|

By RB - 10 Years Ago

|

3 well known Y Block builders, plus my Lincoln Y, are contestants this year.. Should be quite a competition.. the other 3 entries are going to be an Olds, A Chrysler Poly, and I think a Caddy.

|

|

By PF Arcand - 10 Years Ago

|

Are the basic rules in the Vintage class similar to last years? IMHO last years rules in the "vintage" class were, as might be expected from Hot Rod Magazine, far removed from anything remotely vintage, as was demonstrated by the winning entry, which was over the top, both in redesign & cost...

|

|

By RB - 10 Years Ago

|

The rules are very similar.. The test rpm range as been increased to 3500 to 6500 rpm.. Some new engine families have been added. Otherwise things are wide open..

I don't think Kasse will do as radical a rework on his entry this year, but face it he likes to show off his skill on what he is capable of doing. He would certainly be a dark horse to win this year, just because the size of engine he is building would need to make huge power to be competitive with a 600 horse Y block, which we all know John and Ted are capable of building. Frankly one of the reasons that the Vintage class was such a hit was it allowed a lot of innovation and variety.

PS Kaase's winner from last yr was tested with a few mods aimed at making max power. and not just best score in the 3000 to 6000 rpm range. John told me with a cam change and an intake change to a super Victor with a 950 Holley he made over 700 horse

|

|

By charliemccraney - 10 Years Ago

|

|

What will Kaase be running this year?

|

|

By RB - 10 Years Ago

|

Kaase is running an Olds this year, based off a 394.. Ross Racing aluminum heads Pontiac stroker crank.. I think he plans on 460 something cubes.. He would have to make in the 800 horse range to be competitive

|

|

By John Mummert - 10 Years Ago

|

We'll be going up tomorrow to look at the finished version of the new intake manifold pattern. Things need to get moving pretty quick if we are gonna have them ready to run for this years competition.

Its been 14 years since the last time we were personally involved in EMC. Its a big undertaking, hopefully we can find enough time to build a competitive entry.

As far as Kaase goes I'm sure he will do what it takes. It looks like SAM will be re-entering their POLY, which would give them a nice head start for this year.

Good luck to all the Y entries this year.

|

|

By Ted - 10 Years Ago

|

It’s good to see the variety of engines being entered. Assuming all goes to plan, my entry for this years’ EMC engine was found in Comanche Texas. The block so far has checked out good which is saying something considering where it had been sitting for awhile.

|

|

By charliemccraney - 10 Years Ago

|

|

That's an Australian Y-Block.

|

|

By Rowen - 10 Years Ago

|

|

Hahahahaha!!!!!!!!

|

|

By Larry Short - 10 Years Ago

|

|

You Know I was having a bad day, then I saw the Australian Y-Block and started laughing. Little things can sure make your day! Larry Short

|

|

By dbird - 10 Years Ago

|

|

I have to admit I was trying to figure out how Charlie could tell it was Australian until I read Rowen's comment at which I must have let out a sound somewhere between a chuckle and a groan. Good one.

|

|

By charliemccraney - 10 Years Ago

|

I've been checking out the Olds Rocket and they don't seem too impressive. They have the benefit of more displacement but it looks like the best factory heads are roughly equivalent to the best iron Y-Block heads. The Ross racing heads seem to be roughly equivalent to Mummert heads, better than stock but not all out racing.

If Kaase's main requirement last year was the availability of aluminum heads so he can make changes, then I'm sure he's going to do that to the Ross Racing heads to make it work the way he wants. I'm interested to see what he comes up with.

|

|

By Joe-JDC - 10 Years Ago

|

|

After having stood and talked with Jon for quite a while, and looking over his Y-Block modifications, I feel certain he will come up with some "out of the box" thinking on the Oldsmobile heads. He would not pick an engine unless he feels he can take a "sow's ear" and turn it into a "silk purse". He is in it for the challenge, and like many of us, he hates to lose. So again, ----- he will surprise us. I keep hoping John's new heads will be capable of flowing 300 cfm, but so far, they are just shy, especially the lower ports. Have to figure that one out before next EMC competition. What the Y Block needs is a good tunnel ram intake for competition purposes where hood clearance is not a factor. Joe-JDC

|

|

By DryLakesRacer - 10 Years Ago

|

|

I know rules are meant to be read between the lines but IMHO I'd like to see single 4 barrel manifold only must be cast. No hand crafted i.e.: Wilson, etc. EFI allowed must be throttle body style based. Oh well..

|

|

By dbird - 10 Years Ago

|

Not really 2016 stuff, but a nice write-up about Kaase's 2015 Y-block engine if the July issue of Muscle Machines.

don

|

|

By Daniel Jessup - 10 Years Ago

|

Wow, this is great news!

I will have to say though, I really want to see what Jerry Christenson whips out. I know he doesn't do much online, so most of us won't know any "tricks" he would have going.....not that he would tell us any way.

Anyone know what he is up to?

|

|

By PF Arcand - 10 Years Ago

|

Re the comment that the Old's engine has the benefit of more displacement. The EMC is scored on a point system, which focus' on efficiency in a specific RPM range. I don't see how more displacement is an advantage?

|

|

By charliemccraney - 10 Years Ago

|

You're right, the way it is scored, it does level the playing field.

My thought is based on the fact that if everything else is equal a smaller engine generally has to rev higher than than a larger engine to produce the same power and given the relatively low test range, that would give a larger engine the benefit. Most of the entrants do seem to come to the competition with engines which are larger than a simple overbore would allow, so there must be some benefit to it but there could be a point of diminishing returns as well.

