|

By Ted - 11 Years Ago

|

It’s now official. I have been notified that I’ve been selected as a competitor in the 2015 Engine Masters Challenge. Here’s what the current engine lineup for the Vintage Engine class looks like for this year.

Vintage

Kustom Kemps Packard

SAM’s Chris Bennett Mopar 318 Poly

Buck Hinkle Mopar 318 Poly

Ted Eaton Ford Y-block

Jon Kaase Ford Y-block

RB Vintage Engines Ford Y-block

RB’s engine is actually a Lincoln Y-Block but close enough to call this year’s Vintage Engine Class a Y versus Poly shootout.

|

|

By charliemccraney - 11 Years Ago

|

What am I missing? If it is 1954 or earlier, why is a 318 Poly permitted? The poly came around in '55, did it not?

Either way, that will be a neat engine to see run.

|

|

By RB - 11 Years Ago

|

Charlie, The Poly was given an exception to allow participation. I am guessing because early Hemis cannot run in vintage, this would allow Chrysler to compete.I am not so sure that the Packard did not come out in 55 as well. I was really surprised no Buicks, Olds, or Caddillacs are in the competition.

|

|

By charliemccraney - 11 Years Ago

|

I wish they had allowed the Hemi. If they do it again next year, I think they should use a slightly later date, and simply keep all mainstream engines out of it, so no FE Fords, no SBC, no mall block Mopar, and allow the early Hemi, if only to see how the other engines compare to the legend - I bet the results would be surprising.

Can any other participants be added at this point or are these the only 6 that there will be?

|

|

By MoonShadow - 11 Years Ago

|

|

Isn't the Poly motor a Hemi block without the heads?

|

|

By RB - 11 Years Ago

|

Chuck the poly is kind of a semi hemi. It has canted valves but a single rocker shaft. They were introduced in Plymouths. They were cheaper to mfg that the Gen 1 hemi and lighter as well. Their heads flow pretty well. They will make some good numbers. The EMC has all hemis lumped together gen 1 2 and 3 in one class. A few yrs ago a Gen 1 hemi finished 2nd or 3rd overall so they have some big potential..If they were allowed in vintage they would be very tough to beat.

6 engines is a full field..

|

|

By MoonShadow - 11 Years Ago

|

|

Isn't the Poly motor a Hemi block without the heads?

|

|

By charliemccraney - 11 Years Ago

|

There are two Poly motors.

One is pretty much an early hemi with poly heads, which has little in common with later LA engines (273, 318, 340, 360).

The other Poly has little to do with the early hemi and does have more in common with the LA engines. These 318s will be the later variant.

|

|

By jepito - 11 Years Ago

|

|

Jerry christenson and I are both on the alternate list.

|

|

By LordMrFord - 11 Years Ago

|

This year starts to be very interesting.

Especially the Lincoln Y.

|

|

By RB - 11 Years Ago

|

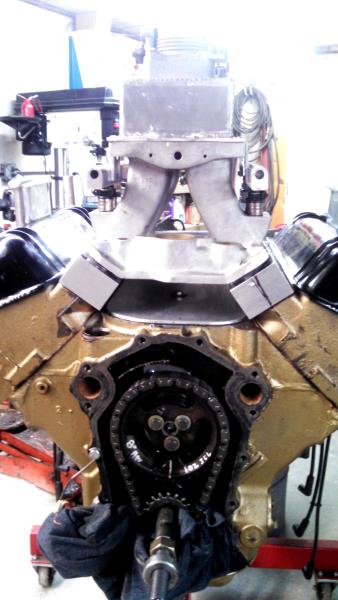

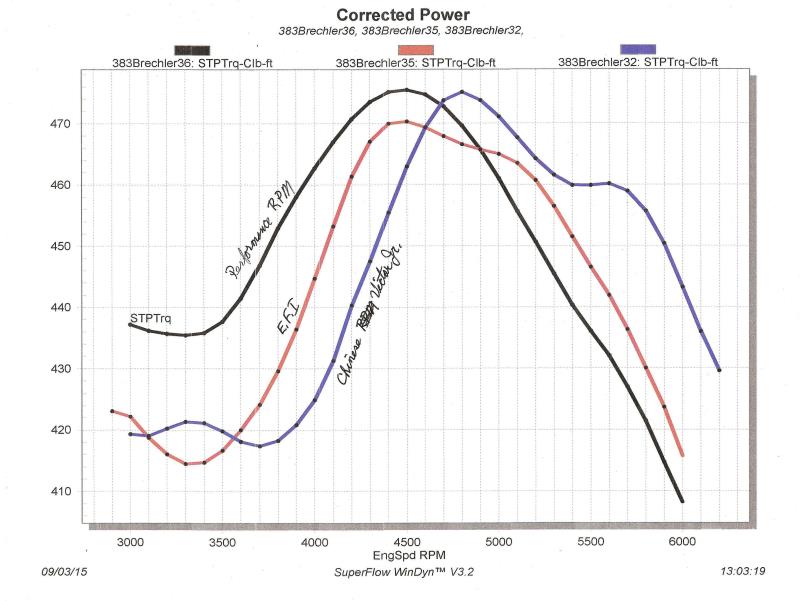

Here is a video from a couple years ago of the engine I am running in EMC.. I ran out of tuning time at the dyno session and just was content with a 500 hp number.. I think there is another 25 or 30 horse in it with some careful tuning.. The cam is actually a little too big for the rpm range of the contest.. I am going to try advancing the cam some to get the torque peak down a couple hundred rpm, I will also try a manifold with long straight runners and Tri Y header to pump up the mid range torque. That torque number needs to be close to 500 ft/lb.

Sorry for the questionable videography

|

|

By jepito - 11 Years Ago

|

|

What cubic inch is it?

|

|

By RB - 11 Years Ago

|

|

It is 383 4.06 x 3.7

|

|

By yalincoln - 11 Years Ago

|

say royce, i believe you can use low deck mopar intakes with adapter plates. that would give you a number of different options on intake. just a thought! have you tryed those big tube spred port SBC headers on anything y-block? just want to know if they work. i figured a big inch lincoln y might like them better, thanks, wayne!

|

|

By RB - 11 Years Ago

|

Wayne, Yes I did use the headers.. The dyno video that made 500 hp used those headers

|

|

By yalincoln - 11 Years Ago

|

hi royce! great, thanks!

|

|

By yalincoln - 11 Years Ago

|

say royce i can't find the post on that engine, can you send it to me, thanks, wayne. any pics.?

|

|

By yehaabill - 11 Years Ago

|

Ted, I bet Kaase will out spend you....but he won't beat you....but, we will get to see what a NO-EXPENSE spared Y-block will do....my 2 cts..

|

|

By PF Arcand - 11 Years Ago

|

What is the RPM range for the Vintage class? I haven't followed the most recent contests, but one thing that has been evident in the past is that unless your engine can produce torque numbers at the bottom of the RPM range, equal to it's displacement or better, the chances of winning were slim & none. Even making the top six was doubtful. I realize this vintage class has limited entries, but Jon Kaase is a master builder/ tuner & everyone else better be on their best game or it's unlikely for them to get close to the front..

|

|

By jepito - 11 Years Ago

|

3000-6000rpm

|

|

By jepito - 11 Years Ago

|

I'm not in, but on the alternate list. Hopefully something wil change because I feel pretty good about my chances. My engine was built for pump gas so it has some room for improvement to take advantage of the VP 101. The cam and headers are set up for a little higher rpm as well. Even as is though its

334ci making 450hp @6000 and solid low end torque.

|

|

By jepito - 11 Years Ago

|

4-6k dyno pull http://youtu.be/FHvN41NNalM

Warm up. http://youtu.be/MY2wkoze6yQ

|

|

By Ted - 11 Years Ago

|

|

PF Arcand (6/23/2015)

What is the RPM range for the Vintage class? I haven't followed the most recent contests, but one thing that has been evident in the past is that unless your engine can produce torque numbers at the bottom of the RPM range, equal to it's displacement or better, the chances of winning were slim & none. Even making the top six was doubtful. I realize this vintage class has limited entries, but Jon Kaase is a master builder/ tuner & everyone else better be on their best game or it's unlikely for them to get close to the front.

Paul. Well said! Jon is noted for thinking way outside the box and being quite innovative along the way.

