|

By charliemccraney - 6 Years Ago

|

I've been having an intermittent issue with missfiring and one time an absolute lack of power. Most of my ignition system was 10 years old and I did find some issues there and have corrected them. Hoped that was it. While checking timing after the install of the ignition stuff it would not idle well but it did eventually clear up. The real short test drive went well and when I got to my driveway it was idling poorly again.

It seems to rev and hold higher rpm well well but won't idle well in the garage, no load. It will stall unless I give it some throttle once in a while and is difficult to start if it does stall like it is flooding So I pulled the aircleaner and looked down the venturis and found fuel coming from the passenger side primary booster, with the throttle closed, in the idle position. Further, I turned the idle adjustment screws all the way in and it kept running. So my thought is bad power valve or gasket or bad needle/seat assembly, or a sunken float. I then unscrewed the sight plug and fuel poored out like a miniature fire hose for about half a second, seeming to support the bad float or needle idea.

Then I though "what about fuel pressure." The pump is electric. I checked that and 12psi is indicated on the gauge, the maximum of my regulator. I tried another gauge and still 12psi so no issue with the gauge. The problem there is that the fuel pump is rated for a 7-9psi but when I installed it, the most I could get was about 5psi so I'm confused about this 12psi indication. If I just let the pump run with the engine off, no fuel overflows anywhere,as if the needle seat, and float is working properly.

The carburetor is a Holley 570 Street Avenger, center hung float bowls. I did remove the needle and seat assembly. The o-ring looks grey and powder like on the outside, where it contacts the bore of the needle/seat cavity of the float bowl. It looks like it may be cracked part of the way around the perimeter but it could also be a molding line from the original manufacturing of the o-ring as I don't know what these should look like when brand new. The needle itself looks ok. I don't really know what to look for but it looks good to me. I can see where it contacts the seat but I don't think it looks significantly worn or anything like that. The carburetor is about 10 years old at this point about July of 2009 that it was installed.

I didn't dig any deeper because I don't understand how there can be 12psi of pressure if the pump is not capable of that. That must mean something.

Maybe if the pump was dead headed it could peak higher than it's rating? But, particularly, if the engine is getting flooded at idle, and seems to rev and hold higher rpm, it wouldn't have that issue, right?

It seems like it may no longer be intermittent. Hopefully it stays that way so I can get to the bottom of it.

|

|

By 57RancheroJim - 6 Years Ago

|

I don't use electric fuel pumps but I assume they have some type of pressure controlling relief valve and it may have been destroyed by the Ethonal fuel. Same with any other rubber carburetor parts. Over the last few years I have been having to replace, pumps, carb parts, fuel lines etc in all my old cars.

|

|

By Ted - 6 Years Ago

|

I agree that there is some kind of regulator or bypass valve in the electric fuel pump that is not functioning correctly. I’ll suggest looking at the fuel pump first.

|

|

By charliemccraney - 6 Years Ago

|

I did get a reply this morning from Carter that it is possible for this to happen if the internal regulator is stuck closed or mostly closed.

The question then becomes why isn't my Aeromotive regulator controlling the pressure to the carburetor. Hope to hear from them today. Maybe beyond some point, it can no longer control it. Something I forgot to mention originally is that the pressure will not change with any change in the position of the regulator adjustment screw - it stays at 12psi no matter what.

