|

By Joe D - 8 Years Ago

|

When engine is up to operating temp (180-195) and while driving around 50-65 mph, engine stalls when trans is placed in neutral. Seems like its starving for gas and not flooding. Does restart with foot to the floor and engine recovers and idles normal after a minute or so. Engine runs great otherwise and this only happens when engine is 180 degrees or higher 195. Vapor Lock in carbs due to ethanol maybe?

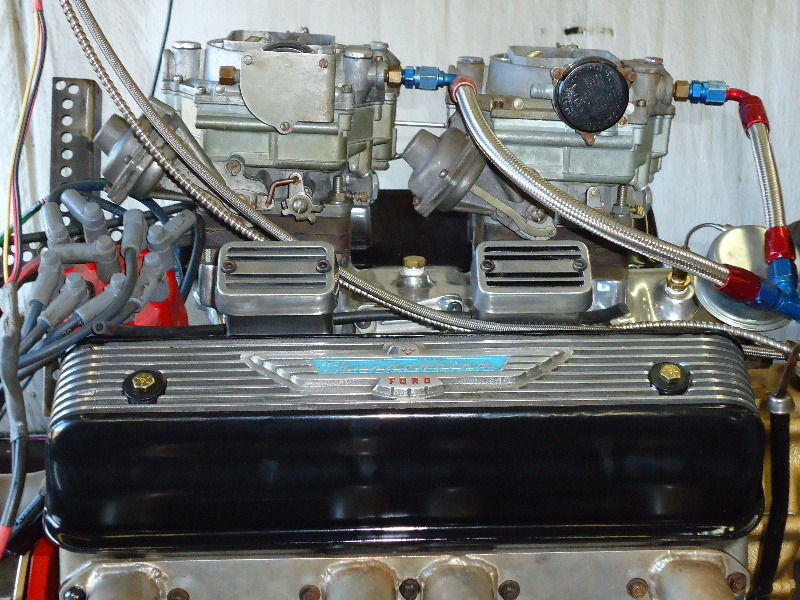

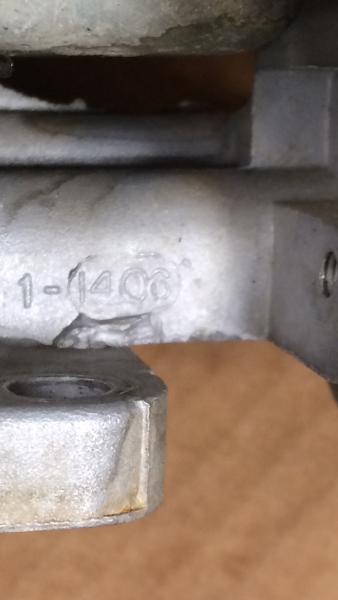

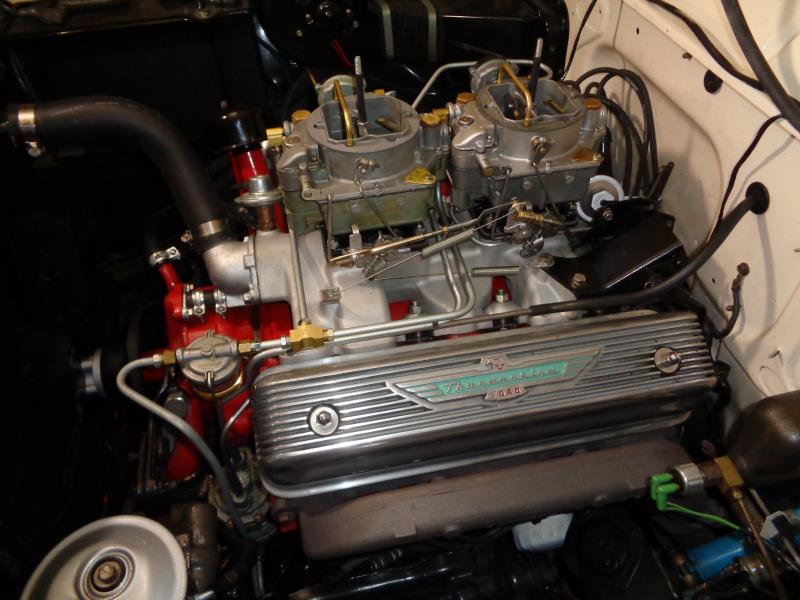

Dual Quads (Carter) are off of a 1957 T -Bird I was told.

|

|

By Sandbird - 8 Years Ago

|

|

'57 TBirds came with a pair of Holley carbs and had aluminum spacers sandwiched in between a pair gaskets under each carb used as insulators. The Holley carbs were special for the dual carb setup. Might be a heat problem if you don't have the insulators and/or your Carters may be a mismatch.

|

|

By KULTULZ - 8 Years Ago

|

"Vapor Lock in carbs due to ethanol maybe?"

When it does this, pull over and check for accelerator pump shot and/or spark.

|

|

By Joe D - 8 Years Ago

|

How would I check the accelerator pump? It does restart so I assume the ignition is ok.

|

|

By KULTULZ - 8 Years Ago

|

"How would I check the accelerator pump? It does restart so I assume the ignition is ok"

No.1 - Never a$$-u-me anything. I thought marriage would be a good idea and got tricked on that one.

To check the fuel, remove the ACL and operate the throttle linkage while looking for a fuel shot down the throat of the carb. If no shot, most likely an empty fuel bowl due to heat soak/boiling of fuel. You may also have bad ignition parts (condenser) that shuts the car down with heat.

If no fuel, you will have to isolate the carbs with phenolic carb spacers and maybe insulate the fuel line from pump to carb.

Also verify pump pressure/volume delivery and any possible air leaks in the fuel line from tank to pump.

It's usually ethanol blended fuel as at temp it experiences blend separation and is more prone to evaporation due to a lower boiling point.

|

|

By Joe D - 8 Years Ago

|

OK I'll check next time it stalls to see if fuel bowl is dry.

I have Pertronix electronic points. do you think they could be the cause?

|

|

By Joe D - 8 Years Ago

|

I forgot to mention that I did try insulating the fuel lines all the way to the carbs and I installed a high flow cartridge type fuel filter back by the fuel tank.

It does look like there are spacers under the carbs that are about 1/2" thick.

Thanks for all your help

|

|

By Joe D - 8 Years Ago

|

|

|

|

By KULTULZ - 8 Years Ago

|

PERTRONIX-

IGNITOR I has given problems

IGNITOR II is a better option.

Check both IGN and FUEL to CYA.

Here is a film showing fuel percolation-

https://www.youtube.com/watch?v=cadNfSNi_Oc

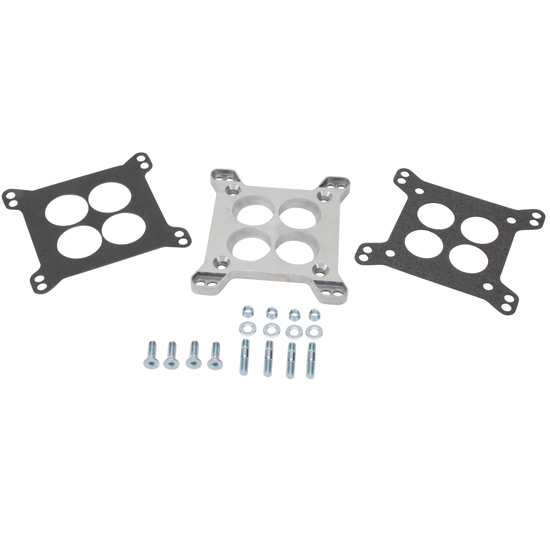

The spacers you see are most likely OEM aluminum, and will conduct engine heat to the carb fuel bowls. You need phenolic (plastic) spacers to cut down on the heat transfer.

Remember, this may also be vapor lock and/or blend separation on the suction side of the pump (tank to pump) also. If the rubber fuel lines are not ethanol rated, they can break down inside and cause a flow restriction too. Just a reminder.

|

|

By Lord Gaga - 8 Years Ago

|

Is there a 'sock' filter on the fuel pickup in your gas tank? Have you checked the fuel pump pressure and volume?

|

|

By Joe D - 8 Years Ago

|

|

There is not a sock filter. just a pick up tube. I installed a new aluminum 17 gal tank under where the spare tire went. Also all new SS braided fuel lines, Summit cartridge type high flow fuel filter near tank (suction side of pump), and a new Edelbrock fuel pump (6 psi).

|

|

By Joe D - 8 Years Ago

|

Thanks Kultulz, I'm going to try get a tank of aviation gasoline (no ethanol) from a local landscape equipment company.

Going to check spacers. I don't think they are aluminum though. I'll let you know.

This was really helpful!

Joe D

|

|

By Joe D - 8 Years Ago

|

I checked and the spacers are aluminum and the gaskets are steel. Do they sell stock material that you can cut yourself. Should I make these as thick as possible to fit under hood? Maybe 1, 2, or 3". I do have room.

Thanks

|

|

By charliemccraney - 8 Years Ago

|

|

Steel gaskets? You sure?

|

|

By Joe D - 8 Years Ago

|

It seems that way since a magnet would not stick to aluminum spacer but did stick to side of top and bottom gaskets.

Thanks a cool truck by the way!

|

|

By KULTULZ - 8 Years Ago

|

Try this for gasoline-

https://www.pure-gas.org/

|

|

By KULTULZ - 8 Years Ago

|

"Steel gaskets? You sure?"

It must be those combination fiber/steel mesh like gaskets.

|

|

By KULTULZ - 8 Years Ago

|

"Do they sell stock material that you can cut yourself. Should I make these as thick as possible to fit under hood? Maybe 1, 2, or 3". I do have room."

Yes, they sell sheet stock if you want to make your own. Usually, you want just 1/4" as raising the spacer height may play with plenum volume.

Here is a set of store bought - https://www.dashman.net/product.html?id=207

Just isolate the problem before throwing money at it. I don't want you to get mad at me.

