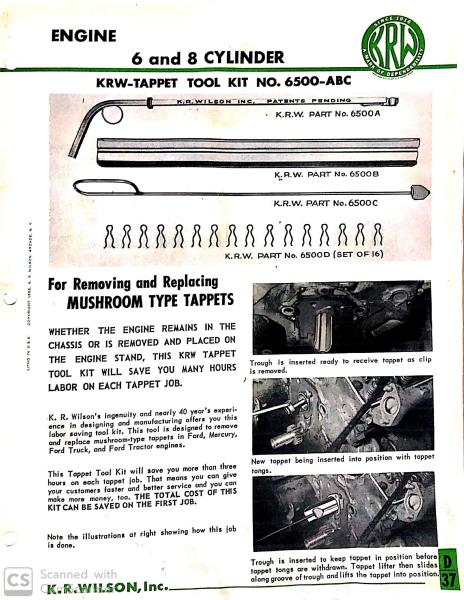

Yes you can, plenty of room around the crank and rods, or if you can find KRW # 6500 ABC tool you can replace the lifters in the car or on the stand without removing the oil pan. without removing the oil pan.

|

|

By MoonShadow - 6 Years Ago

|

|

It can be done with a long armed magnet but is still difficult. I've seen people try to pass the magnet down through the lifter hole and bring them up that way. I would at minimum remove the crank. I couldn't be happier with this cam. It has a nice smooth idle with minimal supercharger surge. Starts great too. When you push on the gas it go's without lag. Great street blower cam in my book.

|

|

By FORD DEARBORN - 6 Years Ago

|

Rono, with the engine on a stand, it can be done with one of those small "super" magnets on a telescoping wand. There is a learning curve getting the magnet to land on the lifter. If I had to do this again I would use the magnet and not pull the crank. Why not give it a try before pulling the crank? Hope this helps, JEFF...................

|

|

By KULTULZ - 6 Years Ago

|

Anyone seen this -

https://www.youtube.com/watch?v=G7teHiBlwcM

|

|

By Cliff - 6 Years Ago

|

Here is the tool

|

|

By paul2748 - 6 Years Ago

|

Every one says never use the old lifters on a new cam. I'm sure it has been done with no bad effects, but!!!!

|

|

By Oldmics - 6 Years Ago

|

Cliff

If that tool is for sale -PLEASE CONTACT ME !!!!!!

Oldmics@Yahoo.com

|

|

By Rono - 6 Years Ago

|

It's a real shame about the lifters because they are like new, just broken in on the Comp Cam. I don't think I should risk using them on the new Isky cam.

I'll try the super magnet to get the lifters out...wonder how it will be trying to get the new ones in with all the assembly lube on them?

|

|

By FORD DEARBORN - 6 Years Ago

|

A couple years ago I posted some information from a fella who I know very well who was involved in the development/testing of the Y-block in one of the "E" buildings on Oakwood Blvd. back in the day. He's now in his early 90's. He explained how a fabricated trough of sort was slid in the cam tunnel to catch and remove the lifters as they were released. A tool was made that would "snare" the lifter and pivot such to allow it to be inserted along this tray, manipulated in such a way while being viewed from above and pulled up into the lifter bore perhaps with a magnet. It's a story that lacked precise detail but the point is, cam and lifters were R & R'd in short order while the engine was still on the dyno. I have never attempted to see how this could be possible but perhaps some day I may have the opportunity to explore this. Just some food for thought.........................

|

|

By Rono - 6 Years Ago

|

|

Very interesting! I can visualize what this device could look like. A half round cardboard or plastic tube with a slot wide enough to fit the shaft of the lifter. I have a practice block I can play with, but the pistons are rusted in the cylinders. I'll try to get them free and start experimenting with some ideas.

|

|

By charliemccraney - 6 Years Ago

|

|

Look at the pictures Cliff posted. That's the tool.

|

|

By FORD DEARBORN - 6 Years Ago

|

Cliff, have you ever tried to use this tool set? It would be interesting if you could post pics of the individual pieces so we could do some brain-storing. Thanks, JEFF...........

|

|

By Lord Gaga - 6 Years Ago

|

I say your existing lifters are safe to use on a new cam. Way back in 1963 I built a 312 for my '48 Ford. I bought a new cam (246 deg. replacement) and new lifters from the Ford dealership. I drove the car about 400 miles when a friend offered me a new 1957 factory "Blower Cam" (B7A6250C). I installed it and new HP valve springs without changing the lifters. That cam and those lifters are still in that engine with NO problems!

