|

By pegleg - 9 Years Ago

|

Maybe somebody will talk John into casting some iron heads!

|

|

By pegleg - 9 Years Ago

|

Ted, Where'd the rocker arms come from?

|

|

By MoonShadow - 9 Years Ago

|

|

Reading the paragraph about repairing ports restrictions makes me a bit curious about how a set of heads were changed from stacked to parallel ports and made the cut?

|

|

By MoonShadow - 9 Years Ago

|

Is that only ONE repair of modification on all of the ports or just one spot in one port?

|

|

By pintoplumber - 9 Years Ago

|

|

I see on the Hot Rod site, the Jon Kasse/Royce Brechler entry had 769 hp 630 tq out of a MEL 473" I think.

|

|

By PF Arcand - 9 Years Ago

|

According to James Eickman's 1984 book on the Y-Block engine, Allan Cleveland was primarily in charge of combustion chamber & upper end design. I wonder if he ever recorded in anyway the reasons for the stacked intake setup? It would likely make very interesting reading if he did..

|

|

By PF Arcand - 9 Years Ago

|

An aside on the flow capability of original heads. When John Mummert was studying & porting the factory Y heads some years ago, he wrote an article on what he found. He discouvered that one of the biggest flow problems, wasn't the heads.. it was the available intake manifolds! No stock intake & most aftermarket intakes wouldn't allow maximum flow. Hense the Mummert 4 Bbl intake he came up with, which was in itself a game changer!

|

|

By LordMrFord - 9 Years Ago

|

Joe-JDC (2/24/2017)

At least the Oldsmobile folks can't use the aluminum head, either. I believe the - G or 113 heads can be ported to be competitive with a bit of valve work and they do allow pushrod tubes in Vintage Class. Interesting. Joe-JDC

Still wont help with lower port short radius.

|

|

By LordMrFord - 9 Years Ago

|

What about mating Windsor or Cleveland oem-heads with Y, custom intake, custom camshaft and custom everything else?

If somebody asks, say it's argy model.

|

|

By LordMrFord - 9 Years Ago

|

Joe-JDC (2/25/2017)

LordMrFord (2/25/2017)

Joe-JDC (2/24/2017)

At least the Oldsmobile folks can't use the aluminum head, either. I believe the - G or 113 heads can be ported to be competitive with a bit of valve work and they do allow pushrod tubes in Vintage Class. Interesting. Joe-JDC Still wont help with lower port short radius.  I have been able to get the lower ports on the iron heads into the 250+ cfm range, and the upper ports into the 264+ cfm range, which is capable of making over 500 hp in a 340ish cubic inch engine. I still believe that it is possible to get close to 550 horsepower with a larger engine and be competitive in scoring. I would like to see a real Y Block make 600 horsepower, NA. Maybe Ted could do it with his 401????

Any pics from runners?

I ported exhaust ports a lot with 1.6" valves but from intakes I took only 1mm from head bolt curves, some from walls and I smoothed bowls.

|

|

By LordMrFord - 9 Years Ago

|

charliemccraney (2/25/2017)

That wouldn't work either. From the rules "OEM cast iron cylinder heads are the only type of heads that can be used. Heads must be originally manufactured for the engine application in which it is being used."

Doh.

Lack of alu heads will keep Kaase away from Vintage class also.

|

|

By LordMrFord - 9 Years Ago

|

|

Is variable lenght or dual plenum intake manifolds legal?

|

|

By RB - 9 Years Ago

|

After the EMC completion Kaase mentioned that he thought with a bigger cam there was a lot more horsepower to be had.

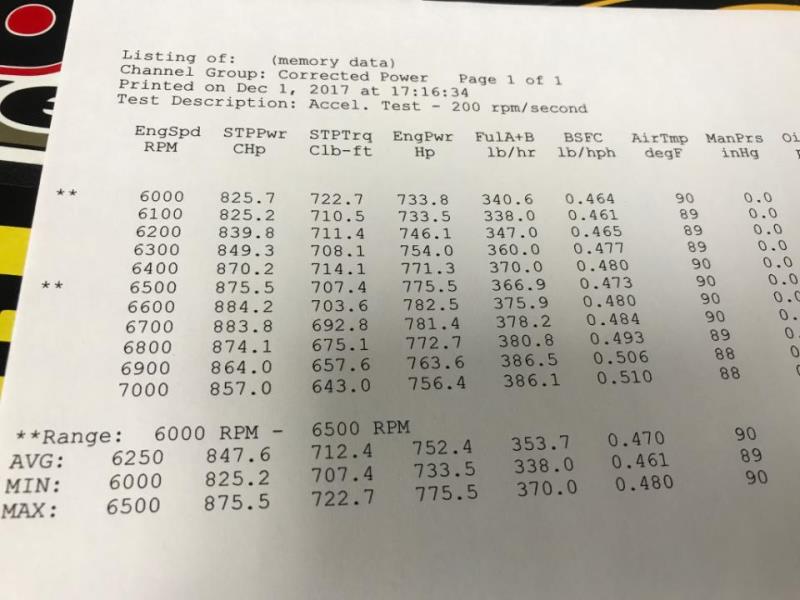

I was all for finding out, so the cam was sent back to Comp for a regrind. While Jon had the heads off he flowed them: 380 int 300 ex @.575 lift

Attached is the dyno sheet from yesterday. Jon thought 900 was possible.. I don't know how he could have been so far off. LOL