Did you say you have an inline filter before the mechanical pump? What micron size?

What is the application, a pickup with a "292"?

|

|

By Lou - 8 Years Ago

|

|

Your problem sounds like a vaccuum leak, not a fuel problem.

|

|

By kevink1955 - 8 Years Ago

|

Did anyone pick this up from the first post

"Does restart with foot to the floor and engine recovers and idles normal after a minute or so"

It's not starving for fuel, it's flooding most likely from fuel boiling in the bowls. insulated carb spacers may help.

|

|

By Joe D - 8 Years Ago

|

The cartridge type filter is 10 micron and is installed back by the fuel tank (pump suction). I recently installed this and removed a small inline filter right before the pump suction. I had heard so much about fuel boiling and pump cavitation.

The dual quads are on a 292 Y block in a 1960 F-100 (The Frig), with 3 on the tree.

|

|

By Joe D - 8 Years Ago

|

Kevin,

I thought if the fuel is boiling inside the carb bowls it would be lean or starving for fuel.

Next time it stalls I'm going to pull off the road and look inside the carb throat and pull back on throttle cable and see if gas squirts out. If it does I'm probably flooding. If it doesn't I would think it's boiling off and causing vapor lock in carb bowl.

Thanks,

Joe

|

|

By kevink1955 - 8 Years Ago

|

Usually when fuel boils off in the bowl it is pushed out the vents in the air horn and drowns the engine with fuel.

When you get it restarted can you smell fuel or does it smoke from the exhaust until it clears the excess fuel and smooths out ?

|

|

By KULTULZ - 8 Years Ago

|

That is a sharp looking pickup and engine detail.

You have a braided fuel supply hose running awfully close to the upper radiator hose/ heater outlet. That may be the source of heat ingestion. How high does the coolant temp go when this happens?

The phenolic spacer(s) also isolate engine heat so as to keep the fuel cooler so as to provide a denser fuel mixture.

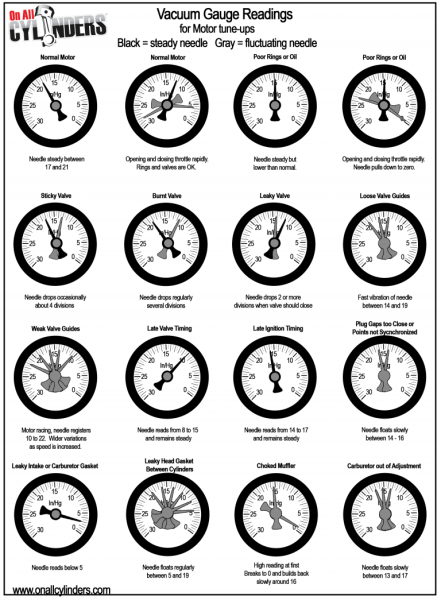

Also was suggested a possible vacuum leak. Do you have a fuel pressure/vacuum test gauge?

|

|

By KULTULZ - 8 Years Ago

|

Hey Joe D,

Any chance of seeing the engine right side? I would like to see how you plumbed fuel delivery. Do you have a filter on the pressure side?

|

|

By Joe D - 8 Years Ago

|

Thanks for the help Men!

I never have smelled gas like its flooding and no smoke or back firing when restarting.

Coolant temperature around 180 degrees and confirmed with a digital heat gun. I also tried insulating pressure side lines up to the carbs and still stalled. I do think its an inside carb issue.

I do not have a vacuum gage but my neighbor does! What would be the test with this?

I'll get a right side photo that shows hard piping going to carbs. I removed the brass screens on the catb inlets but this did not help either. Thanks again!

|

|

By Joe D - 8 Years Ago

|

|

|

By Joe D - 8 Years Ago

|

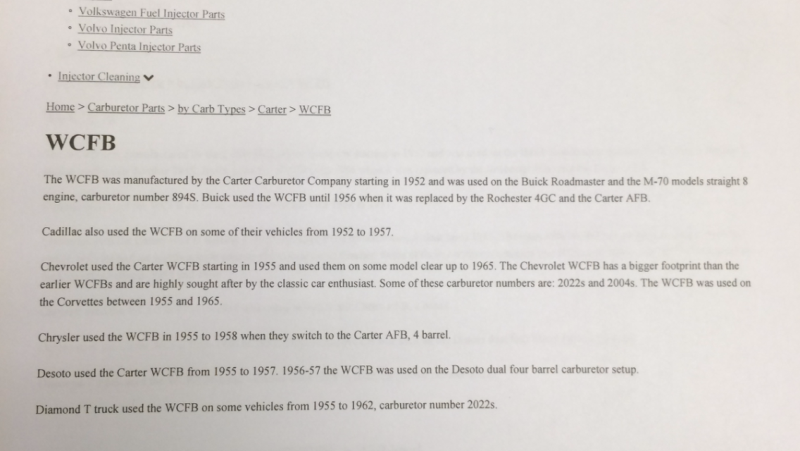

Having trouble ID ing these Carter 4 barrel carbs. No tags and markings around base that I can find.

|

|

By KULTULZ - 8 Years Ago

|

"Having trouble ID ing these Carter 4 barrel carbs. No tags and markings around base that I can find"

Without the ASSEMBLY ID TAG(S), identification is going to be difficult as kits, parts and specs will vary between car makes.

.http://www.secondchancegarage.com/public/186.cfm

I'll attach an interpretation chart a little later.

https://www.onallcylinders.com/wp-content/uploads/2016/03/31/vacumm-reading-1-752x1024.png

By any chance, can you see any CASTING ID NOS. on the actual intake manifold?

"Coolant temperature around 180 degrees and confirmed with a digital heat gun. I also tried insulating pressure side lines up to the carbs and still stalled. I do think its an inside carb issue."

Don't forget ethanol blended gasoline has a much lower boiling point. Shoot the thermometer at that braided fuel line after driving for a while. It is sitting in direct airflow from a hot radiator. Also try to get an engine compartment temp reading. Usually, fuel bowl percolation happens after shutdown and resultant engine heat soak, causing the fuel to boil out of the bowl vents. Much heat is also picked up @ the mechanical fuel pump as it is attached to the engine directly.

You do have a filter before the carbs?

Wish I would get my act together ...

The reason for the vacuum gauge is to insure the engine is tight. Some leaks manifest themselves once the engine is hot and things begin to expand.

|

|

By miker - 8 Years Ago

|

I’m not sure either of these will apply to you, but it’s my experience and involved stalling engines.

I had a fine Moroso fuel filter installed at the rear before the electric pump. New fuel tank, but I got a bad tank of gas. It would plug up while driving, then restart a minute later. I limped home and pulled it, it was full of very fine particles. I replaced it with an oem style filter and solved the problem. I was told the fine filter should have a coarser filter in front on the suction side, and then be pressurized. And the racers clean them between every run. You mentioned you just installed one.

I had a very similar hot/driving problem to yours on a car I move to a new location. Hot day, from sea level to 2600 ft., it loaded up and died. I thought to was vapor lock, but it restarted at full throttle. The local speed shop guys said “it’s the attitude change and the pressure regulator. Either put a gauge on it and reset the pressure, or try lowering the float level just a bit”. Since it was a Holley, I pulled the sight plugs and took it down I/2 turn on the external adjustment. Problem solved. When I can get it on a hoist and get to the regulator I’ll do it right. But this is a boost referenced blow thru supercharged motor. So it could be the increase in temp is affecting the pressure and that’s where the flooding is coming from. I don’t know.

|

|

By miker - 8 Years Ago

|

I’m not sure either of these will apply to you, but it’s my experience and involved stalling engines.

I had a fine Moroso fuel filter installed at the rear before the electric pump. New fuel tank, but I got a bad tank of gas. It would plug up while driving, then restart a minute later. I limped home and pulled it, it was full of very fine particles. I replaced it with an oem style filter and solved the problem. I was told the fine filter should have a coarser filter in front on the suction side, and then be pressurized. And the racers clean them between every run. You mentioned you just installed one.

I had a very similar hot/driving problem to yours on a car I move to a new location. Hot day, from sea level to 2600 ft., it loaded up and died. I thought to was vapor lock, but it restarted at full throttle. The local speed shop guys said “it’s the attitude change and the pressure regulator. Either put a gauge on it and reset the pressure, or try lowering the float level just a bit”. Since it was a Holley, I pulled the sight plugs and took it down I/2 turn on the external adjustment. Problem solved. When I can get it on a hoist and get to the regulator I’ll do it right. But this is a boost referenced blow thru supercharged motor. So it could be the increase in temp is affecting the pressure and that’s where the flooding is coming from. I don’t know.

|

|

By Joe D - 8 Years Ago

|

KULTULZ (10/26/2018)

"Having trouble ID ing these Carter 4 barrel carbs. No tags and markings around base that I can find" Without the ASSEMBLY ID TAG(S), identification is going to be difficult as kits, parts and specs will vary between car makes. . http://www.secondchancegarage.com/public/186.cfmI'll attach an interpretation chart a little later. https://www.onallcylinders.com/wp-content/uploads/2016/03/31/vacumm-reading-1-752x1024.pngBy any chance, can you see any CASTING ID NOS. on the actual intake manifold? "Coolant temperature around 180 degrees and confirmed with a digital heat gun. I also tried insulating pressure side lines up to the carbs and still stalled. I do think its an inside carb issue." Don't forget ethanol blended gasoline has a much lower boiling point. Shoot the thermometer at that braided fuel line after driving for a while. It is sitting in direct airflow from a hot radiator. Also try to get an engine compartment temp reading. Usually, fuel bowl percolation happens after shutdown and resultant engine heat soak, causing the fuel to boil out of the bowl vents. Much heat is also picked up @ the mechanical fuel pump as it is attached to the engine directly.  You do have a filter before the carbs? No, I removed the fine brass screens that were in the carb inlet ports. It didn't help but I left them out for now. Wish I would get my act together ... The reason for the vacuum gauge is to insure the engine is tight. Some leaks manifest themselves once the engine is hot and things begin to expand.