Maybe one of the Pro's can elaborate more on that.

|

|

By LordMrFord - 10 Years Ago

|

|

So competition is only hp/ci contest in specific range on rpm?

|

|

By charliemccraney - 10 Years Ago

|

|

it is average hp and tq over a specified range / ci X 1000 to make it easier to read.

|

|

By PF Arcand - 10 Years Ago

|

It's easy to see why the EMC scoring system might not be understood by a casual reader of the April 2016 Hot Rod magazine. The engine write ups contained some mistakes & the point scores of each engine aren't even mentioned. In the preamble they mention the scoring system, but even then they didn't get it right... but then again we know that H.R. has always had an obsession with peak horsepower figures. It likely is a result of them suffering from a terminal case of "scrubitis.".. edit; (the word I wrote isn't the one in italics, the site auto alters it)..

|

|

By John Mummert - 10 Years Ago

|

The competition will definitely get your wheels turning. The motors have make ridiculous TQ/cu.in as well as make pretty strong amount HP/cu.in... The big motor , small motor thing is a double sided coin, One makes power at one end of the rpm spectrum and vice versa. The smaller engines will be much more camshaft sensitive because induction and exhaust velocities will be slower. Bigger engines will have better combustion chamber shape, ( wont need any dome or possibly dish even.).

Production engines are built with longevity and part throttle efficiency in mind.

Engine Masters Challenge is frame of mind, almost more than what your working with. Generally speaking what your tying to do is make the engine do things about 1000-1500rpm sooner than you ever dreamed possible. Long strokes, short rods, high rocker ratio, etc. etc. All these jack velocities up past speeds they were designed for.

|

|

By LordMrFord - 10 Years Ago

|

|

Hydraulic lifter engine gets a huge benefit over solid?

|

|

By Ted - 10 Years Ago

|

|

LordMrFord (6/1/2016)

Hydraulic lifter engine gets a huge benefit over solid?

I’ll say No. When hydraulic lifters were required, most competitors ran them at the point of being almost bottomed out. Camshaft ramp profiles is where I’d place much of the emphasis. Lots of tuning available in varying the lash on a solid lifter camshaft also.

|

|

By LordMrFord - 10 Years Ago

|

Is retrofitted variable cam timing illegal?

=D

|

|

By Ted - 10 Years Ago

|

|

LordMrFord (6/3/2016)

Is retrofitted variable cam timing illegal?

That would likely come under the heading of ‘Camshaft Drive’ and in that section of the rules, there are no rules. Simply says ‘unlimited’ meaning anything goes. Here’s the link to the website which will get you to the rules.

http://www.hotrod.com/events/1602-2016-amsoil-engine-masters-challenge-new-classes-dates-and-rules-announced/

|

|

By yalincoln - 10 Years Ago

|

|

hey Royce! i'd think you could make a Lincoln Y as big and powerfull as a olds! especially if you had the resources that john has! so much for being a ford man!

|

|

By Y block Billy - 10 Years Ago

|

|

Lord, Maybe you meant solid roller lifters!

|

|

By LordMrFord - 10 Years Ago

|

Y block Billy (6/30/2016)

Lord, Maybe you meant solid roller lifters!

Nope.

Variable cam timing like what some small block scrubs used to have in the eighties? or vanos.

Only dark and crazy ideas rolling in head during sleepless nights but might never get more real than that.

Still might be good solution on contest what needs wide torque curve.

