|

By charliemccraney - 10 Years Ago

|

Ted (5/21/2016)

charliemccraney (5/20/2016)

I watched my in truck video during the last pass I made, paying attention to the oil gauge. The pressure drops a lot, not slightly, by the time I'm at the end of the track so that is something I will have to resolve before I race again.

I installed a gate, made out of piano hinge, on the baffle. Maybe that is not allowing oil to flow as well back to the pickup. Will get a pan gasket set and check things out. Charlie. As long as the oil pan gate door swings to the back, you should be good in that regard. How many quarts of oil do you carry within the pan including what’s in the filter?

Ted, you asked this in http://forums.y-blocksforever.com/Topic119711-1.aspx, so I'll start a new thread to answer and hopefully resolve the issue.

The gate door does swing to the back. I normally run 6 quarts total, according to the shop manual.

In addition to the high rpm drop, which is significant, I notice that the pressure starts to flutter at about 2300rpm. This is consistent whether the oil is hot or cold but of course, the pressure is higher when cold.

I did add a quart, for 7 total. It changed nothing with the flutter and there is not a good place to test the higher rpm aspect close to home.

The plan is to pull the oil pan to verify pickup clearance, 1/4" to 3/8", try to devise a way to observe that the gate is working properly or remove it altogether for testing, the factory baffle will still be in place, and try an additional quart or two.

Here's the post about installing the gate, http://forums.y-blocksforever.com/Topic1469.aspx?. Looking back at that, I may need to trim more off of the baffle. It was designed for low rpm street use, so it's possible it doesn't allow enough flow back to the pickup in performance situations. Also possible is without additional clearance under the baffle, there is not enough surface area for the oil to open the gate as effectively as I thought.

|

|

By Ted - 10 Years Ago

|

|

Charlie. This sounds like a cavitation issue. Assuming the oil pump pickup to pan clearance is okay, then two other things come to mind. First would be an air leak on the inlet side of the oil pump. Next would simply be a faulty oil pump or at least a problem in the oil pressure relief area of the pump. Do you have some specific oil pressure numbers in regards to the variance?

|

|

By charliemccraney - 10 Years Ago

|

The flutter results in about a 5psi variance, around 40psi and it doesn't seem to drop, just bounce around at typical street rpm.

In my video, by the end of the track, pressure had dropped to about 10psi. That was in the neighborhood of 6000rpm.

When the engine is hot, it can't seem to get much above 45psi and it has always been that way, with two oil pumps, one a spur gear and the other gerotor. The spur gear pump was a remanufactured unit. The gerotor was rebuilt with the Melling kit and all clearances are in spec. The gerotor is currently installed. The relief spring is shimmed about 1/8". It will achieve about 80psi, cold.

|

|

By charliemccraney - 10 Years Ago

|

The inlet tube nut was a little loose. I tightened it and there was no difference with the flutter. I did notice that whenever I let off the gas, the pressure jumps about 5psi

|

|

By Ted - 10 Years Ago

|

|

Charlie. That drop in oil pressure when accelerating and then increasing when the load is taken off the engine points me to main bearing clearances being on the ‘big’ side. Increasing the oil viscosity could be one way of determining this without an actual engine tear down.

|

|

By charliemccraney - 10 Years Ago

|

|

Mains were .0025, but that was determined with plastigauge, which I now know is not the best to use.

|

|

By speedpro56 - 10 Years Ago

|

Charlie, make sure the large nut on the oil pan tube going into the oil pump is snug. Caught mine sucking just enough air to cause a flutter. Not saying this is your problem but an easy check.

|

|

By charliemccraney - 10 Years Ago

|

I checked that nut. It didn't help. I did change from 20/50 to 15/40 last year. So maybe I do need to go back.

About 5 3/4 quarts drained. That seems about right considering the filter and other places oil might hang out.