|

|

By Joe D - 8 Years Ago

|

KULTULZ (10/26/2018)

"Having trouble ID ing these Carter 4 barrel carbs. No tags and markings around base that I can find" Without the ASSEMBLY ID TAG(S), identification is going to be difficult as kits, parts and specs will vary between car makes. . http://www.secondchancegarage.com/public/186.cfmI'll attach an interpretation chart a little later. https://www.onallcylinders.com/wp-content/uploads/2016/03/31/vacumm-reading-1-752x1024.pngBy any chance, can you see any CASTING ID NOS. on the actual intake manifold? "Coolant temperature around 180 degrees and confirmed with a digital heat gun. I also tried insulating pressure side lines up to the carbs and still stalled. I do think its an inside carb issue." Don't forget ethanol blended gasoline has a much lower boiling point. Shoot the thermometer at that braided fuel line after driving for a while. It is sitting in direct airflow from a hot radiator. Also try to get an engine compartment temp reading. Usually, fuel bowl percolation happens after shutdown and resultant engine heat soak, causing the fuel to boil out of the bowl vents. Much heat is also picked up @ the mechanical fuel pump as it is attached to the engine directly.  You do have a filter before the carbs? Wish I would get my act together ... The reason for the vacuum gauge is to insure the engine is tight. Some leaks manifest themselves once the engine is hot and things begin to expand. I removed the fine brass screens that were in the carb inlet ports.

|

|

By Joe D - 8 Years Ago

|

I removed the fine brass screens that were in the carb ports.

KULTULZ (10/26/2018)

"Having trouble ID ing these Carter 4 barrel carbs. No tags and markings around base that I can find" Without the ASSEMBLY ID TAG(S), identification is going to be difficult as kits, parts and specs will vary between car makes. . http://www.secondchancegarage.com/public/186.cfmI'll attach an interpretation chart a little later. https://www.onallcylinders.com/wp-content/uploads/2016/03/31/vacumm-reading-1-752x1024.pngBy any chance, can you see any CASTING ID NOS. on the actual intake manifold? "Coolant temperature around 180 degrees and confirmed with a digital heat gun. I also tried insulating pressure side lines up to the carbs and still stalled. I do think its an inside carb issue." Don't forget ethanol blended gasoline has a much lower boiling point. Shoot the thermometer at that braided fuel line after driving for a while. It is sitting in direct airflow from a hot radiator. Also try to get an engine compartment temp reading. Usually, fuel bowl percolation happens after shutdown and resultant engine heat soak, causing the fuel to boil out of the bowl vents. Much heat is also picked up @ the mechanical fuel pump as it is attached to the engine directly.  You do have a filter before the carbs? Wish I would get my act together ... The reason for the vacuum gauge is to insure the engine is tight. Some leaks manifest themselves once the engine is hot and things begin to expand.

|

|

By Joe D - 8 Years Ago

|

Ok tonight I drove the truck and it took awhile to make it stall because it was cool outside (52 degrees). After getting it to stall I pulled off the side of the road and checked the carbs:

I look into the carbs and saw some cloudy vapors. When I pulled back on the throttle gas did squirt in the back carb and then the front carb. I also checked the exhaust and it didn't smell like gas.

I'm going to get a tank full of ethanol free gas and see what happens. Stay tuned!

Thanks for all the help,

Joe D

|

|

By KULTULZ - 8 Years Ago

|

At the minimum, reinstall those screens. You have no particulate protection as the 10 micron inline filter @ the tank acts as a sock filter (as on later applications) and only catches boulders and JAP midget submarines (but it is useful).

When it shut down, did you check for spark also? The condensers coming through now are junk. Once they cool a little, the engine will fire right up.

Also on a possible vacuum leak. When this occurs it will lean out the fuel mixture at that point.

|

|

By Joe D - 8 Years Ago

|

I did not check spark but it always starts back up. I will pull a plug sometime to see if it is wet. Delaying that maneuver since they are hard to get at and those headers are hot!

Ok I will reinstall the fine mesh screens.

I don't have a condenser. I have PerTronix electronic points remember?

Hunting down these ethanol free gas stations. Hopefully it will stop raining someday in Pa!

Thanks again!!

|

|

By Joe D - 8 Years Ago

|

Oh, I also checked for vacuum leaks around carbs by spraying carbs while running with carb cleaner and found nothing yet.

|

|

By KULTULZ - 8 Years Ago

|

"I don't have a condenser. I have PerTronix electronic points remember?"

And I am an old fart that has advanced CRS. Please remember that...

Do you know if you have the IGNITOR I or II?

If you cannot determine a vacuum leak at the actual occurrence timing, you will most likely have an internal carb(s) problem.

Say your intake is not torqued down properly, it may induce a vacuum leak at a certain temp as it is allowed to move. Just something to think about. You need to buy (IMO) a combination vacuum/fuel pressure gauge ($20) just to verify engine condition and tune.

Did you kit the carbs at install or were they ready to go?

|

|

By GREENBIRD56 - 8 Years Ago

|

|

Just opened this to check on progress ...... there is an ancient thread that explains an old problem with the Pertronics being grounded properly. The factory braided copper jumper from the point plate to the dizzy housing must remain effective - and the dizzy must ground effectively to the block. Otherwise the voltage to the little black box doesn't stay at the appointed level. Probably not the case here...

What idle speed are you maintaining with this outfit? Will raising it impact the problem? My bird will go clear down to 450 without too much trouble (factory cam and Demon carb) - but not a good idea with the auto trans in drive. Sounds like your idle drops too low when the temp is up at operating temperature.

Fuel pump may need to be thumping along a little quicker to draw sufficient suction. On my outfit I chose to put a pressurized canister style filter on the carb side - not the tank line.

How do you have the carbs rigged for idle? Front closed and idle off the rear - or what operational scheme is in play here? If you have a GM carb set-up (Corvette or Caddy) this may make a difference. I believe there were Carters on the Mercury engine but I know little about them.

|

|

By DryLakesRacer - 8 Years Ago

|

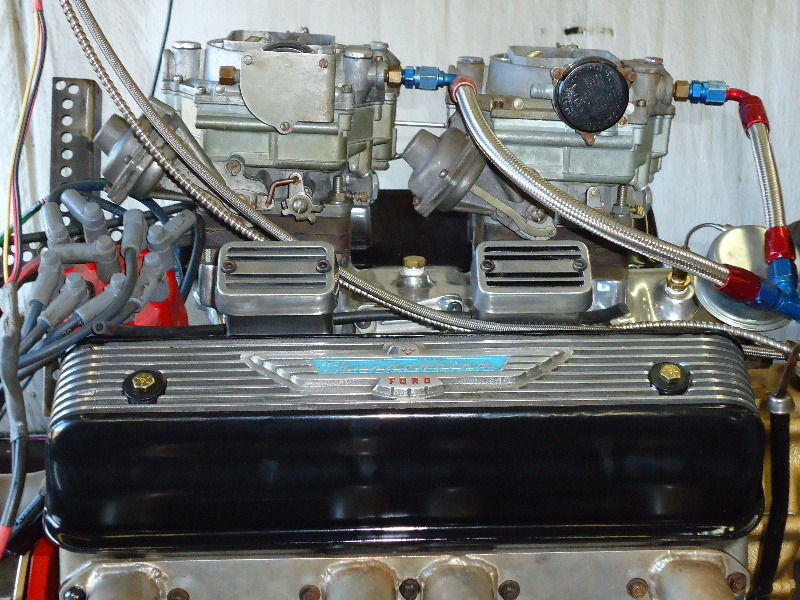

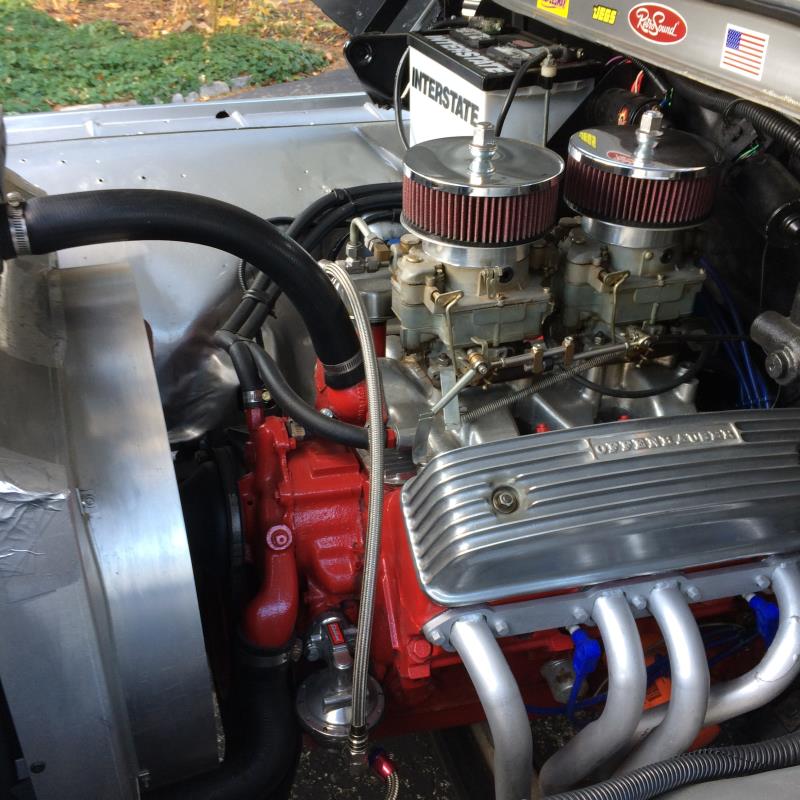

Joe D. Form the begining when you said you had Carter carbs and spacers I assumed AFB's. By the photo of the engine in the truck and the other side view your carbs are Carter small base WCFB's off 55-56 Mercurys. They were used only with Loadmatic distributors which maybe part of your problem. Ted Eaton showed how to modify the teapot Holley to run with the later dist but no one I know has modified these carbs which were also used on Lincolns. I can tell by the vacuum system to open the secondaries. I have a few of these carbs also.