|

|

By John Mummert - 10 Years Ago

|

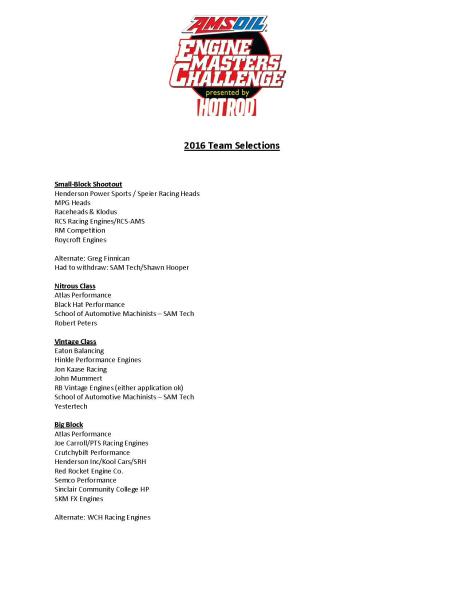

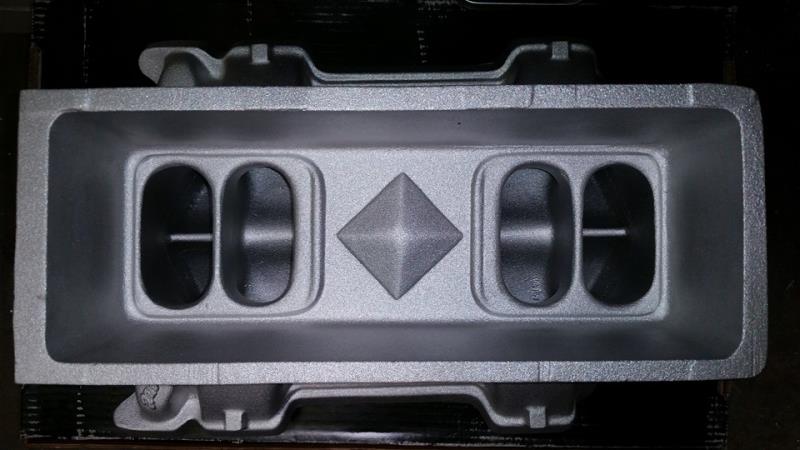

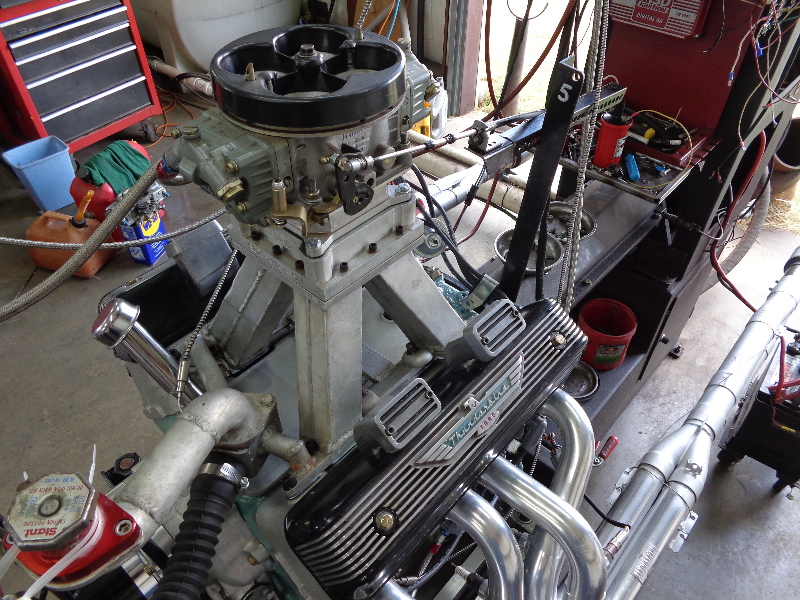

A new part for engine masters testing A new part for engine masters testing

|

|

By stuey - 10 Years Ago

|

Wow what a beautiful casting. How do you hold things down? Endless possibilities.

Got to wait for the £ to recover

stuey

|

|

By Vic Correnti - 10 Years Ago

|

|

Awesome, you got my attention and my mind is stirring. How thick are the runner walls? I am thinking injectors.

|

|

By Rowen - 10 Years Ago

|

YEEHAWW!! John. That looks like TOO much fun!! Can't wait to see how you put that together!! Potential HP? Torque? I know I'm asking prematurely, but that would make cuttin up a stock hood worth it!!

Rowen

|

|

By yalincoln - 10 Years Ago

|

|

hi john! just curious but is the angle wrong? shouldn't it tapper down to the front?

|

|

By John Mummert - 10 Years Ago

|

The manifold has 0 taper in it. The front of the manifold is set up for throttle body, with slight down taper for t-bird hood clearance. The manifold is set up for injectors now, the dividers are held low enough for the injectors to fire across the manifold at the mouth of the runner. This is the straightest shot for the fuel and give more distance for the fuel to atomize and take the natural course of the runner. The bigger cam you run the farther the injector needs to be from the valve to help with scavenging issues. This manifold is built to be versatile and let your imaginations go to work. We have our uses and variation that we will sell it in. But you guys can do what ever you can think of as well.

Some steps have been taken with this manifold to try and help those guys who want to run a single 4 barrel as well. Trying to keep the majority fuel from going down into the center 4 cylinders, and actually be able to perimeter the floor of was the main objective. We do NOT plan to sell it as a single 4 barrel but we are pretty sure someone is going to try it.

|

|

By Joe-JDC - 10 Years Ago

|

|

When will it be available to the public? Pricing range? Is there a waiting list?

|

|

By John Mummert - 10 Years Ago

|

There are only 3 pieces right now. We just got them yesterday. These first articles will be used for EMC testing. And machine programming. We are trying like hell to get one sent to Ted on Sept. 1st.

We are going to machine some heads in early August because the machine is set up and ready to go for that. Hopefully we can have the tooling built to hold the manifold and start programming in mid August.

Hopefully units will be available to the general public by late October or early November.

|

|

By Ted - 10 Years Ago

|

That manifold looks great from my end. Being designed specifically for the stacked ports in the heads definitely makes for a new look but that’s what it’s going to take to get that next step up in performance. It will be interesting to see how the power curve is improved when tested.

|

|

By John Mummert - 10 Years Ago

|

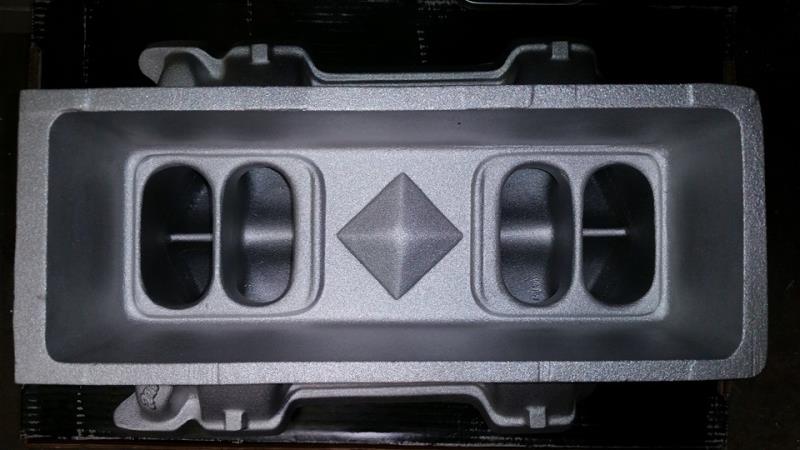

Here's a pic from our last dyno session. Very similiar to the way we will ship it.

|

|

By Ted - 10 Years Ago

|

Here's a pic from our last dyno session. Very similiar to the way we will ship it.