I marked the pickup tube and pan before removal so I had a reference for their proper relation once removed. The pickup is positioned about the best it can be. The only way I can make it better is to flatten the bottom of the pan and try to bend the pickup tube for the new depth. If it's really necessary to go to such measures, I'm just going to send a pan to a place like Canton Racing for proper modification and additional capacity. It's hard to see in the pictures, but the pick up is tilted so it is higher in the front and lower in the rear. This makes sense, given it's position right over the 2nd drop, to the lowest section of the pan. This does seem to indicate that it could start ingesting air even if there is a couple quarts in the pan.

The pickup screen is clean and the tube does not seem to be clogged. I wonder if it would be wise to remove that bit of sheet metal covering the majority of the screen. Alternatively, I think I do have a pickup with a removable screen. Maybe that one would be better to use.

The gate flops around very easily and once installed, it is actually open slightly because of the slight tilt of the engine. I trimmed an additional ~1/8" from the baffle. I don't think that is causing a problem. Here it is held in the open position to show the gap below the baffle

I made this nifty tool to check clearance. It's 1/4", stepping up to 3/8". The only area where clearance is close to ok is right over the curve down to the deepest portion of the pan.

|

|

By charliemccraney - 10 Years Ago

|

More data.

I put about 2.75 quarts of oil in the pan and tilted it back and forth to observe how the oil flows.

It takes about 3 seconds for the majority of that to move from the front of the pan to the back.

It takes about 1:30 for the oil to level back out (move from back to front) so the gate definitely does it's job in that direction.

When the pickup is installed, it is about 1 1/8" to the floor at the front, optimum right over the transition to the lowest portion, about middle and about 1/2" at the back.

I also set up the pan at the same angle it is installed and filled it with water 1 quart at a time to observe fluid levels.

Even with 2 quarts, the pickup opening is not quite completely submerged and there could still be air trapped in the pickup. And when you consider that acceleration will force the oil back, away from the pickup, 2 quarts just isn't enough for any kind of performance. So maybe 3 quarts is the minimum that needs to be in the pan to keep it submerged, which means only 3 quarts (of 5+1 per factory specs) is available to be elsewhere. Bottom line, a factory truck pan is no good for performance applications and it was never intended to be.

Now I need to figure out what to do about that. Canton no longer do 1 off jobs for old motors, (the implication being that they may do a bigger job, hint, hint, anyone else want a good pan for a truck?). So I'll see if I can find anyone else who does that kind of work and if I can't, I'll take it into my own hands.

1 Quart:

2 Quarts:

3 Quarts:

4 Quarts:

5 Quarts:

Any more than 5 quarts and you need to be sure the pickup tube nut is tight:

|

|

By charliemccraney - 10 Years Ago

|

I dug out another style of pickup, one with a removable screen. It is in a much better position. So I may use that temporarily, if the new pan is going to take a while. I think that should be noticeable even on the street, if the pickup position has something to do with the pressure anomalies.

|

|

By Lord Gaga - 10 Years Ago

|

Should be OK now. That bell shaped P/U was wrong for that pan. Never seen one like it...what did it come off of?

|

|

By charliemccraney - 10 Years Ago

|

It came off of a Y-Block, with that oil pan.

I have three other truck pans and pickups which are off of engines and they are the type of pan without a baffle and have the removable screen type of pickup. One is an HD truck pan. Maybe the baffled pan came with the bell shaped pickup.

When I used the non baffled pan, the pressure would drop considerably when coming to a stop. Maybe they revised the pickup position when they added the baffle, to prevent that.

|

|

By DryLakesRacer - 10 Years Ago

|

|

Have you ever thought of making your own pickup? I looked at a lot of them and found a rectangular one where the line was on the side or at a slight angle up from one of the sides and not the top for my GMC 6. I found some 7/8" dia. steel tubing with some bends, cut, and welded until it was where I wanted. I believe it was a Moroso for a pretty large engine like a FE or Pontiac. As I remember the tubing on the pickup was a little smaller than the -12 bulkhead fitting I welded on and the sealed to the pan.. Good Luck.

