|

By HenryFloored - 8 Years Ago

|

Is it too soon to start asking questions about possible entrants in the Vintage class this year? Ted are you building a Y-block this year? Royce? Anyone else?

As a matter of fact is there even a competition this year? I’ve heard precious little.

Chomping at the bit here. Love to see the great numbers put up by you guys with engines the scrub lubbers laugh at.

Thanks and good luck!

|

|

By Joe-JDC - 8 Years Ago

|

|

Yes, there is an EMC scheduled for the first week in October at JE Pistons Facility in Mentor Ohio. The Vintage class has/had three Y block entries. The horsepower numbers will be down this year simply because they require engine belt driven mechanical water pumps, no velocity stacks. Joe Craine will run third on Monday with a 375 Y, Jerry Christensen is scheduled fourth with a Y, Ted Eaton scheduled to run fifth with a 403 Y. Royce will be partnering with Jon Kaase on another MEL to run on Tuesday. Dyno testing has started for Joe, still in progress, Ted will be going on soon. Real problem with parts suppliers, but things are falling into place for two Ys for sure. Expect Ted to set a new Normally Aspirated horsepower and torque record with a true Y block. Joe-JDC

|

|

By charliemccraney - 8 Years Ago

|

|

If Ted is likely to set new records, then it seems like power will be up. Do you mean that it will be lower than it would be otherwise because of the restrictions this year?

|

|

By HenryFloored - 8 Years Ago

|

Aw man this is great news, 3 Y’s and a MEL. I constantly marvel how strong a showing the Y- blocks put out in this class. Glad to hear this will continue.

I realize that the Mummert cylinder head and intake manifold are a huge help and some of the other brands don’t have an aluminum head available.

I know however that the early Olds and Pontiac have an aluminum head available, the Cad, Buick and Mopar Poly not so much which astounds me since they seemed to be embraced by lots of 50’s hot rodders.

No it seems the most unlikely (according to popular opinion back then) engine design has risen to the top or near the top on all three prior Vintage competitions. Of course in large part due to the excellent builders of these Ford’s. For one year I’d like to see the Vintage class open to any engine up to 1957 (including the sbc and the hemis) with 1957 or earlier factory cast iron cylinder heads and blocks.

I’d love to see exactly where each engine would fall in a true factory shootout.

|

|

By charliemccraney - 8 Years Ago

|

I hope it all leads to mainstream manufacturers making products for Ys. Some of them do for other vintage engines, which have yet to show at the competitions, which typically has a roster dominated by Ys, with Y's finishing toward the top, if not the top. It baffles me how they find it worthwhile for those others, but not the Y, particularly with the Engine Masters results objectively verifying, for all to see, that it is an extremely capable performance engine.

A true factory shootout with all makes could be interesting. The key there is how factory is defined. If it's open to any factory part, then the SBC very likely dominates and there would probably be a lot of them, making it kind of boring. There is simply no replacement for the 40 years of development that it had. Like it or hate it, that's just tough to beat with neglected old iron. However, if they put a limit on the era that the parts come from for any engine which had development go on beyond the date range of the competition, that would make it interesting. A potential issue there is how easy a task it is to confirm during tear down of the engine that all parts are legal. If it is as simple as date codes in every instance, then no problem but if expert knowledge is required, then it could be a deal breaker.

|

|

By HenryFloored - 8 Years Ago

|

Charlie that’s why I think it should be factory castings. Maybe even factory cranks and rods. I’d like to see how specifically the Ford, Merc and Lincoln Y’s which were much malingned in those days, stack up against the competition which was mostly embraced and unfortunately installed in the engine bays of the majority of Ford bodied hot rods.

Yes I admit I'd like some redemption and restitution for that unfortunate phenomenon.

|

|

By charliemccraney - 8 Years Ago

|

|

I don't think you understood what I was trying to say. Depending on how it is defined, a factory SBC could potentially use any factory casting into the 1990s. Even if the aftermarket never produced anything for an SBC, there is still that 40 years of factory development by the. That is just about impossible for a vintage engine with little development to beat and would not really work without a firm date beyond which even factory castings are no longer allowed.

|

|

By HenryFloored - 8 Years Ago

|

Charlie what I meant is to restrict the competitors to the castings available in the 1950’s. This would illustrate the potential of each engine design as they were originally.

If those rules were imposed we’d see the raw potential of each of the manufacturer’s first OHV V8 designs at the flywheel without the blurred effect of the chassis and track conditions.

It is kind of common knowledge among drag race enthusiasts that the Mopar hemis were blessed with the best breathing. While that may be true with a blower and exotic fuel, I’d like to see how they do on gasoline and naturally aspirated which is of course what they were designed for.