He is giving a seminar on this engine at the PRI show on Tues if anyone wants more details on this project

|

|

By yalincoln - 9 Years Ago

|

|

looks like a Lincoln Y might be a better choice!

|

|

By yalincoln - 9 Years Ago

|

|

hi ted! it doesn't say if porting the heads is allowed? I would think that if exhaust plates are allowed that porting would be allowed! I remember a guy that raced at milan dragway in Michigan used exhaust plates on a FE engine in a 66 ford shortbed pick-up back in the 70's. the MEL like the FE had small exhaust ports with too much angle to them! do you think that exhaust plates would help the MEL? also, is it possible to use a 460 crank in a MEL? the bore spaceing is the same!

|

|

By yalincoln - 9 Years Ago

|

|

thanks ted, good luck!

|

|

By yalincoln - 9 Years Ago

|

|

any flow figures on the 430 merc. heads! intakes should be great but exhaust might be a little low! can you use intake adaptor plates and a 460 intake?

|

|

By yalincoln - 9 Years Ago

|

|

hey ted! did you get any pulls at all for hp and tq?

|

|

By yalincoln - 9 Years Ago

|

|

does anyone have the final numbers?

|

|

By yalincoln - 9 Years Ago

|

|

thanks Ted! great numbers! sorry you missed the big show! there's always next year! do you have any pics. with all three manifolds?

|

|

By yalincoln - 9 Years Ago

|

|

what happened at the engine masters! what were the results? thanks!

|

|

By yalincoln - 9 Years Ago

|

|

thanks ted! beaytiful engine!

|

|

By Y block Billy - 9 Years Ago

|

God luck to all and may the ford gods shine!

I too was born in 61 and am surrounded by scrub loving bow tie bumkins!

|

|

By Y block Billy - 9 Years Ago

|

Awe, sad to hear!

|

|

By Y block Billy - 9 Years Ago

|

|

Yessa!

|

|

By Kahuna - 9 Years Ago

|

I am the proud owner of a Y Block in my 56 Ford, and someday hope to build, or have built, a bigger, more powerful Y Block engine for the car.

Several years ago, I was present in John Beck's shop in Chico, CA, when a Hemi, that was built by Danny Miller (RIP) & Gene Adams,

was doing dyno duty. I was very impressed, as with iron heads it made over 600 HP, and with aluminum heads was over 650. I believe the displacement was around 360 CI. I don't know if the final configuration was EMC legal at the time.

Many configurations were tried, including a locally cast, very goofy looking 2 X 4 manifold.

In 1958, I was 15 years old and was asked to drive a new 1958 Edsel in the Homecoming parade for the 1958 graduating class.

It was a Corsair convertible. I'm telling you that it would melt the tires without problem.

Jim

|

|

By Vic Correnti - 9 Years Ago

|

|

Someone doesn't like the Y-Blocks winning two years in a row with aluminum heads so they are not allowed this year. If theY's win again this year out goes the stacked ports too.

|

|

By tbirddragracer - 9 Years Ago

|

In 2002 John Mummert freshened-up the motor in my '56 T-Bird drag car. 340CI, 113 reworked heads developed 451 HP on the dyno.

With a little tweaking 500 plus hp should be possible with iron heads. The iron heads are still on the car.

Tbirddragracer.

|

|

By lowrider - 9 Years Ago

|

The rule change doesn't surprise me. If Ford keeps winning in NASCAR watch them make a rule change to handicap Fords.

|

|

By NoShortcuts - 9 Years Ago

|

Chuck. Maybe in 2015 John Kaase told them they were Re-Manufactured aftermarket J. Mummert heads?

|

|

By NoShortcuts - 9 Years Ago

|

It's been awful quiet out there.

The EMC event is October 2 - 6 this year.

Is everyone that is scheduled to participate in the 'Vintage' category still on board after the recent weather events that came ashore in Texas and Florida?

|

|

By HenryFloored - 9 Years Ago

|

Hi gang. I'm very proud of you guys and the Y-block Engine Masters entries the past couple years.

I am also not surprised that the Lincoln Y and MEL did so well. It is my belief that FoMoCo put some very good basic bones out in those days and when in the skilled and capable hands of you fellas the results speak for themselves.

I have mixed emotions about the outlawing of aftermarket aluminum heads. For so long the Y has not gotten the respect it deserves yet when one looks back into the history books and considers the scope and breadth of available speed parts for them you realize something very good was happening.

So here we are in 2017 and the Engine Masters rules are changed most likely because the availability of a good aftermarket head for the Y and not for many other makes is a stumbling block.

I feel that if this is the direction the class is moving let the sbc's run with 50's block and head castings and let the chips fall where they may.

Let's see exactly how these 50's engines compare.

I would predict that a Ford Y block could match or surpass a sbc in power per cubic inch.

I think the MEL could lay a beat down on even an early Hemi if built to the same rules naturally aspirated on gasoline.

Thoughts? I'm

|

|

By HenryFloored - 9 Years Ago

|

I'd rather not see furnace brazing myself.

I'd rather see Ford's superior engineering being put on display once and for all.

I know foot wide Hemi valve covers are cool or Olds and caddy's are the supposed peak of 50's hot rod hierarchy but I think Ford's, Merc's and Lincolns has more going for them and us than the story books tell.

Let's see exactly what was going on back in the day in terms of performance engineering.

|

|

By HenryFloored - 9 Years Ago

|

So I'm sure I'm not alone when I say that maybe the Y-block port design is the "right" way to do an intake port in the first place.

In short an intake valve is what about 2" wide at it's head?