|

|

By FORD DEARBORN - 6 Years Ago

|

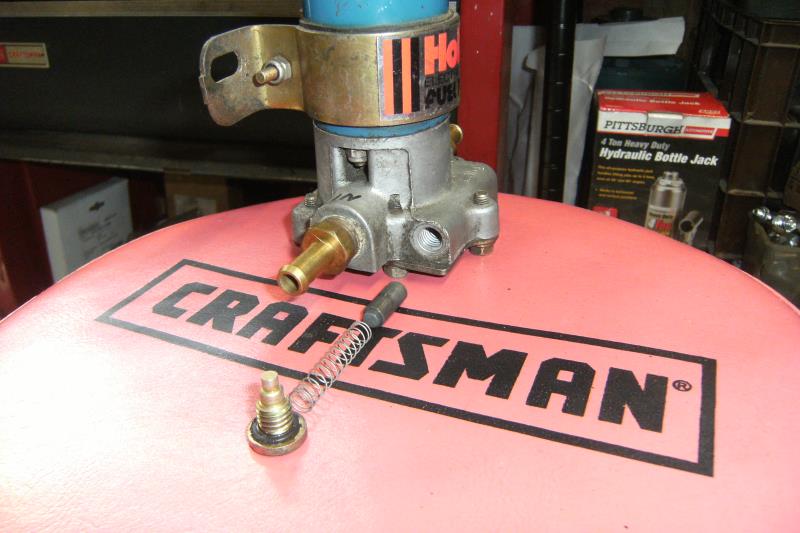

I pulled the plunger assy. from a used pump and here is what it looks like. There is a regulating system within the pump. I might add that the plunger needed to be coaxed with a strong magnet to get it to come out. Looks like a neoprene surface opposite the spring end so being exposed to our alcohol fuel may have a negative effect on these also. This is a Holley branded pump but chances are, others may have a similar system. It is, however, non adjustable, or, at least not intended to be. Good luck, JEFF..................

|

|

By Joe D - 6 Years Ago

|

Charlie,

Make sure the gage is ok. Depressurize line to ensure gage goes to zero.

Hope this helps.

Good luck.

|

|

By 1960fordf350 - 6 Years Ago

|

Do you have a separate pressure regulator in the line, or are you relying on the pump alone? I don't think the carb problem is related, your not overflowing at the bowl. The only thing that might mess with that is if the regulator starts working or allows the pressure to drop all of a sudden and you lose flow to the carb .

The white powder in the carb is from the alcohol eating into the zinc of the carb. I'd suggest a rebuild. I went through that issue about 5 years ago. I got a big load of alcohol in my gas. It ate into the bowl a little and I had quite a bit of that white powder in the bottom of the bowl. It actually plugged up my idle circuits and was eating up the rubber in the accelerator pump. I did a rebuild and it fixed everything. 2 barrel Holley

|

|

By paul2748 - 6 Years Ago

|

What does the carb say for max pressure? If less than 12 it may be too much pressure for the needle and seat.

|

|

By miker - 6 Years Ago

|

|

Charlie, I’ve owned several Aeromotive pressure regulators. Boost referenced, EFI, they all just work. If yours doesn’t pull it apart and look for contamination. This doesn’t address the pump problem, but I’ve gone from 5lbs and boost reference to 40 lbs for EFI by just changing the springs in them. If its passing more pressure, it’s got to have junk holding it open. IIRC they are all alcohol rated, and the springs come in pressure ratings so look for something upstream from it. Or a spring the pump is pushing past.

|

|

By charliemccraney - 6 Years Ago

|

I replaced the pump with my lower pressure spare and the pressure is now under control. I reinstalled the float needle / seat and am able to adjust the float level and it doesn't seem to be flooding because of pressure or float / needle related issues anymore. The problem still exists, no matter the float level so I will dig deeper.

Is there an easy way to test a power valve or is it just easiest to replace it and see what happens?

The Carter does not seem to have an externally accessible regulator. Maybe I'll take it apart to see how it works. I couldn't get the Holleys to last. It is a much different design, and made in the USA, at least 7 years ago, they were.

When I said powder, I was only using that to try to describe the texture of the o-ring. I did not notice anything that was actually powder or grit. I've had the bowls off a couple times over the years probably 2-3 years most recently. It's always been clean. Who knows, maybe something has changed since then. I'll find out soon.

|

|

By Ted - 6 Years Ago

|

charliemccraney (3/25/2019)

Is there an easy way to test a power valve or is it just easiest to replace it and see what happens?

