|

By MoonShadow - 10 Years Ago

|

|

The old blower motor I had Ted rebuild for me had machined steel main caps. This was from a drag boat with a 6-71 blower back in the 60's. Maybe they knew something? The steel caps look pretty simple though I'm sure the machine work isn't cheap. I don't know but perhaps they could be made with 4 bolts. Also has a stud girdle that must provide some lower support. Love the numbers though!

|

|

By MoonShadow - 10 Years Ago

|

Another true performance Y-Block to be recond with. Great time. Stuffs getting better all the time!

|

|

By MoonShadow - 10 Years Ago

|

Glad everyone is in good health. Must have been a scary ride. The way that thing is launching now any little problem can become big! Do they make any special freeze plugs for big engines? Maybe some screw in plugs? Did a quick search on google and found that there are screw in freeze plugs for a lot of engines.

|

|

By MoonShadow - 10 Years Ago

|

I saw the picture but thought it was the gasket you blew earlier. So that was the problem. Certainly blew it out. I know nothing about the sort of boost you are running but its still a super fast Y-Block.

|

|

By MoonShadow - 10 Years Ago

|

|

Excellent!

|

|

By Teros292 - 10 Years Ago

|

You can watch this in live now from http://livestream.com/fhra/events/5709063

Here is times when Jyrki is on track

Thursday, July 7th

Qualification round 1 01:39:30 8.725 250.90 km/h 155.94 miles/h

Qualification round 2 06:08:35 9.19 254 km/h 157.86 miles/h

Qualification round 3 07:52:39 8.421 259.94 km/h 161.55 miles/h

Friday, July 8th

Qualification round 4 08:08:10 8.185 259.50 km/h 161.28 miles/h

Saturday, July 9th

Qualification round 5 01:46:45 8.134 274.59 km/h 170.65 miles/h

Qualification round 6 08:46:57 8.232 268.25 km/h 166,72 miles/h

|

|

By Teros292 - 10 Years Ago

|

You can watch this in live now from http://livestream.com/fhra/events/5709063

Here is times when Jyrki is on track

Thursday, July 7th

Qualification round 1 01:39:30 8.725 250.90 km/h 155.94 miles/h

Qualification round 2 06:08:35 9.19 254 km/h 157.86 miles/h

Qualification round 3 07:52:39 8.421 259.94 km/h 161.55 miles/h

Friday, July 8th

Qualification round 4 08:08:10 8.185 259.50 km/h 161.28 miles/h

Saturday, July 9th

Qualification round 5 01:46:45 8.134 274.59 km/h 170.65 miles/h

Qualification round 6 08:46:57 8.232 268.25 km/h 166,72 miles/h

Sunday, July 10th "part 1"

Elimination round 1 00:34:25 8.345 267.56 km/h 166.29 miles/h lost

|

|

By glrbird - 10 Years Ago

|

|

MAN, ya'll have taken that car a long ways from the start of the project. Those long burnouts are going take its toll on the slicks. new pair in the future budget?

Great job!

|

|

By Hollow Head - 10 Years Ago

|

Over four months to next race and then the story goes on. Hollow Heads Drag Team continues the hunt for the WR run and some preparations for that is done... New transmission is on the floor, new better flowing intercoolers are on the nose and piping process is on the way... Also some new additions to Megasquirt brain box is done to get bump staging and burn out rev limiter working for us. So, more E85 fuel and beer with flow this year as our beer sponsor continues to support us  . .