I learned when I replaced the teapot Holley on my 56 Ford with a 53 Cadillac Carter WCFB (changed to a 57 dist at the same time) the heat from the manifold boiled the gas in the carb. I found a guy on E-Bay that sold phenolic ones for the small base.

When I added my dual quads 5 years ago I naturally bought another phenolic plate. I use the 3/8" ones. I have run my set up for 5 years without problems. Having read you need to hold the pedal wide open to restart says flooded to me (boiled). It can definately be heat causing this. I now use WCFB's from 1953 303" Oldsmobiles (matched set) the only time starting is a problem is when I leave sit over 2 weeks without running which I blame on the gasoline. A standard cold start is press the pedal to the floor to squirt in the front and back of the manifold and it starts right up. When warm I don't touch anything but the key.

I hope some of this helps. Photos of mine have been on here before but here's again. I used a black felt pen on the edge of the phenolic.

|

|

By Joe D - 8 Years Ago

|

KULTULZ (10/27/2018)

"I don't have a condenser. I have PerTronix electronic points remember?" And I am an old fart that has advanced CRS. Please remember that...  Do you know if you have the IGNITOR I or II? The invoice from speedway just says pertronix (6-2015). If you cannot determine a vacuum leak at the actual occurrence timing, you will most likely have an internal carb(s) problem. Say your intake is not torqued down properly, it may induce a vacuum leak at a certain temp as it is allowed to move. Just something to think about. You need to buy (IMO) a combination vacuum/fuel pressure gauge ($20) just to verify engine condition and tune. Did you kit the carbs at install or were they ready to go? The previous owner had one of the carbs worked on as it was giving him trouble. I did not do the frame off restoration or engine rebuild on my truck. I torqued down on the intake manifold bolts. They seems tight.

|

|

By Joe D - 8 Years Ago

|

Idle is around 1000 rpm, tried different setting with no luck but it seems to like 1000.

The rear carb is the one controlling the idle.

Thanks for the help!

|

|

By KULTULZ - 8 Years Ago

|

"Joe D. Form the begining when you said you had Carter carbs and spacers I assumed AFB's. By the photo of the engine in the truck and the other side view your carbs are Carter small base WCFB's off 55-56 Mercurys. They were used only with Loadmatic distributors which maybe part of your problem. Ted Eaton showed how to modify the teapot Holley to run with the later dist but no one I know has modified these carbs which were also used on Lincolns. I can tell by the vacuum system to open the secondaries. I have a few of these carbs also."

... hmm ...

THANX for the wake-up call ...

"Dual Quads (Carter) are off of a 1957 T -Bird I was told.."

The intake may be 57 BIRD but not the WCFB's.

If these are MERC WCFB carbs, they will be LOAD-O-MATIC modified (CARTER FACTORY) to use with a LOAD-O-MATIC distributor. Shown is a photo showing location of the SPARK CONTROL VALVE-

Do you see the SCV under the fuel inlet line? Do you see this valve on either of your carbs? Do you know if your distributor is LOM or 57/ Dual Advance?

May have stumbled across the reason for the shutdown between gears. I will explain once you determine what you have.

Curb idle @ 1000RPM? You either have some type of vacuum leak or one hell of a cam.

|

|

By DryLakesRacer - 8 Years Ago

|

On you tube I've a short video. (Y-Block dual quads) in drive mine idles at 625. The only time mine shows any quirks is after a long run at freeway speeds and coming to stop I sometimes must put it in nuetral. Don't know way but it acts like it's loaded up but there is no black smoke or smell. I do "open it up" every month or so to flow fuel out of every jet and seeing 90-95 mph makes me feel good.

I also have a Lincoln small base Carter WCFB with an aluminum base. It has the vacuum actuator secondaries but no spark control valve on the front. I bought rebuilt on E-bay many years ago and small tag on it said 57 Lincoln and the brass triangle tag matched by a search by me on the Internet.

|

|

By KULTULZ - 8 Years Ago

|

Is your DIST LOM or Dual Advance? If Dual Advance, ported or manifold vacuum (if you are using a vacuum advance)?

I think you said you have GM WCFB's on it.

|

|

By DryLakesRacer - 8 Years Ago

|

KULTULZ, if your askin me and not JoeD, Mine is a 57-up, I mentioned I installed it when I put the 1953 Cadillac Carter WCFB on my "A" manifold.

Funny thing is I always liked the Rochester small base 4GC which was the replacement carb on the Cadillacs and 98 Oldsmobiles and I've spent a lot trying to them make on work on my 296" Y. I have perfect ones but none will work correctly. All the GM style WCFB's work great.

Packard, Mopar, Studebaker, are good sources for Small base 4 barrels it seem FOMOCO used the vacuum secondaries.

|

|

By Joe D - 8 Years Ago

|

Thanks! I'm going to try the spacers. Kultulz added a link for the WCFB spacers.

Still trying to imagine how boiling causes flooding. Is it because the floats drop and let too much fuel in at once or what?

|

|

By Joe D - 8 Years Ago

|

KULTULZ (10/27/2018)

"Joe D. Form the begining when you said you had Carter carbs and spacers I assumed AFB's. By the photo of the engine in the truck and the other side view your carbs are Carter small base WCFB's off 55-56 Mercurys. They were used only with Loadmatic distributors which maybe part of your problem. Ted Eaton showed how to modify the teapot Holley to run with the later dist but no one I know has modified these carbs which were also used on Lincolns. I can tell by the vacuum system to open the secondaries. I have a few of these carbs also." ... hmm ... THANX for the wake-up call ... "Dual Quads (Carter) are off of a 1957 T -Bird I was told.." The intake may be 57 BIRD but not the WCFB's. If these are MERC WCFB carbs, they will be LOAD-O-MATIC modified (CARTER FACTORY) to use with a LOAD-O-MATIC distributor. Shown is a photo showing location of the SPARK CONTROL VALVE-  Do you see the SCV under the fuel inlet line? Do you see this valve on either of your carbs? Do you know if your distributor is LOM or 57/ Dual Advance? May have stumbled across the reason for the shutdown between gears. I will explain once you determine what you have. Curb idle @ 1000RPM? You either have some type of vacuum leak or one hell of a cam.

Do you mean that glass fuel bowl looking thing?

Stock cam I was told. Also have to advance the timing quite a bit from 4 degrees TDC for it to run right.

|

|

By KULTULZ - 8 Years Ago

|

"Do you mean that glass fuel bowl looking thing?"

No, On the carb center base is a valve that appears similar to a power valve-

.

|

|

By KULTULZ - 8 Years Ago

|

"Joe D

Still trying to imagine how boiling causes flooding. Is it because the floats drop and let too much fuel in at once or what"

Yes, and-

When heat causes fuel percolation, high pressure is created in the bowl. As the gasoline becomes a vapor, pressure within the bowl forces the vaporized fuel to discharge through the bowl vents flooding the carb. If the boiling happens in the fuel line, excessive pressure, if not relieved through the pump, forces the needle/seat open giving results as as described above.

Now this occurs on a straight with no turning of the vehicle mainly?

|

|

By KULTULZ - 8 Years Ago

|

DryLakesRacer Posted-

"KULTULZ, if your askin me and not JoeD, Mine is a 57-up, I mentioned I installed it when I put the 1953 Cadillac Carter WCFB on my "A" manifold."

Sorry about that. I (or my browser) have difficulty with this format. I will try to be more considerate in the future.

|

|

By Ted - 8 Years Ago

|

The factory dual quad setups idled off of both carbs but those carbs were calibrated to do that. You can experiment with both carbs sharing idle responsibilities and see if that helps. I’ve always felt that the Y engines were happier in day to day driving with both carburetors being synchronized together rather than running off of one for normal driving. I’ll point to the basic intake manifold design for that and by using the synchronized carbs, then the fuel distribution to all eight cylinders is improved.

From your initial description, if the tranny is simply put into neutral when you’re running 50 mph, it dies. Is that correct? Was the engine running rough prior to putting the tranny in neutral? Does the engine shut down by itself if simply allowing it to idle for an extended period of time? Having to hold the throttle open to start the engine and then letting the engine clear itself out once started sounds like a flooding issue. While much of the prior discussion wants to blame ethanol laden fuel, I’ll suggest checking the fuel for the actual ethanol content. I’ve found as much as 30% in pump gasoline advertised as being no higher than 10% so in that case, it could be a problem. In my part of the country, premium fuel has been no more than 5% ethanol although the pumps say the gasoline can contain up to 10%.

What distributor are you running; early (LOM, 56 and older) or late (’57 and newer)? Are you running the engine with the vacuum advance hooked up? I see from the pictures that you’re using the 1956 Ford/Merc Carter carbs and those need some work if using them on a dual quad setup. The Carters are sensitive to varying fuel pressure and as such can be tempermental on float levels if the fuel pressure is varying. As previously mentioned, those ’56 model Carter carburetors are designed to work with the LOM distributors and if the vacuum advance port is used with the later model distributors, then there’s the potential for too much ignition advance at full throttle or high speed cruising. If not using the vacuum advance, be sure that the ports for the vacuum advance in both carburetors are plugged.

Once you get past the stalling problem, you’ll need to address the secondary spring tension. When using carbs in pairs, the air flow cuts in half through each carb. The metering system in some single 4V carbs is not up feeding enough fuel with the reduced air flow when used in pairs and especially if the camshaft is on the rowdy side where manifold vacuum is significantly reduced or there’s some low speed reversion taking place within the intake manifold. Assuming that’s not a problem, then the secondary spring tension needs to be cut in half so the secondaries open up at a reasonable rpm and not at 5500 rpms and above. This doesn’t mean cutting the springs in half but rather fixing the springs so that they have half the tension. For the Holley carbs, spring kits are available to accomplish this. I’ve seen no such spring kits for the Carter carbs as Ford for ’56 and ’57 were the only Carter carbs I’m aware of that used secondary springs. The rest of the auto manufacturers used alternative means to open the secondaries on their Carter 4V carb equipped engines. I’ve simply had to experiment with both the ’56 and ’57 Carter carbs on cutting and heating the spring coils and trying the modified springs on the engine dyno. This would be tough to do on a running vehicle unless performed on a chassis dyno.

