|

By CoryHoward - 8 Years Ago

|

Not only am I new to this forum, but I am also new to working on old vehicles, let alone a Y-block. Some back story of my truck. Before my father passed a few years ago, he started the restoration of his '59 F-100 with a 292. He took the motor to a local engine shop and had them do a complete rebuild of the block and heads. From what I know, ha had them replace all the original internals with new of the same spec. The only thing I do know is that he had them put in a "mild" cam, but I don't have the specs on it right now. When he got the engibe back, he replaced the old 2 brl intake and carb for a stock "A" code 4 brl intake and a Holley 600 cfm (I know its bigger then needed but it's what dad bought) and installed a set of headers. The only thing that has been changed since this is I installed a Mummert aluminum intake and my brother switched it over to electronic ignition. We are trying to put the finishing touches on the truck and have ran into a fairly big issue in regards to the timing. We tried setting the initial timing using vacuum first but could only manage to get about 12 on the gauge at idle (@650 rpm). When we put the timing light on it to check where we were, it was about 42° advance. We know that this is way off, but are struggling to figure out why. We verrified TDC for #1 cylinder and checked the rotor position on the distributor and it was good, so we are pretty sure the distributor is in correctly. I know very little about distributors but the rotor seemed very loose. I am not sure how much rotational play there should be in the rotor. I also know that the cam timing is set on this engine using the 3 'oclock method with 12 pins between the marks. I think that if this was off, the engine would not run at all so I am pretty sure this was done correctly also. I don't know anything about switching to electronic ignition, but is there anything that could ave been done wrong? It appears that the original distributor body was used in the switch.

I assume I have a lot of missing info to figure out what is going on, but hoping there are some Y-Block gurus out there that can point me in the right direction. Any and all assistance is greatly appreciated.

|

|

By Dobie - 8 Years Ago

|

|

Is the timing pointer pointing to TDC when you have no. 1 piston at TDC on the compression stroke? If not your damper may have slipped, y-blocks are notorious for it when the damper gets some age on it. Your brother probably used a Pertronix, Accel or some other drop-in electronic ignition conversion. The fact that it runs says he did it right. Have a look at the damper with a bright light and an inspection mirror. If the rubber between the crank pulley and the outer ring is deteriorated that's probably the problem. Nobody makes new ones but the Damper Doctor and the Damper Dudes have rebuilt ones on an exchange basis, or they will rebuild yours.

|

|

By CoryHoward - 8 Years Ago

|

|

Thats what I am leaning towards. I need to find a way to actually verify that #1 is true TDC without removing the head. We just bumpend engine until we could feel the compression building then just used the marks. If the rubber has slipped, then we are not actually on TDC on #1. I hope it is this simple. If not then we have a bigger issue that may require us to pull the engine.

|

|

By Gene Purser - 8 Years Ago

|

I had similar cam timing concern with an engine I have that was rebuilt by someone else. This post helped me be reasonably sure that my cam and TDC mark were correct. Carburetor adjustment also plays a part in good vacuum, as does valve adjustment. And vacuum will probably improve some with engine break-in.

https://www.fordbarn.com/forum/showthread.php?t=223428

With the distributor pointing to the # 6 firing position the valves on #1 cylinder are at an equal overlap position and the pointer will be approximately at the TDC mark if everything is as it should be. Use a socket to turn the engine until a strait edge is level across the valve retainers on # 1 cylinder.

|

|

By oldcarmark - 8 Years Ago

|

CoryHoward (7/9/2017)

Not only am I new to this forum, but I am also new to working on old vehicles, let alone a Y-block. Some back story of my truck. Before my father passed a few years ago, he started the restoration of his '59 F-100 with a 292. He took the motor to a local engine shop and had them do a complete rebuild of the block and heads. From what I know, ha had them replace all the original internals with new of the same spec. The only thing I do know is that he had them put in a "mild" cam, but I don't have the specs on it right now. When he got the engibe back, he replaced the old 2 brl intake and carb for a stock "A" code 4 brl intake and a Holley 600 cfm (I know its bigger then needed but it's what dad bought) and installed a set of headers. The only thing that has been changed since this is I installed a Mummert aluminum intake and my brother switched it over to electronic ignition. We are trying to put the finishing touches on the truck and have ran into a fairly big issue in regards to the timing. We tried setting the initial timing using vacuum first but could only manage to get about 12 on the gauge at idle (@650 rpm). When we put the timing light on it to check where we were, it was about 42° advance. We know that this is way off, but are struggling to figure out why. We verrified TDC for #1 cylinder and checked the rotor position on the distributor and it was good, so we are pretty sure the distributor is in correctly. I know very little about distributors but the rotor seemed very loose. I am not sure how much rotational play there should be in the rotor. I also know that the cam timing is set on this engine using the 3 'oclock method with 12 pins between the marks. I think that if this was off, the engine would not run at all so I am pretty sure this was done correctly also. I don't know anything about switching to electronic ignition, but is there anything that could ave been done wrong? It appears that the original distributor body was used in the switch. I assume I have a lot of missing info to figure out what is going on, but hoping there are some Y-Block gurus out there that can point me in the right direction. Any and all assistance is greatly appreciated.