I have a power valve tester made by Moroso that works good in conjunction with a hand held vacuum pump. I typically use it to check the vacuum rating but it also checks for leaking diaphragms.

|

|

By charliemccraney - 6 Years Ago

|

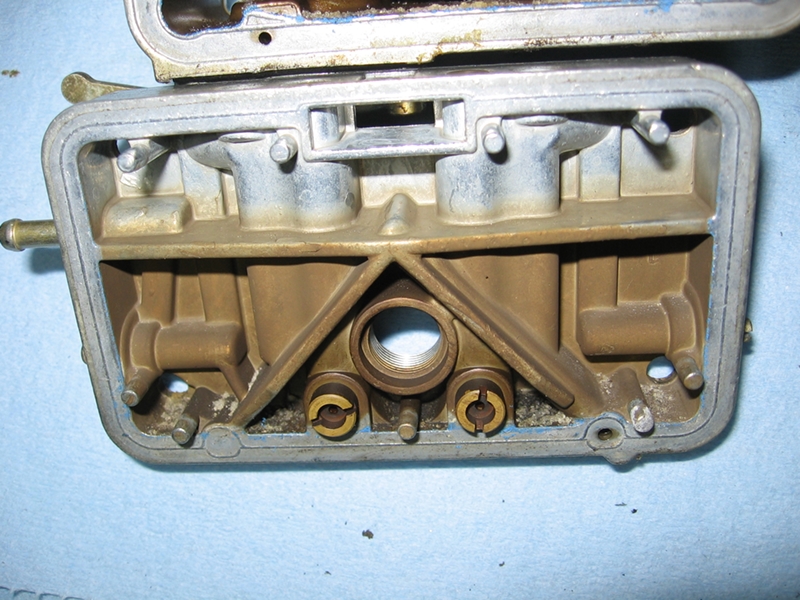

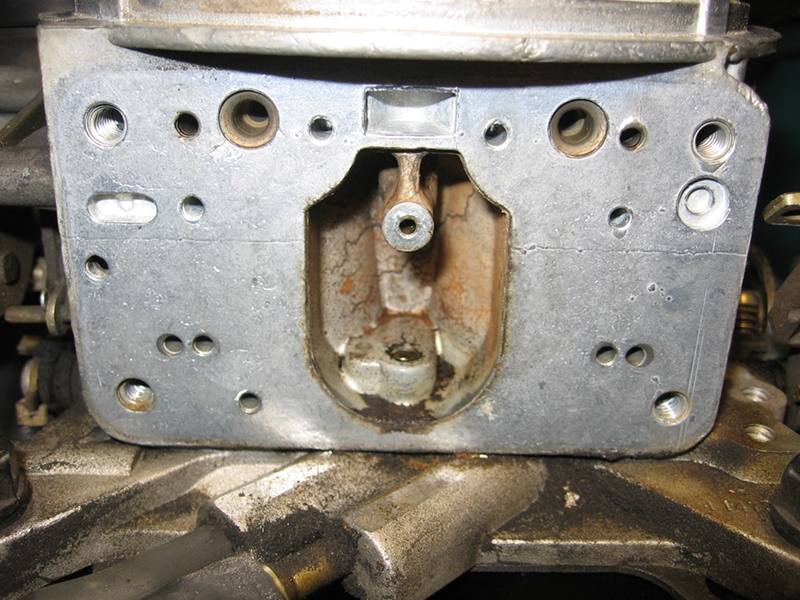

I did find some sediment this time. It starts out somewhat coarse and disintegrates as I rub it between my fingers until it can't be felt. I see it in the float bowl and on the float bowl side of the metering block. I don't see evidence of it on the other side of the metering block or the main body.

Is this contamination due to inadequate filtration?

I also got the power valve tester and the valve is a 7.5 that is fully closed at about 6psi according to the gauge on my vacuum pump and moves smoothly between 0psi and 6psi. I don't know how accurate the gauge is. It does hold vacuum. The portion of the diaphragm that can be seen looks wet. The pintle and seat look ok. There was also fuel in the power valve cavity of the main body. The power valve gasket was moist with fuel but the valve was tight. Given that part of the gasket is exposed to the fuel, I don't know if that necessarily means anything. The power valve cavity and corresponding area of the metering block have black residue consistent with what I have seen when fuel has been seeping or leaking for a while.