I feel like Fords were under appreciated and under utilized in the hot rod classes like Gassers and Altereds etc. For one thing the Ford and Lincoln Y’s had a very strong cylinder block with good oiling. The things had decently thick cylinder walls and of course a skirted bottom and the top was tied together as well. You see this on modern day LS engine’s which are capable of holding good power.

The cylinder heads are what scared guys off I think because they were unconventional. I think there was more there than meets the eye initially. Especially in the combustion chamber area I think Ford was very advanced. Several books I’ve read on the Y credit the combustion chamber characteristics for their ability to tolerate higher compression ratios. I think this is true and I’d love to see some of these scenarios played out by good engine builders that know how to extract these potentials.

|

|

By LordMrFord - 8 Years Ago

|

HenryFloored (9/8/2018)

Especially in the combustion chamber area I think Ford was very advanced. Several books I’ve read on the Y credit the combustion chamber characteristics for their ability to tolerate higher compression ratios. I think this is true and I’d love to see some of these scenarios played out by good engine builders that know how to extract these potentials.

Maybe so but round shaped flamerings in head gaskets would make living much easier when hunting the horses out of Y.

|

|

By Joe-JDC - 8 Years Ago

|

|

A round flame ring would not work unless you got all the combustion chamber inside the cylinder bore. The combustion chamber is the real problem to making better horsepower with the Y in stock configurations. Joe-JDC

|

|

By Ted - 8 Years Ago

|

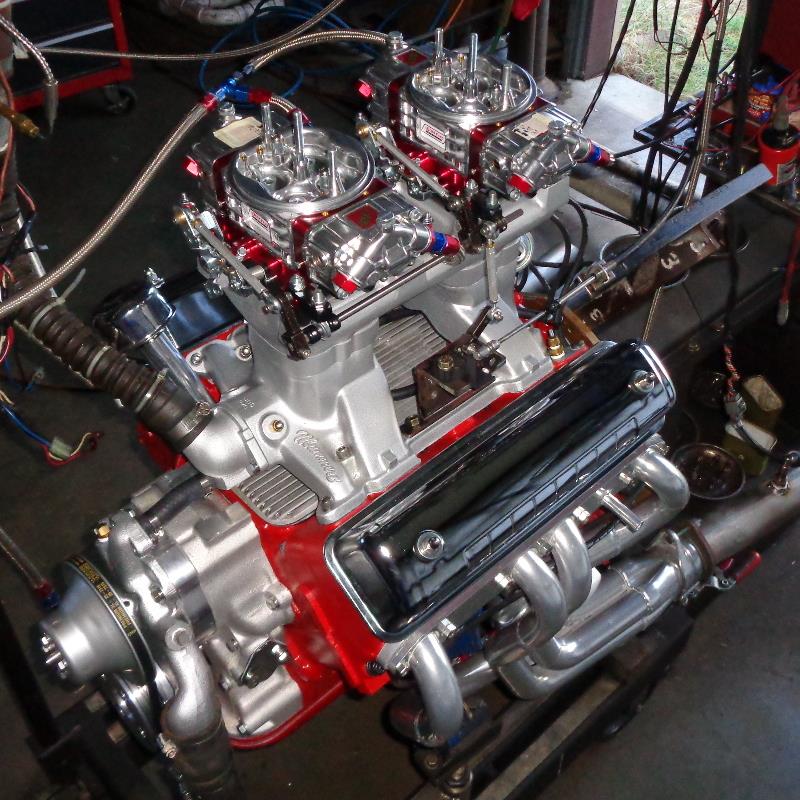

No picture of my engine yet as I’m waiting for four pistons to complete a set. But here’s a picture of Joe’s engine on the dyno.

|

|

By HenryFloored - 8 Years Ago

|

|

Very cool! Looks like Joe is loaded for bear. Wishing you the best of luck this year Ted.

|

|

By Ted - 8 Years Ago

|

|

Still waiting on four pistons to arrive. I’m told that the coatings on the four replacement pistons are the hold up. In the meantime, I have balanced the crankshaft assuming the forthcoming pistons are the same weights as the ones I already have on hand. I plan on installing the crankshaft in the block and degreeing in the camshaft just to speed things up a bit. I’ll only install one rod and piston for this to find TDC as I’ll likely need to tweak the weight on the current four pistons when the four new ones arrive. Murphy’s Law seems to rule in cases where you’re in a time crunch.

|

|

By HenryFloored - 8 Years Ago

|

|

Ted can you share a little bit about your combo this year?

|

|

By NoShortcuts - 8 Years Ago

|

Best Wishes to Ted, Joe, Royce and Jon Kaase in the upcoming competition! I'm looking forward to the first week of October.

