|

By ronsplace - 8 Years Ago

|

|

I'm trying to determine if Y-block cars that came from the factory with air conditioning also came with smaller-diameter water pump pulleys than did Y-block cars that were not equipped with a/c. A friend tells me that all GM vehicles of the same era that came with factory-installed a/c units had smaller-diameter pulleys installed that did cars without a/c. The purpose, of course, was to increase the RPMs of the water pump and the fan to protect against over-heating at idle when the a/c is turned on. If Ford did, in fact, install different size pulleys in their a/c-equipped cars, it would be very helpful to know the diameter of the different pulleys used by the factory for both a/c and non-a/c cars. I'm researching this because I recently installed after-market a/c in my '56 312 c.i. Fairlane that came from the factory without a/c, and while it works well, the engine does heat up quickly on a hot day in slow-moving or stopped traffic. A fix I'm considering is going to a slightly smaller-diameter water pump pulley and it would be helpful to know the best diameter pulley to use. Thanks, Ron

|

|

By DryLakesRacer - 8 Years Ago

|

Ted Eaton replyed here on an overheating thread that Ford did indeed use different pulleys in various parts of the country but did not mention A/C as I remember.

A test for you is to start the engine cold and let it warm up with the cap off and the tank about 1 to 1-1/2" low. If after it has warmed up to operating temp and you see no movement of water by looking in the tank; then just barely raise the idle and if you see movement install a smaller pulley.

My 56 ran hot at signals at idle and drove me nuts. I did the test above and there was no water movement. I bought a pulley and spacer kit from Summit for a 302 67-68 Mustang. It was chrome and I painted it satin black and my cooling problem went away. It was a little over 5" and mine was over 7". I also put a pipe plug in the bypass with a 1/8" hole drilled in the plug. I too will be adding A/C soon. Good luck.

|

|

By miker - 8 Years Ago

|

|

The smaller pulley is a pretty common fix, as is the bypass restrictor and the elimination of the w/p spacer on the bird's and spacing the pulley out to line up. Most aftermarket a/c kits come with an electric pusher fan for the unit out in front of the radiator. Got one of those? They normally aren't big enough to provide any engine/radiator cooling.

|

|

By ronsplace - 8 Years Ago

|

|

I have an electric puller fan that does the job until I hit slow traffic on a hot day. My stock water pump pulley is 7" in diameter as measured from the lips (not from the bottom of the groove) and I think I will install the 6" diameter pulley I have and see if that takes care of the over heating problem at idle. In the back of my mind, though, is whether this smaller diameter pulley is going to cause me problems at freeway speeds on long trips because of the increased pressure caused by the higher RPMs. Any thoughts on that? Thanks, Ron

|

|

By miker - 8 Years Ago

|

Short answer, no. At least no one else has reported a problem. The water pump never moves enough water to be restricted by even the thermostat. If in doubt, fit one of the high flow stats for a mopar. Robert Shaw, can't remember the # right now. Others here will.

Greenbird56 has posted a great description of fitting a Hayden clutch and modified fan. He's in Tucson, and 110 degrees happens in the summer. Might do a search if you need to. The most important thing is a good shroud on whatever fan you use on the puller/radiator side.

|

|

By charliemccraney - 8 Years Ago

|

|

Water pump RPM should be kept below 7000rpm. On a typical street engine, it will never exceed that rpm with even the smallest diameter pulley that can fit and it certainly will not happen at freeway speeds.

|

|

By one piece at a time - 8 Years Ago

|

|

My factory 3 belt ac water pump pulley measures 6 3/4" (1956 312 built in Texas) outside dimensions. I replaced it with an FE big block it measures 5 ".bolted right up. Had a heck of a time getting belts to work. Later discovered that flow kooler makes a high volume wp for the Y. 12 vanes vs 8. $170.00 spent that much on belts and the pulley.

|

|

By GREENBIRD56 - 8 Years Ago

|

Not only is the stock water pump flow pretty low at idle - but more so when in gear with an auto trans. Have a trusted soul sit at the wheel when you try this.....

