|

By charliemccraney - 6 Years Ago

|

In the process of attempting to replace my valve. It stops turning at a point where I'm not comfortable applying more force, with only about 2-3 threads engaged and 3/4 of a turn left to get it where it needs to be in my aluminum intake,. If I back it off, it is too loose. Is there some way to make it fit better or best to try another one?

Are -AN fittings reliable for coolant? That would make outlet positioning much easier and an inline valve could be used.

|

|

By miker - 6 Years Ago

|

When I tapped my Blue Thunder for a second opening, I tapped it shallow. I’m always spooky about aluminum because it’s so soft.

No telling how accurate the threads are on a heater valve. So I’d be inclined to get a quality brass nipple and see how many turns it threads in. If it’s the same, you could run a tap into the manifold a bit farther. If not, I’d be looking for another valve.

I’d use a sealant of some kind either way. My buddy the plumber swears by pipe dope or a loctite product, he really doesn’t like Teflon tape.

|

|

By charliemccraney - 6 Years Ago

|

I do use thread sealant. It does work well everywhere I use it. But it's too loose for that to work without more of a turn. It did seem to thread into an iron intake a little better. The old valve seems to thread into both the iron intake and Blue Thunder just as well. There is no problem I can see with any of the threads. I tried wrapping with teflon tape to see if that would make it stop sooner. That didn't work. That only seems to work as a bandaid when threads are worn.

I may just reinstall the old one for now. Only the valve is wet so it's not a terrible leak, yet and I really need the truck on the road again. Only trying to do this now because I needed to replace the temp gauge.

|

|

By miker - 6 Years Ago

|

I think you do what you have to do for now.

AN fittings are fine for coolant, or pretty much anything else. I’ve run them on coolant, trans oil, engine oil with remote filters, even hydraulic variable pitch propellers on large boats. But the adapter is still dependent on the NPT in the manifold.

When you’ve got time, dry it all out and try J.B. weld epoxy. Even the high temp stuff will give way with a little torch heat, way below hurting the aluminum or pot metal. If you’ve never heated epoxy to release it, don’t worry. It smells to high heaven when it lets go.

|

|

By Florida_Phil - 6 Years Ago

|

Replacement heater valves stink. I had so much trouble with mine, I threw it away and plugged the hole. Here in Central Florida we don't need a heater. My wife does look funny in a convertible wrapped in a blanket.

|

|

By MoonShadow - 6 Years Ago

|

|

Could it be as simple as the difference between a pipe thread and a tubing thread?

|

|

By charliemccraney - 6 Years Ago

|

It should not be in this case. The thread is advertised to be 3/8" pipe thread, which is what the manifold has. The diameter and thread pitch match the specification for 3/8 pipe thread.

What's a tube thread? The thread for flare fittings?

I'm not necessarily thrilled about a replacement valve, either but I do need one. It's cold enough here in the winter. This replacement is made in the USA so it has that going for it.

|

|

By Bobwanna - 6 Years Ago

|

|

Charlie, Before messing with the manifold maybe chase the threads on the valve with a 3/8 NPT taper die. Not sure if you have clearance for the die to remove some metal from the valve. This just might give you at least 3 threads of engagement. Just a thought - Bob

|

|

By MoonShadow - 6 Years Ago

|

|

Yes flare fittings. They are very similar but different.

|

|

By 62bigwindow - 6 Years Ago

|

|

Flare fittings are usually fine thread SAE. I run into this all the time at where I work. A 3/8" NPT die will fix it most likely. We get fitting from China that are like this or worse. Some are threaded so shallow the fitting won't even start and some so long they bottom out on the mating part before it gets tight. A thread or two will make a big difference in the fitment.

|

|

By slumlord444 - 6 Years Ago

|

|

I would try the pipe die. Ordinarily I would say try a pipe tap in the intake but since the orginal worked I would go with the pipe die. Try it the with the tapered end first. If that doesn't work reverse the die but be careful and take youre time.

|

|

By charliemccraney - 6 Years Ago

|

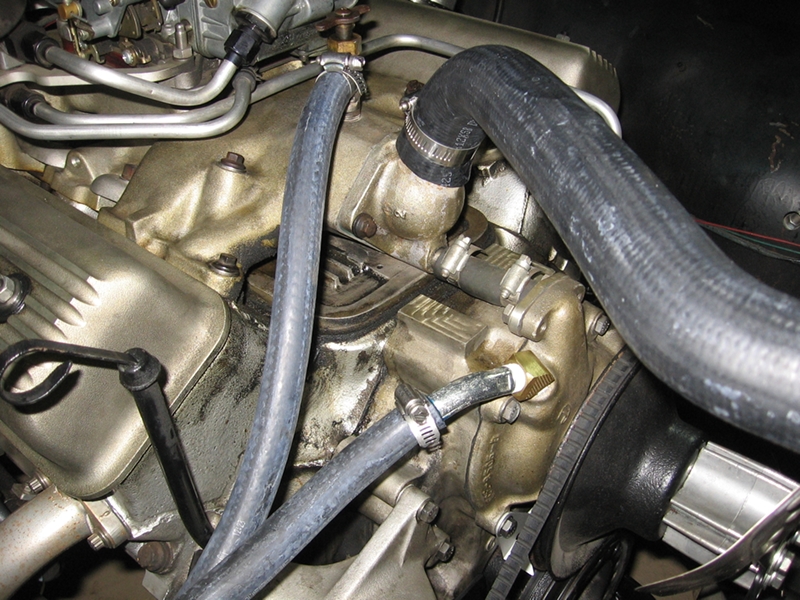

I went the AN fitting route. I hope it's a reliable solution for street use because I like the look. Haven't had a problem with the fuel lines.

I also added some functional bling, the polished aluminum hose separator. I used a zip tie before.

No leaks found while running. It's cooling down now. So hopefully this is problem solved

The AN to pipe adapter fitting threaded normally so the threads of the new valve must not quite be right.

Here's the best before pic I have.

|

|

By FORD DEARBORN - 6 Years Ago

|

Good to see the AN route solved the problem and your fuel lines look really nice. Maybe my eye sight is getting worse but how did you arrange the crankcase oil fill and air intake breather?

|

|

By charliemccraney - 6 Years Ago

|

That fancy looking thing in the valve cover is an adjustable pcv valve. The other valve cover has a breather for crankcase intake air. I fill thgough the breather hole in the other valve cover.

Adjustable valve: http://mewagner.com

|

|

By FORD DEARBORN - 6 Years Ago

|

Thanks for the reply and link...............JEFF

|