GO Y-BLOCK GUYS!

|

|

By Ted - 8 Years Ago

|

|

HenryFloored (9/11/2018)

Ted can you share a little bit about your combo this year?

Bore is 3.862” while the stroke is 4.300”. Not a typo on the stroke as this is a one inch stroker. A one inch stroker just has a better ring to it than the ¼” or 3/8” strokers that were made back in the day for the various engines. And that extra 0.300" stroke over the 2016 engine combination yields an additional twenty eight cubic inches. The camshaft is still a standard base circle so any clearance issues that were going to take place between the connecting rods and the camshaft lobes is rectified by angling the connecting rod big end parting line ~45° which effectively moves the rod bolt boss on the connecting rod out of the way of the camshaft. No other clearance issues within the Y with this much stroke; the camshaft to rod clearance was an issue even when Ford went from a 3.3” to a 3.44” stroke so you can imagine what going to a 4.300” stroke did in that area. I’m planning on running the same heads and intake that I ran on the 2016 EMC engine along with the same camshaft grind. That camshaft was on the large side for the 2016 combination so it should fall more in line with 28 more cubic inches to work with. Engine should have been completed by now and dyno testing done but it looks like it will still be warm when it’s loaded on the truck for the trip to Mentor, Ohio.

Rod comparisons. EMC rod on the left, 312 rod on the right.

|

|

By Cliff - 8 Years Ago

|

|

Nice stuff

|

|

By darrell - 8 Years Ago

|

|

a picture is worth a thousand words.

|

|

By HenryFloored - 8 Years Ago

|

Wow Ted! That 4.300” does have a very nice ring to it. Should be a torque monster.

I’ll bet your cylinder heads can feed all those inches as well.

Love the angled rod solution. I take it those are custom rods. Any reservations about their durability?

Love to see these full on efforts put into these old Ford engines. It’s neat to see what can be done with them.

Best of luck to you sir.

|

|

By Joe-JDC - 8 Years Ago

|

|

Got a couple of clarifications on rules today, and they do not require mufflers, can use air cleaner base, stub stack, or velocity stacks, but must run water pump with fan belt that is engine driven. So, things are getting close to show time. Ted is building a torque monster for sure. Joe-JDC

|

|

By Cliff - 8 Years Ago

|

|

Hi Joe, what heads are you using, are they Johns?

|

|

By Joe-JDC - 8 Years Ago

|

|

Yes, I reworked them quite a bit, changed the valve job, changed the stem heights, milled them, added a 1/2" spacer to the exhaust ports, etc. Should be a good pair of heads for the competition. First dyno session was promising, just trying to get the carburetors figured out. Not happy with the QF carbs right now, but that is a whole different story. Just trying to not finish last! LOL Joe-JDC

|

|

By Ted - 8 Years Ago

|

The pistons showed up so I was able to get this years’ EMC engine together. The engine assembled without any problems and there's plenty of room around the offending items with the new connecting rods in place. Torque numbers are good but horsepower numbers are lacking or at least below what was anticipated. Looks like the heads may be a bit small for 403 cubic inches. Still have some different things to try but only see minor improvements.

|

|

By Cliff - 8 Years Ago

|

|

Nice work

|

|

By HenryFloored - 8 Years Ago

|

Ted not to get caught up in flow numbers but are they where you need them to be at least roughly relative to the horsepower you need to see?

If so is there any way around it like a “faster” intake profile? Etc.

|

|

By Joe-JDC - 8 Years Ago

|

|

Not to confuse the issue, but for the Y block, the Mummert head is the only thing being cast that has the potential to make 600 hp normally aspirated. The old tried and true formulas for airflow needed in making x amount of horsepower would show us that to make 600 hp, the intake and heads need to flow at least 292cfm. To make 640 hp, the heads and intake need to flow 312cfm by the formula. Not trying to be cute with those cfm numbers, but if you plug in cfm x .257 x 8(number of cylinders), you will see what I mean. 292 x .257 x 8 = 600.352 possible hp, and 312 x .257 x 8 = 641.472 possible hp. Many factors need to come together to make this happen. It is all in the details, and removing parasitic loss every place possible, compression ratio, exhaust tuning, intake manifold efficiency, carb tuning, etc.. A Mummert head as cast flows in the 240 cfm range without porting. With their CNC porting program, the street CNC heads flow ~270/280 cfm, and the race heads with their angle mill, 10mm spark plugs, 1.970/1.510" valves flow slightly better, but not much. There is just so much aluminum you can remove before making holes in the heads. I have seen just over 300 cfm on a couple of sets of heads that were hand massaged above and beyond the CNC programs. To reach 312 cfm, a larger valve is needed, and that would require moving the guides and seats, and changing the ports to the new valve sizes, or a completely new head casting. Lots of work, for not much return. Smaller stemmed valves only increase the flow at most 2-3 cfm. Joe-JDC

|

|

By HenryFloored - 8 Years Ago

|

Thanks Joe. I’d like to know if the upper and lower ports flow an equal amount or is one better than the other?