Looking good guys. If all goes well, I’ll have my engine short blocked later this morning. If everything really clicks, I’ll have the engine on the dyno tomorrow. I had a hiccup with the the lead time on the connecting rods and had to change gears midstream which is forcing me to run a 375 incher versus the 401 incher that was originally planned.

Any word on how Jerry Christenson’s build is coming along?

|

|

By MplsMike - 10 Years Ago

|

|

I was at Jerry's a week ago today and he made note of the short build time left. I only saw the block done -- he described it as a good day of work left. I think he also had the porting work done on the heads.

|

|

By ian57tbird - 10 Years Ago

|

|

John what bore/stroke combination were you looking at to get 410 inches?

|

|

By Ted - 10 Years Ago

|

|

That was a misprint on my part. Should have read 401 cubic inches and it gets there by way of a 3.860” bore and 4.280” stroke.

|

|

By PF Arcand - 10 Years Ago

|

Ted: Just musings; I know that there are theories that support going to bigger displacements, but in the case of a Y-block, is there any good reason to want 401cu inches over 375 inches? My amateur thinking on this, is based on the fact that the cylinder head design was never intended for anything like 400 inches. Now, we know that Mummerts heads are a substantial improvement on stock heads, but he was limited somewhat on alterations in order to make them available as bolt ons. I would think the most obvious item possibly compromised, being valve sizes. I'm looking at this from point of efficiency/ cu in. which is what the EMC rules are supposedly about, despite the way Hot Rod tends to present the results..

|

|

By Ted - 10 Years Ago

|

In the EMC competition, a 401 incher would have an advantage over the 375 incher in regards to making better low end torque numbers. And with this years’ rpm test range being 3500-6500 rpms, then having an engine that peaks out at a higher rpm is counter-productive in making a better score. The 401 incher would make for a better score even though peak horsepower numbers are lower. Having restricted flow at the heads as a result of being larger in cubic inches would be suitable in this particular dyno competition where the rpm range is on the lower side.

All theory at this point until actually tested. The 375” Y for the EMC is sitting here waiting on a distributor. Once that’s in hand, it goes on the dyno for some serious tuning. I have installed a EMC specific camshaft that is good only for this competition and will simply be a paper weight once this competition is over. Up until this year, I’ve been using conventional camshafts which made the engine suitable for resale after the competition but did hold the engines back when it came to better scoring.

|

|

By PF Arcand - 10 Years Ago

|

Interesting ideas, thanks Ted..

|

|

By ian57tbird - 10 Years Ago

|

Sorry Ted. I got mixed up with who posted 410 inch with the all the pics.

Didn't realize it was possible to get such a long stroke out of a Yblock. Is that a Lincoln Y?

Thought more low end torque and less peak power might be an advantage for street purposes.

|

|

By John Mummert - 10 Years Ago

|

This years EMC engine for us is a revamp of the old 331cu.in. engine that we ran in Todd Fergusons Falcon. The engine was replaced this year with a 355 cu.in. engine that has been running very well.

The engine was originally brought back into service to have a mule to test the intake manifold with. We were trying to get the manifold done earlier this year to test it on the 355. The time frames just weren't working out. One thing leads to another, as we were pondering, we started figuring out that we would have a spare performance oriented engine, that we would be doing dyno testing and doing R&D with. So being more than 1/2 way there we decided to enter. The headers were built to fit an F-100.

Some general specs.

Bore 3.84" Racetec 13.0:1 comression

Stroke 3.57" offset ground C1TE truck crank

Rods Molnar 6.125

CNC ported Mummert heads

1.7 Roller Rockers

Marine oil pan to match short timing cover

Stock ford oil pump with a few tricks

Custom ground Isky, duration and lobe center a little shorter than the cam we raced with.

We tried a plethora of intake manifolds and the new tunnel ram worked out well so that was a relief. We ran across some interesting things along the way, don't know what it all means but were changing the waterpump to Teds electric unit. We think it will have more water flow than the moroso electric motored stocker.

The engine has a good powerband and made some decent numbers. Engines are funny I still laugh at the things that made power and the things that didn't. Will it be enough, who knows. Haven't been to the event since 2002, so just doing it will be fun.

|

|

By charliemccraney - 10 Years Ago

|

Are the headers one off or a proposed production item? I'm in the market for a better than currently available truck header.

