|

By 57ranchero - 8 Years Ago

|

boring the 292 truck block to 4.00 inch diameter; using 256 merc crank with 3.10 stroke; using 6.252 rod length which yields 2.01 R/S.

This should produce a 311.6 ci displacement hence approximately 312 from a little bit different direction; also, this yields a Bore to stoke

ratio of 1.29. what is best piston to use?

|

|

By Cliff - 8 Years Ago

|

|

Good luck finding a block that will go that far, I think a ECK Block maybe thicker but I don't think it will go 4.0"

|

|

By charliemccraney - 8 Years Ago

|

Sonic check the block to make sure it will go that far. The pistons will probably have to be custom. Since you know the other dimensions, you know the compression height needed. A 4.00" piston should be very common. Look through catalogs and email or call manufacturers to see if there is one that will work or can work with little modification.

|

|

By darrell - 8 Years Ago

|

|

no block will go that far.it takes a good one to go to 3 7/8

|

|

By Rono - 8 Years Ago

|

57 Ranchero;

If you already have the Mercury crank, I can understand why you want to try to go this route. I chose a different approach with my 292 C2AE block; I bored it 0.060", used a 312 crank and had the rod journals turned down to 292 specs. Used C2AE rods and 312 pistons which had to be milled down about 0.063" (due to the longer rod length) to achieve 0 deck height. That comes out to about a 317 cu.in. motor....and it runs really good.

|

|

By NoShortcuts - 8 Years Ago

|

57Ranchero. I'd encourage you to read a thread from 4 months ago titled, 'De-stroked 292 Y-block'. It delved into the idea of using a 3.10 Ford / Merc crank as you have suggested, maximum bore, rpm range, engine torque, etc. Ted Eaton, Joe-JDC, Miker, John Mummert, and others made significant comments in the two page posting.

Click the link below to access this thread from the Archive.

http://forums.y-blocksforever.com/FindPost136569.aspx

I think you'll find the read very informative.

|

|

By PF Arcand - 8 Years Ago

|

As mentioned, forget the 4" bore idea, not going to work! Instead contact J. Mummert Machine re info on his just released 312 " conversion kit for 272/292 blocks..

N.B.- Rono, U errored, I think U meant to say the Main's were turned down to 292" size. Correct?

|

|

By BamaBob - 8 Years Ago

|

|

I have a 292 truck block(1960) that is bored 120 thousandths in my 55 Fairlane and has standard 312ci pistons and rings on a 292 crank and rods runs with no problems. I don't know if this setup is abnormal or not, but in this case,it is working. What do some of you that have more knowledge of this think?

|

|

By charliemccraney - 8 Years Ago

|

|

Bob, Yours can't be .120" over and have std 312 pistons. Standard 312 is 3.80" which is .050" over 292. .120" over 292 is 3.870" (.070" over 312).

|

|

By PF Arcand - 8 Years Ago

|

If I did the math right, on a 292" block that comes out @ 3.870" diameter. (as previoulsy noted) As I understand it, on a block with little core shift that will work. Unfortunately, on quite a few blocks it will result in a near paper thin wall somewhere. The other negative is that in many cases, it likely does not allow enough wall thickness for any safe rebore... Anyone considering a rebore that big or bigger, should "definately" have the block sonic checked. Keep in mind that the "experts" like Ted Eaton, & likely J. Mummert, when building a performance Y-Block, normally don't exceed 3.860" diameter piston size. That equates to a 312 + 0.060 size diameter.. On a 312 crank that results in 322".. IIRC, Ford only made pistons to .040 over for 312s. And that in a 292 block would equate to 306 cu " if I got it right?

|

|

By pintoplumber - 8 Years Ago

|

BamaBob (8/25/2018)

I have a 292 truck block(1960) that is bored 120 thousandths in my 55 Fairlane and has standard 312ci pistons and rings on a 292 crank and rods runs with no problems. I don't know if this setup is abnormal or not, but in this case,it is working. What do some of you that have more knowledge of this think?

I have a 239 that we bored +.125. I knew little about y blocks, so I assumed you could turn a 239 into a 256. Worked out ok for me, it’s been 15 years. I’ve since put a 312 crank in it.

|

|

By Shaggy - 8 Years Ago

|

Bore and sleeve it...

|

|

By Ted - 8 Years Ago

|

As brought up earlier, the link Charlie Brown posted pretty much lays out why stroke is more important than bore size. Here’s the link again.

http://forums.y-blocksforever.com/FindPost136569.aspx

Shaggy (8/25/2018)

Bore and sleeve it...