How do these numbers compare to a contemporary SBF or SBC aluminum head with standard valve configuration?

|

|

By Joe-JDC - 8 Years Ago

|

|

Upper 280, the lower 270ish on the CNC heads. Every head I have flowed, and I have flowed probably 20 sets of the Mummert aluminum heads, have a slight problem with the lower port backing up airflow around .570" valve lift in the lower ports. Not bashing, for the backup airflow can be worked out, but it takes some skill, a flow bench to find it, and sometimes it gets worse before it is worked out. For a street engine that has a camshaft with less than .550" valve lift, you would never know there was a backup in the flow on the lower ports. We are using a camshaft with .639" lift, so it is important to get as much flow as possible out of the heads. I would love to have a camshaft capable of .700" lift to try in my engine. (Jon Kaase's heads for the 2015 EMC engine that he modified to upright ports supposedly flowed >330cfm) Joe-JDC

|

|

By charliemccraney - 8 Years Ago

|

The Kaase Y was 709hp in a different configuration, after the competition. http://jonkaaseracingengines.com/wp-content/uploads/2016/06/MM_July2016_HMMGarage.pdf

Plugging that into the formula works out to 344cfm.

|

|

By Joe-JDC - 8 Years Ago

|

|

That is why I said >330 cfm. If I remember correctly, the intake valve was 2.100" or so. I have ported dozens of sets of SBF heads that flow over 330-340 cfm with 2.050, 2.080, 2.100, 2.135 intake valve sizes. Many of the C302B style heads will flow in the 370+ cfm range with a 2.100" intake valve if they are ported right. Joe-JDC

|

|

By John Mummert - 8 Years Ago

|

Cylinder head geometry has been a bigger player in hp output over the last 20 years than air flow. The C302B is a classic example. Although capable of carrying a bigger valve and more airflow numbers than the Yates head it cannot achieve the power numbers of the Yates head. Even the 20 year old low port versions of the Yates head from the 90's were significantly better.

As Joe pointed pointed out our angle mill head flows a tick better than highly ported regular version, but they run significantly better, as long as the fundamentals are there.

When you are playing with the port on a head, you are only playing with half of the runner. The everyday average guy will try and view the head as the head, and manifold as the manifold.

Classic example many engines have a different intake manifold flange angle Sbf 90* Sbc 80* Y block 75* . You will have to look at your manifold and see if the runners are coming perpendicular the flange face itself. If it is you can achieve decent results if you try and R&D the head by itself.

The Y Block lower port can be finicky by itself, but if you bolt a manifold to it, (or the other half of the runner) it gets very stable and predictable. Years ago when developing our angle milled race head we played with a few different manifolds cast and fabricated to see how the ports as whole responded. I think the funniest thing we saw was that ports that were the touchiest by themselves were a couple numbers better, when the manifolds were installed (Which one do you wanna pick, to spend 2 weeks making a CNC program out of (Which one do you wanna pick, to spend 2 weeks making a CNC program out of  ) )

These days, rates of chamber fall away top angles on the valve job, different runner tapers , placement of the MSCA in the runner , Low lift Flow in relation to camshaft duration or FLOWRATION as I call it are things that I see actually affecting how the motor runs.

|

|

By PF Arcand - 8 Years Ago

|

Since this discussion has moved beyond just flow numbers, I've read in the past about "turbulence & "quench" in cylinder heads. How much effect do those factors have in performance? And, particularly how do Y-Block heads fair, both stock "G's, or 113's & Mummert's?

P.S.- I suppose turbulence involves the intake manifold also?

|

|

By John Mummert - 8 Years Ago

|

Quench or squish velocities are a tuning aid for adjusting meter per second burn rate. Its semi complex and some of it may actually seem backward. Squish (or piston to head clearance), squish pad area in relation to bore area, engine rpm, and rod/stroke ratio are key factors to adjusting burn speed.

The next thing people ask is why would I try to adjust this. At the end of it all your trying to achieve the highest rate of SAFE combustion speed you can.