|

|

By Cliff - 10 Years Ago

|

|

Go John

|

|

By Ted - 10 Years Ago

|

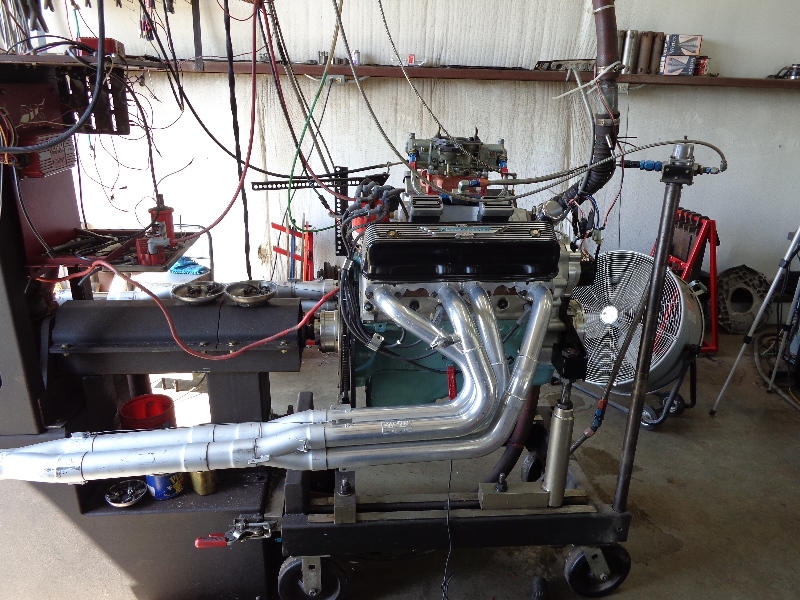

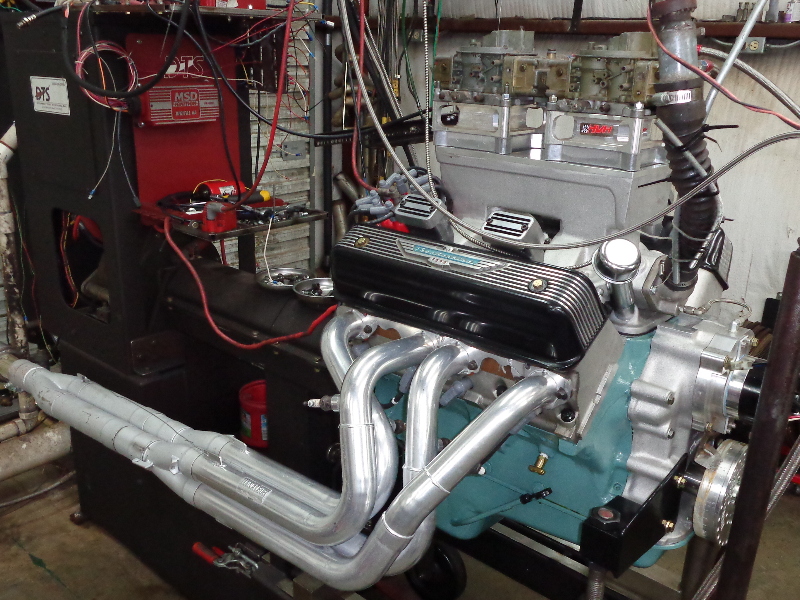

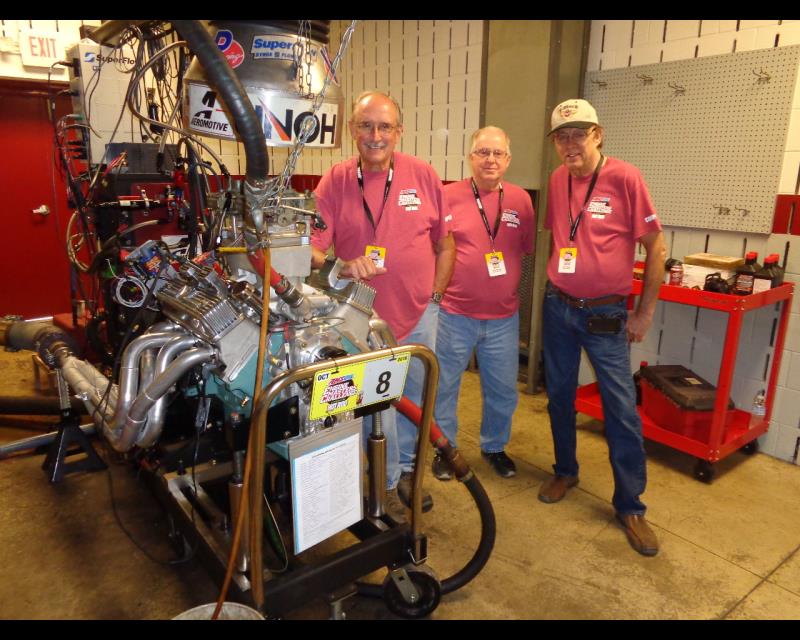

Here are some pics of the Eaton Balancing EMC entry during testing.

|

|

By Y block Billy - 10 Years Ago

|

|

Wow! Just have to ask where you got that color for the motor?

|

|

By Joe-JDC - 10 Years Ago

|

|

Kinda matches the color in the thunderbird logo. Looks unique. I like it. Yes, what is it? Joe-JDC

|

|

By RB - 10 Years Ago

|

It looks close to the Lincoln color for 56 and 57

|

|

By John Mummert - 10 Years Ago

|

|

Nice score on Kaase's headers. Motor looks good. Time is getting close, see everybody there.

|

|

By Ted - 10 Years Ago

|

Y block Billy (9/27/2016)

Wow! Just have to ask where you got that color for the motor?