On a 1955 265" scruby with the intake port that is perpendicular to the valve seat and head you are taking an air column that is about 1" wide and 2" tall and rushing it in and flipping it at the very last moment to pass the valve seat.

Now like anything that goes against conventional wisdom a fella scratches his head and goes why? Why did the Ford engineers flip the intake ports on their side on their very first OHV V8?

There were plenty of so called conventional engines around by the beginning of the Y-block. I have read that the "stacked" port design came from the idea that the engineers wanted the largest possible port volumes for the available area.

Anyone who had taken a look at 239 cylinder heads knows that large ports were NOT part of the equation.

In my humble opinion the Ford Y-block was designed with stacked ports because the horizontal centerline (which represents the largest cross section of intake charge) is parallel with the valve seat thus eliminating an abrupt transition right before the charge enters the cylinder.

While we may yearn (myself included) for a better short side radius on the lower port there may be less of a need for conventional thinking on a port that is completely unconventional.

Finally I find it very funny that an engine that did not get much respect from many in the performance community has come out so well in an actual engine competition.

Shouldn't the Old's, Caddy's, Buick's and Studebakers have completely dominated this competition by now? You would have thought so since so many Flatheads were pulled and replaced with those brand x boat anchors.

It's even richer knowing the rule change is coming because the Ford Y block has such a talented following that there are excellent aftermarket heads and intakes that can put up numbers when carefully built by our Y block enthusiasts.

Based on their popularity shouldn't the Olds and Caddy have figured into the mix here? I'm pretty sure the Olds has an aluminum head available.

Considering all that he rear end kissing the hot rodding community slathers on the Gm engines of that era you'd think there'd be at least a couple choices for each one.

|

|

By HenryFloored - 9 Years Ago

|

Hi guys, to be honest with you this post is to stir the pot a little bit on the EMC 2017 competition.

I have been watching this thread and haven't seen anything new in a couple weeks.

I take it there will be a couple MEL's in competition this year?

Wondering if there are other Ford, Mercury or Lincoln entries in "vintage" this year?

Are the Mopar hemis eligible, and if so what type of flow numbers are those things capable of?

Does an opposed valve engine have an optimal combustion chamber for a naturally aspirated engine on gasoline?

How does the "plank" head MEL combustion process by comparison? This was used on a very limited basis most notably on the MEL's and the "W" headed scrubs. Was it dropped because of an inherent problem?

Anyhow this is a fascinating subject to me. As I have stated before I have always believed that Ford's engine engineering in the 1950's was very underrated.

Watching intently from the sidelines. Good luck fellas!

|

|

By HenryFloored - 9 Years Ago

|

Hey Ted, thanks for the input. (BTW I'm the guy that bought the heads for my Lincoln Y block project from you recently).

Interesting you are doing an MEL. The gentleman that did the MEL last year did a great job and in my opinion there is lots of potential in that engine.

My good friend used to tell me store about his 410" '58 Edsel. I'm pretty sure the valvecovers never came off but was modded with a floor shift, traction bars, opened exhaust, stickey rear tires and a few other tricks to the carb and ignition.

Anyhow he swore that nothing could beat him except for the fuel injected Corvette at the time. First they would laugh then their faces would drop when they got whooped by an Edsel.

Jack said it was a torque monster. I hope the gobs of torque play into your favor.

Good luck to you friend.

|

|

By HenryFloored - 9 Years Ago

|

Well guys I'd like to put my 2 cents in, and that's about what it's worth. Lol!

With the EMC 2017 competition about a week away I'd like to wish Ted and and all the competitors the best of luck.

We on the sidelines appreciate and look forward to seeing what the fruits of your effort produce.

As a Ford enthusiast I have really enjoyed the Vintage class the past couple years. I am very proud of how well the Ford Y block stood up to the competition and how grateful we Ford fans are to have excellent minds working on our Ford stuff.

To tell you a little about me and why I hold the points of view I hold, I am an avid fan of the early cars. Specifically the Flathead era Fords. Throughout my life I have been disappointed that so many of those cars have been bastardized with brand X,Y or Z engines. Seemingly anything but Ford engines.

I understand some of the reasons I guess though I've always been skeptical about what the "magazines" have told us over the years.

So in the first two years of a dyno competition that features 1950's engines (the type that would be candidates for hot rod repowers) the magazine maligned Y block comes out on top.

The Ford Y block which got so little respect from so many managed to impress and even outshine even more modern engine designs.

The naysayers will spout that it was the aluminum head. I find it very funny that with all the Cad and Olds racing going on in the early days that there wasn't a fully flushed out aftermarket for either of those two engines.

I understand that the Olds has an aluminum head available for it but curiously there were no early Olds entries in the first two years.

This year with the factory block and head castings rule it looks like we're going to see some of Ford's big guns come out to play.

I think the Lincoln Y and the MEL will have a lot to say in this year's competition.

I wish the FE, the sbc and the early hemis were in because I'd like to see exactly how Ford's deepest breathers actually hold up against the engines that were chosen 10:1 for repowering Flathead Ford cars.

I didn't come about till 1961 so I missed the golden era of hot rodding. It would be nice to see after a lifetime of suffering through the sbc guys bragging "about the only way to make a Ford run is to put a scruby in it", how they were wrong and that a smorgasbord of power was waiting for them right at the Ford parts counter.

So good luck guys. Win lose or draw we are proud of you!

|

|

By HenryFloored - 9 Years Ago

|

Oh darn it Ted that's tough luck. I'm sorry to hear this after all that hard work.