As Jepito previously mentioned, the rpm band for the Vintage Engine Class is 3000-6000 rpm’s. The fuel being used is VP101 which falls between a pump gas and race fuel and this alone puts the engine in that grey area between a street engine and race engine. My own proposed engine combination for the 2015 EMC competition is going to end up being a dyno queen or a mild race engine due to the fuel requirement. This engine is a combination that’s going to be hard to repurpose without a complete teardown for a piston and camshaft change later.

|

|

By PF Arcand - 11 Years Ago

|

Interesting point Ted.. It also strikes me as odd that a vintage class would have a somewhat narrow RPM range starting at 3000 RPM. But, then again it's Hot Rod running the show now, not Popular Hot Rodding, who would have undoubtedly started it at 2500 RPM.

|

|

By RB - 11 Years Ago

|

Dyno operators do not like to start dyno pulls at a lower rpm.. The water brake often times can not hold an engine that makes a lot of torque at that low of RPM

|

|

By PF Arcand - 11 Years Ago

|

That may be true in some cases, however the University of Ohio's dynos ( I don't recall the make or models, but I believe they used three) were starting at 2500 rpm in Engine Masters tests on engines much bigger than a usual Y-block.

|

|

By Ted - 11 Years Ago

|

|

PF Arcand (7/17/2015)

That may be true in some cases, however the University of Ohio's dynos ( I don't recall the make or models, but I believe they used three) were starting at 2500 rpm in Engine Masters tests on engines much bigger than a usual Y-block.

UNOH uses the DTS dynameters. DTS has sold out to Superflow so the UNOH dynos are now supported by Superflow. It was one of Kaase’s engines that actually ‘smoked’ the water brake on one of the UNOH dyno’s. I’m more in favor of the 3000 rpm start rather than 2500 rpms simply due to some dyno operators not having a soft touch on the controls and operating the dyno controls like a car leaving a dragstrip starting line. If the engine is not tuned for this kind of start, it will cough and spit and in some instances simply die. Assuming the engine gets past that kind of rambunctious start, running the throttle up too fast will make the rpms fall quite a bit below the dyno start rpm and in turn loads both the engine and the dyno extremely hard at that point. If that dyno start rpm is set at 2500, then the potential is there for a high torque engine to drop all the way down to 1800-1900 rpms while the computer is trying to compensate for the sudden load on the water brake. I use the soft touch method at the dyno controls and rarely see more than a 200 rpm drop below the selected start rpm. I rarely make pulls starting at less than 2500 rpms simply due to main bearing and crankshaft loading being severe at low rpms and at full throttle.

|

|

By Small block - 11 Years Ago

|

|

The poly engine was the engine that showed the way for the Big block scruby and 351 Cleveland, The poly had some short comings but the canted valve idea was good enough that both Ford and scruby followed with there own design! If you don't have it you will never win a NASCAR race! This class should be interesting Kaase has a way of making power no matter what he builds!

|

|

By Kahuna - 11 Years Ago

|

As I recall, that early Hemi placed 3rd in the competition several years ago. I was

very fortunate to be able to watch and assist during the Local Dyno pulls in Chico, CA.

I have no idea what HP it made during the EMC, but did get to see it make more than

645 HP on John Beck's dyno. A very impressive engine.

Unfortunately, one of the co-builders (Danny Miller) passed away some time later.

|

|

By RB - 11 Years Ago

|

It was very very sad that Danny Miller passed suddenly and too soon.. He had a very quick and inventive mind and boundless enthusiasm.. That Hemi project was quite an effort

|

|

By Ted - 11 Years Ago

|

The Eaton Balancing Y entry fought me most of the week but it’s now turned into a serious performer. Today will be spent taking care of some loose ends such as bracket for the MSD box and coil and some kind of bracket for the throttle utilizing a Morse cable. Once the engine is fired one last time to insure that the changes are as needed, it comes off the dyno, oil drained, and put on an engine cradle for transportation.

The team heads out for Lima, Ohio early Monday morning. The engine will be teched in on Wednesday and ran on Thursday. My engine is number 4 on the run order list while Jon Kaase’s entry is #5 and Royce’s is #6.

Details on my engine particulars will not be available until after the competition for the obvious reasons.

|

|

By Y block Billy - 11 Years Ago

|

|

Go Get em Ted!

|

|

By speedpro56 - 11 Years Ago

|

The Best of Luck Ted!

|

|

By Rowen - 11 Years Ago

|

|

Smoke em Ted!!

|

|

By John Mummert - 11 Years Ago

|

|

Good luck Ted, sounds like the engine is a runner. Hopefully we can get some updates next week. I'm sure everyone will be interested in whats going on back at UNOH.

|

|

By CK - 11 Years Ago

|

|

Good luck Ted.

I'm hoping there will be another you tube vid. with another Eaton entry as a winner.

|

|

By 62bigwindow - 11 Years Ago

|

|

Good luck Ted. Can't wait to hear the results.

|

|

By Canadian Hot Rodder - 11 Years Ago

|

|

Knock their socks off Ted!!!

|

|

By MplsMike - 11 Years Ago

|

I haven't read this whole thread so apologies if someone already did this. Here is a link to event coverage at the Challenge. Hope it works.

http://www.hotrod.com/events/engine-masters-challenge/

|

|

By speedpro56 - 11 Years Ago

|

Thanks, excellent read!

|

|

By charliemccraney - 11 Years Ago

|

I wonder if a Y could be competitive in the Spec small block class that ran today? By the power numbers, I think so. I wonder if one could get by on a technicality since Edelbrock do make John's heads and Intake.

Oh, nevermind. in the rules, minimum bore 4.00" That would be hard to pull off.

Min rod journal of 2.00", so no 4" stroke crank.

"OEM replacement production style rocker arms only." I guess that means stock rockers - no roller tips or higher ratio aftermarket.

|

|

By Cliff - 11 Years Ago

|

|

Did you guys see the intake manifold on Jon Kaase's engine?

|

|

By charliemccraney - 11 Years Ago

|

Very interesting. I wonder if anything has been reconfigured in the heads or manifold.

We've seen something like that done for a blown motor.

|

|

By Glen Henderson - 11 Years Ago

|

|

Check out the sneak peek of vintage engines on EMC site!! Someone has already won just with the wow factor, going to be very interesting.

|

|

By MarkMontereyBay - 11 Years Ago

|

Wow!

http://www.hotrod.com/events/1510-sneak-peek-vintage-shootout-engines-for-day-four-of-hot-rods-2015-amsoil-engine-masters-challenge/

and...

http://www.hotrod.com/events/1510-fire-ls3-bursts-into-flames-at-7500-rpm2015-amsoil-engine-masters-challenge/

|

|

By glrbird - 11 Years Ago

|

|

Does anyone have a explanation how a SBC intake works on a Y head? Those spacers must be pretty trick.

|

|

By charliemccraney - 11 Years Ago

|

My thought is that he reworked the inside of the manifold. But, this is Jon Kaase, so maybe he found a way to make it work with the port mismatch. We should find out how well it works today!

|

|

By 62bigwindow - 11 Years Ago

|

|

That would be interesting to know. If the spacer could be made relatively cheap that would open up a huge selection on intakes.

|

|

By LordMrFord - 11 Years Ago

|

I bet on reworked manifold too.

Opened up a whole middle wall of runner pair and welded up a new horizontal wall if that is not against the rules.

Do that thing to heads might be against rules and might be quite impossible.

|

|

By Cliff - 11 Years Ago

|

|

Any news yet?

|

|

By John Mummert - 11 Years Ago

|

|

I'm not sure but I think its got side by side ports.

|

|

By LordMrFord - 11 Years Ago

|

That would be something.

I forget that he uses alu heads.

Aluminum is much easier to modify that way than cast iron.

|

|

By glrbird - 11 Years Ago

|

|

Mr. Mummert, are you talking about the head?

|

|

By Rowen - 11 Years Ago

|

|

Any word yet on the vintage class? Rowen

|

|

By Grumpy1 - 11 Years Ago

|

Go to hod rod magazine. Engine masters challenge 2015. Looks like Jon kasse won.

Im hoping Barry Rabotnick with his Fe runs well and possibly beats the big blocks tomorrow.

|

|

By MarkMontereyBay - 11 Years Ago

|

Edit; Kaase made 477HP 557TQ average on 3 pulls, the Lincoln did 463HP, Ted did 542HP. The Packard made 445HP. I can't find anything on Barry's FE. I think he is running tomorrow (Friday).

http://www.hotrod.com/events/engine-masters-challenge/

|

|

By pegleg - 11 Years Ago

|

|

Excellent Ted. I think you gathered some attention with that. Even Kaase had to be impressed!

|

|

By MarkMontereyBay - 11 Years Ago

|

Yep... I am rereading the report online and it says that Kaase reached nearly 600 peak torque with the 557 being an average over three pulls. The HP number is 477.

Ted's torque wqs 496.

|

|

By Rowen - 11 Years Ago

|

|

Do you think the ports twist from the heads to the intake inside that adaptor? Some serious engineering going on there.... Rowen

|

|

By charliemccraney - 11 Years Ago

|

The reporting on the event is terrible. In one article, it says Kaase was 477hp. In another it says 583. All the numbers they've provided are average peak numbers which is not at all relevant to the scoring system.