Can a power valve test good but still be bad somehow?

I'm thinking that the actual cause is either the metering block gasket or power valve or power valve gasket. I'll clean it up the best I can and if it seems like a full rebuild is in order afterwards, then I'll have a good excuse to try the new 670 that I have.

|

|

By Ted - 6 Years Ago

|

|

All good questions. Looks like you need a finer screened fuel filter. My experience with power valves has been if the power valve holds a vacuum, then the gasket is the problem. Those gaskets can be touchy in remaining centered on the power valve when tightening them to the metering block; if not centered then fuel is allowed to seep into the power valve cavity in the main body. When in doubt, just replace the power valve.

|

|

By Robs36Ford - 6 Years Ago

|

The photos of the brown stuff and your description of it sounds a lot like Phase Separation. Where enough water gets into the fuel and causes it to separate into little bits that are soft. Eventually bacteria can get in there. Also the water will rust metal. At this stage of separation : with fuels that have Ethanol in it it will harm the engine when running, with Conventional fuel it does not harm the engine when running. Either way the engine will misfire.

https://www.epa.gov/sites/production/files/2015-09/documents/waterphs.pdf

|

|

By charliemccraney - 6 Years Ago

|

|

I don't think that is the problem given that the symptoms point to too much fuel, causing flooding. It will be easy enough to test with a remote fuel source and fresh gas, though. We'll see how it does after I clean it up and put it back together with new gaskets and power valve.

|

|

By Dave C - 6 Years Ago

|

One other thing to add. The power valve is open to manifold vacuum. When the engine is shut off warm, fuel vaporizes and then will condense in the cavity behind the power valve. If the power valve checks good and the gasket is OK then that is likely where the moisture and discoloration is from.

Although it doesn't sound like this is your problem.

There is a "fix" for leaking holley power valves that are caused by backfires. Holley makes a kit.

https://www.holley.com/products/tools/carburetor_tools/parts/125-500

A little trivia.

Back in the 80's with Fords variable venturi carburetor this vaporization issue cause the rubber diaphragm to deteriorate and since vacuum and the diaphragm was what controlled the ventura there was no throttle. The Ford fix was to drill a drain behind the diaphragm. I had a lot of customers request that I convert the Variable Venturi to a holley 2bbl back in the day..

Dave

|

|

By charliemccraney - 6 Years Ago

|

The Street Avenger comes with the check ball.

I cleaned everything, installed anew power valve and new gaskets. Started it up and it was idling great. I turned the idle screws in and it stalled - seems good. Decided to take it for a test drive and right as I got to the bottom of my driveway, it stalled and no longer idles, again. I got up the driveway fine. I had to rev it to get into the primaries but doing so resulted in plenty of power to get up the driveway with ease.

Fuel pressure good, float level good, still the old needle and seat.

It is easy to start when it stalls now. That actually seemed to change when I replaced the fuel pump.

I tested the new 7.5 power valve and I could not get it to hold vacuum. I tested another new 6.5 power valve, and again, it would not hold vacuum. A very slow bleed in each case. I tested 3 used power valves, including the initial 7.5 and they all hold vacuum. I installed the new 7.5, thinking that maybe I was somehow messing up the testing of the new valves although I don't know how I could do that - it's pretty simple. I guess I'll try a used one and see if that takes care of it. It was idling fine for about 5 minutes. If the new valve is bad maybe that would be just about enough time to fill the cavity and reach the vacuum passage.

The fact that it seems to do fine with enough throttle that it should be mostly or entirely on the primaries indicates to me that it is not a fuel quality or ignition problem Those would just get worse in a situation where it is under load, right?.

And I just realized that I forgot to replace the vacuum cap on the ported vacuum port. So I need to do that but that should have nothing to do with it.