Here are pictures of the ’56 Ford/Merc 312 Carter carbs on the dyno being tested.

|

|

By Joe D - 8 Years Ago

|

Wow, you guys have really helped me a lot. I'm learning, Thanks!

I believe the distributor is stock and not sure if its dual advance or not. I do know that it really does not change the performance of the engine if I plug it or hook it up to one of the carb ports or the manifold port.

The stalling occurs after highway speeds and accelerating fairly hard. Engine has to be fully heated up (180-195). When load is suddenly taken off by placing in neutral she dies. Tach drops to zero but she always restarts. I can keep her running by goosing the accelerator or down shifting so I'm still driving and trying deferent things that are improvements and don't cost a lot. Yesterday I insulated the fuel lines running along the frame near the headers and the pump discharge line to the carbs. I had some thick insulating tape and it took me about 1/2 hour.

Last night I ordered a set of phenolic spacers (from Dashman $90) for under the carbs to replace the aluminum ones. Thanks Kultulz!

I also learned that WCFB stands for Will Carter Four Barrel. ID ing the carb was huge so I could order the spacers and a kit if needed.

Other than the stalling issue the truck has never run better.

Thanks again Y-blockers!

Joe D

|

|

By Joe D - 8 Years Ago

|

[quote]KULTULZ (10/28/2018)

"Joe D Still trying to imagine how boiling causes flooding. Is it because the floats drop and let too much fuel in at once or what" Yes, and- When heat causes fuel percolation, high pressure is created in the bowl. As the gasoline becomes a vapor, pressure within the bowl forces the vaporized fuel to discharge through the bowl vents flooding the carb. If the boiling happens in the fuel line, excessive pressure, if not relieved through the pump, forces the needle/seat open giving results as as described above. Now this occurs on a straight with no turning of the vehicle mainly?

|

|

By Joe D - 8 Years Ago

|

Ted (10/28/2018)

The factory dual quad setups idled off of both carbs but those carbs were calibrated to do that. You can experiment with both carbs sharing idle responsibilities and see if that helps. I’ve always felt that the Y engines were happier in day to day driving with both carburetors being synchronized together rather than running off of one for normal driving. I’ll point to the basic intake manifold design for that and by using the synchronized carbs, then the fuel distribution to all eight cylinders is improved. From your initial description, if the tranny is simply put into neutral when you’re running 50 mph, it dies. Is that correct? yes only when up to atleast 180 degrees for a while. Was the engine running rough prior to putting the tranny in neutral? No it runs great. Does the engine shut down by itself if simply allowing it to idle for an extended period of time? No never. Having to hold the throttle open to start the engine and then letting the engine clear itself out once started sounds like a flooding issue. While much of the prior discussion wants to blame ethanol laden fuel, I’ll suggest checking the fuel for the actual ethanol content. I’ve found as much as 30% in pump gasoline advertised as being no higher than 10% so in that case, it could be a problem. In my part of the country, premium fuel has been no more than 5% ethanol although the pumps say the gasoline can contain up to 10%. I can ask a refinery lab tech since I work at a refinery that supplies Sunoco with their fuel in the Philly area. I do know since I used to blend gasoline that they add more light end components in the winter season (high vapor pressure) as opposed to (low vapor pressure) in the summer months. What distributor are you running; early (LOM, 56 and older) or late (’57 and newer)? Are you running the engine with the vacuum advance hooked up? I see from the pictures that you’re using the 1956 Ford/Merc Carter carbs and those need some work if using them on a dual quad setup. The Carters are sensitive to varying fuel pressure and as such can be tempermental on float levels if the fuel pressure is varying. As previously mentioned, those ’56 model Carter carburetors are designed to work with the LOM distributors and if the vacuum advance port is used with the later model distributors, then there’s the potential for too much ignition advance at full throttle or high speed cruising. If not using the vacuum advance, be sure that the ports for the vacuum advance in both carburetors are plugged. Once you get past the stalling problem, you’ll need to address the secondary spring tension. When using carbs in pairs, the air flow cuts in half through each carb. The metering system in some single 4V carbs is not up feeding enough fuel with the reduced air flow when used in pairs and especially if the camshaft is on the rowdy side where manifold vacuum is significantly reduced or there’s some low speed reversion taking place within the intake manifold. Assuming that’s not a problem, then the secondary spring tension needs to be cut in half so the secondaries open up at a reasonable rpm and not at 5500 rpms and above. This doesn’t mean cutting the springs in half but rather fixing the springs so that they have half the tension. For the Holley carbs, spring kits are available to accomplish this. I’ve seen no such spring kits for the Carter carbs as Ford for ’56 and ’57 were the only Carter carbs I’m aware of that used secondary springs. The rest of the auto manufacturers used alternative means to open the secondaries on their Carter 4V carb equipped engines. I’ve simply had to experiment with both the ’56 and ’57 Carter carbs on cutting and heating the spring coils and trying the modified springs on the engine dyno. This would be tough to do on a running vehicle unless performed on a chassis dyno. A lot of this stuff is way over my head but I do know some great mechanics like you! Here are pictures of the ’56 Ford/Merc 312 Carter carbs on the dyno being tested.

|

|

By DryLakesRacer - 8 Years Ago

|

JoeD, this may seem a little primative and others will probably chime in. To check which distributor you have just take off the cap and try to turn the rotor. If it will not move in either direction it's a Loadmatic. If it will move in one direction about 10-12* it is a centrifugal, which is 57-up. Also stick a long enough hose on the distributor can filling and suck on it to see if the plate moves, if it does that will prove your vacuum can is working. If it will stay moved with your tongue tip over the end of the hose the can is good.

Your truck is a 1960. I cannot believe your dist is a loadmatic.

As Ted stated the Merc WCFB's were used with loadmatics in 55-56 and were not compatible with the 57-up distributors that's why I first went to the GM carbs because they were.

There were many of the guys I knew back in the 60's who ran their distributor vacuum off manifold and not ported and made them work. The engine would always idle faster and the just turned them down. Others ran no vacuum and set the advancing springs as light as possible and kept total advance around 34-37 degrees and just lived where initial advance showed on the balencer. We were just kids, what did we know anyway.

We all have ideas that seem to work. Eventho I'm a California guy I've met Ted and watched him do dyno pulls (thanks to Karol Miller) and he has done more tests and ran every combination known to man on a Y-Block and I take his word as gospel. He and so many others on this site have helped me iron out problems which have never happened to me before and cannot thank them enough.

You will figure this out.

|

|

By oldcarmark - 8 Years Ago

|

DryLakesRacer (10/28/2018)

JoeD, this may seem a little primative and others will probably chime in. To check which distributor you have just take off the cap and try to turn the rotor. If it will not move in either direction it's a Loadmatic. If it will move in one direction about 10-12* it is a centrifugal, which is 57-up. Also stick a long enough hose on the distributor can filling and suck on it to see if the plate moves, if it does that will prove your vacuum can is working. If it will stay moved with your tongue tip over the end of the hose the can is good. Your truck is a 1960. I cannot believe your dist is a loadmatic. As Ted stated the Merc WCFB's were used with loadmatics in 55-56 and were not compatible with the 57-up distributors that's why I first went to the GM carbs because they were. There were many of the guys I knew back in the 60's who ran their distributor vacuum off manifold and not ported and made them work. The engine would always idle faster and the just turned them down. Others ran no vacuum and set the advancing springs as light as possible and kept total advance around 34-37 degrees and just lived where initial advance showed on the balencer. We were just kids, what did we know anyway. We all have ideas that seem to work. Eventho I'm a California guy I've met Ted and watched him do dyno pulls (thanks to Karol Miller) and he has done more tests and ran every combination known to man on a Y-Block and I take his word as gospel. He and so many others on this site have helped me iron out problems which have never happened to me before and cannot thank them enough. You will figure this out.

Take the Cap off. If U can see Springs its a Loadomatic. No Springs visible makes it a Dual Advance 57+ Distributor.

|

|

By charliemccraney - 8 Years Ago

|

Or, with the distributor cap off:

Load-O-Matic, advance springs visible

Centrifugal, advance springs not visible.

I run manifold vacuum because more advance does help an engine to idle cooler and it does feel ever so slightly more responsive right off idle than ported vacuum. There's not much to make work with this vs ported. Adjust idle speed down, readjust mixture screws and that's about it. The functional difference between the two is at idle, no additional advance with ported, full vacuum advance with manifold. Just above idle, ported becomes manifold and they work the same.

In the case here, ported is not an option and it must be manifold or nothing.

|

|

By KULTULZ - 8 Years Ago

|

I think all of this boils down to a mis-match of parts, not know whether the carburetion/ignition is LOM or DUAL ADVANCE, or a possible combination of either..

The vacuum secondary WCFB was offered (by LINC-MERC) in both LOM and DUAL ADV (1957/ ).

That said, we need to know if the carb(s) has a SPARK CONTROL VALVE and DIST TYPE. It would also be helpful to know the INTAKE ID.

The 1st photo shows a LOM DIST BOWL and the second a 57/59 DUAL ADVANCE.

|

|

By KULTULZ - 8 Years Ago

|

PART II

The LOM was a system using modulated MANIFOLD VACUUM. This system (manifold vacuum use) has it's drawbacks and FORD addressed those with the 56 DUAL PORT DIAPHRAM vacuum advance.

What is needed now is positive ID of components.

As for TED EATON, he is the man, plain and simple.

|

|

By Joe D - 8 Years Ago

|

|

Ok, I'll find out what parts I have tonight,

Distributor type? Original equipment Dual Advance distributor. I checked the vacuum advance with a hose and it moves and holds vacuum. Thanks DryLakes Racer! Easy test!

