|

By 55 GLASS TOP - 6 Years Ago

|

Hello I am in the process of rebuilding 1956 292 engine, I am presently cleaning parts and getting stuff in order for assembly. The pump on the engine was a gear type pump , I see rebuild kits are available and I was wondering if I should rebuild or go with a new pump. Thanks for any replies.

|

|

By Florida_Phil - 6 Years Ago

|

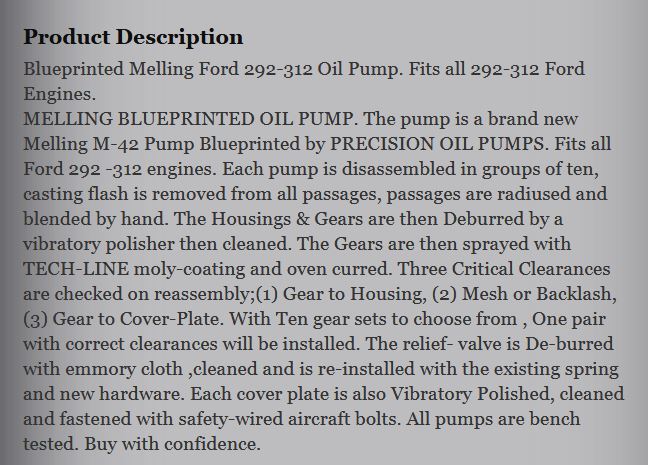

Buy new from a reputable company. Don't cut corners, it will cost you. If you do the job right, the machine work alone is going to ding your wallet big time. Why jeopardize all that work to save a couple of bucks? Here's the pump I used in my motor.

http://stores.precisionoilpumps.com/blueprinted-melling-ford-292-312-oil-pump/

|

|

By oldcarmark - 6 Years Ago

|

|

If its gear type replace it. There are also Kits for the other Type which apparently are better Pumps but I would just replace Yours.

|

|

By 55 GLASS TOP - 6 Years Ago

|

|

Thanks I was leaning towards new but I needed just a nudge. Thanks for the quick replies

|

|

By darrell - 6 Years Ago

|

|

i always take my old pump apart before i buy new.some are still like new.i only replace what needs replacing.

|

|

By 55 GLASS TOP - 6 Years Ago

|

|

I think I am going to go with Florida Phil’s pump looks like a winner . I did take my old pump apart The gears were pitted and a bit galled .

|

|

By Joe-JDC - 6 Years Ago

|

|

Summit Racing has the Sealed Power oil pump that is new for a lot less, and it is actually a Melling 42 pump. Cheaper than the Melling, and has the 42 in the cover and tag. Check with them if you haven't bought the pump already. SLP-224-41123 $84.99 Joe-JDC

|

|

By KULTULZ - 6 Years Ago

|

Buy new from a reputable company. Don't cut corners, it will cost you. If you do the job right, the machine work alone is going to ding your wallet big time. Why jeopardize all that work to save a couple of bucks? Here's the pump I used in my motor. http://stores.precisionoilpump...

Can't beat it ...

|

|

By PF Arcand - 6 Years Ago

|

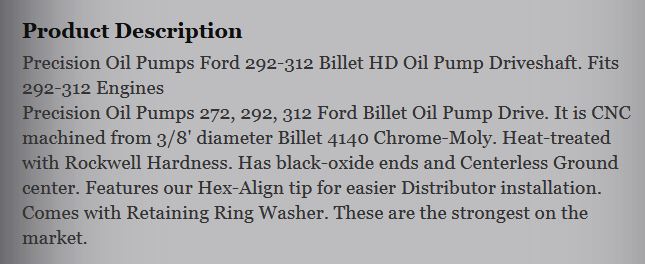

Our senior moderator, Ted, is not a fan of the older gear style pumps. They supply sufficient oil, but apparently aren't as efficient as the Gerrotor pumps & in some instances they have been noisy. What you need to replace if it shows any noticeable wear, is the pump drive shaft. H.D ones are available, but I don't have the source at hand.. Someone here will know..

|

|

By charliemccraney - 6 Years Ago

|

Arp make the HD shaft, part number 154-7906. If you get one, the retaining washer will be installed on the wrong side. You have to remove it and put it on the other side, the oil pump end of the shaft. It's something they've been aware of for nearly 20 years but have not corrected.

This is probably what Precision Oil Pumps sell but it is possible that they make their own.

Either style of pump will be fine for a stock engine. The gerotor does have a few advantages for performance use.

|

|

By 57RancheroJim - 6 Years Ago

|

charliemccraney (9/8/2019)

Arp make the HD shaft, part number 154-7906. If you get one, the retaining washer will be installed on the wrong side. You have to remove it and put it on the other side, the oil pump end of the shaft. It's something they've been aware of for nearly 20 years but have not corrected.

This is probably what Precision Oil Pumps sell but it is possible that they make their own.

Either style of pump will be fine for a stock engine. The gerotor does have a few advantages for performance use. The lasr ARP shaft I used not only had the retaining washer on the wrong end it was also to small and the shaft fell through the block and onto the floor LOL. I had to take the washer off my OEM shaft and put it on the ARP.

|

|

By Florida_Phil - 6 Years Ago

|

I used an ARP oil pump shaft in my motor. It did not use a washer to hold it in place. The shaft had a thicker portion that prevents it from coming out with the distributor. Upon assembly, the end of the ARP shaft bottomed out in the oil pump preventing the oil pump from tightening down causing a bind. I ground the oil pump end of the shaft slightly until I had enough end play. I checked it again with the distributor installed and it was good.

|