Here’s a picture of the paint used on this years’ EMC engine.

|

|

By Ted - 10 Years Ago

|

Today was spent taking care of loose ends in regards to MSD box mounting, wiring, throttle hookups, modifying the Mercury valve covers so they would clear the 1.7:1 rocker arms, etc. Here’s one more picture for y’all.

|

|

By pegleg - 10 Years Ago

|

Looking forward to the results. Good luck to all of you.

|

|

By speedpro56 - 10 Years Ago

|

LOOKS ASS KICKING GREAT TED!

|

|

By 62bigwindow - 10 Years Ago

|

|

Looks awsome. Can't wait to see what it does. Good luck!

|

|

By charliemccraney - 10 Years Ago

|

|

Awesome.

|

|

By John Mummert - 10 Years Ago

|

|

Like the Merc valve covers Ted. I bet velocity stacks were worth a couple numbers.

|

|

By RB - 10 Years Ago

|

Well here it is, all dressed up for the big dance..Could be a zero could be a hero. No time for testing on this one.. I run Wed morning.

|

|

By ian57tbird - 10 Years Ago

|

Was thinking FE, but valve covers aren't overlapping intake.

|

|

By MplsMike - 10 Years Ago

|

Check out he EMC website - some familiar engines and names featured under the "oddball and vintage" section. Just posted today!

http://www.hotrod.com/articles/oddball-vintage-engines-engine-masters-2016/

|

|

By MoonShadow - 10 Years Ago

|

|

Hey guys before you are all done how about a group picture of all the Y-Block entries?

|

|

By glrbird - 10 Years Ago

|

|

Thanks Mike for the link, the pictures are awesome. I thought Royce's engine was green?

|

|

By charliemccraney - 10 Years Ago

|

|

Royce has two engines there. I wonder why the MEL is not pictured in the article. Also no Christensen engine.

|

|

By Rowen - 10 Years Ago

|

Thanks for the link Mike, geez louise!!! Those y-blocks with the new tunnel ram.......well what can I say, horsepower aside, the prettiest dam engines in the competition!!!! Great job John and Ted!!!

Rowen

|

|

By charliemccraney - 10 Years Ago

|

Royce's MEL "550+ horsepower." Not bad at all for no testing time.

http://www.hotrod.com/articles/forgotten-ford-big-block-makes-comeback-engine-masters-2016/

|

|

By charliemccraney - 10 Years Ago

|

Ted wins it!

http://www.hotrod.com/articles/ford-y-block-takes-vintage-class-win-engine-masters-2016/

|

|

By hjh - 10 Years Ago

|

|

Just returned from EMC from watching yesterday Ted`s win & all the attention the Y-blocks are getting. Great job by all. Royce`s MEL got a lot of looks and done very well on the dyno especially since that was the first pull`s for the engine and no adjustments made . Even though I seen it all I will let some else do the #`s as I seen so many Dyno #`s the last few days I my get something incorrect. Very good job Jerry,Geoff & John Harry Hutten

|

|

By ian57tbird - 10 Years Ago

|

|

Already sending the link to GM lovers. Congratulations to all!

|

|

By speedpro56 - 10 Years Ago

|

A big congrats to Ted and all the other Y blockers including the Mel engines who participated and made us all proud!!!

|

|

By glrbird - 10 Years Ago

|

|

That is awesome!! Ted and the Mummerts have done a lot to help the advangement of the Y-Block. Great to see them get recogniation. Beating out SAM is no small feat.

|

|

By charliemccraney - 10 Years Ago

|

The top 3 scores this year were better than the top score last year. I think I saw somewhere that they changed the dynos this year. If they did, then the scores may not be useful for comparing previous years. It would be pretty sweet if Ted and John really did outdo Jon Kaase's entry last year.

|

|

By LordMrFord - 10 Years Ago

|

|

Congrats! Old Fords are rocking better than ever!

|

|

By RB - 10 Years Ago

|

Props from John Kaase from the SpeedTalk website.

by JonKaase » Tue Oct 04, 2016 5:01 pm by JonKaase » Tue Oct 04, 2016 5:01 pm

Y-BLOCKS RULE!!!!!! |

|

By Small block - 10 Years Ago

|

|

Is that a Cleveland intake your using on the Edsel 410!

|

|

By RB - 10 Years Ago

|

|

Small block (10/8/2016)

Is that a Cleveland intake you're using on the Edsel 410?

It is a 460 Performer RPM airgap..

|

|

By Small block - 10 Years Ago

|

|

Yes I guess that would be a closer fit, nice to see a different engine I like your choice.

|

|

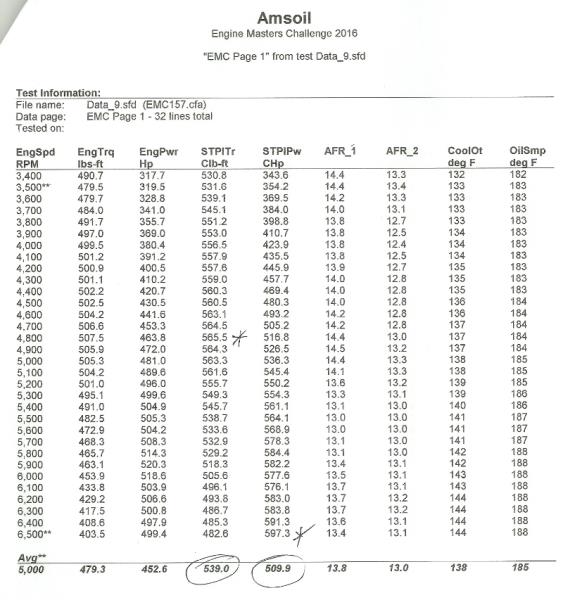

By Ted - 10 Years Ago

|

Congrats goes to all the competitors in all the Engine Masters Challenge classes. The only losers would be the ones that don’t go to the trouble to submit an entry in one of the engine classes that are available. Giant Kudos goes to Royce for bringing three engines to the competition. That was impressive as he was also dealing with three different engine families. Because of time constraints, Royce was not able to dyno test the MEL (Edsel) engine before bringing it and it had a simple bolt failure at the rocker arms once it was put under a dyno load at the UNOH. That engine on its only good pull sounded great and the numbers are very stout. Lots of potential there for sure.