Thank you for your effort.

|

|

By HenryFloored - 9 Years Ago

|

Here is a link to the vintage class winner.

http://www.hotrod.com/articles/photo-gallery-video-jon-kaases-amazing-mel-engine/

|

|

By FORD DEARBORN - 9 Years Ago

|

Greetings to all: Like the Ford Y-block, the M E L engine is of special interest dating back to my early days. I purchased a rag-tag 62 Galaxie with a 292 and 2 speed automatic from the lady next door. Some time later I salvaged a 383 from a 58 Merc that eventually went in the Galaxie. Also installed a 3 speed manual trans. The only modification I did to the 383 was installed a set of solid lifters and adjustable rocker arms from a 427FE so I could play with valve timing in a limited way. The son of the lady who sold me the 62 Galaxie had a 65 scrubrolet 327 with a 4 speed. I could never ever race anyone from a stand still without shearing every tooth from 1st gear and the cluster. However, from a 40 roll it was a different story. If I can remember, the Galaxie had a 3:1 rear gear and the 383 had a huge window of extreme torque. From a 40 roll the 383 Galaxy beat the 327 scrubrolet. Imagine getting beat by your Mother's old rag-tag Galaxy. It was all in fun as we were very good friends in the old neighborhood. I know this is a Ford Y-block forum but I hope Ted can keeps us informed of how he takes advantage of the very unique features of the M E L engine. The best to all, JEFF.................

|

|

By MplsMike - 9 Years Ago

|

Looks like they are starting to post results. I don't think they are to the vintage category yet.

http://www.hotrod.com/articles/first-four-competitors-2017-amsoil-engine-masters-challenge/

|

|

By MplsMike - 9 Years Ago

|

Here is a link to the hot rod site

http://www.hotrod.com/articles/photo-gallery-video-jon-kaases-amazing-mel-engine/

|

|

By Joe-JDC - 9 Years Ago

|

|

At least the Oldsmobile folks can't use the aluminum head, either. I believe the - G or 113 heads can be ported to be competitive with a bit of valve work and they do allow pushrod tubes in Vintage Class. Interesting. Joe-JDC

|

|

By Joe-JDC - 9 Years Ago

|

LordMrFord (2/25/2017)

Joe-JDC (2/24/2017)

At least the Oldsmobile folks can't use the aluminum head, either. I believe the - G or 113 heads can be ported to be competitive with a bit of valve work and they do allow pushrod tubes in Vintage Class. Interesting. Joe-JDC Still wont help with lower port short radius.  I have been able to get the lower ports on the iron heads into the 250+ cfm range, and the upper ports into the 264+ cfm range, which is capable of making over 500 hp in a 340ish cubic inch engine. I still believe that it is possible to get close to 550 horsepower with a larger engine and be competitive in scoring. I would like to see a real Y Block make 600 horsepower, NA. Maybe Ted could do it with his 401????

|

|

By Joe-JDC - 9 Years Ago

|

Small block (3/2/2017)

Is furnace brazing allowed? I seen some pretty Exotic modifications done on the351 Cleveland heads Back in the mid1970's through furnace brazing stock Cast iron heads!

No. Only one repair in one intake and one exhaust port on each head with epoxy. Cannot be used to direct airflow, only repair a leak.

|

|

By Joe-JDC - 9 Years Ago

|

Small block (3/5/2017)

I like the new rule Let the chips fall were they may and we will see the best stock as cast head in Vintage Class! Who will win

As cast is not a good way to win. The only way for the 292/312 heads to really pick up performance is with porting and larger valves. The flow as cast is dismal even though you CAN make just over one horsepower per cubic inch with them. Also, a portion of the combustion chamber is out of the cylinder bore, and that is not the greatest way to improve flow or power even though they were trying to tumble the air into the cylinder. JMO, but please don't put a bug in anyone's ear about as cast, you would kill the EMC with poor outcome of dyno results. Allowing the engine builders to modify and tweak is the whole idea of competition using a set of guidelines that will bring the builders skill into the equation. Joe-JDC

|

|

By Joe-JDC - 9 Years Ago

|

|

I just flowed a set of mint -G heads with 1.925/1.510" valves, and stock the upper port flowed 177 cfm, the lower 180 cfm, and the two exhaust ports flowed 123/124 cfm--as cast. In theory that would support 370 horsepower.( 180 x .257 x 8 = 370.08 hp). All of the stock intakes I have flowed are capable of flowing around 185 cfm average or slightly more. The 2009 EMC entry with porting and larger valves (2.020/1.600) flowed ~223/211 cfm with extensive porting. All the new aluminum heads I have flowed as cast and without any porting flowed ~240/224 cfm in upper/lower ports and around 180 cfm on the exhausts. Almost all the new Mummert intake manifolds I have flowed as cast flow ~ 274/276 cfm average, and the BTs almost always flow 278/279 cfm average. John's new Race heads flow ~290/280 and 190ish on exhaust. Big difference in horsepower potential. We don't need to handicap the Y by going back to "as cast" in EMC competition. JMO. Joe-JDC

|

|

By Joe-JDC - 9 Years Ago

|

|

Actually after removing the EGR hump out of the exhaust passage, and with good porting techniques, the exhaust has a very good shape and flows very well. Just have to make sure the rear of the exhaust bowl is not messed with much, or it's water time. Very capable of over 70% exhaust bias flow. Joe-JDC

|

|

By Joe-JDC - 9 Years Ago

|

|

I could tell you, but there are a couple of MELs entered in this year's EMC, and that would be considered a no, no. No telling what Jon K or Ted will come up with. Just have to wait and see upon teardown. LOL I understand there may be an early Hemi entered which will make it difficult to get the flow high enough on a MEL to keep a Ford at the center of the podium. But that is what the EMC is all about, taking the underdog and coming out a winner! At least the Hemi is required to have a head designed for the block, not a later rendition. Joe-JDC

|

|

By Joe-JDC - 9 Years Ago

|

Small block (4/11/2017)

That is a real good balance between the intake and exhaust what kind of number can be had For CFM on the intake side. What size would have the most advantage between the three engines?