|

|

By Hollow Head - 10 Years Ago

|

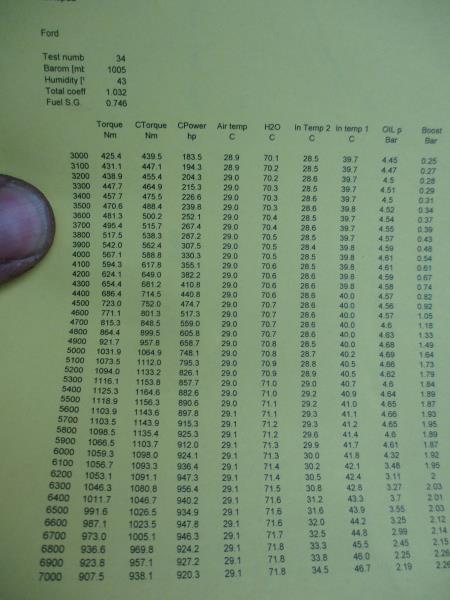

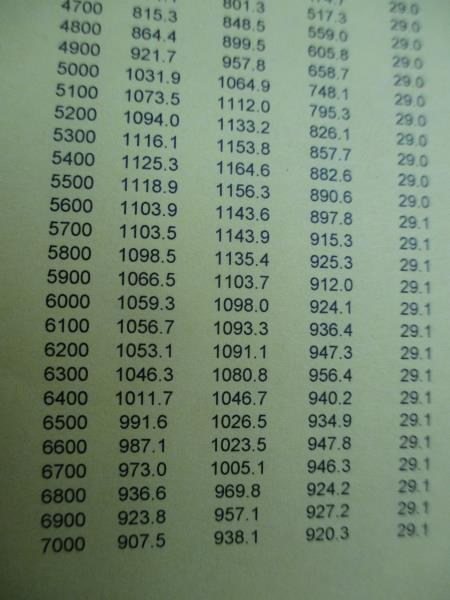

Todays dyno slips...

|

|

By Hollow Head - 10 Years Ago

|

956.4 horsepower @6300 rpm and 1164 Nm / 858 pound foot of torque @ 5400 rpm. Boost 2.2 bar / 32 psi. I thought HP is universal value  . .

|

|

By Hollow Head - 10 Years Ago

|

|

Video as usual... https://youtu.be/eiuEtZ5JwGo

|

|

By Hollow Head - 10 Years Ago

|

|

Thanks Ted. That 300 hp estimate can well be true and maybe even little high as our compression ratio is well under 8.5. But still, those iron heads still stand strong! And, we hit that over 900 hp many times yesterday.

|

|

By Hollow Head - 10 Years Ago

|

Imagine what that set up would give with Mummerts latest heads  ??? ???

|

|

By Hollow Head - 10 Years Ago

|

Video about first elimination round at second race weekend of the year. Jyrki lost to Söderqvist with poor reaction time. Also, engine was hitting against boost limiter 5 to 6 times... Time was something like 8.7....

https://www.youtube.com/watch?v=gJVdi_yJX2k&feature=youtu.be

|

|

By Hollow Head - 10 Years Ago

|

Three race weekends done, three times lost in first round. This is the latest. No the way we wanted to start the season, but at least new records are made... Not in this run though...

https://www.youtube.com/watch?v=nifjJfVSisQ&feature=youtu.be

|

|

By Hollow Head - 10 Years Ago

|

Compilation of all runs at last event. Wheelie bar does it's job well.

https://www.youtube.com/watch?v=YIZ0EXkLEFQ&feature=youtu.be

|

|

By Hollow Head - 10 Years Ago

|

|

yes we have grooves in heads, but that wire was blown away with gasket. Cometics could be done for Y-block too, but cost will be too high for individual. Believe me, we have asked them...

|

|

By Hollow Head - 10 Years Ago

|

|

|

By Hollow Head - 10 Years Ago

|

Spectators got our best run captured! Nice, as we forgot to put cameras on the car at that run...

https://www.youtube.com/watch?v=QL9SALnUcc8&feature=youtu.be

|

|

By Hollow Head - 10 Years Ago

|

Wheelie bars do help to control excessive wheelies.

Long burn outs lay down more rubber...

Picture taken in previous race.

As is this too...

Now we are burning some rubber...

Good ole transporter.

|

|

By Hollow Head - 10 Years Ago

|

Next step in progress...

EDIS coils, wasted spark, no need for distributor... Simo can tell you more. I just install...

|

|

By Hollow Head - 10 Years Ago

|

And then pics about Seppo's 10 year old son driving his Junior Drag Bike...

|

|

By Hollow Head - 10 Years Ago

|

|

John, you're correct with that oil pressure issue. It has to be issue with crank case pressure under heavy load. Vacuum pump or do you have any other solution? Dry sump would be great with three or five stages.

|

|

By Hollow Head - 10 Years Ago

|

|

Paul, There's nothing much you can do. Either it stands the boost or not... Crank is still the same old forged truck crank and Callies Compstar rods should stand at least 800 hp as they advertise. Well, we went a little over that... 292 +.030 block has no cement and main caps are stock with stock bolts and that may be the issue with losing oil pressure. What I think is that under heavy load the caps deform and let the oil flow out of bearings. That's definitely not a good thing and for next block we have to change better caps and put that girdle on what is almost done already. We just haven't needed it yet... For now all we can do is chance arp studs to main caps.

