|

By Rudder2fly - 9 Years Ago

|

I have been through 3 pan gaskets and tried different gasket sealers but still can't stop the pan leaking. I guess I took too much material off the holder to clear the main bearing stud nuts. What have you folks done to use the studs and still have enough pan material to hold the gasket? Also what is the best sealer to use to join the main neoprene seal halves at their parting line? I have bought another seal holder so I can start over. I want to replace the main seal with a new neoprene seal. My question is can I just rotate the new seal in place without loosening the main bearings? Thanks G.S.

|

|

By charliemccraney - 9 Years Ago

|

The retainer on my engine clears the rear man nuts. The clearance is required only for the stud, which is quite a bit less than you have in yours. On one other engine block and retainer combo, it is the same, the nut clears just fine, only a little is required for the stud.

Are you positive it is the gasket surface of the retainer that is the source of the leak? One idea is to cut some shim stock to fit on top of the retainer bolts. Make sure the shim is thick enough to be level with the retainer surface. Glue it onto the bolt with a dab of silicone. That may offer a little better support, for a better seal.

You can see, from the change in color of the retainer at the very back, that the gasket seal seal takes place at the front of the retainer, so material removed from that point may compromise the effectiveness of the seal. You might also want to use a little silicone to level out the valley between the retainer and block.

|

|

By Rudder2fly - 9 Years Ago

|

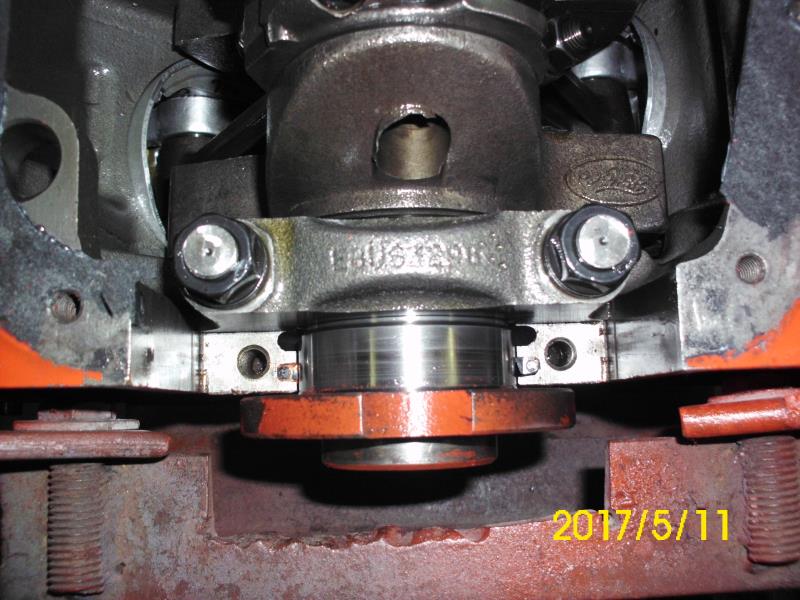

My retainer does not clear the nut. If I remove the washer under the nut it will clear. Can these washers be removed? Attached is a picture of the nut and the new retainer I have bought. I tried to fill the retainer bolt holes to provide more surface contact but so far that did not work. The leak definetly at the rear pan gasket. My retainer does not clear the nut. If I remove the washer under the nut it will clear. Can these washers be removed? Attached is a picture of the nut and the new retainer I have bought. I tried to fill the retainer bolt holes to provide more surface contact but so far that did not work. The leak definetly at the rear pan gasket.

|

|

By charliemccraney - 9 Years Ago

|

Interesting. Maybe the main caps changed throughout the years. As long as the studs have enough threads, you might have about 1/8" removed from the caps, where the washer rests. Then use the replacement retainer with only enough removed to clear the studs.