Ted's engine is indicated to have made the exact same hp and tq as the Poly 318, and has LS7 HIlborn efi, factory cast iron heads, ported, according to the report. While it is certainly possible that it produced the exact same numbers as another engine, it is not very likely and given all of the other errors, I'm sure that is a mistake as well.

So at this point, we don't really know how it has turned out. IF the numbers reported are correct, then Ted has won as Kaase did not produce enough power and torque for his displacement. That's IF they are correct, and my guess is they are not.

I hope there is a results article or summary with accurate info. Or maybe Ted or Royce will chime in with the real scoop.

|

|

By John Mummert - 11 Years Ago

|

|

Charlie is right! the reporting is BAD. From what I can gather KAASE 1st SAM 2nd and Ted is 3rd right now, but without some better clarification I can't promise this is right. 477 is probably Kaases avg hp. Not Avg. PEAK. hp

|

|

By MarkMontereyBay - 11 Years Ago

|

|

Yep..I stopped trying to make sense of the numbers so far. Those tasked with the media chore for the event seem to be a bit confused.

|

|

By MarkMontereyBay - 11 Years Ago

|

Some photos and "commentary" now on the EMC site.

http://www.hotrod.com/events/1510-you-wont-believe-this-engine-is-60-years-old/

|

|

By DryLakesRacer - 11 Years Ago

|

Very interesting reading. With the Ford Y-block being wider at the manifold/head split using adapters to a narrower manifold makes perfect sense. John Kaase must have read the rules really close to figure on changing the intake port design within the confines of the head. Aluminum sure makes this easier. If that was not allowed and no aftermarket aluminum heads were allowed I'm sure he would have picked another make: Lincoln/Merc would have been a better choice just because of head design alone. I did think they (L/M) would have made a better showing. I also would like to see a single carb or throttle body of no more the 4 holes/venturi.

I feel Ted did us true Y- Blockers proud and he has proven again how stout these Fords are....Thank you Ted.

|

|

By Genuinerod - 11 Years Ago

|

|

Going by the formula of Engine masters (torque + HP x 1000 / cu. in.= score. Ted wins. The way I figure it is Ted: 3075, Klaase: 2943, the poly eng: 2769.

|

|

By CK - 11 Years Ago

|

I think Kaase ran his Y block in two classes and that is why its mentioned having two HP stats.

477Hp cut off at 6000rpm Vintage class

600HP, well that's peak HP and has been compared to LS engines having a greater Torque figure and what 50 plus years have done for the V8.

John I think your heads really opened the worlds eyes on the old Y.

But The EMC site is shocking and hoping Genuinerod is right

|

|

By glrbird - 11 Years Ago

|

http://www.hotrod.com/events/1510-prehistoric-power-the-winner-of-vintage-class-competition-at-2015-amsoil-engine-masters-challenge/

kaase won

sam second

ted third

Packard fourth

Royce fifth

|

|

By NoShortcuts - 11 Years Ago

|

THANKS for posting that, Gary.

Ted's performance and Royce's were EXCELLENT. We'll all be interested to hear what they put together in their engine builds. As has been said earlier, some of the EMC reporting is incorrect.

For those of us that have not followed John Kasse, I found the article that follows on the Internet. Click the link if you're interested in a profile of his performance engine operation.

http://www.jonkaaseracingengines.com/html/about.html

Kasse, Ted, and Royce have breathed new life into the y-block story. That said, John Mummert has provided THE cylinder heads that have revolutionized the capability the 'little' y-blocks fielded by John Kasse and Ted.

Kudos to all of the vintage category EMC participants on their accomplishments. WoW! What a showing!

|

|

By glrbird - 11 Years Ago

|

|

Ted and Royce have plenty to be proud of, Competing against Kaase is tough, lots of money and equipment to build what ever he needs. I wonder if Royce is thinking tunnel ram now.

|

|

By Y block Billy - 11 Years Ago

|

|

Ya, John adden 10 lbs of welding rod to the heads and reported them to side by side ports, talk about going to extremes!

|

|

By Doug T - 11 Years Ago

|

|

Congratulations to all who fielded an engine, the amount of technical understanding work and organizational skill are truly awe inspiring. And of course special thanks to long time friends of the Y Block Ted and Royce who are definitely not picking an engine to fit the class but making the Y fit the class. Ted's engine is obviously much simpler and more practical than some of the others. I did not find on HRM's site anything about Royce's engine, is there something there?

The HRM coverage of the event was as usual snarky about Fords, especially Y's and filled with mis-information. Is HRM owned by GM or what?

|

|

By hjh - 11 Years Ago

|

EMC Report Rick Martin , Bob Martin and myself just returned from Lima EMC site. The order of finish # 1 Kaase

# 2 S. A. M.

# 3 Ted

# 4 Royce

# 5 Packard

Ted was only 60 total points from the SAM # 2 spot that is a couple of H.P. & torque #`s out of second .Ted & Royce done us very proud .Royce had a lot of interest in his engine especially with the Turnpike Cruiser valve covers The Kasse engine was something to see, pictures will never do it justest. If he only used 10lb .of rods he made good use of them because there was major mods. made all within the rules because the only Tech item was cubic inch claimed.

The reason for incorrect reporting is trying to determine scores from the screen shown is hard as it is not left on very long. Harry Hutten

|

|

By mgcookwv - 11 Years Ago

|

|

Congrats Ted, wish you well.

|

|

By speedpro56 - 11 Years Ago

|

A big congrats to Ted and Royce for a job well done indeed!

|

|

By 62bigwindow - 11 Years Ago

|

|

Ok. We have the order but what about the hp numbers?

|

|

By NoShortcuts - 11 Years Ago

|

Hmmmmm...

For me, because of the formula for computing the final score (utilizing average hp and torque readings and factoring in engine displacement) I'd be interested in the final score for each of the entries.

|

|

By RB - 11 Years Ago

|

Thanks to all who sent congrats and best wishes.. What a fabulous experience for a gear head to rub elbows with some of the most accomplished builders in the industry.

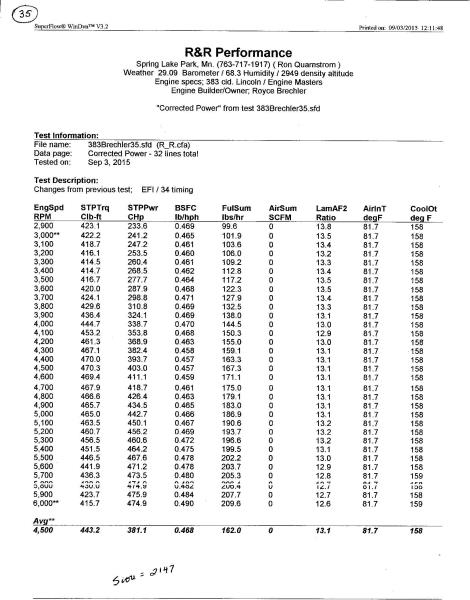

The Y Block contingent was well represented with Ted Eaton and his team, my team, and some additional Y block guys who showed up to observe. As far as performance, SAM and Kaase routinely pull out all the stops to tailor their engines to win the competition, and it shows by the number of wins accumulated between them. An examination of their engines reveals what is necessary to make a score that can win.. For the rest of us that cannot have unlimited budgets, we work with what we have and try to tune for the best possible score. Ted did a remarkable job, using parts that are not exotic or one off, to post a VERY competitive score. Ted's engine could be dropped into a car and raced just as it is.. Not so for the two winners. I knew my effort would be challenged because I do not have aftermarket heads that flow a lot of air. I was pleased with how my engine performed as it mirrored very closely my test scores.. UNOH dynos are known to be stingy and every competitor was down from 20 to 50 horse from what they scored on their home dynos. My numbers were off the least of any that I talked to. On my home dyno I made 480 horse and 480 torque and an EMC score of 2183. On the UNOH dyno I made 462 horse and 467 torque for a 2129 score. The trick to making a good score in EMC is to find a combination that balances low end torque with high end horsepower. In a drag race engine you shoot for high end horsepower. In race trim this engine will make 510 horse at 6500 rpm but only 400 ft lb of torque at 3000 rpm..Since I pulled this engine from my race car I had to find a way to beef up the torque at 3000 rpm without killing all the horsepower at 6000. It was a given that I had to use my existing cam since solid roller cams for Lincoln Y blocks can't be ordered from J.C. Whitney. To do this I opened up the valve lash from .016 to .028 to make the cam seem smaller to the engine.. I also switched to a dual plane intake rather that the single plane I usually run in my race car. In 3 dyno sessions, I made over 100 dyno pulls, tested 5 intakes, 4 carburetors, 3 sets of headers, and a lot of spacers to come up with my combo.