|

|

By Hollow Head - 10 Years Ago

|

|

Ted, have you ever had a thought of building a window to oil pan to see exactly how much oil goes to upper part of engine on a dyno pull? In our case there will be some of oil quantity going to turbos and return hoses too. Too bad, we didn't remember to take our full oil cans with us to dyno. Stupid me! So, that is not crank case pressure issue... We are thinking about adding an oil pressure logging to megasquirt too to see how things go at the strip in the future.

|

|

By Hollow Head - 10 Years Ago

|

Thanks Ted! We will chance the bearings anyway now after that dyno visit, Before it we just checked those and as they were all good after one full racing season, we let them be there. Or was it two racing seasons  ... hard to remember... We broke two turbos as a result of too low oil level couple of years ago but I guess we will never learn. ... hard to remember... We broke two turbos as a result of too low oil level couple of years ago but I guess we will never learn.

|

|

By Hollow Head - 10 Years Ago

|

In case if someone is interested to see how things went...

https://youtu.be/_zI4Rz3-T8w

|

|

By Hollow Head - 10 Years Ago

|

Excellent article. Thanks.

|

|

By PF Arcand - 10 Years Ago

|

Wow!! Congratulations! Not only are the numbers almost un believable, but what are you doing to keep that engine together?!

|

|

By PF Arcand - 10 Years Ago

|

Seppo: re the main caps etc. Micheal Henaults who writes in Y-Block magazine on occassion, has reported that his oval dirt track engine, running in the very hot summer in Calif. appeared to have what he called main cap "walk". He used an idea that apparently came from Verne Schumann, former racer years ago, (Schumann's Sales & Service, [Y-Block parts] Iowa U.S.A) where the caps were "pinned". However, I don't know any details on the method. Maybe someone else here can comment on that method?

|

|

By LordMrFord - 10 Years Ago

|

Cliff (1/16/2016)

Hi, what cylinder heads do you use?

Non-posted '56 ECZ-C with large exhaust valves, flame rings and port job.

...and brain box will have electronic boost control also if electrician isnt his lazy mood whole spring.

|

|

By LordMrFord - 10 Years Ago

|

Cliff (3/19/2016)

Is that U.S. numbers? how much boost? Cliff

Mister Santala's dyno is quite hard for them who want to get big numbers.

Many brand new crate motors lost power during ship transport from US if you are looking what stands in selling brochure.

|

|

By LordMrFord - 10 Years Ago

|

Working link

https://youtu.be/eiuEtZ5JwGo

|

|

By LordMrFord - 10 Years Ago

|

BTW. Advance was 38 degrees in 32 lbs boost at 6300 RPM / maximum power point.

Dynoman thinked, under that engine cant even run without popping.

E85 is quite hard to get knocking.

|

|

By LordMrFord - 10 Years Ago

|

First of today on left...

|

|

By LordMrFord - 10 Years Ago

|

http://kuvia.1g.fi/kuvat/2016/FHRA/Spring+Nats/Final+Day/MOP_7479.jpg

No results today.

Freeze plug popped during the mighty wheelie and water went under the left slick what caused wall hit.

Jyrki is fine and front wheel bended under the dragster.

|

|

By LordMrFord - 10 Years Ago

|

Clad to see that somebody dont know yet, so I copy the longer version of details.

Driver is Jyrki Peltonen from Finland. I just am playing with wires and computer.

292 + 0.030 Ford Y-Block with two turbos and intercoolers and got 8-point injection.

Crank is forged truck stuff and has survived three big motor explosion. Pistons are SPR lightweight with scruby pin size, 1.059" compression height and rods are 6.5" long H-profile Callies Compstars.

Camshaft is 284/292 custommade with 116 lobe separation from Schneider or was before wear.

Cylinder heads are homeported iron heads with 1.92" intake and 1.70" exhaust titanium valves. Springs are from Comp Cams.

Intake and Exhaust manifolds are homemade also.

Turbos are 70mm Garrett / Holset HX's.

E85 is injected with 8 x 1600cc injectors with 4,7 ohm resistors. Max ignition timing is 38 degrees at 5666 rpm / max boost.

Fuel pumps are 2 x Bosch 085 and regulator is from Holley.