Do the 2 studs have thread sealer?

|

|

By Rudder2fly - 9 Years Ago

|

|

Motor is a B9AE, everything standard, looking at all the crud inside I would say it had never been torn down. I marked all the caps as to position of them. Block line bored I believe everything went back as original. Best I remember the studs were installed hand tightened per instructions with no thread cement.

|

|

By charliemccraney - 9 Years Ago

|

Sorry, I meant the two oil pan studs. They need thread sealer.

I took another look. You are right, the nuts do not clear with washers underneath on the assembled engine. So you do need that much clearance.

Did you apply sealer to the base of the retainer, where it contacts the block?

|

|

By Robs36Ford - 9 Years Ago

|

I have the same leak but not the mod you have. Did you check the amount of blowby? Silly me, I thought I could block of the downdraft tube on my 56 312 and rely on just the filler breather but NOPE! when it is over 3000 rpm it leaks, no, it bleeds. I had a broken ring in one cylinder! Argh!

|

|

By Vic Correnti - 9 Years Ago

|

|

Wouldn't a 12 point nut be smaller then the 6 point one?

|

|

By Ted - 9 Years Ago

|

For sealer, I use CopperCoat at the rear seal retainer parting line. You might consider that the seal retainer bolt holes are the source of the oil leak. Filling those exposed cavities with RTV after tightening the bolts may help in that case.

I’ve performed similar notching of the rear seal retainer for studs that have been used with a main girdle without pronounced oil leakage problems from that area. I do use a thin film of RTV at the pan rail in lieu of a pan gasket when using the main support girdles. Verify that the oil pan gasket is covering any voids that may be exposed if the gasket is not wide enough. Also insure that the oil pan itself is straight in that area. As a last resort, have you considered milling the bolt pads on the rear main cap just enough that would lower the nut/washer combo? Vics' suggestion of using 12 point nuts is also a good one.

|

|

By Rudder2fly - 9 Years Ago

|

|

Ted, Can the RTV Sealer be used in place of the pan gasket? I do not have any leakage at the 2 pan studs or at the seal holder parting line at the block. I used Coppecoat at the parting line. I have been under the motor with it running with a mirror and the leak is definetly at the pan between the seal holder bolts. When I took the pan off yesterday the gasket was stuck good at both surfaces except between the holder hold down bolts. I have cleaned up both surfaces of gasket material and will lay the pan on the block to see if it is level. I tried K/W Coppercoat on one gasket and I used NAPA Form-A-Gasket on the other two.

|

|

By Ted - 9 Years Ago

|

|

Rudder2fly (11/29/2016)

Ted, Can the RTV Sealer be used in place of the pan gasket? I do not have any leakage at the 2 pan studs or at the seal holder parting line at the block. I used Coppecoat at the parting line. I have been under the motor with it running with a mirror and the leak is definetly at the pan between the seal holder bolts. When I took the pan off yesterday the gasket was stuck good at both surfaces except between the holder hold down bolts. I have cleaned up both surfaces of gasket material and will lay the pan on the block to see if it is level. I tried K/W Coppercoat on one gasket and I used NAPA Form-A-Gasket on the other two.

Before proceeding further, I'll suggest that the oil pan be put in place with everything clean but without the gasket. Then take a feeler gauge and see exactly where the distortions are between the pan and the retainer. Once this is known, then you can make a suitable correction.

If that fails, I’ll suggest a thin bead of RTV and then the gasket on top of that but only in the retainer area. You didn't mention the brand or composition of the oil pan gasket which can be a player. I can see where cork would be a problem in your case.