Water movement in my 'bird radiator (as seen through the radiator cap opening) was just about nil. In neutral, I revved the engine until the disturbance looked closer to what I used to see in my old '67 Cougar. It cooled just fine and I don't believe the waterpump was over-revved even at full throttle. The increased RPM level was a hint at how much smaller I was going to have to go to get the desired results.

|

|

By ronsplace - 8 Years Ago

|

|

I see that CASCO has a "High Output" water pump that I spotted on page 29 of their 2016 catalog, part #8501HO. The price is set at $149 and includes a new gasket. Of interest, they also say they will modify owners' stock water pump for increased output for $50 (part #8501HOY). Seems that something like this along with a 5" or 6" down-sized pulley would bring the temp down to reasonable levels on hot days at idle with the a/c blowing. Has anyone installed one of these HO water pumps? Ron...

|

|

By charliemccraney - 8 Years Ago

|

|

The casco pump is for T-Birds, which have a 1" water pump spacer (which is a big part of their cooling problems) so it will not fit your Fairlane. The stock pump works perfectly fine as long as it is in good condition. Check coolant flow at idle, as already mentioned, and adjust as necessary.

|

|

By ronsplace - 8 Years Ago

|

|

Thanks, Charlie. I didn't realize it wouldn't work on my Fairlane. Ron...

|

|

By DryLakesRacer - 8 Years Ago

|

|

My fix came from Greenbirds. It worked. I've never had a problem in traffic since I followed his fix. I did install the upper radiator shield to hood seal which made all the air from the front of the car go through the radiator prior to his fix on my 56 Victoria and it did help but it was cured by the pulley.

|

|

By Ted - 8 Years Ago

|

Here’s a picture of the Casco water pump for the Thunderbird engines. The ‘thicker’ impellor helps to move water in the oem TBird 1” spacer that would normally inhibit water movement with the stock water pump.

|

|

By paul2748 - 8 Years Ago

|

Ted - have you tested this water pump to see if it works as advertised?

|

|

By ronsplace - 8 Years Ago

|

|

Not familiar with Greenbirds. Do you have a website address? The smaller pulley is sounding like an excellent option to tame the over-heating at idle issue. Curious what diameter pulley you went with--5" or 6"? Thanks, Ron

|

|

By miker - 8 Years Ago

|

|

It's Greenbird56 on this site. Just run a search for his postings.

|

|

By DryLakesRacer - 8 Years Ago

|

My original was over 7" and the one I put on was over 5". I had to buy a shorter belt too. When I bought the pulley I also bought a spacer kit so I wouldn't need to move the water pump flange. I think I put in the 1/8" one. It was 4 years ago.

Sometime after that Ted told us there 5 or 6 different pulleys. I remember guys saying here the trucks had a larger diameter so I needed to watch that. The 302 Ford Mustang from 68 was perfect for me.

In 55-thru 64 the yblocks my mom and dad had never heated up here in SoCal. I don't know why they do now and I don't really give a s--t. The pulley deal that Greenbirds suggested worked. I also have the hi-flow thermostat for a Mopar. It seems to work fine also.

|

|

By charliemccraney - 8 Years Ago

|

|

Trucks have a smaller diameter pulley but the pilot diameter and offset are different, so not easy to use on a car.

|

|

By Ted - 8 Years Ago

|

|

paul2748 (5/22/2017)

Ted - have you tested this water pump to see if it works as advertised?

I have run the previous renditions of the Casco pump on the dyno and they appeared to do the job. I say ‘appear’ because the dyno water system can easily mask problems that only show up once the engine is in the vehicle. No customer complaints on any of those previous versions once put into service. Casco has gone out of their way in addressing some of the low rpm water pump issues that occur simply due to the 1” spacer being in place. The Casco Thunderbird specific water pump is a much cleaner solution than doing away with the one inch spacer and contending with getting the belt pulley alignment back where it belongs.

This latest Casco w/p version has a much better looking impellor casting and looks like it will do the job. The pictured pump is going on a customers’ engine and will be dyno tested in the near future depending upon when the customer can come down to the shop and see his engine run. The real test for the water pump will come once the engine is installed in the car.

|

|

By Flatrod - 8 Years Ago

|

|

What about the plate that goes between the pump and the spacer on the T Bird? I got one with my Bird when I bought it. I have it installed on my new engine, but have not run it yet. Was/is it worth while?

|

|

By GREENBIRD56 - 8 Years Ago

|

FLATROD - For an answer to your question, please google "Casco water pump testing". Some have complained about the testing method, but all in all - it looks suitable to me (40 years of mechanical engineering)..... the plate didn't get good results in their test. I have one under my parts bench wasting space - never installed.