2 x 60mm Throttle bodies are from two Mustang GT.

Engine management system is Megasquirt 3 with 60-2 trigger, CherryCorp HALL, Crane HI-6 and stock dizzy. Lambda system is Innovate MTX-L.

Transmission is race case powerglide with ~5000 Stall converter.

Rear end is stiff aluminum case with spool and 1:3.7 gears.

Tubular frame is homemade.

We dynoed 965hp / 1100Nm / 812 lbs ft with 2.2 bar / 32 psi boost (with stock main bolts ) Current 1/4 mile record is 8.134 s / 170 mph. I think it was made with 1,9 bar / 27.5 psi. ) Current 1/4 mile record is 8.134 s / 170 mph. I think it was made with 1,9 bar / 27.5 psi.

We race in Finnish national series in Super Pro ET Class (because there is no other proper class to altereds without nitro or funny frame in here)

Engine must stand almost 50 pulls in every year and current combination has made about three years now, so there is something made right in Y-Block's bottom end.

It is quite stupid to race in ET class with turbos and very stupid to race 50 y old obsolete iron in anywhere but Y-Block starts to be quite famous in Finland's drag race scene.

Meet us in https://m.facebook.com/HollowHeadsDragTeamFinland

...and keeping the sponsors in mind:

Remember to drink a lot of Keisari beer from Nokian panimo and if you need good engine machinist at the trip to eastern Finland, call to PP-Autokoneistus.

|

|

By LordMrFord - 10 Years Ago

|

I wonder how is lexan intake manifold working. Alky engine runs cool but how it might work on daily driver?

You might want to get your cylinder heads tight enough with those compressions.

|

|

By LordMrFord - 10 Years Ago

|

I, myself run ARP bolts with 12 kilos and Dragster got 13 kilos (100lbs) with ARP studs and flame rings. Gaskets are Fel-Pro blues.

Like Seppo's video shows, Y-Block's threads will survive and stock bolts surrenders at 14-16 kilos. So ARP's can stand that well.

Never did that stress test with ARP's, thou.

|

|

By LordMrFord - 10 Years Ago

|

|

|

By LordMrFord - 10 Years Ago

|

|

Somewhere about 2100 lbs.

|

|

By LordMrFord - 10 Years Ago

|

Thanks.

Engine starts to be in twiligh zone. Injectors are running full duty at max pressure and fuel/air mixture is not so rich what we are hoping but ignition starts bugging also if going richer.

Crane HI-6 ignition box, spark plugs and stock distributor had come to an edge.

Still, if tomorrow's pass is clean from start to the finish line, there might come some good numbers.

Those Top Fuel's can really make lane sticky.

|

|

By LordMrFord - 10 Years Ago

|

Maybe little bit more fuel pressure if its possible and I have thinking about wasted spark coils from '96 Mustang to next race.

It's 1/8 mile race so it's not so have to thing yet.

|

|

By LordMrFord - 10 Years Ago

|

Direct coil control by Megasquirt3X via four ignition channels, modular Mustang coil packs, hybrid edis-stock style plug wires to get longer but weaker spark.

High tech (in '90ies) stuff for beated up low tech firetruck engine costing only wires and stuff from garage.

I dont think that average Y-Blocker want to know more.

|

|

By LordMrFord - 10 Years Ago

|

Some limiter rattling, burnout clouds and eight second pulls for your long winter from last summer...

|

|

By LordMrFord - 10 Years Ago

|

We founded that head gasket went again. So that wasnt normal water pressure damage.

What caused that gasket failure second time in this weekend is mystery still.

Maybe boost control is not fast enough to hold pressure still in raging launches or something.

|

|

By LordMrFord - 10 Years Ago

|

MoonShadow (5/22/2016)

I saw the picture but thought it was the gasket you blew earlier. So that was the problem. Certainly blew it out. I know nothing about the sort of boost you are running but its still a super fast Y-Block.

Target pressure is 29 psi and total cut off pressure for fuel and spark is 36 psi.

We changed turbo screw/bleeding valve to electronic boost control in last winter, so there is lot of learning there.

Rapid pressure rise and harder learning curve vs. Simplicity and bleeding boost pressure.

|

|

By LordMrFord - 10 Years Ago

|

Tried that but water went in wrong hole whatever we did.