I can tell you that two of the different types of heads flow very similar as cast, with the tall port heads flowing 246 intake, 184 exhaust before porting with 2.190/1.88 valves, and the short port heads stock flowed 249 intake, 183 exhaust with 2.140/1.775 valves. You can figure on iron heads that a 20% increase is very good, and more is possible with oversize valves, undercut stems, multi-angle valve job, etc. With iron heads, there is a limit on flow because you can only take out so much metal before the casting becomes useless and will leak under pressure. When that happens, welding does not always stop the leaks, and the casting is ruined. Aluminum is forgiving in that respect, because it can be repaired and can even be modified by adding material where needed to increase flow or velocity.

I believe that for best results with the MEL and excellent heads, around 430 cubic inches would be ideal, but with smallest bore and longest stroke to achieve those cubic inches. JMO, Joe-JDC

|

|

By ian57tbird - 9 Years Ago

|

Sorry to here that Ted. It must be disappointing for you.

|

|

By Rowen - 9 Years Ago

|

|

Jeez Ted, I'm VERY sorry to hear that! We need builders like you in there fighting for these disrespected engines of ours. Knock em dead next year!

|

|

By Small block - 9 Years Ago

|

|

Is furnace brazing allowed? I seen some pretty Exotic modifications done on the351 Cleveland heads Back in the mid1970's through furnace brazing stock Cast iron heads!

|

|

By Small block - 9 Years Ago

|

|

Thanks joe I understand the rules now. As for the Y block holding its own I think it did OK for it self in its time and the only reason it was over shadowed was because of the big block engines that Ford built. In 1958 you could order a Thunderbird with a 430, that don`t leave much place for a 312.

|

|

By Small block - 9 Years Ago

|

|

I like the new rule Let the chips fall were they may and we will see the best stock as cast head in Vintage Class! Who will win

|

|

By Small block - 9 Years Ago

|

|

If all the engines were restricted to as cast, I would bet they would all be close, Non of the heads from vintage engine were what I would call spectacular For the engine size!

|

|

By Small block - 9 Years Ago

|

Ted (3/30/2017)

Joe. Thanks for the detailed flow information on the various heads and intake manifolds. That very short but precise post could eventually end up being the holy grail of Y head information down the road. I did send in my entry for this years’ Engine Master Challenge. I didn’t see much point in going backwards in Y-Block performance in using the iron heads; I had already done a Y engine with iron heads at the EMC back in 2009 and it was a respectable performer but was severely outclassed that year due to the better aluminum heads available to the other engines. While I believe that the iron heads would be competitive against the other iron heads, I simply don’t see them being the top place finisher considering some of the other iron headed engine options out there. The driving force in entering this years’ competition with a different engine family ultimately boils down to expense; in my case an iron headed Y that is built to be competitive against some of the other players out there is cost prohibitive as that particular engine would not be easily repurposed at the conclusion of the competition. With that in mind, I’ve started working on what I’ll call a bored and stroked 383 M-E-L Mercury engine as the basis for the 2017 EMC competition. That engine family not having a combustion chamber within the cylinder head does present some challenges but at the same time opens up some head flow capabilities not seen on conventional and/or regular production heads.

Ted just curious Why is the MEL Engine allowed into the Vintage class? I thought the Engine had to be introduced before 1955?

Was the MEL engine not first built for the 1958 model run?

|

|

By Small block - 9 Years Ago

|

That is a real good balance between the intake and exhaust what kind of number can be had For CFM on the intake side.

What size would have the most advantage between the three engines?

|

|

By Small block - 9 Years Ago

|

|

What is the RPM limit for the class? You think a stroked Edsel 410 would be better than a big bore 383 Merc engine.

|

|

By charliemccraney - 9 Years Ago

|

Rules:

http://st.hotrod.com/uploads/sites/21/2016/06/2017-engine-masters-challenge-vintage-class.pdf

I was thinking something like that might happen. At least it is only aluminum heads that is not allowed. They need to make it appealing to others and having only one vintage engine that can win does get boring from other perspectives. This should level the playing field and make it more interesting, at the expense of impressive hp and tq numbers..

|

|

By charliemccraney - 9 Years Ago

|

|

That wouldn't work because the rules specify OEM cast iron heads. I wish the SBC could compete in vintage, just put a limit on them so they can't use Vortec heads, or some other good modern OEM iron head. Make it so they have to use a head from the same period as all of the other engines.

|

|

By charliemccraney - 9 Years Ago

|

|

That wouldn't work either. From the rules "OEM cast iron cylinder heads are the only type of heads that can be used. Heads must be originally manufactured for the engine application in which it is being used."

|

|

By charliemccraney - 9 Years Ago

|

It would be awesome to show up with an iron headed engine and still have a 500+ hp entry. That would very likely win and people who question the potential will have nothing more, that is credible, to say.

