|

By Pops57 - 9 Years Ago

|

Hello y block fans, first post here my names Jesse. I have a 1957 ford fairlane 500 292yblock and I love her. She runs and drives. Started doing some maintenance and noticed some stuffs just not right.im not the best mechanic but I take my time very persistent and organized, and like shit done right the first time. So here it is.

Vacuum gauge hooked up to fuel pump to intake line Rapids bounces at 19-20

Gauge hooked up wipers line same thing bounces 19-20

The dizzy to carb line steady 15

When balancer is 0 degrees dizzy rotor is not pointing at #1

|

|

By Pops57 - 9 Years Ago

|

|

Any help is greatly appreciated.thank you in advance

|

|

By Talkwrench - 9 Years Ago

|

Well Im not sure about the vacuum at the fuel pump , sounds like that could be normal.. How do the wipers work?

The dizzy to the carb is probably on the low side indicating late timing.. BUT you shouldn't be reading anything on that line? Its normally ported vacuum its sounds like you have it to manifold vacuum.

The rotor wont be spot on at 0 degrees due to the advance [or retard] .. BUT how far out are we talking here....??

|

|

By Pops57 - 9 Years Ago

|

Wipers work good. Shouldn't the gauge be a steady reading of 16-20 it rapidly bounces at 19-20. The dizzy lines goes to bottom of under the bowl.

Both valves are closed/up position. Intake was last one to come up felt air coming out of spark hole. Pistons at TDC rotors at #1 on cap balancer is at like 50degrees

|

|

By paul2748 - 9 Years Ago

|

Balancers have been known to rotate. If the both valves on #1 are closed , it on the compression stroke and the rotor is pointing to # 1 it sounds like you may be close on the timing. Research on how to find TDC using the plug in the spark plug hole and find TDC

|

|

By charliemccraney - 9 Years Ago

|

The damping mass slips on the damper. Since the timing marks are on that mass, the timing indicated is incorrect once it has slipped If yours is original, then it is well past time to replace or rebuild the damper.

I don't know about the fuel pump vacuum.

If the 15 inches is manifold vacuum, then it's not too bad. It is a little low but this is a 59 year old engine and might be getting close to time for a rebuild. A compression check along with a thorough tuneup and assessment and repair of the ignition and fuel systems will be a good idea.

|

|

By Pops57 - 9 Years Ago

|

That's how I find it.although when the intake closes the piston comes up after its closed and tdc is #1 on dizzy. But balancer is 50degrees past 0degrees.

0degrees is BDC exhaust valve open/down position

When my intake valve closes/ up position I'm about an inch past 0degrees but when the piston is tdc its like 50degrees now

|

|

By Pops57 - 9 Years Ago

|

|

Weird thing is that it runs pretty good

|

|

By miker - 9 Years Ago

|

Measuring the vacumn at the double acting fuel pump wil show the "bouncing" and high vacumn. It's made to run the wipers at WOT when vacumn is low. The 15" reading, if steady, isn't bad. I don't know if the carb on the motor used manifold or ported vacumn to the carb. But it sounds like you're looking at manifold vacumn. Any cam over stock will read a little lower.

If it runs good, make a mark on the balancer where the timing pointer is at TDC. If it's slipped, you need to be able to find it again. also mark the the TDC line on the balancer so it show well with a timing light. Start it up, and check the timing. Remember to disconnect the dizzy vacumn advance. Start it up and take a reading. If it's running good, and you've got a mark 50 degrees off, it's a slipped balancer. Not a big deal right now, and now you've got a mark that works. If it shows up on the original mark, the balancer's good, and you didn't find TDC. Make sense?

Either way, you've got a mark that works for now. Now you can add a couple degrees, or back off a couple, but at least you can get back to your starting point. Now you can advance or retard it, looking for the highest vacumn reading, and test drive to see if it pings.

Mark everything, write it down, use two colors of paint. I can't tell you how many times I've regretted not having a base line, and not knowing what to go back to.

|

|

By Talkwrench - 9 Years Ago

|

Wipers work good - great. Shouldn't the gauge be a steady reading of 16-20 it rapidly bounces at 19-20 If you are checking the lines off the fuel pump I would say it may bounce around as its a small diaphragm that's working. If your checking the engine you need to get manifold vacuum from below the carb butterfly or out of the manifold direct. The dizzy lines goes to bottom of under the bowl. ..What carb are we talking about original or new style Holley , Eddie????