.

It was a great experience. I enjoyed myself greatly. It is stressful, expensive,and hard work to prepare and run an engine in competition,, but like so may things in motorsports, it is addicting.. If the rules are favorable in 2016 I will probably be back, hopefully a little more competitive that this yr,

|

|

By charliemccraney - 11 Years Ago

|

Kaase talking about his engine.

|

|

By '60 Fairlane - 11 Years Ago

|

Congratulations to all the Y-Blockers who competed! I probably shouldn't say this, but when you completely change the architecture of the cylinder heads as Mr. Kaase did..., well, is it really still a Y-Block? I understand his modifications are legal under the letter of the law (rules) although they don't seem to keep up with the spirit of the vintage engine class, He might as well have started with some chunks of metal and carved a motor. Guess I'm biased. Still good to see the real Y-Blocks make a good showing. -Dave

|

|

By CK - 11 Years Ago

|

Well done guys, very impressive no.'s.

Those head mods. are inspiring though.

|

|

By CK - 11 Years Ago

|

Well done guys, very impressive no.'s.

Those head mods. are inspiring though.

|

|

By NoShortcuts - 11 Years Ago

|

Royce: THANKS for writing and sharing what you did behind the scenes to accomplish the results produced with your Turnpike Cruiser. Kudos for ALL of your time, effort, and accomplishments. In my book, you and Ted were the 'Davids' that met the 'Goliaths' at this year's EMC. You both did FANTASTIC in my understanding of the results. WHAT a SHOWING of TALENT and EXPERTISE!

Best Wishes!

|

|

By pegleg - 11 Years Ago

|

|

I'm more impressed with Royce and Ted's efforts than Kaase"s. They have maintained the spirit of their engines history, Kaase showed us how to build another Small Block scrub out of a Y. When is a Y block no longer a Y block? Very clever engineering, but so? How about a set of Four valve overhead cam heads on a Y? Is that still a Y block?

|

|

By Rowen - 11 Years Ago

|

pegleg (10/11/2015)

I'm more impressed with Royce and Ted's efforts than Kaase"s. They have maintained the spirit of their engines history, Kaase showed us how to build another Small Block scrub out of a Y. When is a Y block no longer a Y block? Very clever engineering, but so? How about a set of Four valve overhead cam heads on a Y? Is that still a Y block?

AGREED !!!!!!!!

|

|

By charliemccraney - 11 Years Ago

|

For one thing, the Che vy has the same siamesed port layout as earlier engines, such as the Lincoln Y-Block. The SBC was derived from earlier engines and is not unique in that respect.

An sbc intake was fitted, in a similar fashion to 2 of the other engines because there simply was not an intake specific to the engine family that would do what the builder wanted.

Another thing to remember, is Kaase entered the competition to win, not to appease the diehard fans - and that is what he did. I'm glad he did. Having his name attached to a Y that won and produced, to the best of my knowledge, record amounts of power in naturally aspirated form, 584hp and 596ftlbs, is great. That is just what is needed to have aftermarket companies wake up and start producing things. There is certainly no guarantee it will happen, but every example that can get mainstream attention is a step in the right direction and demonstrates, undeniably that a Y is capable of serious power with proper support.

To answer the question When is a Y no longer a Y (or any engine is no longer what it was, for that matter). My opinion is when that engine's major components are no longer genuine Ford (or che vy, Dodge, Packard, etc). At that point it is a Ford based engine, but is no longer a Ford engine. By that Definition, both Ted's and Kaase's engines are not true Y-Blocks. Kaase's certainly deviates even farther. About the only genuine Ford thing left in each is the block. However, I do not have a problem with someone calling it by that name as long as the facts are not overstated.

|

|

By Kahuna - 11 Years Ago

|

Charlie

Some years ago weren't there cylinder heads from Brazil, or Argentina, or somewhere else that had chambers and port layout similar to the newer 5 liter Ford engines?

|

|

By charliemccraney - 11 Years Ago

|

Yes, and those are genuine Ford parts, phase II Y-Block.

|

|

By Grumpy1 - 11 Years Ago

|

I agree jon kaase went to far. I would like to see a "Super Stock" class. Stock bore and stroke. No aluminum and only off the shelf parts. Something the average guy could relate to and afford and apply to his own engine.

Also how about a class dedicated to inline, straight six engines. Yblocks are becomming increasingly rare, inlines are everwhere and a dime a dozen.

|

|

By John Mummert - 11 Years Ago

|

This conversation is one that we knew would happen eventually. The engine is called a Y- block and the reference refers to the block. Cylinder heads take much time to develop and turn into a sellable parts.

We are already working on an all out race head with revised intake side. I cannot give the farm away however. Its NOT the typical cadillac, lincoln, scrubrolet intake that most are familiar with. That is the easiest way to go that requires the least changes. Flow testing models like that show good gains. But we feel it would have the least room for growth especially with the way the rocker stands are laid out and the rockers are a peice we will hang on to.

It has revised intake valve angle but still operates from a common shaft. And will take the stock y block valve cover and exhaust systems. Unlike an FE we feel the alum head exh. port to be capable of much more power. We have two version that we have been doing R&D work on and off with for the last year and a half. Our goal is to be able to make 700hp eventually. We are still probably an easy year out.

It not that surprising that Kaase did what he knew he could make work in the time that he had. Remember he hasn't spent the last 30 years of his life working on Y blocks.

Please do not knock innovation. Choose the parts that fit your application, and make you happy. HAVING ENOUGH PERFORMANCE PARTS TO KEEP "EVERYONE" HAPPY WILL TAKE MUCH MORE HARD WORK.

|

|

By speedpro56 - 11 Years Ago

|

Well said John.

|

|

By Canadian Hot Rodder - 11 Years Ago

|

I agree with John, and no matter what modifications were done, in all it brings the long overdue publicity to the Y-Block! It shows you can go extreme like Kaase, or you can keep pretty close to stock form and make great horsepower /torque like Ted & Royce.

So kudos to all, maybe now, nay sayers like Vic Edelbrock Jr. will eat their words and give the little Y the respect it deserves! I know personally, I have opened the eyes of a dye hard LS scrub lover, with both my basic street motor and showing him the articles of what Ted, John, Kaase, Royce, Jerry, etc. Have done! Congrats to all!!!

|

|

By glrbird - 11 Years Ago

|

|

Jon Kasse is a racing engine builder, innovation and thinking outside the box is the only way to make gains on performance. He uses that thinking when building a EMC engine. If no one wanted better performance from the y-block, Mr. Mummert would not be making heads and manifolds.

|

|

By Ted - 11 Years Ago

|

Thanks to all for the Kudos and ditto on John Mummert’s comments. While it’s been generally accepted in the Y-Block community that the stacked intake ports are what makes a Ford Y-Block unique, Jon Kaase’s redesign using the LYB (Lincoln Y-Block) side by side port design does fit within the letter of the rules for this competition. Within that same line of reasoning, it has been widely known that the SBF heads would fit on a Y with some work but it simply wasn’t going to happen here in the States for the Y competitions simply due to doing away with the stacked ports. On the other hand, the Argentina Y-Block did go with the SBF port orientation and firing order which was used for a couple of decades after the Y was discontinued here in the States. To Jon Kaase’s credit, he did start with a pair of Y castings and simply cut the stacked ports out and replaced them with side by side ports in order to have the ports positioned where the valves could have a straight shot through the intake runners. That was an incredible amount of welding in which to make that happen. The remainder of Jon’s engine was just as innovative so there was definitely a lot of work performed in just a short period of time. Jon’s engine was built specifically for the 3000 to 6000 rpm band and the final point score was very good as a result.

With all that being said, The Eaton Balancing entry did rank third in the points scoring. With Jon’s engine being ~200 points ahead of mine (2586 vs 2389), that was going to be a bunch to compensate for with what I had to work with. I ended up with a 362 inch engine simply due to not having enough lead time for a longer arm crankshaft. On the other hand, the School of Automotive Machinists Poly entry was second at 2454 points which was within the range that my entry might be capable of exceeding with just a few changes. Some more testing in the next couple of weeks on the current combination will prove or disprove that.

As Royce has already mentioned, the UNOH dynos were stingy with their numbers but this applied for all competitors so it was a level playing field. I had repeatedly posted a 574HP value at 6000 rpms on my own dyno but could only achieve a 542HP value on the UNOH dyno at that same 6000 rpms. The other competitors also noted a similar drop in numbers from their own dyno testing. The HP numbers for my entry at 6800 rpm though were very stout and that’s with the EMC tuneup and not a tuneup conducive for even higher topend HP numbers. Part of that was the result of not running the camshaft originally designed for this combination as I did have some problems with the original camshaft and had to go with one that was sitting on the shelf.