Maybe its time to try again...

https://scontent-amt2-1.xx.fbcdn.net/v/t1.0-9/fr/cp0/e15/q65/13256132_802635709835929_6747214157751701007_n.png.jpg?oh=3f4b941a6c5c3f597358894c846aa80c&oe=57D187E5

|

|

By LordMrFord - 10 Years Ago

|

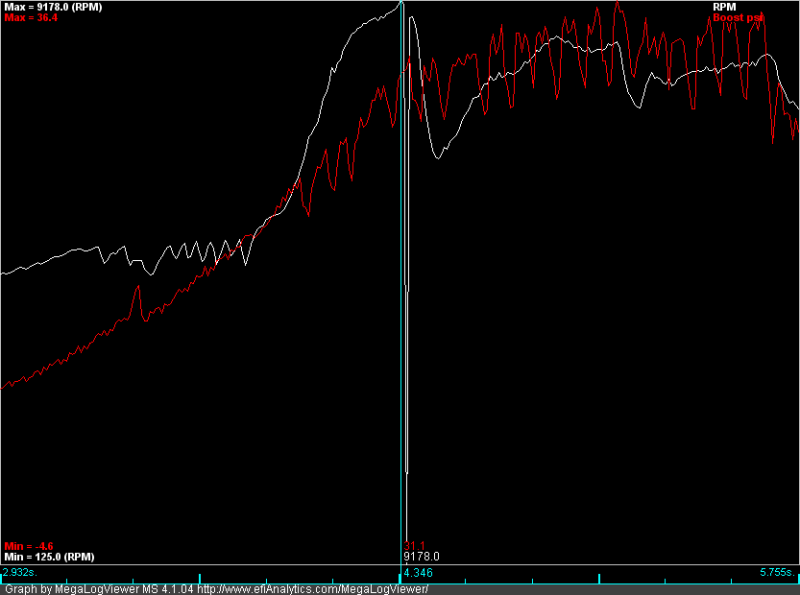

When you go flat out, remember put your rev limiter on...saturday's record was 9178 revs per minute during burnout and only couple broken valve lash caps.

Doubled the original maximum ~4500 limit.

Some short of record maybe. =D

|

|

By LordMrFord - 10 Years Ago

|

|

|

By LordMrFord - 10 Years Ago

|

Today's best, 8.185/162mph and good claps for long burnout.

For tomorrow a little bit more boost and more fuel...and maybe even longer burnouts.

Btw. We got oldest engine in whole finnish serie and fastest machine in the Super Pro ET class. Faster than stroker windsor RED, big block Ranchero, turbo Buick and various set of big block scrubs.

|

|

By RB - 10 Years Ago

|

Yikes!!! Glad to hear everyone is OK.. Hope that chassis is not too badly damaged. I want to see you guys race more this year

|

|

By RB - 10 Years Ago

|

Do you guys have a receiver groove in the head for your wire O-ring? I am thinking the only way to hold that much boost is O ring groove and copper gasket.. The small block Ford crowd has pretty good luck with Cometic style gaskets but none are available for a Y block.

|

|

By RB - 10 Years Ago

|

Is there is a reason you are not using a copper head gasket with the wire?

|

|

By RB - 10 Years Ago

|

When you use copper every water passage has to be sealed with a bead of RTV on both sides of the gasket or it will leak.. I think copper is your only option for holding that type of cylinder pressure.. I use copper and O Rings on my Lincoln Y blocks and it took me a while to figure out how to seal up the water leaks

|

|

By stuey - 10 Years Ago

|

wow scaaary.

love the sound.

stuey

|

|

By John Mummert - 10 Years Ago

|

The numbers look great. Good job. It looks like oil pressure is falling form 70 to 25 psi during the run. Hopefully you guys have a handle on that. Look forward to seeing more videos.

|

|

By Bobwanna - 10 Years Ago

|

|

Seppo, The burnout and time score was awesome! Thanks for posting - Bob

|

|

By Lord Gaga - 10 Years Ago

|

Hollow Heads,

You may find this article informative;

http://www.enginebuildermag.com/2016/04/high-tech-tightening/

|

|

By Lord Gaga - 10 Years Ago

|

WOW! Nice work you guys. What does your machine weigh?