Both valves are closed/up position. Intake was last one to come up felt air coming out of spark hole. Pistons at TDC rotors at #1 on cap balancer is at like 50degrees

|

|

By Pops57 - 9 Years Ago

|

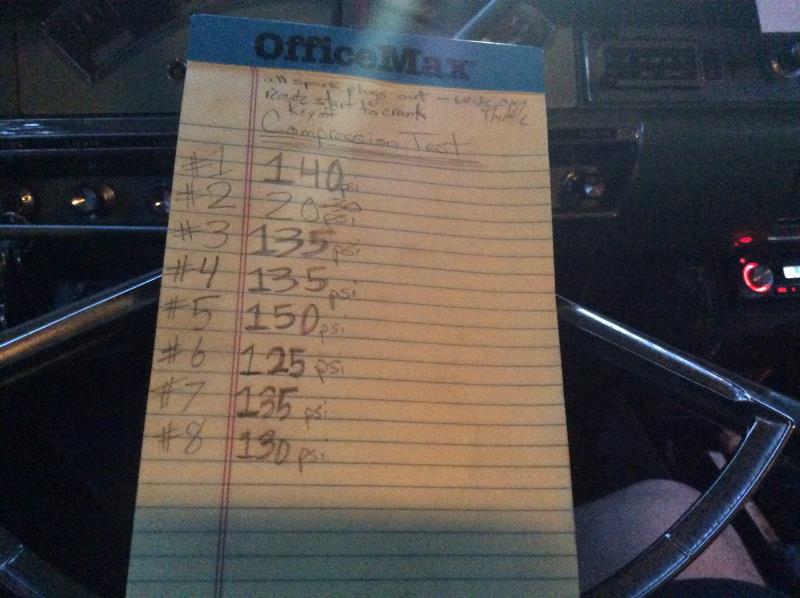

So I ran a compression test today.what should I do next as #2 is shot?thanks in advance.

|

|

By miker - 9 Years Ago

|

|

I'd pull that valve cover, and see if #2 has the valves visibly moving, or a thrown pushrod. If it's a valve stuck open or a pushrod off and stuck closed, I wouldn't just replace the pushrod until I knew the valve would move. Then I'm afraid the head comes off to see what you've got.

|

|

By Ted - 9 Years Ago

|

A Leak Down Test would help to isolate why the cranking compression is ‘low’ on cylinder #2. Without the leak down test, check the valve lash and make sure you don’t have one that’s too tight. Oil in the cylinders and repeating the test for cylinder #2 can help to determine if the rings and/or the piston is the problem. Assuming the oil in the cylinder and the valve lash checks out okay and based on the very low test value, I’m betting on a valve sealing problem on cylinder #2 which will require the cylinder head to come off in order to fix.

The valve stem seals remaining in the raised position on the valve stems is normal. Once the head(s) is pulled, then the condition of those seals can be verified and replaced if needed.

|

|

By Pops57 - 9 Years Ago

|

|

I've had it off and they all move valve lash is .019 .As I was pulling spark plugs #2 was dirty and oily

|

|

By Pops57 - 9 Years Ago

|

|

How do I perform a leak down test

|

|

By Ted - 9 Years Ago

|

|

Pops57 (7/5/2016)

How do I perform a leak down test

A leak down tester puts air to the cylinder while both valves are closed and gives a percent value for the air leaking past rings, valves and/or gaskets. A cheap test is to simply put air pressure to the cylinder and see if you can hear air come back out the carburetor, exhaust, or oil fill tube. Having the rocker arms off while you do this eliminates the need to have the piston at exact TDC on the compression stroke. By doing this you know in advance where to look once you start pulling the engine down.

|

|

By Pops57 - 9 Years Ago

|

|

Opened her up and found #2 cylinder pushrod was out. That would cause no compression right? Can I just pop it back in and check it or do I need new pushrod? Is this something common that happens?

|

|

By Ted - 9 Years Ago

|

|

Pops57 (7/5/2016)

Opened her up and found #2 cylinder pushrod was out. That would cause no compression right? Can I just pop it back in and check it or do I need new pushrod? Is this something common that happens?

If it was an intake pushrod, then there will be minimal compression on that cylinder. An exhaust pushrod being off will have the engine popping back through the carb. Just stick the pushrod back in place if it's not bent and recheck the compression on that cylinder. If it's bent, replace it.

|