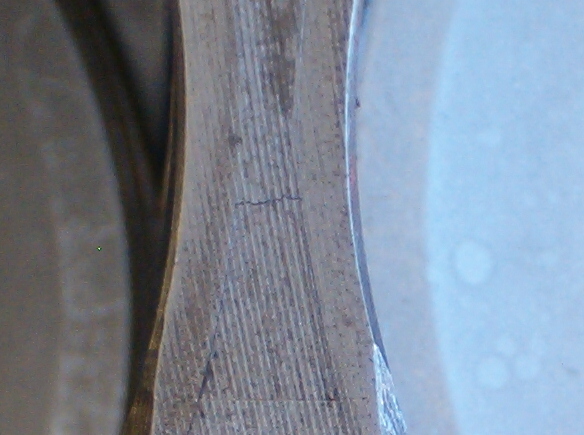

Sleeving a Y can prove to be problematic and especially if doing it for the purpose of creating a big bore Y. Some if not all the cylinders will break into the coolant passages when boring for the sleeves and that in turn allows a coolant seepage point between the original cylinder (what’s left of it) and the sleeve. Because the head gasket fire ring is irregular in shape, it doesn’t seal on the edge of the cylinder and in this case the sleeve; this gives the coolant a place to enter the combustion chamber. Torquing the head bolts simply exasperates the problem in that the decks are no longer fully supported to the core of the block which allows the decks to be pulled loose from the sleeves. I’ve had the decks crack between the cylinders as a result. Here are pictures showing just one of the six cracks in a 4" bore sleeved block.

Sonic test. Sonic test. Sonic test. And make sure the sonic tester is calibrated with a piece of Ford cylinder wall material and not with the steel calibration button located on the front of the tester. You’ll get artificially larger cylinder wall thicknesses if the tester is calibrated with steel rather than cast iron. Enough larger in fact that you’ll think that you have a 4” bore capable block. Measuring the clearance between the cylinder walls at the core plugs will help to validate the sonic test cylinder wall thicknesses. I have cylinder wall material from the various blocks from the Big Three and they all vary in cylinder wall thickness readings from actual measured thicknesses if the tester is not calibrated accordingly for each type of material.

Haven’t come across a 292 block of any year or casting number that will make a 4” bore with a cylinder wall thickness in all eight cylinders that will handle much in the way of compression ratio increase and/or higher rpms. A number of 292 blocks are maxed out at 3.860-3.870” for normally aspirated performance applications and that’s only after sonic testing to verify where the core shift lies. Many blocks simply do not pass the sonic test for max bore due to core shift. If the block had already been previously bored, then the opportunity to offset bore the cylinders into the thick sides of the cylinders is diminished.

Some of the early 272 engines are 4.000” bore capable but finding one of these is getting more infrequent. I've only come across a handful of these thick walled 272's over the years as most of them are only able to bore out to a standard 292 size and that's it. Too many of these ‘extra thick cylinders’ 272 blocks have gone to the scrap yard simply because they were 272’s instead of 292’s and 312’s. The 272’s just don’t get any respect. There’s a 4” bore 272 running around here locally for the last number of years but it was built as an experiment without performance in mind. It was selected for a 4” bore based on the sonic test numbers being very good. It was originally going to be bored out to be a standard bore 292 but the extra thick cylinder walls made boring to 4” possible. At 332 cubic inches, it’s a big Y with nothing but a massive over-bore. The cylinders were marginally on the thin side based on the sonic test results after the boring operation but it’s held up well to this point. Keep in mind that this engine has not been hot rodded and is simply a driver.

If you do go the 4” bore route and find it doable, I do have Best Gasket 4.030” bore head gaskets available for the Y in the event you’re having trouble finding them from the normal suppliers. These particular gaskets have revised coolant passages and also accommodate ½” head bolts if going that route.

|

|

By darrell - 8 Years Ago

|

|

i never knew any block made 4 in.the 272 truck block is thicker than the car block according to an old y magazine article.the trucks are dif blocks and the cars are cf.the 272 blocks i bore measure about .290 to .300 on average between cylinders.292 blocks a good one goes around .250.that means my 272 will have the same thickness at 292 that a 292 will have at 3.8.i have done 3 of these blocks now.all are ceby.

|

|

By BamaBob - 8 Years Ago

|

Charlie, first I must apologize for relying entirely on my 70 year old memory to recall facts about the 292 engine I rebuilt 28 years ago. I remember that it does have standard 312 pistons and rings in it, so that means that it is a 292 bored .050" over. I don't know where the idea of the .120" over came into my memory from! Anyway, I do appreciate the correction and I really like the vast amounts of Ford Y-block engine knowledge available here.Bob, Yours can't be .120" over and have std 312 pistons. Standard 312 is 3.80" which is .050" over 292. .120" over 292 is 3.870" (.070" over 312).

|

|

By 57ranchero - 7 Years Ago

|

Thanks for all of the replies. The intent is to have a Y-block engine at the 312 ci that will rev faster with all components staying OEM including engine components, transmissions,

clutches or torque converters; thus maintaining that the engine is a 312 y-block.

|