Get a high flow thermostat for your engine - a no brainer. Mr. Gasket part, 180º for a big block Mopar (440 / 426) is a "Robertshaw" type, large diameter and works well enough. The Mr.G 160º versions seem to have quality problems. I hope you already have at least a 6 blade fan of a diameter that fits the T-bird shroud properly.

To get the higher fan and impeller speed I needed, I've fitted my engine with a 302 small block W.P.pulley - originally two grooves - with the rear most groove machined off. That netted the closest match I could easily find of the mounting face to the groove centerline.

|

|

By charliemccraney - 8 Years Ago

|

The MR Gasket thermostats are Chinese. Milodon sell a US made thermostat.

I had a 180 degree MR gasket fail on me.

|

|

By GREENBIRD56 - 8 Years Ago

|

Charlie - Do you have the NAPA number for their 170º t-stat? It was the other poppet style (not like Robertshaw), but had a full size opening and 2" overall dia. I should have retained the number when I found it.........! You just don't want to end up with the itty bitty size of opening fitted into a large blank disc seen on the left below.

|

|

By charliemccraney - 8 Years Ago

|

|

I don't know the Napa part number.

|

|

By GREENBIRD56 - 8 Years Ago

|

I've got an idea that it is NAPA p/n THM 170 - dislexia has set in in my old age ...... that part number is for a 180º t-stat (which would be a good temp choice for most applications). The NAPA site says the OD is 2-1/8. The main idea we need to pursue is to end up with a poppet opening of 1-1/2 inches (not 1 inch like a chebbie). When I looked the part up, it was only listed as being a $6.00 purchase - and that is what I remembered about the part we found before - very inexpensive.

My new office isn't right next door to NAPA (as it was before) - so maybe someone can check it out......?

|

|

By Flatrod - 8 Years Ago

|

Greenbird56

Thank you for the info. My 56 bird has wider belts, so the 302 pulley will not work for me. It looks like I will be needing a new pump anyway, so I will go with Casco water pump. I already have the right thermostat.

|

|

By 2721955meteor - 8 Years Ago

|

I have some questions regarding y block users in extreme hot conditions.

1 does every one use anty frees,or other any corrosion additive.

2 how maney restrict the by pass.

the reason for this info is i recently took a core from a user in la aria, 292 from57 ford car,low milage. the front cover was eaton threw from erosion the damage to front cover far more evident on driver side wher water enters block. it as right threw the casting at that point (no coolest additive or anty freez). have yet to clean block to check for damage due to cavitation.

with no bypass you will have cavitation,i run 2 temp gauges there is always a spread of temp of apron 10dgrs.higher at the stat end. in our cooler climate we do not have over heat issues as long as the cooling system is maintained.good pressure cap good therm, any frees winter and summer

|

|

By GREENBIRD56 - 8 Years Ago

|

|

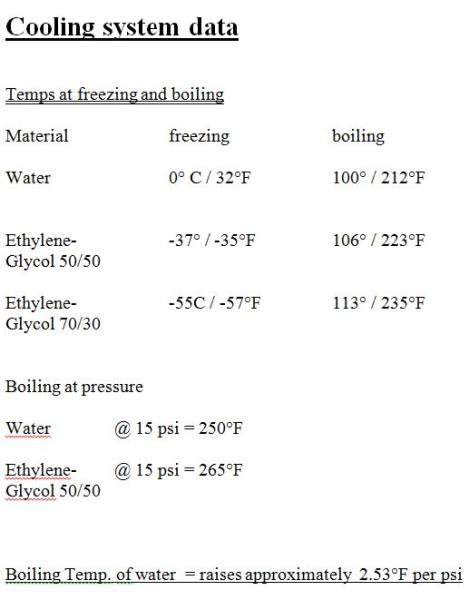

(1) The use of anti-freeze is necessary if you wish to suppress the boiling point of the coolant - whether the climate is hot or cold either one........