LordMrFord (7/8/2016)

Today's best, 8.185/162mph and good claps for long burnout. For tomorrow a little bit more boost and more fuel...and maybe even longer burnouts.  Btw. We got oldest engine in whole finnish serie and fastest machine in the Super Pro ET class. Faster than stroker windsor RED, big block Ranchero, turbo Buick and various set of big block scrubs.

|

|

By ian57tbird - 10 Years Ago

|

|

It may also be the bolts stretching. And congrats, that is amazing power out of an old Y.

|

|

By ian57tbird - 10 Years Ago

|

|

Congratulations on the win and the time.

|

|

By Cliff - 10 Years Ago

|

|

Hi, what cylinder heads do you use?

|

|

By Cliff - 10 Years Ago

|

Is that U.S. numbers? how much boost?

Cliff

|

|

By Cliff - 10 Years Ago

|

GOOD JOB, I'm doing all I can to make 625 HP form 320 CID with iron heads (don't know if i'll make it).

Cliff

|

|

By Cliff - 10 Years Ago

|

John did the heads and piston domes I have now.

Cliff

|

|

By Cliff - 10 Years Ago

|

|

Hi, what's in the engine? how big?

|

|

By Cliff - 10 Years Ago

|

|

NICE, Just finishing my Dragster Engine (Super Comp 234" wheel base), ECZ-G heads ported by John, 13 1/2 Comp, (3.810), CITE Crank heat treated ( 3.60 Stroke) Carrillo rods (6.380 with .927 pins and 1.850 bearing), Roll Master timing set (heat treated), Comp Cam (heat treated, 280@50, 5.50 lift), trend Tool Steel lifters, Trend push rods, Isky springs and retainers (180lbs on the seat), main caps cut flat with steel straps and ARP studs (all 5), Marine oil pan and timing cover, Home Made Lexan manifold, Hilborn 4 port (short) with belt driven pump, Speedmaster head studs (?), ATI Damper (sbc), don't know what ignition yet, 7" converter, short power glide, 7al msd box, this is a alcohol burner.

|

|

By Cliff - 10 Years Ago

|

I am painting inside of the runners with clear epoxy so it will not cloud up from the alcohol, I think it stands up to the heat, however I worry about a back fire so I made a popoff plate, funny about Lexan is that you form it with a metal break not heat.

PS how tight do you run the heads?

|

|

By charliemccraney - 10 Years Ago

|

|

Sweet

|

|

By charliemccraney - 10 Years Ago

|

|

I've noticed my pressure drop slightly during a pass. Maybe I'll add an extra quart.

|

|

By charliemccraney - 10 Years Ago

|

I watched my in truck video during the last pass I made, paying attention to the oil gauge. The pressure drops a lot, not slightly, by the time I'm at the end of the track so that is something I will have to resolve before I race again.

I installed a gate, made out of piano hinge, on the baffle. Maybe that is not allowing oil to flow as well back to the pickup. Will get a pan gasket set and check things out.

|

|

By charliemccraney - 10 Years Ago

|

So effectively, you ran 8.134 while running out of fuel and with something in the ignition system operating insufficiently. I think you'll get into the 7s without a problem once you resolve those. Awesome.

|

|

By Ted - 10 Years Ago

|

|

Seppo. Great numbers and reinforces why adding boost is a great power adder. Rough math has that engine making almost 300HP in a normally aspirated setup which is still respectable even without the boost. Thanks for providing the lb/ft torque numbers. That helps to keep the torque values in a U.S. numbers format.

|

|

By Ted - 10 Years Ago

|

Hollow Head (3/21/2016)

John, you're correct with that oil pressure issue. It has to be issue with crank case pressure under heavy load. Vacuum pump or do you have any other solution? Dry sump would be great with three or five stages.

That’s a good catch by John on the oil pressure drop during the dyno run. The oil pressure is expected to increase if the crankcase is experiencing a pressure build up which is what I would expect in a boosted application. If you can manage to pull a vacuum on the crankcase, then the oil pressure typically drops in that scenario. Assuming the various engine bearing clearances are not excessive, how much oil is in the oil pan and what kind of oil pickup to bottom of pan clearance are you running?

|

|

By Ted - 10 Years Ago

|

Hollow Head (3/22/2016)

Ted, have you ever had a thought of building a window to oil pan to see exactly how much oil goes to upper part of engine on a dyno pull? In our case there will be some of oil quantity going to turbos and return hoses too. Too bad, we didn't remember to take our full oil cans with us to dyno. Stupid me! So, that is not crank case pressure issue... We are thinking about adding an oil pressure logging to megasquirt too to see how things go at the strip in the future.