While previous years’ entries were good in recapping my expenses by selling or repurposing the engine, it didn’t lend itself towards being a top contender. For this years’ entry, I took a different approach to the overall combination. This years’ combination was built more specific to the EMC competiton which meant using parts that make the engine less sellable without major reconfiguring. As usual, this competition makes one think way outside their comfort zone but all the learnings do enventually get passed along into future engine builds. This year had a number of new revelations in what it takes to get those good scores at the EMC. Special thanks to all that contributed funds and/or time to make this years’ engine a solid winner.

While this particular sheet doesn’t show a 600+HP number, it does give you a good indication of what the torque values on this years’ Y entry do look like when setting the engine up for a good points score.

|

|

By Talkwrench - 10 Years Ago

|

|

|

By John Mummert - 10 Years Ago

|

EMC 2016 is in the history books. It was a good time had by all. Ted held up the Y block 2-0 Vintage class victory. We all can hold our heads high for another year, this time with a cylinder head,manifold package that is more agreeable to the Y-Blocker. EMC 2016 is in the history books. It was a good time had by all. Ted held up the Y block 2-0 Vintage class victory. We all can hold our heads high for another year, this time with a cylinder head,manifold package that is more agreeable to the Y-Blocker.

The Mummert build came about this year with many different reasons in mind and EMC wasn't the first on the list, but was a consideration being pondered. As stated earlier in this post the new manifold was supposed to be done earlier in the year and get tested on the new 355 cu/in motor being raced in the falcon. The 343in had been running in John Hildebrands 31' coupe and weren't wanting to yank it out of the car to replace that manifold dyno test it, just to take the manifold back off and get prepped to put it back in the car, because the coupe has so much engine set back that the tunnel ram won't fit without cutting up the car.

Having many of the parts for the 331cu/in motor on the shelf the decision was made to get it running again. A running engine was worth more than a shelf full of parts and it would give us more latitude to do manifold testing or EMC and not have to pull one of the race cars apart.

Once we had decided to enter the competition we knew the work load in the shop was going to get harder, it now had to more than a good dyno mule it was going to have to be a competitive EMC entry. We had to call on John Hildebrand and Todd Ferguson to help us out. This engine would not have been possible without everyone rolling up their sleeves.

Having competed in the EMC in 2002 we had some good knowledge of what we wanted to do, but much of this information was 14 years old so we knew we would have some catching up to do as this competition has gotten more competitive every year.

The bottom end of the engine is comprised of a B9AE block, bored to 3.84". The block was tapped for screw in freeze plugs and 1/2 filled with Embeco. The crank is a C1TE steel truck crank. ( seeing the part number on the crank did give some inspiration) It was offset ground to 3.57" 1.889" honda journal, nitrided and undercut outer counterweights 53lb ready to run. ARP main studs with factory main caps deburred and shot peened. Molnar 6.125" rods with Race-tec pistons. The original pistons were set up with 10cc domes. Looking at technology through the year we decided to reshape the dome to a 4cc finished size and reduce the combustion chamber down to 49cc.

After pondering right up until we made the phone call the camshaft ordered was 248@.050" .345" lobe lift ball nose grind on the intake and 247@.050" .337" lobe lift, on a 104 lobe center. With the start rpm raised to 3500rpm the cam was installed straight up at 104. (In 2002 we ran a 106 installed on a 100, but we were starting at 2500 rpm.) I think I would advance it some or reduce the intake duration a tick, doing it over again, hind sight is always 20-20. Trend tool steel lifters, and Smith Bros pushrods

Oiling duties were left to an OEM ford gerotor pump. The idea was to use this engine to try a direct AB test on the two styles of oil pumps available to see if there was any measurable power difference between them. After researching it more we decided to build a better gerotor. Dual inlet feeds and adjustable external bypass was the surest method to reduce aeration, raising the quality of the oil entering the engine. It would also raise the efficiency providing a more linear flow allowing good low speed oil pressure without having to run to much pressure at high speed. (We may have over thought this, but it did work well and looked good doing it.) The marine oil pan made perfect sense for us. It has large capacity, built in windage tray, fits our short timing cover, and fits just about nothing but a boat or a dyno. Still never got to AB the two styles of oil pump.

The top end of the engine was really the easiest part. The head gaskets are OEM steel shim units. Mainly to reduce the dead area around the bore an raise the combustion quality. Deck height was set to .015" . The cylinder heads are our angle mill CNC race heads milled to 49cc. The rocker arms are 1.7 Mummert roller rocker assemblies. New Tunnel ram intake topped off by C&J modded 650 double pumpers. and R2C velocity stacks.

Headers are 15/8 to 13/4 built to fit the F-100.

We were very pleased with the performance of the engine generating 100hp/litre @6400rpm while still making good low and mid power. However the score is what matters in EMC competition, and we have to pick up some grunt in the first 1000 rpm. We may take it to the dyno and see if a few tweaks get it headed in the right direction.

I really enjoyed meeting everybody. We may do it again if John is up for it, but for now its time to go back to work.

Geoff Mummert

|

|

By speedpro56 - 10 Years Ago

|

Fantastic job for sure and your hard work is much appreciated ( John and Geoff ). A job well done!

|

|

By Ted - 10 Years Ago

|

Geoff. Thanks much for the summary on the EMC engine you entered. That little engine is indeed a powerhouse. Congrats on the high points finish your team put up on the board. The win with my engine could not have happened without the work you had done on the heads and likewise all the parts you provided. Thanks for all that.