Since most of our efforts are directed toward avoiding a boil over, a 50/50 mix is the usual formula for most of us. Using the chemistry data above - you could further suppress boiling by using a "richer" 70/30 mix.

Step next would be to optimize the pressure cap - if the radiator is in good repair and of modern construction methods - then choose one that suits your equipment (or the OEM spec).

|

|

By Bobwanna - 8 Years Ago

|

Flatrod (5/26/2017)

Greenbird56 Thank you for the info. My 56 bird has wider belts, so the 302 pulley will not work for me. It looks like I will be needing a new pump anyway, so I will go with Casco water pump. I already have the right thermostat.

I like the idea of using the late 60's 302 water pump pulley for increased pump speed. Flatrod made note of different belt widths for 56. I had forgot about different belt widths. I thought Ford used a wider belt up to 56 and changed to a narrower belt starting in 1957 for most car engines. I will take a look at my 56 Fairlane and 68 Ranchero tomorrow and take some measurements.

Question. For those of you that have made the switch to the 302 pulley did you also change gen/alt pulley and crank? Or is the change in width insignificant?

272meteor, You raise a question about people in non-freezing climates not using antifreeze. Yes, many uninformed people back in the 50's or so did not have to worry about freezing and would use just water!!! I am from the rust belt area so I know about need for antifreeze. Later transplanted to no freeze area. I must admit that I did not bother with antifreeze in my cars in SoCal unless they had aluminum parts exposed to water. Yea, hard to believe. I now know better

|

|

By Ted - 8 Years Ago

|

Flatrod (5/23/2017)

What about the plate that goes between the pump and the spacer on the T Bird? I got one with my Bird when I bought it. I have it installed on my new engine, but have not run it yet. Was/is it worth while?

The results are unclear as to whether adding the stainless steel plate that sandwiches between the water pump and 1” spacer helps or not. My experience has been it does not not provide any additional cooling. Here’s a link to a past discussion regarding that plate. Doing a search will bring up some more threads regarding that plate.

http://forums.y-blocksforever.com/FindPost82934.aspx

|

|

By ronsplace - 8 Years Ago

|

|

Thanks everyone for all the great info on pulley sizes, thermostats and other over-heating remedies. When I started this thread I had no idea so much helpful information would be offered up. Hope everyone has a great Memorial Day weekend. Ron...

|

|

By 2721955meteor - 8 Years Ago

|

antifreeze is also useful in stoping erosion cast iron exposed to moving water,and essential if you are useing aluminum parts,such as radiators.Caterpillar learned years ago that linner erosion and alum. water components eaten up was NOT electrolysis ,bur water making sharp bender,and colideing with flexing linners during combustion. good quality antifreeze eliminated thes issues. if you question this go to a cat truck engine dealer and you will be surprised.

ps most of us are aware of anty freeze increasing the boil point. my concerns ar what the guys in hot climates use to control erosion.

|

|

By charliemccraney - 8 Years Ago

|

|

Antifreeze. Even in most hotter climates of the US, it still gets below freezing in the winter, making antifreeze a necessity for that reason alone.

|

|

By GREENBIRD56 - 8 Years Ago

|

I think that "answers" to the various cooling woes - that go with hot weather and "hot" engines are found by using a methodical approach. The Y powered vehicles we all seem to have collected up - they all had some sort of decent heat control capability built-in to start with. Restoring that capability can take a bit of troubleshooting - and assuring that the basics are in place. Just make a check off list and grind your way through it.....

(1) Radiator needs to be the right size and in good shape - not full of gunk and sediment. Because I live in southwest USA, I had mine reworked by an outfit that often works on desert driven vehicles. They make sure the re-conditioned units will take a healthy pressure cap of the OEM rating. If it has (or had) any shrouding - be sure you have it or are aware of the need for missing parts.

(2) Make sure there is a good, working thermostat in place. It needs a large enough opening to flow the "gallons per minute" the system was designed for. I found that my engine had a small thermostat poppet (fitted in a big blank disc) - which seems to be common practice for cheapo Chinese parts these days. Tests have shown that you lose a couple of GPM with the small poppet at low idle - and more as the rev's climb. Test the one you choose, by heating it and making sure that it opens and closes properly before you install it. A 180ºF rated unit should work well just about anywhere.