Manifold markings? 5-13 See photo to be added

WCFB Carb spark control valve? See photo to be added

While checking distributor and wires I noticed #5 spark plug was loose as it was turning as I moved the spark plug boot. Maybe Stalling issue??

Saturday I removed an old choke mechanism from the front carb since it was never hooked up. While running engine discovered vacuum leak where the choke was. A small tube sticking out a little where the choke mechanism once was.

Test drove: Ran great and idling around 1000 rpm. Seems like I can not get idle any lower with the idle screws on front and back carbs. Screws all the way out. Vacuum advance hooked up to back carb port, manifold port capped.

Did not run long enough to test stalling issue. Hope to drive 21 miles to work tomorrow. That will be a good test.

Ethanol Free gasoline search in Philly area - You have to go to Reading area (1 1/2 Hr. from me) to find it out of a pump or by it in a 5 gallon can (95 octane) for around $50. You can get higher octane racing fuel also VP Racing 100,109,110.

I Talked to a refinery Lab Tech and he believes all gas in philly area has 10% added to it. 87 OCT and 93 OCT. I thought less was added to the 93 OCT before I spoke to him.

Thanks to all for the info!

Joe D

|

|

By Joe D - 8 Years Ago

|

DryLakesRacer (10/28/2018)

JoeD, this may seem a little primative and others will probably chime in. To check which distributor you have just take off the cap and try to turn the rotor. If it will not move in either direction it's a Loadmatic. If it will move in one direction about 10-12* it is a centrifugal, which is 57-up. Also stick a long enough hose on the distributor can filling and suck on it to see if the plate moves, if it does that will prove your vacuum can is working. If it will stay moved with your tongue tip over the end of the hose the can is good.

Your truck is a 1960. I cannot believe your dist is a loadmatic. Thanks I will perform this test and report back.

As Ted stated the Merc WCFB's were used with loadmatics in 55-56 and were not compatible with the 57-up distributors that's why I first went to the GM carbs because they were.

There were many of the guys I knew back in the 60's who ran their distributor vacuum off manifold and not ported and made them work. The engine would always idle faster and the just turned them down. Others ran no vacuum and set the advancing springs as light as possible and kept total advance around 34-37 degrees and just lived where initial advance showed on the balencer. We were just kids, what did we know anyway.

We all have ideas that seem to work. Eventho I'm a California guy I've met Ted and watched him do dyno pulls (thanks to Karol Miller) and he has done more tests and ran every combination known to man on a Y-Block and I take his word as gospel. He and so many others on this site have helped me iron out problems which have never happened to me before and cannot thank them enough.

You will figure this out.

Thanks old pal!

Joe D

|

|

By KULTULZ - 8 Years Ago

|

Joe D Posted-

"Ethanol Free gasoline search in Philly area - You have to go to Reading area (1 1/2 Hr. from me) to find it out of a pump or by it in a 5 gallon can (95 octane) for around $50. You can get higher octane racing fuel also VP Racing 100,109,110."

Just a thought. If you are in the Philly area, ethanol free gasoline is also usually sold in marinas and may not be listed in the fuel reference site. Common areas to find are agricultural regions, small airports and marinas

Waiting for more definite engine assembly details/photos..

|

|

By Joe D - 8 Years Ago

|

Manifold 5-13, off of a 57 T-bird According to previous owner.

|

|

By Joe D - 8 Years Ago

|

Bottom of front carb. Spark Valve?

|

|

By Ted - 8 Years Ago

|

|

If you cannot get the engine to idle down with the idle mixture screws backed all the way out, then I’ll suggest removing the carbs from the manifold and checking out the carbs in detail. First off look at the rear secondaries to insure that they are completely seated when closed. If the throttle blades have been removed from their shafts in the past, then there’s a good chance the assembler did not get the blades properly realigned on the shafts and you have one or more blades out of sync with the others simply making for an uncontrolled air leak. Hence the failure to get the engine to properly idle down with the idle control screws.

|

|

By Joe D - 8 Years Ago

|

Stock 1960 F-100 MD 292 V-8 Dual Advance Distributor with Pertronix electronic points. Not Pertronix II. I was told there is no Pertronix I. Bought them in 2015. Checked vacuum advance with hose (DryLakesRacer) and it moved and held vacuum.

Drove to work this morning and ran great until I got off the highway and place her in neutral. Engine died again and restarted by placing back in gear and had to goose the accelerator to keep her running. Idled kind of rough between 800-900. Before this happens its idling at 1000 and smooth. Coolant temp went to around 190 as I parked and let it idle rough.

Hope the phenolic spacers Work!!

Thanks Y-Blockers!

Joe D

|

|

By Ted - 8 Years Ago

|

|

Thanks for the detailed pictures of the front of your carb. Do you have the Carter carb numbers stamped on your carbs handy? No spark control valves and vacuum secondary diaphragms makes this carb an oddity.

|

|

By Joe D - 8 Years Ago

|

The only numbers I can find is on the top of each carb, throttle side - 6-1273

on the front Patent Re 21610 followed by a bunch of other patent numbers. The previous owner said they and the intake were off of a 57 T-Bird.

When I take the carbs off to install the Phenolic spacers I'll get someone to look at them with your suggested checks. I'm certainty not qualified for that inspection.

Thanks for the help!

Joe D

|

|

By charliemccraney - 8 Years Ago

|

|

1000rpm idle is pretty high. Unless you have a cam that requires that, it could be a clue to what's happening. Is there a reason for that idle speed?

|

|

By KULTULZ - 8 Years Ago

|

OK, so now we know it is not LOM. The CARB style points to 1957 MERC (368 CI) and 1957 LINC (368 CI).

As Ted has posted, most likely now the problem(s) lie within the carb and/or throttle linkage. Make sure when inspected the secondaries close completely. When you adjust multi-carbs, you do so with linkages removed. Once satisfied with carb balance (your system is using two primary carbs), you then install linkage and adjust from there.

BTW- If the intake manifold is FORD 1957 8V (ECG-9424-D), it takes a special valley cover pan to allow the bottom of the intake not to overheat and be subject to damage.

NOTE TO SELF- Could the throttle bores/plates be larger on the 57 WCFB and be causing the interference if any?

|

|

By Joe D - 8 Years Ago

|

|

Charlie McCraney, No reason for the high idle (1000 rpm). I spoke to the guy who did the restore and he said when he tried to back it down it did not run right. I did try to lower recently but the idle screws where all the way backed out. (see other posts and comments).

Kultulz, When I take the carbs off to install spacers I will have someone inspect, rebuild or replace with something less unusual! A friend of mine suggested EFI but I kind of like the dual quads carburetors. Old school cool, you know?

Any suggestions on a set of carbs that would be good for this application?

What is that a picture of??

NOTE: The truck ran good for 3 years before I had this stalling issue after heating up. The previous owner said he drove it for 4 years or so without any issues also.

Thanks Y Blockers!

Joe D (The Frig)

|

|

By DryLakesRacer - 8 Years Ago

|

A lot has been discussed here. Teds response saying both need to be set up to work at idle definately worked for me. If your going to keep them and I would you might want what I show in the enclosed photos. It is an Edelbrock Uni-Syn for synconizing mult-carb engines. All 3 parts I made mine from are available from Summit and others. The aluminum cap is for a 5-1/8" carb with a 1-1/4" hole in it and the black adapter is plastic for a 4-7/8" carb to to the top cap. Its attached with RTV. About $45 for odd the parts. Once I set mine I've checked it only one other time. The number isn't as important as them being equal.

|

|

By KULTULZ - 8 Years Ago

|

"Kultulz, When I take the carbs off to install spacers I will have someone inspect, rebuild or replace with something less unusual! A friend of mine suggested EFI but I kind of like the dual quads carburetors. Old school cool, you know?

Any suggestions on a set of carbs that would be good for this application?

What is that a picture of??"

I would try and use what you have (they are FORD issue). Most likely, the problem(s) is in either the carb(s) or linkage adjustment. Maybe something binds when hot and not cold? Will cause a vacuum leak and very lean mixture and she wants to shut down.

The photo is of a valley pan especially for the 1957 E-CODE (8V). Re-read the description.

|

|

By KULTULZ - 8 Years Ago

|

Joe-

Did this 8V setup come with the truck or you bought the set as a take-off and installed them yourself?

Regarding balancing carbs, watch this- https://www.youtube.com/watch?v=mNzjAyHAl0A

|

|

By Joe D - 8 Years Ago

|

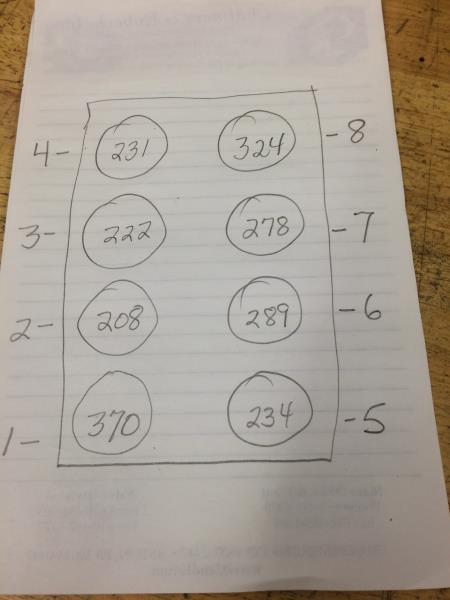

I did not put this set up together. I bought the truck 3 1/2 years ago from a small dealer. It was about 80% finished. I recently talked to the owner from Ohio who did the restoration. I found him through receipts that came with the truck. This is a sign he made that came with the truck. Sorry I tried to flip it!

|

|

By KULTULZ - 8 Years Ago

|

THANX for that!