|

|

By Y block Billy - 10 Years Ago

|

|

I think your on the right track with cavitation issue, are you restrickting flow to the top at all? The FE guys swear by running 1 quart over because they say the FE's will suck the pan dry on a hard run.

|

|

By charliemccraney - 10 Years Ago

|

|

I've pinched the overflow tubes so that they have about a 1/32" opening.

|

|

By tomfiii - 10 Years Ago

|

It's from a x-block article about cavitation.

http://www.enginelabs.com/news/moroso-offers-an-expanded-line-of-performance-wet-sump-oil-pumps/

|

|

By charliemccraney - 10 Years Ago

|

The link goes to what is essentially an advertisement for Moroso Oil pumps. Is that what you meant to link?

|

|

By tomfiii - 10 Years Ago

|

Yes it does, I was thinking their description of cavitation and what they did was why I placed it.

|

|

By glrbird - 10 Years Ago

|

Here is a couple of choices, maybe you could make work.

http://www.ebay.com/itm/Moroso-Oil-Pan-21960-U-Weld-It-Oil-Pan-Kit-Oval-Track-Steel-/291639690486

http://donrossfab.com/oil-pan.htm

|

|

By charliemccraney - 10 Years Ago

|

I'm actually working with Moroso, to have one made. They'll have all of the engine specific info to build pans for Y-Blocks. Chassis clearance and such will be the responsibility of the buyer to provide.

|

|

By charliemccraney - 10 Years Ago

|

Lord Gaga (6/21/2016)

Should be OK now. That bell shaped P/U was wrong for that pan. Never seen one like it...what did it come off of?

Saw this on eBay. The '57-'66 Ford Truck Parts Book also shows a similar looking pickup, along with the more common removable screen type. So I can be sure that it is correct and not some previous owner's well made improvisation.

|

|

By charliemccraney - 10 Years Ago

|

Pulled the pan off of one of my parts motors and it also has the forward positioned pickup and baffle. So the pickup absolutely is a correct y-block part and the baffled pan comes with the forward positioned pickup.

This pan is no good so I'm going to cut it up and make a tool.

|

|

By speedpro56 - 10 Years Ago

|

Charlie , the style pickup does look somewhat restrictive compared to the one with the removable screen so you might want to consider using that one just for comparison and try another oil pump just in case of a flaw in the one you've been using. I've had oil pumps go bad for no reason at all.

|

|

By charliemccraney - 10 Years Ago

|

I will be trying the one with the removable screen. I think either pickup style is adequate. When you consider the cross sectional area of the inner diameter of the 5/8" tube, you simply don't need a huge pickup for the supply.