Not sure I understand your Reference to the Rotor being "Loose". The Rotor should be tight on the Distributor Shaft and not move at all.Is the Rotor in good Shape inside? It should fit Tight with the Slot in the Distributor Shaft.

|

|

By CoryHoward - 8 Years Ago

|

|

Mark, the rotor is brand new. I didn't think it should move on the distributor shaft but infact rotates quite a bit with ease. Gonna have to see why it is loose.

|

|

By 57RancheroJim - 8 Years Ago

|

Are you sure the rotor is loose? The rotor may appear to being loose but it will rotate a little, the shaft is also rotating with it, you may be feeling the mechanical advance. It will only rotate in one direction and when let loose it should spring back to the original position.

|

|

By CoryHoward - 8 Years Ago

|

|

Jim, I will check to see if it springs back. Due to the truck being at my parents house, I won't be able to check it until this weekend. If it doesn't spring back that tells me the mechanical advance is bad right?

|

|

By charliemccraney - 8 Years Ago

|

You probably have a combination of problems. It doesn't have 42 degrees of initial timing. The engine simply would not turn over if it did.

Your method to set initial is not correct. It is not vacuum that you use to set timing. You set it with a timing light. You also need to be sure that the vacuum advance is disconnected and the vacuum port plugged when setting timing. If you do not, it will add timing to the engine, making it appear to have more than it actually has.

Another reason you might see higher than actual timing is that the damping mass has slipped. That is the part with the timing marks on it. If the damper is original or an old rebuild, then that is high on the list.

|

|

By oldcarmark - 8 Years Ago

|

charliemccraney (7/11/2017)

You probably have a combination of problems. It doesn't have 42 degrees of initial timing. The engine simply would not turn over if it did. Your method to set initial is not correct. It is not vacuum that you use to set timing. You set it with a timing light. You also need to be sure that the vacuum advance is disconnected and the vacuum port plugged when setting timing. If you do not, it will add timing to the engine, making it appear to have more than it actually has. Another reason you might see higher than actual timing is that the damping mass has slipped. That is the part with the timing marks on it. If the damper is original or an old rebuild, then that is high on the list.

Old Time Mechanics would often set Timing using a Vacuum Gauge. Simply advance the Distributor to get Highest Vacuum reading and then turn back until vacuum starts to drop. Set Distributor half way between highest and lowest. If it knocks under load back Timing back until it stops.

O

|

|

By 57RancheroJim - 8 Years Ago

|

You don't need to pull the head to check for TDC, you can use a piston stop tool that screws into the plug hole. Turn the crank until it hits the tool, make a mark on the damper, then turn it 360 in the opposite direction until it hits the stop and mark the damper again, TDC will be half way between the two marks.

Also a low vacuum reading isn't unusual with a non stock cam, best I can get is 14..

|

|

By charliemccraney - 8 Years Ago

|

|

I know people use vacuum to set timing. It does work to get close. If a timing light was not available, but a vacuum gauge was, I certainly would do it. However, that method does not usually end up with the right timing for the engine. It is more of a get you down the road method. When trying to solve problems such as these, you want to eliminate all of the uncertainty that you can. That means a timing light is required.

|

|

By GREENBIRD56 - 8 Years Ago

|

My outfit has the factory cam - so its no thumper (unless its running severely retarded). Even in that state of cam time, best vacuum is a bit more than 10º - more like 18º. If I set it there - with the vacuum disconnected - the additional mechanical advance I have in the distributor would over-advance the engine as the revs go up. So the mechanical advance would need to be restricted to prevent that. This has happened to more than a few "experimenters" when they try to do a set-up purely utilizing a vacuum gauge.