So the truck was bought with the 8V assembled on the engine? Was the drive-ability problem noticed at purchase or started later?

|

|

By Joe D - 8 Years Ago

|

I did not assemble the engine KultulZ. Issue started this year back in March and seems to be getting worse lately. I drove for 3 years without the issue. This morning after restating it did recover but took several minutes before it returned to somewhat steady 1000 rpm.

Does anyone know someone or a good company that I could ship carbs to and have them rebuild and adjust.

|

|

By KULTULZ - 8 Years Ago

|

Sounds like they need to be gone through. That's the trouble with multi-carburetion, it's neat but requires more maintenance.

I forgot to ask, is the vacuum signal to the DIST ported or manifold?

Also when you applied lip vacuum (in lieu of a MITY-VAC) to the DIST advance canister and after confirming it held vacuum, did you notice free movement of the top plate, both advance and retract. No binding?

|

|

By Joe D - 8 Years Ago

|

The distributor vacuum advance is hooked up to a port on the rear carb. I also tried the manifold vacuum and also plugging vacuum advance off and did not really notice any difference in performance so I hooked it back up the way it was when I bought the truck.

When performing the lip vacuum test, I varied the vacuum applied to the diaphragm and the plate seemed to slide back and forth with no binding or erratic movements. However, after performing this test procedure, I did feel a little light headed and I needed to sit down for awhile !!

|

|

By DryLakesRacer - 8 Years Ago

|

Joe, do you open it up every so often? I do about once a month. You need to flow fuel thru all 8 barrels. That's what happened to a lot of 3-2 and 2-4 sets ups from the factory. Grandma didn't do it. Fords Y's were not progressive as Ted said and Carters and Rochesters have fairly long arms on their floats which do change on a vibrating/running engine. I haven't touched mine in 5 yrs after synconizing them and other than a little less fuel milage I see no reason to remove them. It also sounds like you also have a minor vacuum leak. Check the bottoms of your carbs really close when installing the isolation plates. I'd run a flat body file over both and check the manifold surface too.

Remember to get 4 new gaskets ( small base) I thing the guy who I got my plates from sold them. They should be soft..not crispy critters.. that will make the best seal.

|

|

By Joe D - 8 Years Ago

|

I do open her up often. Today is the third day I drove her into work this week and it's 21 miles of highway driving each way. I'll look over the carbs real good and have a someone else check them as well since I'm a novice. I'll keep you updated. Yesterday while adjusting the idle on the front carb I heard a whistling sound but could not figure out where it was coming from? Maybe from inside the carb throat since I have the air cleaners off.

Thanks again! I'll keep you Y-Blockers updated.

Joe D (The Frig)

|

|

By KULTULZ - 8 Years Ago

|

Don't forget to get back as I wish to know what you finally come across...

|

|

By Joe D - 8 Years Ago

|

|

|

By Joe D - 8 Years Ago

|

That's a cool video. I'm gone make one of those instruments!

Thanks, Joe D

|

|

By Joe D - 8 Years Ago

|

DryLakesRacer (10/30/2018)

A lot has been discussed here. Teds response saying both need to be set up to work at idle definately worked for me. If your going to keep them and I would you might want what I show in the enclosed photos. It is an Edelbrock Uni-Syn for synconizing mult-carb engines. All 3 parts I made mine from are available from Summit and others. The aluminum cap is for a 5-1/8" carb with a 1-1/4" hole in it and the black adapter is plastic for a 4-7/8" carb to to the top cap. Its attached with RTV. About $45 for odd the parts. Once I set mine I've checked it only one other time. The number isn't as important as them being equal.

Thanks I'm going to make one of those!

He is adjusting the mix screws right, not just the idle?

Joe D

|

|

By KULTULZ - 8 Years Ago

|

Well, actually both. You disconnect the linkage(s) and adjust mixture on each carb to get the best idle and then use the UNI-SYN to match balance/same idle speed. Then you go to the linkage(s). Then re-check with the UNI-SYN.

The trouble is with solids and multi carb, you need to go over it frequently to keep all in tune.

.

|

|

By Joe D - 8 Years Ago

|

Thanks Kultultz!

I ordered a uni sync and vacuum gage test kit and received the insulated spacers and gaskets yesterday.

DryLakesRacer

The gaskets are nice and spongy and not crispy critters!

Should these gaskets be sealed with Gaskacinch or just put on dry as they come?

|

|

By KULTULZ - 8 Years Ago

|

Dry and make sure both carb(s) and intake carb pad(s) are clean and flat.

Torque to spec.

|

|

By Sandbird - 8 Years Ago

|

|

Did you ever consider trying a 160 deg, thermostat to see how things work out?

|

|

By Joe D - 8 Years Ago

|

I actually have a 160 degree thermostat and I drilled a 1/8 hole it to always keep a flow going through it. I was told this helps prevent pump cavitation.

The engine cooling system has never boiled over and the hottest its ever gotten is around 195.

Thanks Sandbird!

Joe D

|

|

By Joe D - 8 Years Ago

|

KULTULZ (11/2/2018)

Dry and make sure both carb(s) and intake carb pad(s) are clean and flat. Torque to spec.

Ok, I'll make sure they are nice and clean and flat, especially since this could be a vacuum leak.

|

|

By Joe D - 8 Years Ago

|

|

|

By Joe D - 8 Years Ago

|

|

|

By Joe D - 8 Years Ago

|

|

|

By Joe D - 8 Years Ago

|

I removed carbs. Hopefully I can ID to be able to get rebuild kit. Not sure if 1-(1406) means anything?

Also manifold ID 5-13 mean anything?

Front carb primary and secondary valves did not snap shut as well as the rear carbs did when manually operated off the engine Possible issue with secondary's not closing like Ted had mentioned?

Thanks Y blockers!

Joe D

|

|

By Joe D - 8 Years Ago

|

Also manifold where carbs mount seem nice and flat and true. Gaskets and spacers seemed to be ok. They are composite and not aluminum like I thought. Oh well I guess its not fuel boiling in the carbs.

|

|

By Joe D - 8 Years Ago

|

|

|

By KULTULZ - 8 Years Ago

|

Joe D (11/5/2018)

I removed carbs. Hopefully I can ID to be able to get rebuild kit. Not sure if 1-(1406) means anything?

Front carb primary and secondary valves did not snap shut as well as the rear carbs did when manually operated off the engine Possible issue with secondary's not closing like Ted had mentioned? The operation of the throttle shafts/blades is your first step. Sounds like you found your first defect. The blades have to operate freely in the bores. Now for some bad news. It seems CHRY used this same design also (vacuum secondaries). So without the ID TAGS it is going to be difficult to ID and find the correct kit/parts. The CASTING ID NO you showed (and others) can be used to ID a carb, but all the references I have come across seems to be GM. I am going to E-MAIL you a possible source of info about this CARB SERIES as I don't know if posting it is allowed. Whatever happens or you decide to do please let the board know as I am on a steep learning curve here.

|

|

By Joe D - 8 Years Ago

|

KultulZ

I gave up on ID ing the carbs and finding the right kits for them. Even if I found one I would then I'd have to find someone to do the rebuild because It's above my capabilities.

I'm sending them out tomorrow to be rebuilt and hopefully have them back in 2 weeks.

I'll be asking for help when I have them re installed and it comes time to adjust them. I should have my uni-sync ready by then and my new vacuum gage kit!

Thanks Again!

Joe D

|

|

By KULTULZ - 8 Years Ago

|

|

COPY!

|

|

By Joe D - 8 Years Ago

|

Well I got the carbs back reinstalled and test drove. Still stalling after up to temp!!!! Runs great until up to 180 degrees.

Carb idle screws backed all the way out. Idles around 1000 RPM. Mix screws backed out two turns. tried to adjust but really didn't seem to change how it idled. Carbs are synched at idle. Manifold vacuum reading 14 " at 1000RPM.

Drove to work this morning and stalled coming off of highway and I could not keep it idling without goosing the accelerator. Before carbs were rebuilt it seemed to recover after a couple of minutes of goosing and idling. Matbe because mix screws are not adjusted yet.

HELP!!!! Y Blockers!!!

Joe D

|

|

By KULTULZ - 8 Years Ago

|

... ain't this a b!tch ... ... ain't this a b!tch ...

Wherever you sent the carbs, was he able to ID them and also as a matched set or different models?

Do you know if the set has a PRIMARY and SECONDARY (or both primary) carb and are you using direct linkage or progressive linkage? Did the guy you bought it from give any info on the cam installed? This is using a 57/ DUAL ADVANCE DIST?

1000RPM curb idle has to hide one heck of a cam (or vacuum leak).

Let me re-read all of th posts again.

|

|

By Joe-JDC - 8 Years Ago

|

|

Every time I read your entries, I come back to the idea that happened to me with a similar situation with stalling, idling ok, and stalling after driving a short distance. After rebuilding my carb, changing everything, plugs, points, cap, rotor, etc., it would crank up fine, idle fine, but stall when I drove a short distance, or came to a stop. I finally traced it down to a fuel filter that was pulling sediment up against the opening and closing it off, especially under deceleration. When the car stopped, the sediment settled back level with the filter, and fuel would fill the carb bowl and the engine would start and idle just fine. Changed the filter and no more problem, until the filter started clogging up again. These older fuel systems need to be flushed occasionally, if possible, to remove any moisture from the oxygenated fuel that settles to the bottom of the tank. The moisture will cause the tank to rust if not removed immediately with fresh fuel, or a moisture agent to mix it with the fuel again. Had the similar experience with EFI, and added a bottle of fuel injector cleaner with additive to remove moisture, and skipping went away almost immediately. Joe-JDC

|

|

By KULTULZ - 8 Years Ago

|

|

Every time I read your entries, I come back to the idea that happened to me with a similar situation with stalling, idling ok, and stalling after driving a short distance. After rebuilding my carb, changing everything, plugs, points, cap, rotor, etc., it would crank up fine, idle fine, but stall when I drove a short distance, or came to a stop. I finally traced it down to a fuel filter...

... hmm ....