Without having this turn into an overly drawn out out explanation, if you have a low compression engine, a low rpm engine, poor cylinder head design. In general poor cylinder heads have air fuel separation problems.

These things will cause slow or erratic burn speeds. Tightening your piston to head clearance, and looking for heads with high squish to bore area will help force air and fuel into the chamber more completley and at a higher rate of speed.

Heres where slope gets a bit slippery. When searching for heads with high squish to bore ratios, this usually indicates the combustion chamber footprint is small, valve area and shrouding can be a problem.

As things start going the other way, compression starts getting high, cylinder head geometry improves, rpm starts rising, the need to try and do thing to increase the rate of burn speed dont become as critical because they are getting faster naturally.

Just remember that the rules come through experience in working with certain engines. Some engine with 10.0:1 compression and 89 octane are on the edge of detonation while others are very safe at 12.0:1 compression with 87 octane. Some engine are at the end of there rev range at 6000rpm and others cruise at that speed.

|

|

By HenryFloored - 8 Years Ago

|

John with this in mind how do you think an engine like the early Chrysler Hemi compares to a good wedge cylinder head when running on gasoline such as the stuff available in the 1950’s?

We all know that a Hemi is great at stuffing cylinders full of exotic fuels especially under the pressure of a blower.

I’ve kinda always wondered cube for cube how efficient is a hemi compared to other head designs when thinking in terms of their targeted purpose which was a powerful and efficient passenger car engine.

Heck these early hemis were even used in industrial applications with low compression and lazy camshafts.

What if anything did Chrysler have on the competition, or what did they do I wonder to make a pure Hemi chamber perform on the street?

|

|

By John Mummert - 8 Years Ago

|

Cylinder heads don't work on any one function. I guess you can break a cylinder heads performance down into about 4 main functions. They are related though.

1. Airflow: Everyones favorite, Its measurable, its easy to throw out a number during a bench racing session, and there is math to project power levels of a given cfm. Based on a particular efficiency. When the efficiency changes the math changes.

2. Velocity: This is a good indicator of incoming port energy, this must be backed by a cfm number relative to the power level you are looking achieve to have truly have energy. One without the other doesn't work.

3. Efficiency: This is where you start to here crickets. This where all the magic is. The secrets. The heads that make high horsepower and torque. The ability to handle high amounts of compression, on minimal octane.

4. Valve train: It seems a little out of place with the others. But if it is not up to task than the rest is a waste of time.

Others may disagree, but the old hemi's of the 50's and 60's weren't really exciting naturally aspirated. I do feel that the particular weaknesses they had as naturally aspirated engines were not drawbacks as blower engines.

1. Enormous combustion chamber, hard to get high compression without the ugliest top heavy piston you've ever seen.

2. Huge low velocity exhaust port, not exciting for naturally aspirated.

3. Mediocre flowing intake port, but its placement far away from the cylinder, the port being very straight would keep swirling to a minimum as it would keep fuel separation to minimum.

(Connie Kalitta went into extreme detail on why the valve cants Ford puts into there Boss 429 to try and make a better naturally aspirated Hemi were a complete disaster in a Top Fuel motor.)

4. Very heavy exhaust rocker arm, but a roots blown nitro motor doesn't have to turn a bunch of rpm.

I think its safe to say you can make just about anything work if you put the time into it. But you will have to understand what the strengths and weaknesses are of whatever your building, and attack the weaknesses first.

|

|

By HenryFloored - 8 Years Ago

|

Thanks John, excellent explanation of cylinder head and induction science. I always thought Ford really pushed technology forward in the areas you described above especially during the Total Performance era.

The 1954 Lincoln 317 cylinder heads I have on the docket for my next build (thanks Ted) look like they have an “active” combustion chambe. Lots of quench pad and the chamber looks to have surfaces which concentrate the fuel charge near the spark plug. It looks purposeful and thought out.

To my eyes this is unique and unlike most 50’s inline valve engines. I’ve read that the Y-block cylinder head development was largely misunderstood by most hot rodders. The turbulence and swirling that looks like it was built in from Ford was somewhat rejected and the simpler basic wedge engines like the Cads, Olds and scrubs were more accepted.

This Engine Masters Challenge is an excellent opportunity for the Y-blocks to shine.

Good luck to all the competitors.

|

|

By Small block - 8 Years Ago

|

The Hemi may well have been the best with nitro and a blower, the Ford Cleveland head was the engine that made the most

HP per Cubic inch in a naturally asperated engine! All the teams in NASCAR are running a Head copied from the Cleveland. The LS series scruby is a Copied version of a Cleveland head.

|