What a tease, idling great for a moment and then back to the problems.

|

|

By FORD DEARBORN - 6 Years Ago

|

If there is a very slight bleed of fuel from, say, the power valve into the main body cavity, more throttle means more air and may utilize this bit of extra fuel bleed and run ok at any throttle setting other than idle. The pics supplied look very similar to what stale fuel will cause. The phase separation mentioned by Robs36Ford in a previous post is what it looks like to me at this point. The gritty brown slime and the overall brown color on everything "wet side" suggests this. About 4 years ago, someone brought in a Motorcraft 4350 that looked very similar to your Holley with the pump plunger totally destroyed and air bleeds with this gunk in them. It was so amazing that I took a few pics of this and will later look for them. I'm sure your vehicle takes on assumed to be fresh fuel on a routine basis so stale fuel shouldn't be a factor .I also beginning to question what these swings in chemistry are doing to the specific gravity? However, this brown debris and all that was a result of the fuel in question. Also, stale fuel produces it's own (nasty) odor along with irritating the sinuses and eyes but that wasn't mentioned. Very interesting unsolved mystery................my thoughts, JEFF..........

|

|

By charliemccraney - 6 Years Ago

|

I know what bad gas smells like. This still smells and looks fresh. This particular fuel is about 2 months old because I've been doing other stuff on the truck. But generally I drive it regularly and it does not sit more than 2 weeks, so fuel is always fresh and it was fresh when I initially started noticing the intermittent problem. Stale old fuel just isn't the reason for this to have started. I've had it sit this long several times in the past while I did other work with absolutely no problem. The inside of the float bowl does not look out of the ordinary for a 10 year old fuel component compared to others I've seen. I suppose it's possible I've seen only exclusively bad things but I doubt it

I also don't think phase separation is the problem. I have a fuel cell with a sump. If that was going on, I'd be getting the separated alcohol and water first and it simply wouldn't run or smell like gas.if that was happening. It certainly would not have started out idling well yesterday. Simply bad gas also isn't likely because the first 3/5 of this tank was fine. I use premium fuel which is typically about 5% ethanol near me so separation is possible with that but it would not be nearly as bad as it is with the lower grades. And again, when it initially happened the fuel was fresh.

I will test it with fresh gas shortly if nothing else seems to take care of it but I'm just not convinced that it is a fuel quality problem.

|

|

By FORD DEARBORN - 6 Years Ago

|

Hmmmm, thanks for posting. Well, not noticing the foul odor means a lot. It sure looks like something dissolved in a batch of fuel. Is this the unibody pickup? Are you perhaps using the in-cab tank? I ask this as with my 64, it's easy to shine a good LED flash light into the filler opening and have a peek at the interior of the tank. Would be curious to know if any of this is evident there? Or could something have broken down/dissolved in the old fuel pump that was "stuck" at 12psi?? Same applies to the regulator that may have a neoprene parts??

|

|

By charliemccraney - 6 Years Ago

|

|

I have a fuel cell. I have 2 screen filters installed. It's been a long time since I got them but I think they are 40 microns each. One installed between the fuel cell and pump and the other between the pump and regulator. I have removed the screens that came in the carburetor so there is nothing between the regulator and carb. The regulator would have a diaphragm. If that has failed, it is not what was in the float bowl.

|

|

By Tedster - 6 Years Ago

|

Charlie, what is the average engine manifold vacuum at idle?

I seem to recall it's got a cam in it right?? Maybe your carb & engine wants a 5.0" PV and not a 7.5" or a 6.5" ? Or even lower, at least for initial tuning purposes. I think even a cutout plug is available. Altitude especially & ignition timing play a role as you are undoubtedly aware.