Where is the filter on the supply side? I remember your saying you removed the inlet screens.

A 10 micron filter @ the pickup will not stop all trash. That is for accidental ingestion of Godzilla or perhaps a midget submarine. Didn't you say that it has a new fuel tank?

That cross-over fuel line worries me. Too close to the radiator hose.

|

|

By Joe D - 8 Years Ago

|

|

Kultulz,

The guy who rebuilt the carbs was not interested in trying to IDing. He said they had all the parts and would rebuild.

I know they are Carter WCFB with vacuum operated secondary's

The linkage operates the rear carb first and then the front carb as you accelerate more.I guess that's progressive right?

I would like to have them operate together for daily driving as advised in an earlier post.

Stock cam was used in rebuild the previous owner said.

I believe its a dual advance distributor as stated in earlier post.

Thanks for your help!

Joe JDC

I installed a high flow canister type of racing filter that is mounted back by the fuel tank. I had a small clear glass one before the pump suction and I thought that it could be causing pump cavitation or a restriction.

New fuel tank, new fuel lines, new mechanical fuel pump, new fuel filter and rebuilt carbs with screens in the inlet.

I did try running truck with the gas fill cap off to see if maybe a vacuum was occurring from tank vent being blocked.

Thanks for your help Joe

|

|

By Joe D - 8 Years Ago

|

Kultulz,

I did insulate the fuel lines running up to the carbs since that picture was taken.

Thanks,

Joe

|

|

By Joe-JDC - 8 Years Ago

|

|

If you are driving with the rear carb only off idle, and then the front carb comes in later, you are not progressive, you are starving the engine when letting off the accelerator. Both carbs should at least be supplying idle fuel, and I would prefer the engine operate off the front carb just for fuel distribution purposes. There are many fuel linkage kits available from Jegs, Dashman, Summit, etc. that you should be able to make yours work together, or progressive without much trouble. Joe-JDC

|

|

By KULTULZ - 8 Years Ago

|

|

The guy who rebuilt the carbs was not interested in trying to IDing. He said they had all the parts and would rebuild.

How in the world did the guy calibrate the carb(s) if he had no idea what they were off of?

You say it happens once it is at operating temp. Either she is too lean (choke off), if IGN I in the DIST (you have an electric TACH?), or something is opening with heat to cause a vacuum leak.

Are you using manifold vacuum or ported vacuum for the DIST advance?

Let me re-read the thread. There was a period service bulletin on a certain WCFB.

|

|

By KULTULZ - 8 Years Ago

|

OH!

I see an EDEL fuel pump on yours. Test the fuel pressure. It may be too much for those carbs.

|

|

By Joe D - 8 Years Ago

|

|

JDC,

Both carbs are supplying idle fuel now and as of yesterday afternoon both are operating together with the throttle linkage. I just had to move a stopper back on the linkage. It ran fine after changing this but still stalling after its up to temp.

Thanks,

Joe D

|

|

By Joe D - 8 Years Ago

|

Kultulz,

I didn't realize carbs were calibrated when they were rebuilt. I thought you just adjusted the mix screws and the idle screw and away you go. I will ask about that. Thanks.

The carbs have no choke plates at all. They were removed.

I have a Tach installed on my dash.

Using port off of the rear carb but also tried manifold port (14" vacuum) and also plugging all three. I did not seem to notice any difference in performance after trying these combinations.

Edlel fuel pump is rated at 5 psi. and worked fine for about 2 years. Could be famous last words right!

I'm going to install a clear fuel filter before the carbs to see what happens after a stall. It seems to be starving for fuel and not flooding. I have never smelled a lot of gas nor have I noticed any black smoke out of the exhaust when re starting which would indicate flooding.

Thanks for your help!

Joe D

|

|

By Joe D - 8 Years Ago

|

[quote]Joe D (12/19/2018)

Kultulz, I didn't realize carbs were calibrated when they were rebuilt. I thought you just adjusted the mix screws and the idle screw and away you go. I will ask about that. Thanks. The carbs have no choke plates at all. They were removed. I have a Tach installed on my dash. Using port off of the rear carb but also tried manifold port (14" vacuum) and also plugging all three. I did not seem to notice any difference in performance after trying these combinations. Edlel fuel pump is rated at 5 psi. and worked fine for about 2 years. Could be famous last words right! I'm going to install a clear fuel filter before the carbs to see what happens after a stall. It seems to be starving for fuel and not flooding. I have never smelled a lot of gas nor have I noticed any black smoke out of the exhaust when re starting which would indicate flooding. Thanks for your help! Joe D

|

|

By KULTULZ - 8 Years Ago

|

|

Mix screws backed out two turns. tried to adjust but really didn't seem to change how it idled. Carbs are synched at idle.

Manifold vacuum reading 14 " at 1000RPM.

Drove to work this morning and stalled coming off of highway and I could not keep it idling without goosing the accelerator. Before carbs were rebuilt it seemed to recover after a couple of minutes of goosing and idling.

OK, let's start again.

When the truck de-accelerates, it shuts off? Is this in gear or out of gear (between gears)? Does it stall straight ahead or on a turn? Re-start easily?

Your manifold vacuum is 14HG and steady? Right now, where is your source of DIST vacuum advance?

If you adjust the mixture screws without any change, there is going to be an internal carb problem. The style of carb the builder chose to use are both Primary. Both will have idle circuits. If you want both to open in unison, all you are doing is wasting gasoline on a street engine (again IMO). It will be difficult to trace a carb problem with two working together.

Now does it ever idle erratically or the TACH reads incorrectly?

No chokes?

|

|

By Joe D - 8 Years Ago

|

Kultultz,

When on the highway and coming to a light or exit and trans is placed in neutral engine dies. You can watch the tach drop to zero rapidly.

If left in gear as long as possible when coming to a stop and then goosing the accelerator, I can keep it running and eventually it recovers and runs good until its placed in neutral again.

Straight ahead driving but it does it while turning as well.

It does not happen until engine is up to around 180 degrees. When placed in neutral at lower temperatures it hold 1000 rpm steady.

It restarts fairly easy with no gas smells or black smoke or backfires.

Distributor vacuum advance is hooked up to the rear carb port.

It does idle erratically after stalling but recovers after a few minutes.

Tach reads fine.

No Chokes. Its a pain for a few minutes but warms up pretty quickly.

Thanks for the help!

Joe D

|

|

By Joe D - 8 Years Ago

|

Oh one more thing! I hooked up a clear fuel filter at the inlet of the carbs. After the truck stalled I checked the filter without trying to restart. The filter remained full of gasoline so that should eliminate any fuel starving issues.

Thanks again!

Joe D

|

|

By KULTULZ - 8 Years Ago

|

|

Distributor vacuum advance is hooked up to the rear carb port.

When you say carb port, are you referring to a port on the carb body or the nipple in the intake manifold plenum I tried to show on the photo?

If on carb, any outlet above the throttle plates is ported and below throttle plates is manifold vacuum.

What I am thinking is that with the high idle and 14HG manifold vacuum @ idle is that the initial timing is retarded. If connected to manifold vacuum, the vacuum advance feature will go full advance giving the high curb idle RPM. Someone may have tried to correct this by mis-adjusting the throttle plates.

This is why identification of the carb(s) is important to choose the correct kit and make adjustments such as throttle plates.

Also, ensure proper operation of DIST breaker plates with either a vacuum pump or a hose and sucking. Confirm that the upper plate moves easily when vacuum is applied, the canister holds vacuum and a fast and smooth return when vacuum source is ended.

If using full manifold vacuum on an advance, when the throttle plates are suddenly closed, a full manifold signal is sent to the DIST advance and may cause stalling. That was one of the purposes of the dual diaphragm on the 56 LOAD-O-MATIC.

Other than this, the only thing I can think of is a dash-pot to prevent the throttle blades from snapping shut.

And of course, the idle mixture screws not responding. It sounds like the guy just threw a kit(s) into them and called it a day. Why CARTER didn't ID their carbs with stamping like HOLLEY is beyond me.

|

|

By KULTULZ - 8 Years Ago

|

|

|

By KULTULZ - 8 Years Ago

|

|

|

By KULTULZ - 8 Years Ago

|

Sorry about the multiple posts but I have difficulty with this forum format.

The above excerpts are pertaining to the 56 MERC WCFB 2361S and SA. Whether it pertains to any other year or manufacturer usage (GM - CHRY) I have no idea. But this info is what a quality re-builder should know.

I don't know if they are the source of the problem(s) but just posted the info for anyone in the future that may come across and need it.

EDIT- Trying to master the KING'S ENGLISH

|

|

By Joe D - 8 Years Ago

|

Kultultz,

The vacuum line from the distributor is hook up to the rear carb port. This port down low on the front of the carb. Like I mentioned before, no matter what I do with the distributor vacuum hose it really does not effect engine performance and stalling issue.

Anyway a friend of mine has a computer box that runs the engine ignition and you can observe while driving what the vehicle is doing and see exactly what happens during a stalling event. He thinks there is some sort of ignition problem and would at least like to rule this out before trying other things.

I will keep you and any other interested Y-blockers updated.

Thanks for your help!

Joe D (The Frig)

|

|

By Ted - 8 Years Ago

|

|

Distributor vacuum advance chamber working?

|

|

By KULTULZ - 8 Years Ago

|

|

... a friend of mine has a computer box that runs the engine ignition and you can observe while driving what the vehicle is doing and see exactly what happens during a stalling event. He thinks there is some sort of ignition problem and would at least like to rule this out before trying other things.

COPY!

Get me some info on that box he is talking about. Got me curious.

Years ago ... (yeah, I know) ,,, there was a spark tester that had a long lead and suction cup that you stuck to the WS and drove to see if the IGN was cutting out.

|

|

By Joe D - 8 Years Ago

|

Ted,

I had the cap off and pulled a vacuum by sucking on the hose attached to the distributor vacuum diaphragm. The plate moved smoothly and the diaphragm held vacuum. As vacuum was released it returned to its original position.