I am still happy with the performance of my own engine as it’s still very conventional in nature. And this years’ entry can be repurposed very easily to another application. I am already thinking of a combination for next year’s EMC competition as I do have some more ideas on getting that performance level up much higher. As usual this year presented me with more new learnings and I’ll apply some of those to the new combination.

Congratulations to Royce on his 4th place finish with his Lincoln Y-Block entry as it was a very repectable showing. The 5th place finish was a Packard V8 which also ran quite well. The sixth engine on the list was another Poly motor that did not run due to an oiling problem in its topend.

Much thanks to those of you that contributed to this year’s entry. Those contributions were put to good use.

|

|

By John Mummert - 11 Years Ago

|

I did find it interesting to see what Kaase has done with his engine as he was pretty tight lipped. I know he says in his video that He and SAM "essentially" had some info sharing, as employees and students talk. I however didn't know just how far he was taking it.

I think many have found it fascinating to see Kaase's engine apart and on display. Hearing more about the other Y blocks in the competition would give us more appreciation for their accomplishments.

Building engines for these competitions is a ton of work and expense. A lot of learning, frustration , and happiness comes out of these projects.

Knowing that Ted and Royce went through a lot of effort with their engines I think it would be very interesting to hear some more in depth stories. Teds score shows large gains over his 2010 entry. From my calculations Ted achieved more hp/cu in than any other engine in the class. That's saying something.

As has been pointed out Ted and Royces engine could be duplicated and owned by anyone. Kaase's engine as interesting as it was, realistically could not, in any reasonable time and budget.

A lot of credit needs to go to the guys that put themselves in the arena, and compete.

Geoff Mummert.

|

|

By speedpro56 - 11 Years Ago

|

Kaase's engine was really impressive and Mummert is right, that's the way things are made to be on top for which he went for, but Ted and Royce were just as impressive with their builds for which those parts are available and you can set their engines as is in a hot rod and kick some serious hiney! All three of those guys did a really great job for the yblocks (Ford and Lincoln).

|

|

By John Mummert - 11 Years Ago

|

Here is a fun pic of Mummert head #001, its life has been dedicated to R&D. This design started coming to life the day that people started talking about building a big bore block. The plan was to have a valve location that would be very good in original blocks, and have the room to go 2.08- 2.125 in 4.00-4.125 bore blocks..

We just got our new angle milled CNC ported race head with standard port design out to Ted before the EMC competition. It seems to have some real promise.

|

|

By pegleg - 11 Years Ago

|

|

Rotated Valves?? It's a Cleveland? You got some Splainin' To do Lucy!

|

|

By John Mummert - 11 Years Ago

|

We've tried lots of experiments with old #001. Side by side ports were tried some time ago and showed promise on the flow bench. Looked a little too scrubbie for us to think it would be well received. We've looked at some other configurations that I wouldn't want to mention. Still considering some other options but we feel we are getting near the limits of the OE stacked port layout. There are limitations build into that configuration that limit the potential. The heads we sent Ted are the best to date we have come up with. The numbers Ted achieved are remarkable with the cam not being of his choosing and having to use a dual plane intake manifold.

The biggest limiting factor of the original port layout is that the lower port starts out near the deck surface and needs to rise to attain a reasonable short turn height. This is critical to get the air/fuel to aim down the cylinder and not centrifuge around the chamber. Unfortunately, the lower port is under the upper port and can't rise very much until it clears the upper port. At the same time the upper port needs to start turning toward the valve seat. Again, it can't because the lower port is under it. The interaction of the two ports in physical space is the limiting factor of the design. We have considered moving the valves closer to the center of the bore, which is the best place for the intake valve. However, moving the valves closer to the intake manifold shortens the distance the ports have when they are not interacting with each other even more.

It appears that the next step has to be a layout without stacked ports if the power levels are to exceed 600hp.Very few will want to exceed that number, but somebody will, so the quest continues.

|

|

By '60 Fairlane - 11 Years Ago

|

Why does it sound better when Mr, Mummert talks about rearranging the ports on the Y-Block? Maybe it's because we know he is in it for the long haul.

Thank you for all you've done for this obsolete little mill and all of us who love it!

-Dave

|

|

By aussiebill - 11 Years Ago

|

I think standing back and looking at Teds participation in EMS with what is basically original style engine running single 4 bbl carb compared to jon kaases highly modified 2 x 4 engine, ted finished ahead in my book.

|

|

By RB - 11 Years Ago

|

If I had not had a running engine that I was confident in, I could never have put together the effort to get an engine to the Engine Masters. What Ted did in a compressed time frame is amazing..

The idea was to pull the engine from my drag car and massage it a little bit and run it at EM. I was figuring maybe a couple weeks work and that would be it.It did not turn out that way LOL..I run E-85 in my drag car and the contest has a spec fuel so I needed a different carb. I run an automatic and the contest required an SFI certified flywheel so I had to lean on John to get his supplier to custom make one for me. With a 3000 to 6000 rpm range I was not sure if a single plane intake or a dual plane would score better so I ordered a couple to try.. I do not have any dyno headers that would match that rpm range so i had Yestertech modify some Schoenfeld headers to fit the Lincoln. We decided that Tri Y headers would likely make more low end torque so Jerry whipped up a set of those too. I had always wanted to try a tunnel ram and EFI on this engine.. On my shelf I had the lower half of an EFI tunnel ram intake that Mercury Marine used on one of their scrub based boat engines. I fabricated an upper plenum and rigged up a fuel rail with 42 lb injectors, 2 65mm throttle bodies all controlled by a FAST EZ EFI port injection system. I sent 2 intakes and the tunnel ram to Joe Craine for porting and flow testing. When i had finally collected all the parts I needed I ran my first dyno test in July.. We tested a single plane and a dual plane intake 2 different headers and 4 different carbs. Learnings from the first dyno session were that a 750 carb was all it wanted, and that Jerry's Holley 750 HP Ultra was the best of the 750 carbs we had. The Schoenfeld headers were better than the Tri Y's and the single plane and dual plane intakes were almost identical in score.. Peak power occurs at 6300 and peak torque at 4600 so the cam is not ideal. After thinking about results for a while I decided the only thing that was really nailed down was the carburetor. Everything else was still a question.. On intakes it seems what the engine wanted was a bigger dual plane intake for more top end or a single plane that has smaller runners to make more low end torque. I had confirmed that the cam is really to big for the RPM range I was working with so it decided on the next test to open the lash and advance it 4 degrees to pick up the low end torque. I purchased 2 more intakes, A Performer RPM Air Gap and a Holley Strip Dominator. My thinking was that if the RPM Air Gap could be made to flow a little better it could help the top end score.. The Strip Dominator has a smaller plenum and runners so I surmised it might make a bit more low end torque I sent these 2 intakes off to Joe Craine for tweaking and flow balancing. Also by this time I had completed fabrication on the EFI tunnel ram, so that needed to be tested as well. I was back on the dyno just before labor day. The EFI intake was a disappointment. It was down on Performance across the board. It was short on low end torque and also high end horsepower , so after tuning it the best we could with no better results it was set aside. The testing on the single plane Holley and the Air Gap Edelbrock produced scores that were very close to one another, so there was no clear choice on manifolds. Advancing the cam moved torque peak 300 rpm lower which I thought would improve the score, but it did not. Gains in low end torque were offset by equal loss of power at the higher range, with the net gain or loss being 0..Loosening the lash did help and i picked up about 20 points of score... I ran into a couple mechanical issues in this session as well, water in the oil, and the cam was walking in the block enough to change the timing 20 degrees at idle. So back to the shop to fix the problems and settle on a final combination to run at EMC.The mechanical issues were easily solved and after some thought I settled on the dual plane Air Gap intake. I also could not help thinking I could find a better header to make more torque, so I had Yestertech make 1 more set with very long primaries and a 3 inch instead of 3.5 inch collector. Last week in Sept I am on the dyno again this time trying to find the best spacer combination dial in the carb for the final time and test the long tube headers. It turns out the long tube headers did not make any more torque than the set I started with.. The engine turned out not to be real sensitive to jetting so we picked a middle of the road carb tune.. The spacer combo that we ended up choosing was a semi open 1 inch spacer shaped like a clover leaf, with a 1/4 open spacer underneath it. We could have tested different combos for days but at some point I had to settle on something so i went ahead and locked in the combination.. I made well over 100 dyno pulls tried 4 carbs 5 manifolds 3 sets of headers many spacers, cam timing and valve lash.. In the end I was able to pick up about 90 points and make a score of 2183. HRM covered the actual dyno run pretty well so I will not repeat that.. I was happy it was drama free and no surprises we made 8 pulls in 35 min and the engine never missed a beat

Here is what my combination looks like:

1957 mercury 368 block and heads.