I have run an engine on the dyno with a lexan cover in place of the valley cover and with the holes drilled in the lifter valley, there is a large volume of oil coming back up through those drilled holes. when the engine is running at rpm

While I haven’t modified an oil pan with any kind of viewing panel so that the level can be observed while running the engine, I do have a couple of ‘low oil in the pan’ experiences I can share. I recently had a Ford 390 FE on the dyno that was experiencing an oil pressure drop when the engine was being held at 3000 rpms for as little as 20 seconds. The oil pan was a factory design with a total of five quarts with filter which was the recommended factory fill amount. The oil pump was a standard volume pump and not a high volume pump. The oil pump pickup to pan clearance was between ¼” and 3/8” so that was good. Adding one additional quart of oil solved the oil drop issue which showed how critical it was to have sufficient oil in the pan. In this particular instance I’d feel more comfortable with seven quarts of oil in that five quart designed system.

Another instance I can share is from years ago when running a Ford 427 Hi-Riser in a drag raced ’64 Fairlane. This engine was carrying a total of seven quarts with an aftermarket deep sump pan and was experiencing a pressure fluxuation at the end of each quarter mile pass. It eventually spun a rod bearing and it was at that point it was realized that the pan was being sucked dry at the end of each quarter mile pass. Upon putting the engine back in the car, the oil capacity was upped to 9 quarts (two quarts over the full mark) and this engine ran flawlessly for another eleven years without any further issues. As a side note, the performance of the engine did not falter or fall off as a result of the additional oil.

I had my Y powered roadster up to nine quarts and was still having issues with controlling the oil in the pan either at launch or stopping depending upon where the oil pickup was placed. I put a dry sump oil system on the engine and now it runs a total of five quarts of oil without issue.

|

|

By Ted - 10 Years Ago

|

|

charliemccraney (5/20/2016)

I watched my in truck video during the last pass I made, paying attention to the oil gauge. The pressure drops a lot, not slightly, by the time I'm at the end of the track so that is something I will have to resolve before I race again.

I installed a gate, made out of piano hinge, on the baffle. Maybe that is not allowing oil to flow as well back to the pickup. Will get a pan gasket set and check things out.

Charlie. As long as the oil pan gate door swings to the back, you should be good in that regard. How many quarts of oil do you carry within the pan including what’s in the filter?

|

|

By Ted - 10 Years Ago

|

LordMrFord (5/21/2016)

First of today on left...

That’s very impressive. Keep up the great work.

|

|

By Ted - 10 Years Ago

|

|

That video of the car from the rear showing the launch is scary when that freeze plug comes out. Some of the circle track engines I work on have a strap across the freeze plugs to keep them from blowing out. This might be easier than tapping the freeze plug holes and installing screw in style freeze plugs. There are some different varieties of screw in freeze plugs with some simply being a straight thread with the plug having an O ring and another variety being a tapered pipe thread which simply needs a corresponding ‘thin’ style pipe plug.

|

|

By Ted - 10 Years Ago

|

Teros292 (7/9/2016)

You can watch this in live now from http://livestream.com/fhra/events/5709063Here is times when Jyrki is on track Thursday, July 7th Qualification round 1 01:39:30 8.725 250.90 km/h 155.94 miles/h Qualification round 2 06:08:35 9.19 254 km/h 157.86 miles/h Qualification round 3 07:52:39 8.421 259.94 km/h 161.55 miles/h Friday, July 8th Qualification round 4 08:08:10 8.185 259.50 km/h 161.28 miles/h Saturday, July 9th Qualification round 5 01:46:45 8.134 274.59 km/h 170.65 miles/h Qualification round 6 08:46:57 8.232 268.25 km/h 166,72 miles/h

Congratulations on some great times. That Saturday run of 8.134 seconds officially moves you in the second place on the list of ‘all time’ quickest Y runs. The late Randy Gummelt previously held that second place record at 8.157 seconds and that particular ET has been in place since 2005. In 2005 it was the quickest ¼ mile time ever posted for a Y vehicle but has since been eclipsed by Bob Lindsay.

Good job by all on getting those times quicker. Keep whittling away at those ¼ mile elapsed times like this and the top spot (7.966) is not that far away.

Be sure to update your time on the ‘Best Times’ thread and move yourself up a notch.

|