|

By Florida_Phil - 8 Years Ago

|

I installed the rear seal retainer in my new 292 Y Block today. The instructions on the neoprene seal that came in the gasket kit said the nails go on the block side of the side seals. Ted's instructions say the nails should go on the retainer side. Which is correct?

|

|

By darrell - 8 Years Ago

|

|

ted.you can see the groove in them where the nails go.

|

|

By Ted - 8 Years Ago

|

The nails install to the retainer side or crankshaft side of side seals, not the block side. The side seals I use have grooves on both sides so I can see where some confusion might come from. If there are some instructions out there stating that the nails go to the block side of the seal, that might explain why there are so many problems with ‘rear main seal’ leaks.

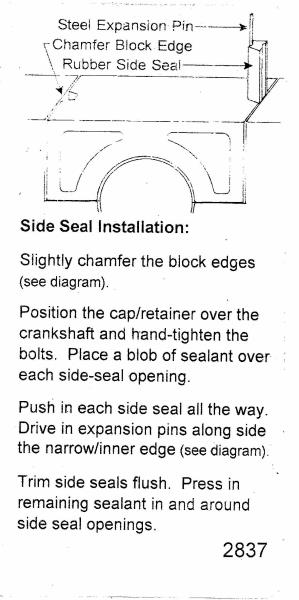

Here are the instructions that come with the ‘Best Gasket’ side seals.

|

|

By oldcarmark - 8 Years Ago

|

|

Ted -I seem to recall You made a slight change to your Instructions regarding rear Main Seal Installations. Instead of completely tightening the Seal Retainer and then installing the Side Seals with the Sealant being pushed into place did You not say to leave the Seal Retainer slightly loose so that Sealant also gets into the slight Space under the Retainer? Let it setup for a few Minutes and then Torque the Retainer? Somewhere I recall reading this. I did it this way last Time I replaced the Rear Main Seal on mine.

|

|

By Ted - 8 Years Ago

|

Mark.

My instructions do vary slightly from the instructions provided with the seals. I prefer that the seal retainer lack about an 1/8” from being seated when I install the side seals. This allows the RTV to fully fill the void at the retainer to block parting line while also allowing some movement of the retainer when installing the side seals. Using a small bladed screw driver at the side of the retainer that’s getting the seal, the retainer can be pushed away from the block edge thus allowing the side seal to slide easier in its slot. I do this for both sides. Once the side seals are within 3/8” of being flush with the pan rails, I install the nails on the retainer side of the seal and tap the nails in place while at the same time the side seals become flush with the retainer. I then fully tighten the rear seal retainer bolts and tap the side seals and nails once more so they are flush. If everything works out as it should, I expect a small amount of RTV to protrude from the retainer to block parting line.

|

|

By Florida_Phil - 8 Years Ago

|

Great. I installed my seals according to Ted's instructions. My seals had grooves on both sides. The instructions on the seal package and the assembly guide have it the other way. I did it right!!

|

|

By oldcarmark - 8 Years Ago

|

Florida_Phil (9/23/2018)

Great. I installed my seals according to Ted's instructions. My seals had grooves on both sides. The instructions on the seal package and the assembly guide have it the other way. I did it right!!

Doesn't exactly inspire Confidence in a Product when they include Instructions that are wrong for the Product they sell does it?

|

|

By Florida_Phil - 8 Years Ago

|

Not really. Good thing I wasn't buying condoms...

|

|

By Lord Gaga - 8 Years Ago

|

I left the side seals out and filled cavities with RTV....no leaks after 1800 or so miles. Also used a trimmed 318 Mo-Par seal on the same 312. No probmento!

|

|

By 57RancheroJim - 8 Years Ago

|

I have an old set of side seals with the hole in the center for the steel pin, I think they came out of an old Detroit gasket set, never tried them.. Anyone ever seen or used them?

|

|

By oldcarmark - 8 Years Ago

|

Lord Gaga (9/24/2018)

I left the side seals out and filled cavities with RTV....no leaks after 1800 or so miles. Also used a trimmed 318 Mo-Par seal on the same 312. No probmento!