I superglued one side of the PV gasket, to the PV itself. This holds up in gasoline pretty well. The PV itself takes a pretty good torque, heat cycles will cause them to loosen up a bit otherwise. The thing about powervalves is they have to be known good, and out of the cruise circuit, or tuning is impossible. The backfire issue I think is probably exaggerated.

|

|

By charliemccraney - 6 Years Ago

|

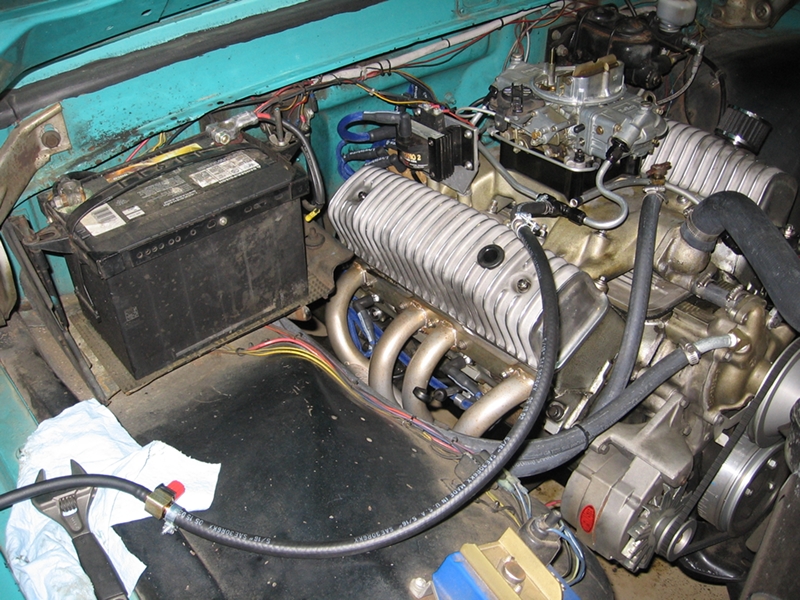

I have what is suppose to be a repop of the '57 high lift cam. It actually has about 17" hg at idle. It took some tuning and intake mods to get it to that point, mostly by accident, a good consequence of other modifications and upgrades. The valve was chosen when manifold vacuum was 15" which was over a year and a half ago at this point. Since the 7.5 power valve has been in use for years and nothing else has been changed that would affect the vacuum spec required, the valve spec is not the problem.

I'm not having any problem with backfires.

At this point, I only have a 6.5 pv that tests good and was not installed when the problem started so I'll put that in and see what happens.

|

|

By Tedster - 6 Years Ago

|

That's what I figured. And it's tough to imagine 2 or 3 bad power valves in a row, though it's possible I guess. Does it cruise on level ground around 15" of vacuum?

Strictly speaking, how often is it necessary to pull a carb and clean it just on GP? I think once a year sounds good, though this soon seems to stretch to 2 years.

|

|

By charliemccraney - 6 Years Ago

|

|

I don't know what the vacuum is at cruise. I've never checked.

|

|

By charliemccraney - 6 Years Ago

|

I put the 6.5 pv which tested good in. No change. So at this point I'm going to say that it has nothing to do with the power valve. This time it just didn't idle at all, unlike last time where it did idle for about 5 minutes after cleaning everything and replacing the gaskets and pv.

I also disconnected the vacuum advance and pcv valve and plugged the ports since I had not tried that yet. No change.

The slowest I can get it to run is about 2000rpm, which should be into the primaries. It accelerates well with a pump of the gas and I can confirm visually that the accelerator pump works while it's not running. So it really seems like an idle circuit fuel problem.

I got a remote fuel supply so I will check with fresh fuel and see if anything changes. If not, then I will put the new 670 on and see if that will idle.

|

|

By Ted - 6 Years Ago

|

You might check that the throttle plate to main body screws are tight. There’s also the chance the gasket at that location could also need replacing.

|

|

By charliemccraney - 6 Years Ago

|

I tried fresh fuel. No change.

For those who may not know what a remote fuel supply is, it is a small tank that gravity feeds the carburetor. You can get them at motorcycle and other powersports shops.