Using RTV by itself without an oil pan gasket would be a mess and very difficult to clean the next time the pan would need to be pulled. I've pulled down other brands of engines where this was done and they were still leakers at the oil pan rail which means RTV is not a cure all. If the pan is only leaking at the rear seal retainer area, then that would be the only area I would consider putting a thin layer of RTV. It’s important that the RTV be allowed to ‘skin over’ before actually placing the gasket on top of it. In your case, you may need RTV on both sides of the gasket at the rear seal retainer area depending upon if the pan or the retainer or both is the problem.

|

|

By Rudder2fly - 9 Years Ago

|

|

This maybe revelent to my problem but I don't think so. I have a 312 crank installed with the slinger removed. I find not a sign of oil leakage at the crank flange so really hate to disturb that seal. I placed the pan on the block and I need to get it to contact better especially at the rear. The gaskets I have used are all cork,2 were Fel-Pro OS10701 C-1, 1 was from a gasket set, Pro Torque KS32120. I was careful to not over tighten the gaskets. I believe that Victor also has a pan gasket and I will get that one which I may install. Has anyone used the Victor? Earlier it was mentioned about crankcase venting. All looks good there if you will take a look at a video post of the engine running.

|

|

By Rudder2fly - 9 Years Ago

|

I have both pan gaskets. The Victor is thicker, .015, than the Felpro. Also the cork material seems to be denser. My question is where do I start the RTV sealer? Do I use a little bit of the RTV with Permatex on the back edge of the pan or stop the Permatex at a given point and start the RTV? I think the Victor gasket will take a little more torque than the Felpro.

|

|

By charliemccraney - 9 Years Ago

|

|

Permatex is a brand which produces many products, including RTV. When you say Permatex, which product are you talking about?

|

|

By Rudder2fly - 9 Years Ago

|

|

Aviation Form-A-Gasket sealant liquid.

|

|

By Ted - 9 Years Ago

|

I’ve had no issues with the rear seal crankshaft slinger being removed from the crankshafts. When installing some of those 292 sized rear main seal cranks in the early 272/292 blocks, the slinger had to be removed from the crankshaft simply due to the early blocks not having the groove in the block to accommodate that crankshaft slinger. Where I’ve seen a majority of oil leaks at the back of the Y is with the side seals on the rear seal retainer. A dollop of RTV in the hole before installing the side seals seems to take care of this area in most cases. In rare cases, I’ve found the rear seal retainer either cracked or warped at which point the retainer is simply replaced with a usable unit.

You don’t mention how you’re tightening the oil pan bolts. Using a torque wrench at this spot can get you in trouble so hand tightening is recommended and then only tightening the bolts just enough that you see only a slight deformation in the gasket as it’s being squeezed in place.

In your case, I’ll suggest getting away from the cork and into something more substantial. I use the Best Gasket oil pan gaskets which is a ‘black’ dense fibrous material for want of a better description. These oil pan gaskets simply get coated with white grease when installing them and are leak free. Due diligence is taken before hand to insure that the timing cover and rear seal retainer are flush with the pan rail. The oil pans are also dry fitted to the block or a flat surface to insure that the sealing rail is flat. The oil pan bolt holes are reverse peened to get the oil pans’ sealing surface flat where necessary.

I have managed to reuse the Best Gasket oil pan gaskets when needing to remove the oil pan for various reasons. The 2016 EMC Y used one of these and had to be torn down at the competition. That particular used oil pan gasket has been reinstalled back on the engine twice since then and is still leak free without using any sealer.

I’ve used oil pan gaskets using a similar ‘black’ material that are available by FelPro for the Ford FE engines; these gaskets are available as an alternative to the cork oil pan gaskets also available by FelPro for the same engines. FelPro calls these gaskets rubber coated fiber gaskets. I’m not aware offhand if this material is also available by FelPro for the Ford Y engines but any retailer that handles Fel Pro should be able to look that up for you.

|

|

By Rudder2fly - 9 Years Ago

|

Thanks Ted, I will check out the Best Gasket before I install the pan. I don't have any leaks at the crank seal or the side rails. I was careful to hand tighten the pan bolts on every pan gasket I installed per your method. I will have the pan with good contact all around before installation.

|

|

By Rudder2fly - 9 Years Ago

|

Ted, This white grease? Is it white lithium grease? I looked for just white grease at NAPA didn't see anything but WLGrease.

|

|

By Ted - 9 Years Ago

|

|

Rudder2fly (12/14/2016)

Ted, This white grease? Is it white lithium grease? I looked for just white grease at NAPA didn't see anything but WLGrease.