Teds last iron headed entry did put out good numbers but at that time, I think it was ci limited by the rules.

|

|

By charliemccraney - 9 Years Ago

|

|

The rules change yearly. Was that also in the 2015 rules?

|

|

By charliemccraney - 9 Years Ago

|

|

They make exceptions for less known, less used engines. The Mopar Poly Engines are the same. I think it is best to think of the vintage class as the not mainstream class. If it's not a common, popular, engine, there is a good chance that it will be approved.

|

|

By charliemccraney - 9 Years Ago

|

Ted,

I can't find other links. Search for Hot Rod Magazine on facebook and go to the videos section.

|

|

By charliemccraney - 9 Years Ago

|

|

Torque didn't drop below 630. I think it produced 715 ftlbs. He said in one video but I couldn't hear it clearly. It's over 700.

|

|

By charliemccraney - 9 Years Ago

|

If you've watched the Facebook videos, you may have noticed that one of the intake ports is clear plastic on the Kaase MEL. Here's an interesting video with that same intake on another engine.

|

|

By charliemccraney - 9 Years Ago

|

That's impressive.

|

|

By charliemccraney - 9 Years Ago

|

|

I'm sure it has nothing to do with preventing Ford from reaching the top. The Ford Y-Block is the SBC of the vintage class, in terms of the development behind it. Eliminating aluminum heads makes it more fair for everyone. Hopefully it brings some different engines out, as well. There are lots of neat vintage engines that could run and have not yet.

|

|

By charliemccraney - 9 Years Ago

|

|

An early hemi will be interesting. In past competitions, they really don't seem to live up to the legend but they also have not been in a class where the rules required oem heads.

|

|

By charliemccraney - 9 Years Ago

|

|

3700 - 6300 for the scoring

|

|

By charliemccraney - 9 Years Ago

|

One of the hemi's was vintage, and produced an excellent score.

I thought they weren't allowed, but looking back at the rules, nothing excludes them. I'm glad to see that.

|

|

By charliemccraney - 9 Years Ago

|

There's a video on facebook showing the Jon Kaase entry. Interesting stuff - what you would expect from him. I don't know how I can share it here, though.

He used a thick head gasket to bypass the no deck plates rule and extended the combustion chamber into the bore to increase the short turn radius.

I think I figured it out. Pretty sure you need to be logged into facebook to see it. Royce is in this one.

https://www.facebook.com/hotrodmag/videos/10154766914402540/

https://www.facebook.com/hotrodmag/videos/10154767035997540/

|

|

By charliemccraney - 9 Years Ago

|

Royce's Lincoln

https://www.facebook.com/hotrodmag/videos/10154766566677540/

|

|

By Ted - 9 Years Ago

|

The cylinder head rule for 2015 and 2016 for the Vintage Engine class were for the most part ‘unlimited’ as long as the heads being used were originally designed for the engine that was being entered. This allowed Jon Kaase in 2015 to completely re-engineer the Mummert aluminum head from a stacked intake port orientation to a side by side port layout. For 2016 I was using the stacked port heads on a smaller cubed Y and made higher peak HP numbers to boot which simply proved that the stacked port design was not so bad after all.

For 2017 the rules have been revised such that only OEM heads belonging to the engine being used are allowed. That means a SBF head cannot be used on a Y even if it’s a factory OEM head. As Joe brings up in regards to the 2017 rules, only one intake and exhaust repair per head. This cylinder head rule change was to help level the playing field as the Y engines up to this point were the only engines being entered that capitalized on the aftermarket aluminum heads that are available. There are some aluminum heads available for some of the other vintage engines but those simply haven’t come to the forefront in this competition during the last two years. As a result, the rules have changed so that only OEM heads originally designed for the entered engine can be used in the Vintage Engine class.

|

|

By Ted - 9 Years Ago

|

|

Another advantage to the stacked port layout not commonly mentioned is it permits the intake manifold plenum floor under the carburetor to be level for both planes. This allows the torque band to be maximized in that the intake runner lengths can be more equalized. On engines with a more conventional intake port layout, the factory supplied dual plane intake manifold ends up with a stepped plenum floor which makes four cylinders running a different torque band than the other four. There are camshafts now available for the main stream engines with two sets of intake and exhaust durations to help equalize this stepped plenum intake runner length nuance. The Y engines is one of the few engines out there that has a level plenum under the carburetor while still maintaining a true 180° or dual plane runner configuration.

|

|

By Ted - 9 Years Ago

|

|

MoonShadow (3/7/2017)

Is that only ONE repair of modification on all of the ports or just one spot in one port?

Here’s the excerpt from the 2017 Vintage Engine class rules regarding the cylinder head modifications. Without further clarification from the rules people, I’ll take it to mean ‘for each head where two heads are being used’.

305 - CYLINDER HEADS

OEM cast iron cylinder heads are the only type of heads that can be used. Heads must be originally manufactured for the engine application in which it is being used.

Any valve seat size and/or valve size permitted. Any commercially available

stainless steel valve permitted.

Titanium valves and/or springs prohibited. Titanium retainers permitted.

Up to one intake and / or one exhaust runner may be repaired by use of epoxy. Flow and / or directional changes by use of said epoxy is strictly prohibited. Push rod tubes are permitted. The use of exhaust “port plates” are permitted and may be constructed of aluminum.

The stock OEM intake bolt flange must be used and maintained.