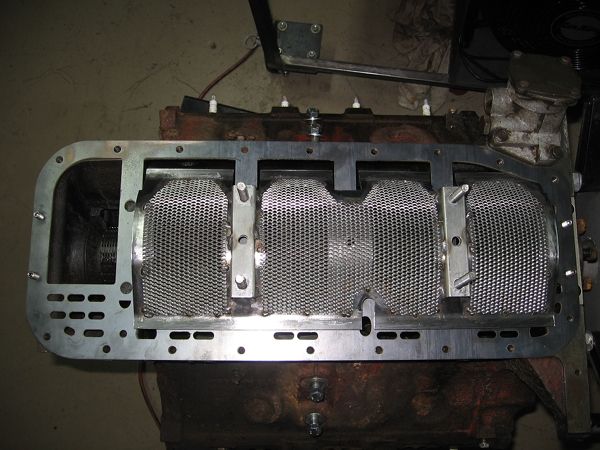

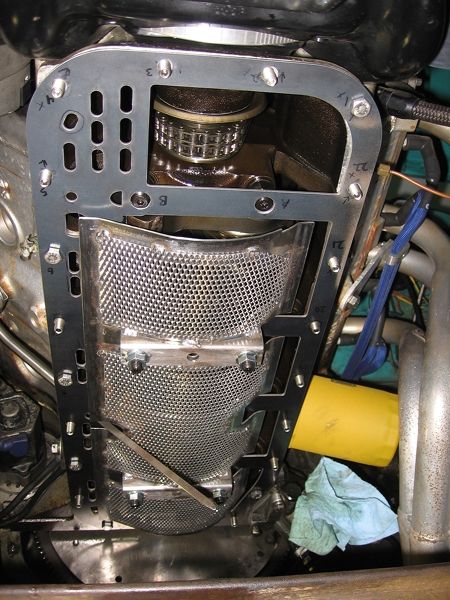

For those who don't use facebook, this is what I've been working on since about 2 weeks before Indiana. Doesn't look like all that much for 4 months of work, but it was a lot of work. Mostly weeknights. Mostly measuring, making paper templates, checking, adjusting, repeat until the paper fits, then make it out of steel. I think I have the dimensions of anything that drops below the pan rail now, though. I'm sure that will be useful.

I was going to install it this weekend but the oil pickup I want to use hits a windage tray mounting stud so I have to modify a pickup to get around that. Making the stud shorter is not an option. I'm going to try to leave the pan unaltered, from where it already is, anyway, for now. The difference in pickup positioning should make a big difference, along with these pieces to make sure oil gets back into the pan.

I have an oil pan from one of my parts engines that has a big hole in it for some reason. I'm going to cut the bottom off of that pan so I can use it to make a tool so that I can have the pickup installed properly so I can see exactly what I need to do for it to work.

Windage Tray.

Crank scraper / girdle / general below the pan rail dimension checker.

|

|

By Bob Gardner - 10 Years Ago

|

Nice work Charlie. Having made my own windage tray and scraper for my MG race engine I know how much work goes into getting one right.

Bob

|

|

By speedpro56 - 10 Years Ago

|

I agree, very nice work!

|

|

By ian57tbird - 10 Years Ago

|

|

Lucky these things are a labour of love because you wouldn't want to be making money from them.

|

|

By charliemccraney - 10 Years Ago

|

Definitely not for one off items. The windage tray took 18 hours from cutting out templates to the final product. That's not including the time getting measurements and making the CAD drawings.

The scraper was cut by water jet so not much labor. Much cost for only 1, though. A small run of scrapers might be reasonably affordable.

|

|

By charliemccraney - 9 Years Ago

|

I made the new pickup, to get around the windage tray stud and finally got it all installed this past weekend.

It's looking promising. The flutter around 2300 rpm seems to be gone. The slight increase of pressure when letting off the throttle is still there. I'll switch back to 20w50 and see if that takes care of that but I'll need to find out what is going on there. I bought all of the proper measuring devices, so no more plastigauge for me. I won't find out about the high rpm aspect until I can get back to the track but I'm optimistic.

I'm going to put my action cam in the truck, focused on the gauges, to record a drive to work, so I can focus on the road and watch later, in order to give full attention to what is happening with the pressure and verify that things are good, at least for street use. If that remains good, then I will be ready to get back to the track.

The Moroso oil pan fell through, so no aftermarket oil pans at this time.

A 5/16" bolt (1/2" head) for scale.

The factory rear positioned pickup has about 1/2" to 1" of clearance between the pan. The reason has to do with the shape of the pan floor and the large pickup diameter. So while the positioning is better with the rear positioned pickup, clearance will never be ideal. It can be made better, but not ideal.

This is in about the same position as the rear-positioned factory pickup. That was just by chance, really. I followed the instructions for the positioning of the pickup box and that's where it ended up.

|

|

By charliemccraney - 9 Years Ago

|

Well, it looks like I am on the right track. Hot pressure seems to be about 5psi better throughout the range, with no strange behavior for street use. Cold pressure, on the other hand has gotten worse. Max is about 40psi and it gets worse as the ambient temperature drops. This is a new issue as there was never any problem with cold pressure before and it would always reach the bypass pressure of about 80psi. I can see bubbles in the oil on the dipstick when this occurs. Once the coolant temperature gauge starts to register a temperature, pressure looks great. When I say "starts to register a temperature," the gauge starts at 100 degrees so right about when the gauge moves off the 100 mark is what I mean. I've checked the easy stuff, inlet tube nut, pump bolts, oil level and those seem good.