Yes. It would be white lithium grease.

|

|

By Rudder2fly - 9 Years Ago

|

Thanks Ted. I be putting that pan back on next week. I will post how the Best Gasket does.

|

|

By Rudder2fly - 9 Years Ago

|

I used the Best Oil Pan Set 24026E. Block side I used sealer Versachem Mego Black, and pan side CKC White Lithium Grease. So I will see if this stops the pan leaks.

|

|

By charliemccraney - 8 Years Ago

|

Some other options I've thought of, if whatever you did does not work

Use allen bolts with washers / shims under them to bring the top of the bolt flush with the surface of the retainer. Use rtv to fill in the small gap between the bolt and retainer, taking care not to fill in the allen socket. That will provide very sturdy additional surface area for proper support, probably about equal to what is available with an unmodified retainer.

Another is to use a stud and allen nut (or socket nut). Same basic idea as the allen bolt but you may be able to machine the allen nut for tighter clearances within the retainer.

|

|

By Rudder2fly - 8 Years Ago

|

I have the engine about ready to run again. Thanks for these new suggestions to my problem. I will post the result when the engine is running.

|

|

By Rudder2fly - 8 Years Ago

|

|

Success, I ran the engine about 15 minutes. Looks very good as to oil leaks. I was a little disturbed that I had a little shake in the engine and it was not as smooth as it had been. I had crossed #2 and #3 plug wires that will give you shake every time. SMOOTH NOW!

|

|

By Rudder2fly - 8 Years Ago

|

I am beginning to think all the cussing my Dad had for Henry Ford was on the money. As stated in previous post the pan oil leak had been corrected. However I decided to run the engine one more time before installing same in the car. This time I set the RPMs at 2400 which is about 65MPH in my car. I ran this for 15 minutes. Yep a drip-drip of oil at the bellhousing. Well the best I could tell the leak was at the seal. I should have left well enough alone but it has been a log time since I put the short block together and I wondered if I had put the seal in correctly? At 79 years the memory isn't what it use to be. Now this is the 4th time I have dropped the pan. Needless to say I am wore out with this oil problem and it is about to whip me. This is a 312 crank turned to 292 specs. The journal for the seal checked out right on the money. There was no sign of oil at the seal parting line, seal holder side rails, seal holder parting line. The bell housing had oil splatter behind the flywheel consistent with a leak at the seal. Ted what am I missing here? Now what to do? I have bought another seal from BEST thinking it might be different than FELPRO which is what is in the engine. Nope the BEST is a FELPRO P-61411. I have not removed the upper half of the gasket because I do not want to remove the crankshaft from the block. Anybody have any thoughts on my next move. I have the car about ready for this motor.

|

|

By Rono - 8 Years Ago

|

Gene;

I know you must be anxious to get the motor back in and get on the road again, but in my opinion you should replace that front cross member while everything is all apart. Much easier that way. Just completed this task on my 56 Ranch Wagon.

Rono

|

|

By Rudder2fly - 8 Years Ago

|

I have completed the cross member repair and suspension rebuild.

|

|

By miker - 8 Years Ago

|

Gene, here's an old link on this topic. This winter I replaced the "orange" seal in my 312 with the newer black style. So far so good. Engine was in the car, and I followed the last post.

Good luck

http://forums.y-blocksforever.com/Topic106586.aspx

|

|

By Ted - 8 Years Ago

|

Hard to tell from the picture but are you offsetting the seal in the groove so it’s sticking out ~1/4-3/8” from the parting line? This is important as it allows the seal halves to match up to their ends in a more exact manner. I also like to put some Coppercoat sealer at both the block and the seal retainer where they meet up with each other.