Here’s the link to the complete set of rules for the 2017 Vintage Engine Class.

http://st.hotrod.com/uploads/sites/21/2016/06/2017-engine-masters-challenge-vintage-class-03012017.pdf

|

|

By Ted - 9 Years Ago

|

Joe. Thanks for the detailed flow information on the various heads and intake manifolds. That very short but precise post could eventually end up being the holy grail of Y head information down the road.

I did send in my entry for this years’ Engine Master Challenge. I didn’t see much point in going backwards in Y-Block performance in using the iron heads; I had already done a Y engine with iron heads at the EMC back in 2009 and it was a respectable performer but was severely outclassed that year due to the better aluminum heads available to the other engines. While I believe that the iron heads would be competitive against the other iron heads, I simply don’t see them being the top place finisher considering some of the other iron headed engine options out there. The driving force in entering this years’ competition with a different engine family ultimately boils down to expense; in my case an iron headed Y that is built to be competitive against some of the other players out there is cost prohibitive as that particular engine would not be easily repurposed at the conclusion of the competition. With that in mind, I’ve started working on what I’ll call a bored and stroked 383 M-E-L Mercury engine as the basis for the 2017 EMC competition. That engine family not having a combustion chamber within the cylinder head does present some challenges but at the same time opens up some head flow capabilities not seen on conventional and/or regular production heads.

|

|

By Ted - 9 Years Ago

|

|

Small block (4/2/2017)

Ted just curious Why is the MEL Engine allowed into the Vintage class? I thought the Engine had to be introduced before 1955?

Was the MEL engine not first built for the 1958 model run?

When the Vintage Engine class first came into being in 2015, it was pretty much unlimited as far as blocks, heads, intakes, etc. which put the SBC engines at a definite advantage had they been allowed. Sixty plus years of SBC development would have shined in an unlimited class as I’ve seen 860HP in my own shop on those engines still being normally aspirated. In that particular case, that engine did not have a single oem piece remaining but it was still SBC architecture. Hence the ‘before 1955’ rule which simply took the SBC engines out of the fray in this particular class. With this years’ oem iron head rule and no epoxy or welding allowed within the heads other than for a simple repair, the Ford Y-Block could easily go head to head with the SBC engines also equipped with oem heads.

As Charlie mentions, exceptions are allowed to the ‘before 1955’ rule with the Poly and M-E-L engines now being on the exception list. Simply writing in to the rules committee with a proposed engine for the class is all it takes to start the process to add an engine to the exception list. I had a 312 engine prepared for the 2008 EMC but it was disallowed due to the mushroom tappets rule for that year; "no mushroom tappets allowed". For the 2009 competition I pushed for an exception that allowed mushroom tappets for those engine originally equipped with them. That exception was approved and as a result I was able to enter a Ford Y in the 2009 competition and that was the year that I entered the competition with an iron headed Y.

With the Ford Y-Block taking a first place finish for the first two years of this particular competition, it was inevitable for a rules change to help level the playing field. Hence the move back to oem iron heads.

|

|

By Ted - 9 Years Ago

|

yalincoln (4/5/2017)

Hi Ted! It doesn't say if porting the heads is allowed? I would think that if exhaust plates are allowed that porting would be allowed! I remember a guy that raced at Milan Dragway in Michigan used exhaust plates on a FE engine in a 66 ford short bed pick-up back in the 70's. The MEL like the FE had small exhaust ports with too much angle to them! Do you think that exhaust plates would help the MEL? Also, is it possible to use a 460 crank in a MEL? the bore spacing is the same!

You can port the heads to death as long as you don’t break through. Only one epoxy or weld repair per intake and export per head which eliminates the extensive modifications seen in the past. The rules are not clear on the exhaust ports though in what happens if you break into the water ports. Pushrod tubes are allowed though.

A 460 crankshaft drops into the MEL with just a few modifications. Besides having to turn the mains down to the MEL journal sizes, the front crankshaft timing gear would need to move forward to align it with the cam gear. There are a couple of other items but are not show stoppers.

|

|

By Ted - 9 Years Ago

|

yalincoln (10/20/2017)

hey ted! did you get any pulls at all for hp and tq?

Only one dyno pull was made before coming to the realization that the cam/lifters had something going away. That single dyno pull was from 3500 to 5000 rpms to get a feel for the ignition timing and fuel mixture before taking the engine into the higher rpm ranges. On that single pull where the total timing was too much, the jetting too rich, and the lifters were eating themselves up, the torque was 692 lb/ft at 4000 rpms and the horsepower was 618 at 5000 rpms and climbing. A good tune up as well as higher rpms was going to net some much better numbers. Once the cam issue is figured out, the engine will go back together for some serious testing. There are three different intake manifolds here to test with those being a single four, three deuces, and a dual quad tunnel ram.

I’ve just sent Bruce Young (Y-Block Magazine) the article covering the MEL engine build which gives specific build details and a copy of the dyno sheet. If all goes as scheduled, that article will be in the next YBM (issue #142).

|

|

By Ted - 9 Years Ago

|

yalincoln (10/24/2017)

Thanks Ted! Great numbers! Sorry you missed the big show! There's always next year! Do you have any pics with all three manifolds?

Here are pics of the three intake manifolds for the M-E-L project.

|

|

By Ted - 9 Years Ago

|

|

Royce. Those are some really great numbers. Should power your station wagon very nicely.

|

|

By Ted - 9 Years Ago

|

Henry. As far as I know, there are at least two MEL engines being entered in this years’ EMC. It’s too bad the SBC engines have been excluded from the class as with the current oem head rule as I believe an iron headed Y would be in a position to best that particular family of engines. Beyond that, the Y would have a tough time being top dog with some of the other entered engine families with the current iron head rules so that had me looking at some other options.