I'm a believer in utilizing live manifold vacuum (not "ported") to operate the vacuum advance. So - I set my initial timing at 10º - and I have the vacuum pot restricted to only adding a maximum of 8º. So when starting the engine, the 10º contributes to a quick "fire", the 8º then quickly adds on and takes the engine to the max vacuum "sweet spot". The sum of my initial and mechanical is 35º and its all in by about 2500 rpm. Springs to do that are available from Mr. Gasket - but in my case, it had to be done by trial and error (no access to a Sun "distributor" machine).

|

|

By 57RancheroJim - 8 Years Ago

|

He said they used a timing light. If he can read 42 degrees it must be a dial back type. Makes me think about a friend who had a similar reading, he worked on scrubies all his life and when timing the Ford he had the light connected to #5 LOL. About 45 degrees off...

|

|

By charliemccraney - 8 Years Ago

|

|

You're right. And that could be another part of the problem. Dial back lights are not as accurate as standard lights and can be quite a bit off.

|

|

By CoryHoward - 8 Years Ago

|

|

It was not a dial back style light. The marks on the damper go up to 50. Just found a receipt in all of dad's paperwork where he ordered a new damper from Mummert. Just don't know if he ever put it on or if its on a shelf somewhere. One more thing to look into.

|

|

By charliemccraney - 8 Years Ago

|

|

No stock damper is marked to 50 degrees. If he got it from Mummert, it may be a Powerbond damper. That could have more marks than stock. I've never seen one.

|

|

By CoryHoward - 8 Years Ago

|

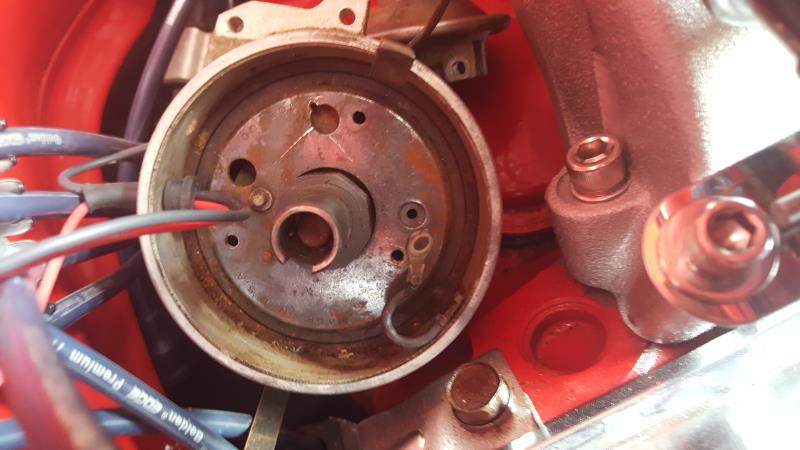

Ok, so I verified TDC and the timing marks are right on for TDC. Checked the rotor in dist. and it has no spring back from mechanical advance. Started to take apart to check and have ran into a problem. Even after reading shop manual, I cannot get the breaker plate out. It's almost like there are more screws holding it in that I cannot see. Anyone have any tips or experience with this.

|

|

By oldcarmark - 8 Years Ago

|

|

According to my 59 Truck Shop Manual there are only 2 Screws holding the Breaker Plate in Place. Looking at your Picture it looks like it may simply be stuck to the Housing with Corrosion. Have You tried spraying some WD-40 or similar around the Breaker Plate where it sits in the Housing. If there is no spring back from the Cam Assembly it must be pretty Rusty under the Breaker Plate. If this Disributor is in bad Shape once You get it apart the Cardone 30-2808 is a replacement and it easier to Setup because it has the later Vacuum Advance which can be adjusted with Allen Key. The One You have uses spacers and Springs to change the amount of Advance. Its probably easier to work on the Dist. on the Bench. If you set the timing with rotor pointing at #1 on the Cap and TDC on the Balancer and make a mark where the advance unit is pointing You will have reference when You put it back in. Hard to work on these in the Vehicle because of Location on the Engine.

|

|

By Gene Purser - 8 Years Ago

|

|

Doesn't that C-clip have to come off the pivot post?

|

|

By CoryHoward - 8 Years Ago

|

|

Mark, I agree. The dist. is very hard to get to while on the truck. Think I will just get a reman and be done with it.

|

|

By oldcarmark - 8 Years Ago

|

|

Before You take it out setup on TDC and Rotor pointing at #1 on Distributor Cap. Makes it easy to replace with another. Vacuum Advance may not be pointing in same direction. Make sure You have enough turning Space to set Timing.

|