Tomorrow, the 570 comes off and the 670 goes on. Hopefully that solves it because my car developed a cold idle problem this morning (fuel injected) so I need the truck back on the road. I'll check the base plate screws when the 570 is off.

|

|

By charliemccraney - 6 Years Ago

|

I did find the two base plate screws closest to the primary bowl to be a hair loose. I'll estimate no more than 10 degrees, probably not that much. I don't think it would be enough to cause any kind of leak but maybe.

I started getting the 670 ready. It's an aluminum Street Avenger, part 0-85670. It has 4 corner idle. Holley's instruction manual says we know best, leave it where it is and don't question us. I'm paraphrasing, of course. They should know best but the baseline spec would be nice so it can be verified. The primary screws have 1 1/8 turns and the secondary screws have 3/8 turn. David Vizard suggests in his book to start 2 turns out on all four. Should I leave it as Holley set it or would something else be better for the initial startup?

They also have the primaries way open but that may be to make it easier to get started initially. I can see quite a bit of the transfer slot.

I did find one base plate screw a hair loose and all of the accelerator pump screws needed to be tightened. The bowls are good. I had them off when I got it to verify the calibration against their specs and install a 7.5 power valve so if anything is loose in them, it's most likely my fault. I replaced the inlets with -6 fittings and left the screens in place for now.

|

|

By FORD DEARBORN - 6 Years Ago

|

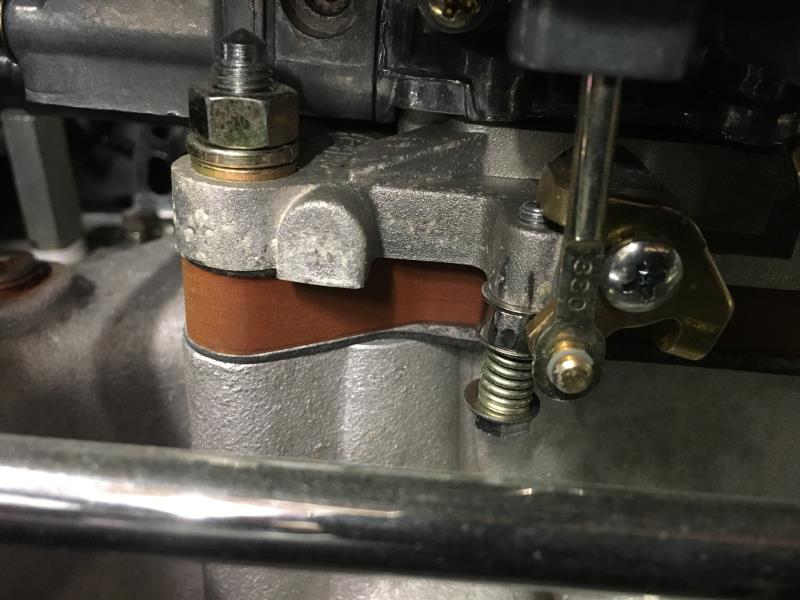

Here's a little trick making it very easy to adjust the secondary throttle stop. This was on a 302 build and if I can remember correctly, the carb was a 570 Aevenger.

|

|

By Ted - 6 Years Ago

|

|

charliemccraney (4/3/2019)

...I started getting the 670 ready. It's an aluminum Street Avenger, part 0-85670. It has 4 corner idle. Holley's instruction manual says we know best, leave it where it is and don't question us. I'm paraphrasing, of course. They should know best but the baseline spec would be nice so it can be verified. The primary screws have 1 1/8 turns and the secondary screws have 3/8 turn. David Vizard suggests in his book to start 2 turns out on all four. Should I leave it as Holley set it or would something else be better for the initial startup...