Don't worry about it! Rono (10/3/2019)

Frank; Thanks for the advice! Here is some additional information I have learned thanks to Moonshadow and Ted. Comp Cams are NOT a good choice for Y Blocks because of the lifter bore angle. Apparently, Comp Cams grounds their cams based on a 41 degree lifter bore angle common to scrub motors. The Y Blocks use a 43 degree lifter bore angle, so in my case, the valve timing was off. I think this is what caused my issue on the dyno. Ted provided me the Isky cam card he used with Chuck's build, so with Chucks blessing, I plan on having a new cam ground with those same specs. Bad news is I will have to replace the lifters also which requires a complete tear down of the motor. Well, the coupe is not done anyway so I may as well do it now...this winter.

|

|

By Dave C - 6 Years Ago

|

To me.. Is it worth saving the money using a set of used lifters, no matter how many runs, versus having to replace the cam and the lifter if they fail.

Remember you break in an engine by seating the rings to the bore, the bearings to the crank, and the lifters to the cam. That means they wear into each other, so old lifters wearing in to a new cam just means additional wear.

I've seen new lifters fail during break in several times.

My opinion, yours may vary.

Dave

|

|

By Cliff - 6 Years Ago

|

Take out your lifters, put a straight edge across them, if there is any crown their usable, polish the foot with 600 wet/dry paper, do not sand only remove the glaze (shine), if any lifter is flat it needs to be refaced (most cam grinders can do it) around here cost is about $3.00 per lifter, however I don't like to do it, I think it removes the hardness, yes you can change the cam and lifters on the stand, there is plenty of room, you do not need to take out the crank.

It took me 25 years to find that tool, it's not for sale, Ford sold them and almost all dealers had them, also KR Wilson and Manzel sold them.

|

|

By Cliff - 6 Years Ago

|

Check out Manzel tools on E Bay

|

|

By Rono - 6 Years Ago

|

|

Checked out Ebay for any Manzel tool that resembles the one you have, but nothing there. The other thing that concerns me about using my lifters with a new Isky cam goes back to Ted's information regarding the lifter bore angle. If my lifters are broken in on a Comp Cam which was ground based upon a 41 degree lifter bore angle and I install the Isky Cam which is ground on a 43 degree lifter bore angle, my lifters will not be making contact in the same position on the new Isky cam. Does this really not matter or is this a real concern?

|

|

By Cliff - 6 Years Ago

|

All you care about is the crown on the lifter, if it's there means little or no wear, If your worried, get new lifters, the best ones are made by Trend, they never wear and can go from cam to cam

(tool steel)

|

|

By charliemccraney - 6 Years Ago

|

Trend tool steel lifters, I think is what Cliff means.

If you want that tool, keep scouring eBay. One is bound to show up. But you need to be willing to pay whatever is being asked. It's one of those things that you need to buy when available. No going to the guy across town for a better price. Probably not a solution for the time frame of the next several months.

|

|

By Ted - 6 Years Ago

|

Here are pictures of a couple of different lifter tools for the Y. The original boxes eventually fell apart and I’ve put these in some custom wooden cases to keep all the parts together. You can see the troughs that are used to capture the lifters. It’s wood on one of the units and metal on the other. Both lifter tools swivel the lifter 90° when working the triggers.

|

|

By slumlord444 - 6 Years Ago

|

|

Personally taking the chance of used lifters failing on a new cam is not worth the price of a new set of lifters. When I was young and broke I would have chanced it. Not today.

|