Block bored ..060 JE pistons with 1/16/1/6 3/16 rings 10cc dome 12:1 compression

Forged crank with offset ground rod journal to 2.2 for a 3.7 stroke

TFS SFI Damper. Mummert billet SFI steel flywheel

Scat 7.1 inch BBC rod

SCE copper head gasket with O Ring

Heads max ported by Joe.D.Craine 2.05 intake 1.65 ex. Flow 255/195 @.600

Edelbrock SBC Performer RPM Air Gap intake ported by Joe.D.Craine

Holley 750 HP Ultra carb

Solid roller cam by Mike Jones Jones Cam designs 252/252 .625 lift

Lunati solid roller lifters

Smith bros 5/16 chrome moly push rods

Harland Sharp 1.6 aluminum roller rockers

PAC beehive valve springs

ARP main studs and Head studs

Stock timing set.. 57 type distributor with locked timing at 34 degrees

Pertronix Ignitor firing a MSD 6 with a Blaster coil.

NGK WR5 plugs 7 quarts Amzoil 10/30 K&N oil filter Stock truck oil pan with windage tray stock oil pump

|

|

By NoShortcuts - 11 Years Ago

|

WoW! THANKS for making the time to write all of this up for the Forum! My appreciation for what went into getting you to the EMC and attaining the numbers you had in the competition G-R-O-W-S, Royce!

I hope that Ted will consider doing some variation of your accounting for his 'small' y-block entry.

I know Ted used beehive valve springs on one build he wrote about in (?) Y-Block Magazine...

Again, THANKS, Royce. Very informative and insightful!

|

|

By jepito - 11 Years Ago

|

I expected it would be a race for 2nd. Kaase history and resources is on another level.

Just wish the guys with the oil issues would have pulled out sooner as I would have done a 30 hr cannon ball run to Ohio.

Since I was on the alternate list I finished building my engine for pump gas as originally intended.

With only 10.5 compression and 333.6ci it makes

429ft/lbs @4400rpm and 444.6hp @5800rpm

Mr Mummert has done a great job with these heads. while they may be limited for the big inch race motors my plan was to go with smaller ci and less impressive peak numbers and try for better average score. With different pistons and some more time it could have been a strong competitor. Hopefully next year I'll make the real list.

Congrats to all involved every vintage engine there was impressive. I love seeing these old engines built to run and not just look pretty.

|

|

By John Mummert - 11 Years Ago

|

Royce, that was a tremendous amount of work but that's what it takes even with a running engine to start with. A guy without his own dyno is at a real handicap building for this event. There are so many things to try it gets expensive when paying by the hour. You've shed a lot of light on what is required to participate on competitive level. We owe you a big thanks for representing all of us.

John

|

|

By RB - 11 Years Ago

|

John and Geoff,

Since Ol casting 001 has been mercilessly hacked and welded on, and you have pondered side by side ports, How about you just stretch it a little to fit on my Lincoln... If I had a 300 cfm port I could make some noise... I am sure sales of such a head would be brisk.

Funny story... While we were standing around answering questions from spectators and students a guy came up and engaged me in conversation. Of course he had never heard or seen a Lincoln Y Block.. After some explanations about Lincolns he asks me "what crowd do you build these engines for.".. I pointed to Rick Martin and then myself and I said "just us two".. 'Oh' he says "you just build for your own use" I said "no, that is the total market"

|

|

By John Mummert - 11 Years Ago

|

Royce, Ol 001 had side by side ports a couple of years ago. They're gone now. As I said, it looked too SBS.

I'm sure there would a renaissance of the Lincoln Y if the right parts were available. Or not.

There must be 1 or 2 others interested in the Lincoln.

|

|

By RB - 11 Years Ago

|

Here are a couple of pictures of the failed EFI tunnel ram. I am speculating too big of a plenum or too big a cross section on the runners or both.

|

|

By John Mummert - 11 Years Ago

|

Royce, the EFI set-up sure looks like it should work. Any conclusions about it. I get a lot of inquiries about EFI for the Y-Block so there is interest.

When do you go into production on the Linc-scrub port plates?

|

|

By RB - 11 Years Ago

|

Funny you should mention the port plates...... I am putting out bids to guys who can do CAD and have a state of the art CNC equipment..

I can send you my EFI manifold for the Ford Y Block if you want to play with it.

On the tunnel ram I am not sure why it does not work, but I am speculating the runners have too much volume and are very lazy. Maybe if the engine runs to 7000 they will come alive. Also I have no idea what size plenum it wants...What does Geoff think? I need more more dyno time.. UGH

|

|

By John Mummert - 11 Years Ago

|

Do you have any BSFC numbers? Did you run the return line through the B fuel turbine so you could A-B to get actual fuel flow? Sometime guys will run the return line back to the inlet of the pump. Just asking to see if if fuel consumption was close per hp generated to other manifolds. How big are the throttle bodies? You might try to put a decent pair of carburetors on it just to verify plenum size, runner size. If its happier with carburetors you might try moving the injectors up high shooting down on each runner.

On youtube (Renault F1 Engine) its a 1:51 min video. Its cool!

Injector size, pulse width, and plume formation are gonna be more finicky that close to the head, especially if the cam has some overlap.

I haven't played with it much, but I think in a sequential firing efi you can run a bigger injector and shorten up the pulse width. In a batch firing system I think you want to run an injector closer to rated Hp and turn the pulse width up.

Our EFI tunnel ram combo manifold should be ready early next year and I'm sure we'll be knee deep injector placement and styles. After we test the carbs.

If the plenum is 1/2 the size of the engine it should be good enough to get started. I know some of the big drag guys like plenums 100% of displacement or more. 1/2 should be enough to see more power than a conventional type dual plane.

I like hearing Engine Master stories, the couple of times I've been involved in with engines its been a lot of work. Its amazing how many parts you go through. Its funny to see projects years later that have of something or other that were left overs from those engines..

I do think trying a set of carbs is a good place to start. Because the they are a mechanical device they will only respond to the way the engine moves air. If the engine is running well and the headers cooperate with the plenum sizing the fuel curve will be smooth and fairly easy to jet. At that point finding the best place for the injector should have similar results.

Hopefully this helps

Geoff Mummert

|

|

By CK - 11 Years Ago

|

So what is the theory popping open the inlet with high lift and less duration than lower lift and longer duration in the exhaust as the comp cam does "thumper" which I see kasse runs.

|

|

By John Mummert - 11 Years Ago

|

|

Kaase used a Comp cam but it was nothing like a Thumper. The Thumper has a LOT of additional exhaust duration and is ground on wide lobe centers (LDA in magazine speak) to open the exhaust valve early while there is still significant pressure in the cylinder making a louder exhaust note. Purely a gimmick. Kaase's cam has less duration on the exhaust than the intake. His cam was a steel billet with the distributor gear and rear bearing journal from a standard Y-Block cam grafted on. This is not a new idea and is actually done to save the cost of trying to hobb a distributor gear on a steel billet. Also, you don't need a bronze gear that way.

|

|

By Ted - 11 Years Ago

|

Here’s a quick summary on what happened with my EMC Ford Y entry. The lead time for a custom crankshaft is 4-6 months and when the 2015 EMC rules came out, there was only five months remaining in which to get the engine ready for the dynos at UNOH. Obviously not enough time to order a crankshaft. In the meantime, I went through six blocks with five being C2 castings and one being a C1 casting. While there were some other blocks on hand, only these blocks were looked at due to these having reinforced main webbing and the earlier blocks did not. Of these blocks, one was cracked in the cam tunnel area while another had eight sleeves in it. Those two went to the scrap pile. Another two blocks had cylinder core shift bad enough that they were not suitable for a 0.110” overbore even with offset boring. These were simply set aside for engine builds that did not require excessive boring. Another C2 block had good cylinders but the ear under the starter was broken and would require welding up and redrilling the bellhousing bolt hole. That block was also put to the side so it could be repaired and used later. The block selected for the EMC build was a C1AE casting which is also the casting Jon Kaase used for his build.

Due to the lead time problem with the crankshaft, I used a 3.860” stroke billet crankshaft that was sitting here for another project. Coupled with a 3.860” bore, the final claimed cubic inch for the EMC was 362. While waiting for pistons, a considerable amount of testing was performed on the +060 over 312 dyno mule in regards to intake manifolds, carburetor spacers, and headers. That dyno mule now has well over eight hundred dyno pulls on it and is still running well.