Unfortunately leaks that occur at the seal retainer side seals can be confused with the rear main seal itself. I put much emphasis on getting those rubber side seals and nails properly in place. This involves installing the side seals with the seal holder about 1/8” from being seated in place. A dollop of RTV is placed at the top of each side seal groove and then the side seals are started. It helps to take a small blade screwdriver and wedge the seal holder over so that the side seal can be inserted within the hole so that only 3/8” of side seal is sticking up. Then the other side seal is inserted in the same manner with that same small blade screw driver prying the rear main seal retainer over so that seal can also be more easily slid in place. At this point and with both side seals sitting about 3/8” above the retainer, the nails are tapped in place on the seal retainer groove side with a hammer. With a screw driver blade on top of the side seals while the nails are being tapped down, just enough pressure is applied to the tops of the side seals so that the nails and seals are flush with the top of the seal retainer. The seal retainer is tightened down and then the side seals are tapped again in which to insure that they are flush with the top of the retainer. At this point you should see a slight squeeze of RTV at the chamfer at the seal retainer where it meets the block.

Also confused with the rear main seal leaking are the two oil pan bolt holes in the seal retainer. Studs were standard fare here and if removed should have sealer put back on them. If the studs are missing, then a liberal coating of RTV on the oil pan bolts at that particular location is expected to seal the deal assuming the area is clean of oil so that the RTV can do its job.

|

|

By Rudder2fly - 8 Years Ago

|

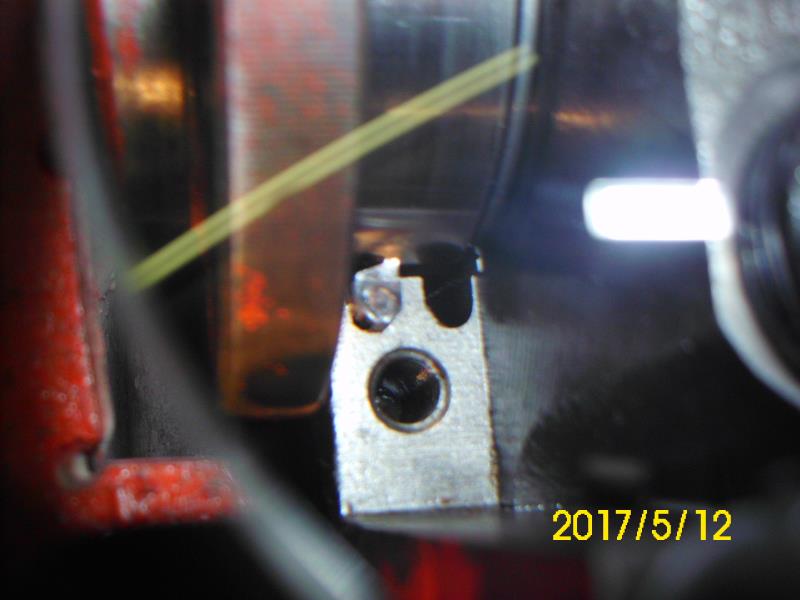

The leak is from the seal lip. All other leak sources show no sign of oil. I have 2 pictures that show seal offset and what looks like good compression of the seal lip in the engine block. When I place the lower half that would be in the seal retainer on the upper half I don't think there is enough compression or any of the seal lip. Has anyone taken a light sanding of this seal to get more compression of the seal? The leak is from the seal lip. All other leak sources show no sign of oil. I have 2 pictures that show seal offset and what looks like good compression of the seal lip in the engine block. When I place the lower half that would be in the seal retainer on the upper half I don't think there is enough compression or any of the seal lip. Has anyone taken a light sanding of this seal to get more compression of the seal?

|

|

By Rudder2fly - 8 Years Ago

|

|

I think what I am going to do is take a couple of thousands of the seal holder where it mates to the block and reinstall the same seal half and side rails.

|