Now that you know what the factory fuel mixture screw adjustment is, you can always go back to it if you decide to start the engine with a different initial f/m adjustment. I’m in the David Vizard camp on the four corner fuel mixture idle adjustments. I like to start with all four screws at 1½ turns out and keep all adjusted the same when making fuel mixture adjustments. When making adjustments whether leaner or richer, I’ll make the adjustments in 1/8 turn increments.

|

|

By charliemccraney - 6 Years Ago

|

Well, I still have work to do tuning but I'm going to give it a cautiously optimistic it's fixed. I started it. It idled great, surprisingly smoothly almost instantly. I haven't run it very long, yet. Just wanted to make sure it would start and idle. The other carb did fool me by idling again at one point, so we'll see.

I found more problems with the new carb, right out of the box. After installation, the accelerator pump wasn't working. I pulled the bowl off to take a look. It was assembled as incorrectly as it can be assembled. The spring was on the outside and the diaphragm was upside down. Without a close look, it seemed like it was working when I was checking it out on the bench because the lever was still pushing on the spring. I suppose the loose screws should have clued me in to take a closer look.

I decided to leave the idle screws as they were delivered. Assuming it is deliberate, they must know best about the initial setup for their carb but the issues make me wonder. I bought this carb years ago. It could be a fluke or they could be better now... or worse. I didn't have any of these out-of-the-box issues with the 570. I didn't even check that one so maybe I was lucky.

|

|

By charliemccraney - 6 Years Ago

|

I got idle dialed in and the preliminary tuning of the accelerator pump and it's doing well. The idle screws only needed 1/8 additional turn out. Any more or less and vacuum dropped off.

For some reason, when one of the transfer slots is approximately square, the other is still slightly rectangular. I guess that may just be the result of manufacturing tolerance. I found that I'm able to reach the secondary idle speed screw with a small screwdriver, thanks to the 2" spacer I'm using.

Still need to check/adjust secondary actuation and need to see if my regulator works.

The 570 was really lean for this engine in the out-of-the box tune. Reving the engine resulted in the rpm staying high for a couple seconds then coming down and it felt really sluggish. It ended up 7 jet sizes bigger to be acceptable. This 670 does seem to be a much better match out-of-the box. My O2 sensor is not working so I'll probably wait until I get the gauges installed with the new wide band sensor to get the mains dialed in. It should be good enough to drive. If the plugs fowl or mileage is considerably worse, those should be clues, too.

It's amazing how many things I found that could have been causing this problem, some seemed to be obvious and the problem still isn't obvious to me but was something to do with the carburetor. Maybe some of that contamination stopped up a part of the idle circuit in the metering block.

|

|

By DryLakesRacer - 6 Years Ago

|

|

I think your story is typical with Holley. We bought a 750 double pump for our dirt 1/2 mile car and before we ran it took it to SMI ((Shawn Murphy) in Huntington Beach well known in the performance carb business. We heard and he showed us everything that would have made a struggle out of the box... It seems like this should not be but quality control seems to be lost today..good luck.

|

|

By charliemccraney - 6 Years Ago

|

I haven't done much more, yet because I noticed that my temperature gauge stopped working so i want to fix that before going out on the open road.

I did check the regulator and it does adjust now. So maybe the failed pump was putting out enough pressure that the regulator could no longer control it. I was also able to set it to 6psi and it will go higher but I did not see how far so there may still be something going on because I'm sure I could not set it that high before, which is why I got the higher pressure pump. I'll keep an eye on that.

I contacted Holley tech to verify the baseline idle screw spec and they said 1 1/2 turns on all 4. So assuming that the tech guy knew what he was talking about, that's another thing that was wrong out of the box. I'll try adjusting them equally and see how that does.

|

|

By charliemccraney - 6 Years Ago

|

Just an update. I still haven't done anything else regarding fine tuning. Since it does seem to be running fine, I'm focusing on other projects that I already had parts for and had hoped to be done by now, until the original subject happened.

So far it appears that mileage remains the same and it feels like it could be more responsive. That last one is hard to be sure, though because it was a little more than 3 months that I didn't drive it. It may have simply been the result of getting used to it again. Big difference in terms of acceleration between it and my car (stock and slow). So it seems that a bigger carb is not necessarily worse, if the engine can use it. It's all in the fuel curve.

6/25/2019

|