Even though the pressure is good hot, there is evidence of aeration even then, but it is much less severe. Unfortunately, I never had a proper dipstick and tube for the rear sump before, so I can't know if that is any different.

I think the problem has to do with the windage tray and the way I designed it for use with the scraper. They sort of overlap on the business side of the scraper, with only about 3/8" of clearance between the tray and scraper. So oil that the scraper has removed does not really have an effective way to drain and the problem is compounded by the cooler, thicker oil. The tray is more or less U shaped and I think a more J shaped tray with a little more room between the pan wall might be better. I think I'll remove the tray all together to see if it improves. If it does, then it is back to the drawing board with that.

|

|

By Bob Gardner - 9 Years Ago

|

Charlie,

You may need to increase the gap between the windage tray and the scrapper. I can't tell from the pictures if you can tilt the windage tray or not to provide mor room for the oil from the scrapper to retun. You may need to cut the windage tray back some. The scrapers I have designed in the past mounted on a window frame (like the one you had water jet cut) on the side of the facing the cylinder bores and angled up away from the windage tray towards the crank centerline. I had series of slots cut in the window frame to allow the oil from scrappers to flow directly back to the pan. So my windage tray design was mounted short of these openings. Also mine were done for a dry sump system and the pan was only about 3 1/2" tall.

Bob

|

|

By charliemccraney - 9 Years Ago

|

I can move the tray about 1/8" farther from where it is. I can try that to see what happens. I can't tilt it much since I did not design it for that.

The scraper you describe sounds like a down-stroke scraper. It would go on the opposite side. I wanted to try that but I don't have any good way to bend the 11 gauge steel (.105")

|

|

By Ted - 9 Years Ago

|

Charlie. Two things come to mind regarding the lower cold oil pressure. Your windage tray design is neither of these.

First is insure you have at least a ¼” clearance between the oil pickup and the bottom of the pan. Based on your pictures, the target clearance was good. Whether that happened on the final version is something you’ll have to determine.

Second is the rubber grommet at the inlet of the oil pump. Any air sucking in right there will have an adverse effect on both the cold and hot oil pressure. Packing the outside of the rubber seal with white grease (my cure for almost everything) during the inlet tube installation helps with the seal at that junction.

|

|

By charliemccraney - 9 Years Ago

|

Pickup clearance is good. I was very careful about that, checking with all of the actual parts being used when tacking together and once more after welding was completed.

I used Permatex Hylomar HPF on the grommet. It's a very tacky, non drying sealant. It is the Fel-Pro grommet, which I know you are not fond of. Trying a different bushing will be far easier than removing the pan. So I can do that. The grommet I was using is Melling, which is very much like Best Gasket so that is something else that has changed since the tear down.

|

|

By charliemccraney - 9 Years Ago

|

It looks like the inlet tube seal was the problem. It looks like there is a manufacturing defect in the metal bushings of the Fel Pro seal because both halves have identical problems in the exact same position. It's hard to notice unless you look close and hold it at the right angle. I replaced it with an all rubber Best Gasket seal. The Best Gasket seal has a smaller inner diameter than the Fel Pro seal, about 1/32" smaller so it also fits the tubing better right from the start. I have another Fel Pro seal from a gasket set I bought about 15 years ago, to verify that this aspect is not just another defect. The Best seal is actually a little smaller than the tubing and the Fel Pro seal is about the same amount larger.

The engine is ready to get back to the track to see if the high rpm part is fixed and hopefully get my best time slip, yet.

The engine seems less cold-natured, though it wasn't too bad before, and the mid range does feel more responsive. It'll be nice if those aren't my imagination. Won't really have a way to tell, though.

|

|

By charliemccraney - 9 Years Ago

|

|

The engine is using about 10% less fuel. I've filled up 4 times now, and each time, it takes about 10% less gas than expected. And that is city, hwy might be a little better. That's a plus.

|