(3) A decent fan and belt needs to be in place. In the US and Canada, a six blade is a good choice and usually readily available. If it is fitted into a shroud make sure it is the right diameter and spaced correctly.

(4) The water pump must actually work. We had a fellow visit the site - who had a lot of heat problems with his 272 - and when he finally got some gaskets and removed the water pump, he found that the impeller blades had long since rusted away to nearly nothing. It pumped nothing - with a replacement pump, the system worked.

(5) The engine block has to have some useable water passages - many are found to be full of rust and other deposits - and water is just not circulating. Flushing a running system with white vinegar - or a made for the purpose acidic "cleaner" can sometimes do the trick. In the worst cases, fellows have had to remove the "freeze" plugs and auger out some of the deposits by mechanical force. The degradation of the cooling ability of our old blocks can really work against the other components we've put in place.

(6) Its OK to test and prove your system with tap water - but when real world use is what you need - use the chemical advantage of a 50/50 antifreeze mixture. The elimination of "boil over" being a numero uno goal - the additional suppression of the boiling point is what you want on a long summertime trip.

(7) Pressure Cap rating - many find that when their systems are in good condition and well balanced - they can run a lower than factory rating cap. If they aren't experiencing "boil-over" situations, it can be sensible to avoid stressing an old radiator. I run mine (reconditioned as above) with the factory cap rating - and I had it tested to be sure - because the desert here is an unrelenting heat load.

(8) Know for sure what "HOT" is. Hot is when your system is prone to boiling over - and not especially when a poorly calibrated 60 year old dash gauge says so. Find a good way to determine the actual temperature of your thermostat housing at the water exit - you may be surprised.

|

|

By John Didde - 8 Years Ago

|

|

why did you plug the by pass down 1/8 inch, don't understand the reason, please explain. thanks john

|

|

By charliemccraney - 8 Years Ago

|

|

That forces more of the coolant to pass through the radiator, rather than bypass the radiator.

|

|

By GREENBIRD56 - 8 Years Ago

|

The by-pass tube is a "short circuit" from the exit of the intake manifold - directly back into the water pump. When you start a cold engine, it provides a way to speed warm-up of the water in the block. When warm water circulates in this manner - it eventually opens the thermostat and allows hot water to flow into the radiator. The by-pass pipe never closes during operation and its direct connection to the suction side of the pump means that a lot of water does not go through the cooling cycle.

When trying to improve the cooling of my t-bird engine, I rigged up a plug for the waterpump port and then temporarily routed a length of 5/8 garden hose from the intake opening. With the engine running, I then had a good look at the large quantity of water coming out of the hose (which I simply directed back into the open radiator cap while testing). It is a huge cooling efficiency loss - that I don't need in southern Arizona. So, I used a technique I found at "Stewart Components" (NASCAR waterpump suppliers) - they drill (3) x 3/16 holes in the thermostat - and then block the by-pass of the engine. These holes let water immediately flow to the radiator - over the thermostat, at a reduced rate. It eliminates the tremendous loss of water flow due to the (still open) by-pass after the thermostat opens The hole I placed in a plug in the by-pass port simply adds some heat to the system -when cold, but not a lot.

This method slows cold start warm-up, then allows for more cooling efficiency after the engine is warmed up and operating through the thermostat.

|

|

By John Didde - 8 Years Ago

|

|

Very good explanation, I understand now, I will make a plug and block the by pass and do 3 holes 3/32. Thanks for advice. john

|

|

By John Didde - 8 Years Ago

|

|

Should I go to 2 grove pulley, will I have slippage with 1 grove.

|

|

By Rudder2fly - 8 Years Ago

|

|

I believe you will. I had to go to a 2 groove pulley. Even with the 2 groove your belt contact is less than half the pulley diameter.

|

|

By charliemccraney - 8 Years Ago

|

|

If it's just the crank, water pump and generator (or alternator) pulleys, then you won't need 2 grooves. What exactly are you doing?

|

|

By John Didde - 8 Years Ago

|

|

I am changing the pulley dia to 5 inch and putting on a 6 blade fan and adding AC, thinking that contact of the v belt and pulley will cause the belt to slip john

|