I’m doing a M-E-L entry this year for the EMC simply due to having a bunch of MEL parts laying loose. I didn’t see much use in going backwards with a Y using iron heads as I had a 640-650HP Y combination in the works for this years’ entry had the aluminum heads still being eligible. I had also considered doing a Mopar Poly engine as there is one of those as well as some exotic parts laying loose here for that engine family but no way to repurpose that engine after the competition so that engine was not a choice. I do have a plan for the MEL engine after the competition which was the driving force in building one of those.

The question now is whether to build the engine as a period correct engine or to step outside the box and do something more exotic in the intake manifold area. I’m sure that Jon Kaase is not going to be holding back and it will be interesting to see what he does on the heads to improve the flow with the rules limitations that are in place. With Jon’s affinity for tunnel ram intakes, I’m guessing his MEL entry will also have one.

|

|

By Ted - 9 Years Ago

|

There have been a couple of drop outs in the Vintage Engine Class. As far as I know, those drop outs are not related to the storms here in Texas. I’m the second engine running on the Monday schedule so I’ll need to be in Lima that previous Saturday night so the engine can be loaded on a dyno cart on Sunday.

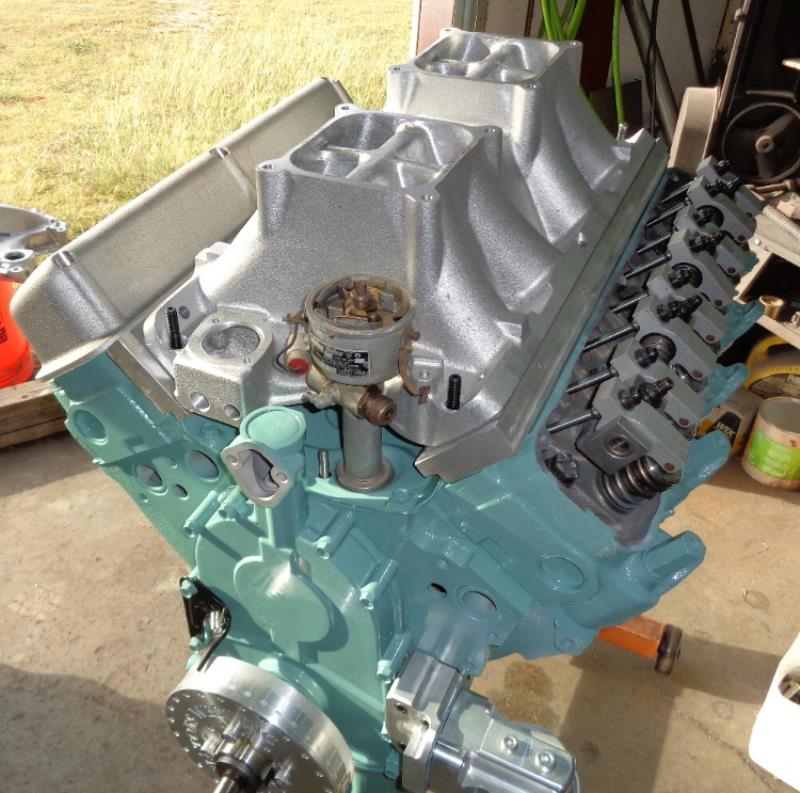

My own M-E-L (Mercury 383) entry is going to take right up to the last minute to get it completed though. Parts for the MEL engines are just about non-existent so I’ve been having to make a bunch of them. Engine is expected to be a power monster though. Here’s a picture of the pistons before and after adding the various coatings. Finished pistons have also had 145 grams removed from their insides.

|

|

By Ted - 9 Years Ago

|

|

pegleg (9/23/2017)

Ted, Where'd the rocker arms come from?

Those rocker arms are Harland Sharp 1.76:1 ratio. This particular set is not anodized to the orange color that HS rockers typically are and are simply the original aluminum finish. While FE rockers come close to working, these HS rockers are specific for the M-E-L engines. The MEL rockers have a different angle to the adjusting screw versus those for the FE engines.

|

|

By Ted - 9 Years Ago

|

My M-E-L EMC entry is not going to make it for the scheduled running on Monday morning. It has had a serious lifter failure and there’s simply not enough time now to address that. I’ll know more about the cause of that failure once the cam and lifters are pulled from the engine. This all happened yesterday evening so the plan is to pull the engine completely down later today. Depending upon the rules for the EMC competition next year, this engine may see life at that venue again.

Here’s a picture of it sitting on the dyno prior to being torn back down.

|

|

By Ted - 9 Years Ago

|

|

Just a quick update. Disassembled the engine and pulled all sixteen lifters from the bottoms of the bores. They are all plenty bad with a couple I checked getting very close to the pushrod being exposed to the camshaft lobes. These are shell lifters so the pushrod runs in the bottom of the lifter to begin with. The camshaft came through looking surprisingly good considering the amount of carnage on the bottoms of the lifters. While the camshaft lobes exhibit some scoring and scuff marks, the lobes themselves are far from being wiped out. I suspect the camshaft core is chilled iron rather than flame hardened which may explain the lack of lobe damage. I’ll be taking the camshaft and the lifters to a local shop later today for some hardness testing of each.

|

|

By Ted - 9 Years Ago

|

|

Charlie. Your facebook link does not work for me. Can you provide a different link or access point?

|