I don't think I would personally use RTV for that. There is another Product that some others have used for same Purpose which apparently works very well but less chance of getting loose into Oli Passages. Maybe someone will post that Product. I read somewhere that the majority of Rear Main Seal Leaks are not the actual Crank Seal Leaking but the Side Seals.To replace the Side Seals with Sealant can only be done with the Engine out of the Car on a Stand upside down I would think??

|

|

By Lord Gaga - 8 Years Ago

|

I replaced the rear main seal with the engine in the car. I used Permatex Ultra Black instead of the side seals. I was able to fill the voids with the plastic nozzle that comes with the product and wiped off the excess that squeezed out of the gaps between the seal retainer and the block. If I ever do it again I would use Flex Shot (as seen on TV) as it is neoprene, fuel proof and comes in a pressurized container.

|

|

By Florida_Phil - 8 Years Ago

|

I use Permatex. It's been working for me for 50 years.

|

|

By CSPIDY - 8 Years Ago

|

Florida_Phil (9/23/2018)

Great. I installed my seals according to Ted's instructions. My seals had grooves on both sides. The instructions on the seal package and the assembly guide have it the other way. I did it right!!

|

|

By Florida_Phil - 8 Years Ago

|

This is the original 1955 292 engine block. The block had been hot tanked back before the EPA put the kibosh on harsh chemicals. I don't know how many times it had be rebuilt in the past, but the block was a mess. One side was higher than the other and the crank caps were misaligned. The block was bored .060, shot-peened, decked and the mains were straightened out. New cam bearings were installed. The crank and rods came out of a 1957 Ford station wagon with 40,000 miles on it. The crank is standard. The rods were rebuilt with ARP bolts and the crank was polished. The rotating assembly was balanced. We had a hard time finding standard bearings.

The cam is an Isky RPM 300 with a Rollmaster double roller timing chain. We deepened the cam oil groove to .035. The cam degreed in right on the numbers. The heads are 1957 "G" heads and rockers. The intake is a 1957 "E" code cast iron Ford 4V with a Holley 1848-1. This motor is going in a 1955 Thunderbird with 3.89 rear gears, 3 speed manual with O/D. It should run pretty strong. We'll see.

|

|

By oldcarmark - 8 Years Ago

|

Florida_Phil (9/30/2018)

This is the original 1955 292 engine block. The block had been hot tanked back before the EPA put the kibosh on harsh chemicals. I don't know how many times it had be rebuilt in the past, but the block was a mess. One side was higher than the other and the crank caps were misaligned. The block was bored .060, shot-peened, decked and the mains were straightened out. New cam bearings were installed. The crank and rods came out of a 1957 Ford station wagon with 40,000 miles on it. The crank is standard. The rods were rebuilt with ARP bolts and the crank was polished. The rotating assembly was balanced. We had a hard time finding standard bearings. The cam is an Isky RPM 300 with a Rollmaster double roller timing chain. We deepened the cam oil groove to .035. The cam degreed in right on the numbers. The heads are 1957 "G" heads and rockers. The intake is a 1957 "E" code cast iron Ford 4V with a Holley 1848-1. This motor is going in a 1955 Thunderbird with 3.89 rear gears, 3 speed manual with O/D. It should run pretty strong. We'll see.

By deepening the Camshaft Oil Groove to .035 You may find the Oil Flow to Head is excessive with the Oil flowing faster than it can drain .I ended up taking the Rocker Shafts off and tapping and installing a restrictor plug with small Hole drilled in the Plug. I don't remember what size Hole I drilled in the Plug but it still allowed good flow of Oil but not too much that it would build up faster than it could drain.

|

|

By Florida_Phil - 8 Years Ago

|

Noted. We will be installing the oil pump and pan in a few days. The rockers are pressurized with the drain tubes closed about half way. We'll be sure to check the oil drain back with the engine running. How did you know you had a problem? Did your engine smoke excessively?

|

|

By oldcarmark - 8 Years Ago

|

|

Just letting it run with Covers off. It started to overflow the side of the Head. If the Cover was on to contain the Oil it could end up flooding the Valve Seals.

|

|

By Florida_Phil - 8 Years Ago

|

Got it. I'll check that. Thank you.

|

|

By 2721955meteor - 8 Years Ago

|

|

i eliminate the drain tubues,new shafts and rockers that are in decent shape,use 302 umbrella valve seals,grove deepend cam groves.all rockers get oil,no isues with oil returning ,set valves with engine running. did this with 292 in ranchero was 3yeares on engine when i sold it, used 1 quart of oil i 1000 miles. present truck 1949 merc with 292y same storey has 800 miles on re build has 25 psi oil presure at idea hot,55 psi 2000 rpm hot,no issues still does not need oil. so i am convinced with decent valves and guides,along with good rocker shafts and rockers,302 valve seals the only way to go. every y block i have worked on with high miles, rocker shaft and rockers thrashed at end of shaft away from drains.

|