In the spare time around keeping customers happy with engine balancing, engine assemblies, and dyno testing, some of the miscellaneous parts were being acquired and built. One of the items being pursued was a new cam bearing made from bearing brass that would place all the oil holes at the 3-4 o’clock position looking from the front of the engine. The idea here was to promote the formation of a dynamic oil wave under the cam journals. That meant building test bearings that could be installed in blocks to determine interference fits and the amount of internal hole dimension changes that occur with that interference fit. During this same time frame, Joe Craine was also taking care of porting heads and intakes in different configurations. Also being worked on is the block which has been pressure tested, main bores align honed, cylinders rough bored for pre-assembly and then torque plate honed once the pistons were in hand, and decked.

It’s now the week before the EMC competition and the engine goes on the dyno on Monday. After thoroughly heating the engine up and breaking in the cam and seating the rings, the #4 cam bearing decides to seize to the cam journal and spin in the block. I’ve heard that sound before so there was no question as to what that funny sounding squeal was. The engine is torn down and reassembled with a set of standard cam bearings. The camshaft and lifters all look good at this point. It's still a hard two day job to disassemble and reassemble the engine as the block must be cleaned again. Still pondering why the #4 cam bearing spun as it had 0.007” oil clearance during the assembly checks. The remaining brass bearings look good but are replaced anyhow. Comes Tuesday evening the engine is back together and going back on the dyno.

On Monday, the new cylinder heads from John and Geoff Mummert arrives. These do not have any valve springs so the heads are machined accordingly for a set of Isky beehive springs. Because these heads have a revised valve angle, they require the use of John’s 1.7:1 rockers which are also supplied. The other heads being tested are using the Harland Sharp 1.6:1 rockers. These new heads use a 10mm spark plug so that the plug can be placed closer to the roof of the chamber versus the standard aluminum heads using a 14mm spark plug. A quick check of the combustion chambers on the new heads finds some interference issues between the piston domes and the combustion chambers. This is resolved with some light grinding in exhaust side of the combustion chambers so that the engine rolls through freely without the head gaskets in place. This all takes place on Tuesday while the engine is down for the replacement of the cam bearings. The engine is initially assembled with the conventional but highly ported aluminum heads during this time. The new heads with the valve angle change will be tested later in the week.

The engine is fired up and run back in Wednesday morning but after only five minutes of running a light metallic sound is heard coming from the valve covers. A quick check finds the #5 intake valve with looser than normal valve lash. That particular valve is tightened up and the engine ran for another two minutes. The valve is checked again and the lash has grown. Twenty five minutes later the engine is off the dyno and back on an engine stand. While the oil is draining, the rockers and pushrods are removed along with the damper and timing cover. The engine is flipped upside down where camshaft is removed showing the lobe and lifter that is going away. The pan is then removed and with the aid of a magnet, the lifters are removed by fishing them up through the crank throws and rods. At this point, there is no spare 2015 EMC specific camshaft so the grind used in 2009 and 2010 EMC engine is retrieved from the storage building and deemed suitable for use although it has a wider lobe centerline angle than is desired. A new set of lifters are inspected, lubed, and reinstalled back in the lifter bore from the bottom of the engine using a magnet. The cam is lubed and also reinstalled. A quick check with the degree wheel has the camshaft five degrees advanced with the lower crank gear in the 4° retard position. All is good at this point and the engine is reassembled. Late Wednesday afternoon the engine is fired back up and this time all is well. Valve lash is checked and all are holding steady at their settings.

Joe Craine comes up Thursday and assists with the dyno testing. Also in attendance are Jody Orsag and Pat Duecy to assist with the testing. Carburetors, carb spacers, cylinder heads, and intake manifolds are all tested. Three different carbs are tested with the 1050cfm Holley Dominator carb getting the edge over the others. The new heads supplied by John and Geoff are installed later in the day with a noticeable step increase in power. These are the heads that are ultimately used for the EMC competition. The original plan was to use a set of Mercury valve covers but the relocated valves in the new Mummert heads prevented the modified steel Mercury covers from fitting. The aluminum Thunderbird covers used on the 2010 EMC entry fit fine and used instead. The original plan was to enter this engine as a Mercury engine so that Ford, Mercury, and Lincoln could all be represented. This was just another plan that would be changed. Carburetor spacer testing was interesting as what worked on the dyno mule did not work on the EMC engine. Where the dyno mule preferred the left and right manifold planes to be completely separated, the EMC engine wanted some shared space. At this point it’s apparent that some of the other intake manifold testing performed on the mule engine probably is not applicable either. I’ll eventually get around to retesting some of those scenarios and will not be surprised if some EMC points were left on the table.

Came Friday, the engine was refired for a baseline run. Once that is done, another intake change is made and that intake simply is not as good and pulled back off. The previous intake manifold is reinstalled and the dip in the torque curve that was completely taken care of on Thursday reappears. Much of the day is then spent trying to get rid of that pesky dip through carburetor and spacer changes. As a last resort, the intake gasket was even changed out again as part of the effort in getting rid of that dip in the torque curve. While that dip is not severe, it’s simply bothersome in that is was completely gone the day before. The Valvoline oil is removed during the afternoon and the desired grade of Amsoil oil put into the crankcase. Oil pressure doesn’t change so all is good on that front. Different grades of fuel are also tested on Friday and that proved to be interesting. For what it’s worth, this engine responds very nicely when the RVP (Reid Vapor Pressure) of the fuel is on the low side. Much to think about for sure.

Saturday is spent taking care of building brackets for the MSD box and coil along with some miscellaneous loose ends. Karol Miller comes by and lends a hand so he’s there to watch a couple of 6800 rpm pulls with the new wiring, MSD box and coil in place. Engine runs good at this point and is ready to pull off of the dyno. The engine comes off the dyno on Sunday and loaded in a trailer for its trip to Ohio. Monday and Tuesday are spent travelling with the engine being unloaded at the UNOH facility late on Tuesday. The engine is set up on a dyno cart Wednesday in preparation of it running on Thursday. The rest at this point is history.

I’m sure some details were left out as that was a very very busy week. Additional detail on all this will be in the write up for the Y-Block Magazine.

|

|

By Y block Billy - 11 Years Ago

|

|

Well done Gents!

|

|

By John Mummert - 11 Years Ago

|

Ted, I'm guessing you didn't get much sleep that week. Between the work load, unexpected problems and trying to figure out which parts to try next. The results prove it was all worth it with the showing you had at the EMC. Thank you for the insight on what it takes. I doubt people realize what a scramble it turns into.

Congratulations. Maybe next year it will all come together without a hitch. Only in our dreams.

|

|

By RB - 11 Years Ago

|

Geoff, Here are a couple of sheets from my pre EMC testing on the EFI intake.

My current plenum volume is right at engine CID. The throttle bodies are 65ish mm pirated from a 4.6 crown Vic. We had basically 0 vacuum at WOT. BSFC numbers look good.. The dyno has it's own bypass fuel system, . we are using 43.5 lb of fuel pressure and 42 lb/hr injectors

|

|

By charliemccraney - 11 Years Ago

|

Ted,

I'll lend some spacers for testing if you don't already have them. I have ordinary stuff, 1/2" divided, 1/2", 1", 2" 4-hole, all 1 3/4" bore. Those are phenolic or wood fiber. I also have fancier stuff, an HVH Street Sweeper which is supposedly designed for dual plane use but has features of a 4-hole, tapered, open and divided all in one, 1" tall. And a 1" HVH Super Sucker. The HVH spacers are aluminum.

|

|

By aussiebill - 11 Years Ago

|

Ted, i thank you on behalf of everyone here for your details of what goes into getting an engine ready for this comp.I can see where you had to go back to the tried and proven components to make it on time, a gallant effort indeed. It is interesting that there might be improved heads coming along? and with further development with the cam components there is more HP to come. Salute!

|

|

By pegleg - 11 Years Ago

|

|

It's gonna take me a long quiet weekend to absorb all of this. The guys who designed the Y are probably watching in awe at these results. Long, LONG way from a 239 and 130 hp engine they first envisioned.

|

|

By glrbird - 11 Years Ago

|

|

So this is not just a bunch of 'old gray hairs" playing with their vintage cars?

|

|

By CK - 11 Years Ago

|

|

Thanks for clearing that up for me John

|

|

By Ted - 11 Years Ago

|

|

charliemccraney (10/14/2015)

Ted,

I'll lend some spacers for testing if you don't already have them. I have ordinary stuff, 1/2" divided, 1/2", 1", 2" 4-hole, all 1 3/4" bore. Those are phenolic or wood fiber. I also have fancier stuff, an HVH Street Sweeper which is supposedly designed for dual plane use but has features of a 4-hole, tapered, open and divided all in one, 1" tall. And a 1" HVH Super Sucker. The HVH spacers are aluminum.