I’m in the process now of getting the various parameters on my engine for an upcoming YBM article. I’ll be sending the blueprint sheet on the engine to the Hot Rod people for their article. That engine was put together in a hurry and as such, I didn’t get a chance before the EMC to get all the documentation summarized. There’s a clipboard of paperwork here I’ll have to go through and collate into something meaningful.

I will be putting this years’ EMC engine back together for a some additional header testing and to also see what the engine will do in a race day tuneup rather than for maximum scoring. Once that’s done, that engine will be history and work on a Y engine that will hopefully jump up another level of performance will start.

|

|

By Ted - 10 Years Ago

|

Special thanks to the team members on my 2016 EMC team. In the dyno room helping to make tuning changes to the engine were Jody Orsag, Fred Hertzog, and Steve Culp. Others making this engine a success includes Joe D. Craine, Lonnie Putnam, and John and Geoff Mummert. With all the Mummert parts involved, this could have easily been a Mummert entry. Thanks also goes to Jon Kaase for technical advice and the loan of his headers from his 2015 EMC Y-Block winning entry. Thanks guys.

|

|

By Y block Billy - 10 Years Ago

|

|

Great job and hats off to all the guy's and efforts put in to to make our favorite engine stand out! And for a statement from Kasse that Y Blocks Rule is outstanding!

|

|

By yalincoln - 10 Years Ago

|

|

great work everyone!!!!

|

|

By Ted - 10 Years Ago

|

Hot Rod has updated some of their links to reflect the 603.2 HP number that was run on the Eaton Balancing Y entry at the EMC. Here are a couple of the links.

http://www.hotrod.com/articles/2016-amsoil-engine-masters-champions/

http://www.hotrod.com/articles/ford-y-block-takes-vintage-class-win-engine-masters-2016/

|

|

By RB - 10 Years Ago

|

Hot Rod posted a nice You Tube video about vintage class, prominently featuring the Y block crowd

|

|

By MoonShadow - 10 Years Ago

|

|

The announcer was a little bit scrub! He couldn't help but put down the engines even as they blew his mind a bit. Made the MEL sound like it was the only time a Ford won at the nationals and like it was this big surprise. And John Kasse would have done better with the extrea 500rpm (that and his home made scrub heads). Take out the occasional wise crack and all in all very impressive. What happened to the Poly Mopar? Looked like a new window in the block.

|

|

By RB - 10 Years Ago

|

Poly Mopar looked worse that is was Gasket blew on the oil filter starting an oil fire.. They put it out and the guy made a few more pulls

|

|

By Joe-JDC - 10 Years Ago

|

|

Actually Jon's camshaft was done by 5600 rpm last year, and he struggled to make the three good pulls. Where his engine shined was the torque was monstrous at 3000 and stayed up most of the pulls, which brought his score up. Joe-JDC

|

|

By CK - 10 Years Ago

|

Question for Ted

Curious of the difference in tune you found in the tri-y's opposed to the 4 into 1's

And just clarifying you ran a 375 this year?

Not a 400cu ???

So you had an extra 500rpm, though kasse had an extra 25cu !

|

|

By Joe-JDC - 10 Years Ago

|

|

Not Ted, but: Last year the pulls were 3000-6000 rpms. This year the pulls were averaged from 3500-6500 rpms. Still averaged the pull for 3000 rpm total, just moved them up the scale this year. Camshaft makes all the difference in the rpm in which you make torque and horsepower. Ted could have made pulls last year to 7000 rpm with his entry and made a lot more horespower than was posted. Jon could not have with his camshaft. Lots more to be said, but I will let Ted answer any specifics since you addressed him. Joe-JDC

|

|

By Ted - 10 Years Ago

|

|

CK (11/1/2016)

Question for Ted

Curious of the difference in tune you found in the tri-y's opposed to the 4 into 1's

And just clarifying you ran a 375 this year?

Not a 400cu ???

So you had an extra 500rpm, though kasse had an extra 25cu !

A 401 cubic inch Y was the original plan but Carrillo dropped the ball on the connecting rods that were being made for this combination. By the time I had switched to Cunningham as the supplier for the rods, the lead time for a finished set was going to be too late to have them here in time to assemble that engine for the EMC competition. Joe Craine offered up his 4” stroke crank and Eagle rods which I then used in the already machined 401 block to make a 375 incher. This allowed for the same bore as the 401 engine but instead used a shorter stroke than was initially planned. The connecting rods in the 375 engine were ultimately shorter than originally planned for the 401 engine but still worked out well.

The 4-2-1 header design decreased the top end horsepower but the gain in lower rpm torque numbers more than offset this to increase the EMC points score. The key to this competition is keeping the emphasis on the average HP and TQ numbers and not so much about the peak numbers. The score is calculated using the sum of the average numbers and those are divided back into the cubic inches. Peak numbers are great for advertising but in this competition, they are not the money numbers. The headers I used in last years’ EMC competition were making much higher peak horsepower numbers on this years combination but the 4-2-1 headers had much better average numbers; hence a higher score.

|

|

By Ted - 10 Years Ago

|

Hot Rod has added another link and video for this years’ winning EMC Y-Block. This gives a bit more detail on the engine and is a precursor to the article that is forthcoming in Hot Rod Magazine.

http://www.hotrod.com/articles/make-600-horsepower-vintage-y-block-engine/

|

|

By Lord Gaga - 10 Years Ago

|

Cross bolted eh? Pretty cool!

|