Charlie. Thanks for the offer but will not need them in the short term. During the EMC engine testing, Joe Craine brought down a large selection of spacers which were tried in various combinations. Once it was determined that the engine preferred some shared plenum volume space, carb spacer testing leaned towards that direction. The EMC engine basically liked 3” of spacer with two inches simply dropping the scores and 4” being no change or a slight drop in numbers depending upon the combination.

|

|

By charliemccraney - 11 Years Ago

|

You said you'll eventually get around to it. When you do, let me know if you want any of them to test.

|

|

By yalincoln - 11 Years Ago

|

|

great job everyone! great results! say john, an aluminum head for the Lincoln y sounds like fun!!!!

|

|

By NoShortcuts - 11 Years Ago

|

THANKS for your write-up, Ted. Like Royce's, very revealing of what you've been through as an EMC entrant.

I look forward to your write-up for Y-Block Magazine and hope that Royce will consider making the time to do one as well.

As a hobbyist, you and Royce have grown my understanding and appreciation of what's involved in making a modified engine perform. It's certainly not just a matter of ordering a bunch of performance parts and carefully assembling them together. UGH!

I'm pleased to learn of John and Geoff Mummert's continuing involvement in y-block development and of Joe Craine's porting work for both you and Royce. It's neat the fraternity of enthusiasts who have helped you and Royce in preparation for the EMC and at the actual competition. Thanks to all for what you've done as participants and supporters of our mutual interest.

|

|

By John Mummert - 11 Years Ago

|

Its pretty interesting, to see the manifolds overlayed. The tunnel ram is the odd man in the graph. Seeing the dual plane come on strong in the early game and taper off on the top end, as well as seeing the single plain dog it for a while and then come on strong and out perform dual plane on the top end all makes sense.

Tunnel rams have always been the International Manifold of Mystery. The street style version are usually known for making big mid range, while race versions are know for being 8000+rpm monsters.

It seems that the most knowledge to gain sits with that manifold.

Geoff Mummert

|

|

By Daniel Jessup - 11 Years Ago

|

Ran across this just tonight...

https://www.youtube.com/watch?v=XaOhdZSPd1M

is there anything from HOT ROD on Royce or Ted?

While I appreciate John Kaase using a Y block to build, Royce and Ted have motors that are more true to life and what we actually put into vehicles.

|

|

By LordMrFord - 11 Years Ago

|

Daniel Jessup (11/19/2015)

Ran across this just tonight... https://www.youtube.com/watch?v=XaOhdZSPd1Mis there anything from HOT ROD on Royce or Ted? While I appreciate John Kaase using a Y block to build, Royce and Ted have motors that are more true to life and what we actually put into vehicles.

Well, Kaase got a ridiculously amount welded aluheads, Ted got canted valve one of kind factory aluraceheads and Royce got a good ported iron heads so I think Royce wins in that meter.

|

|

By PF Arcand - 11 Years Ago

|

While we haven't seen the full coverage of the Engine Masters, I tend to agree with Daniels assessement of the vintage class. As might be expected from Hot Rod Magazine, (who took over the contests from PHR) the perameters for the vintage class were hardly appropriate. Kaase's version of our favorite engine was over the top, likely not reasonably streetable & hardly vintage.. Too bad, for me, it spoiled the whole exercise..

|

|

By MoonShadow - 11 Years Ago

|

|

It will be up to Ted, John, Geoff and Royce to decide what parts of the Kasse engine would be any improvement on a Y running the street or racing. He did a lot of wild mods and changes but I think when all is said and done his engine would be lousy for the type of performance we are looking for. Just my thoughts.

|

|

By Ted - 11 Years Ago

|

Jon Kaase is very proficient at port and valve angle design so it’s no surprise that his Y heads were totally reworked to get a winning combination out of them. My own heads were simply angle milled so that the valve angle was 16.8° rather than the stock 18°. It’s hard to say exactly what that’s worth HP wise as the valve sizes, compression ratio, spark plug sizing (10mm), and rocker ratio was changed at the same time as the valve angle was changed. But all those changes were worth 22HP which was significant. I was handicapped on the camshaft as my short lobe center camshaft failed early on and I was simply forced to use a less desirable camshaft. As a result I had an engine that was peaking 594HP at 6800 rpms and was not the player it should have been in the 3000-6000 rpm range.

I am considering an EMC specific Y for next year’s competition which I would expect to be a better player than the engine I used this year. This year’s engine was built with many parts that were sitting here in the shop so from that regard, it did really well.

|

|

By speedpro56 - 11 Years Ago

|

|

Ted , your engine did Great and did the Y blocks a Great honor on how well it preformed!

|

|

By Ted - 11 Years Ago

|

|

Thanks Gary. I’ve got a buyer for my 2015 EMC engine once the pistons have been changed out to run on pump gas. This will give me the funds to start on next year’s EMC engine.

|

|

By RB - 10 Years Ago

|

The latest Hot Rod magazine is out and has extensive coverage of Engine Masters Challenge... There are nice write-ups on Ted's, mine, and Jon Kaase's engines.. Also a cover shot of Jon's motor..

In the coverage of the event, a story headline pronounces how a scrub LS was humbled by an ancient Y Block in torque production. Am I dreaming?

|

|

By Barry L - 10 Years Ago

|

|

Congratulations on the Hot Rod coverage. Good to see the Y write-ups , your Linc.. engine looks great! There was a pic of your Merc in Hot Rod Deluxe, as well, pg. 80. Barry L

|

|

By pegleg - 10 Years Ago

|

Royce, you may be dreaming, BUT the dream would not exist without your work, time, Effort and money. You Jerry, John, Ted, Timmy and some hundred others. Thanks!!

|

|

By Small block - 10 Years Ago

|

I think there should be a adjustment to the rules, What Kaase did to his heads is an improvement no question but it is not in the same direction the Y guys will be doing in there garage!

I can see some port rework but building the heads out of welding rod is a little over the top! I also thought he gained little for the trouble he went to compared to the Y with the unmolested heads.

|

|

By charliemccraney - 10 Years Ago

|

Engine Masters is not about building an engine that represents what the average guy builds in his garage. It is about building an engine that dominates the other entries by whatever means necessary, within the stated rules.That's exactly what Jon did. While his hp numbers weren't that far out there, the torque produced by his engine eclipsed that of all the others (and even some of the engines in other classes). That indicates that his mods worked very well for the competition.

Even Ted's entry, while certainly more conventional appearing, is far beyond what the average Y guy will do in his garage.

|

|

By Small block - 10 Years Ago

|

|

This is true but Every body that knows any thing about an engine knows any thing about engines knows the power of an engine is in the heads! if you want to spend the money and the time you can re configure a head to make any designee possible! You may as well Put a set of AFD Cleveland heads on the Y engine and make some real power!

|

|

By LordMrFord - 10 Years Ago

|

Small block (2/7/2016)

This is true but Every body that knows any thing about an engine knows any thing about engines knows the power of an engine is in the heads! if you want to spend the money and the time you can re configure a head to make any designee possible! You may as well Put a set of AFD Cleveland heads on the Y engine and make some real power!

That might be quite hard.

LS1 heads are closer but that needs some serious work.

|

|

By PF Arcand - 10 Years Ago

|

Small Blocks remarks have some merit. However, J. Kaase's "over the top" engine mods were within the rules.. For most entering that class, modifications of that magnitude, would probably cost upwards of $ 35,000! That said, the problem lies with Hot Rod Magazine. Trust those SBC blinded types to get it wrong! It was supposed to be a "vintage class". They then set a 6000 RPM limit, which seemed reasonable, but then left the rules totally open to a complete architectural redesign of the engine. Ridiculous!..

|

|

By CK - 10 Years Ago

|

Well the 2016 rules have been posted

http://www.hotrod.com/events/1602-2016-amsoil-engine-masters-challenge-new-classes-dates-and-rules-announced/

EMC 2016

305 - CYLINDER HEADS

OEM or commercially available aftermarket cast cylinder heads manufactured for the engine type permitted. Heads must be originally manufactured for the engine application in which it is being used. Billet heads prohibited.

Any valve seat size and/or valve size permitted. Any commercially available

stainless steel valve permitted. Titanium valves and/or springs prohibited. Titanium retainers permitted

https://image.adam.automotive.com/f/96800853/2016EMC%20Day%204%20Vintage.doc

|

|

By Ted - 10 Years Ago

|

|

Rules are rules and as with any racing venue, competitors work within them. Those competitors that can cut up the heads and completely rework them are definitely a cut above the rest at this point. Aluminum just makes it so much easier to do those kinds of modifications. The School of Automotive Machinists had their hands full in working with the cast iron Poly heads but they did make it happen. Judson had mentioned that it had been a long time since they had worked with cast iron heads and had to relearn much of what had been lost over time.

|